Abstract

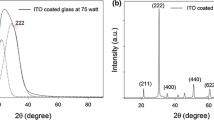

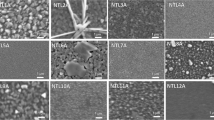

In this research, the effects of target sputtering power on the structure and optical properties of radio frequency (RF) sputtered Ti6Al4V films were investigated. Different sputtering RF powers were used to produce different thicknesses of Ti6Al4V thin films. From the X-ray diffraction, it was found that the Ti6A14V films had polycrystalline cubic and hexagonal structures and increased films crystallinity and crystalline size with increasing the sputtering power. Atomic forces microscopy (AFM) gave us a nanometric film character, films homogeneity, and surfaces roughness. A higher degree of roughness and average grain size with increasing RF power was exhibited. Band gap and refractive index of Ti6Al4V thin films varied with sputtering RF powers.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

C. M. Garzón, J. E. Alfonso, and E. C. Corredor, “Characterization of adherence for Ti6Al4V films RF magnetron sputter grown on stainless steels,” D. Reidel, 1981, 81(185): 175–181.

A. C. Faria, R. C. Rodrigues, A. P. Claro, M. D. G. C. de Mattos, and R. F. Ribeiro, “Wear resistance of experimental titanium alloys for dental applications,” Journal of the Mechanical Behavior of Biomedical Material, 2011, 4(8): 1873–1879.

S. Roessler, R. Zimmermann, D. Scharnweber, C. Werner, and H. Worch, “Characterization of oxide layers on Ti6Al4V and titanium by streaming potential and streaming current measurements,” Colloids and Surfaces B Biointerfaces, 2002, 26(4): 387–395.

H. Copete, F. Vargas, and A. Echavarría, “Mediante proyección térmica por combustión oxiacetilénica sobre un sustrato de ti6al4v in vitro evaluation of oxy-fuel thermal sprayed hydroxyapatite coatings onto ti6al4v substrates,” Dyna, 2013, 10(177): 101–107.

A. E. B. Torres, S. B. Neves, J. C. N. Abreu, C. L. Cavalcante, and D. M. Ruthven, “Single-and multicomponent liquid phase adsorption measurements by headspace chromatography,” Brazilian Journal of Chemical Engineering, 2001, 18(1): 121–125.

S. Roessler, R. Zimmermann, D. Scharnweber, C. Werner, and H. Worch, “Characterization of oxide layers on Ti6Al4V and titanium by streaming potential and streaming current measurements,” Colloids and Surfaces B Biointerfaces, 2002, 26(4): 387–395.

T. Falcade, L. M. Antonini, T. E. Schmitzhaus, and C. D. F. Malfatti, “Tribological study of ti6al4v coated with amorphous carbon films obtained by electrodeposition,” in 15th International Conference on Experimental Mechanics, Porto, Portugal, pp. 1–11, 2012.

D. H. He, P. Wang, P. Liu, X. K. Liu, F. C. Ma, and J. Zhao, “HA coating fabricated by electrochemical deposition on modified Ti6Al4V alloy,” Surface and Coatings Technology, 2015, 277: 203–209.

B. Song, S. Dong, B. Zhang, H. Liao, and C. Coddet, “Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V,” Materials and Design, 2012, 35: 120–125.

S. Xu, J. Long, L. Sim, C. H. Diong, and K. Ostrikov, “RF plasma sputtering deposition of hydroxyapatite bioceramics: synthesis, performance, and biocompatibility,” Plasma Processes and Polymers, 2005, 2(5): 373–390.

K. V. Dijk, H. G. Schaeken, J. C. G. Wolke, C. H. M. Maree, F. H. P. M. Habraken, J. Verhoeven, et al., “Influence of discharge power level on the properties of hydroxyapatite films deposited on Ti6A14V with RF magnetron sputtering,” Journal Biomedical Materials Research, 1995, 29(2): 269–276.

N. Muslim, Y. W. Soon, C. M. Lim, and N. Y. Voo, “Influence of sputtering power on properties of titanium thin films deposited by rf magnetron sputtering,” ARPN Journal of Engineering and Applied Sciences, 2015, 10(16): 7184–7189.

M. F. A. Alias, K. M. Rashid, and K. A. Adem, “Optical properties for Ti doped thin Zno films prepared by PLD,” International Journal of Innovative Research in Science, Engineering and Technology, 2014, 3(8): 15538–15544.

Acknowledgment

We acknowledge the support of the Dept. of Physics, College of Education for Pure Sciences, University of Anbar and Ministry of Science and Technology, Center of Applied Physics, Baghdad, Iraq. We acknowledge Aqeel F. Hasan, Jamal. F. Hamodi, and Mohammed Odaa for their precious help.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Khalaf, M.K., Al-Taay, H.F. & Ali, D.S. Effect of radio frequency magnetron sputtering power on structural and optical properties of Ti6Al4V thin films. Photonic Sens 7, 163–170 (2017). https://doi.org/10.1007/s13320-017-0390-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13320-017-0390-8