Abstract

This paper presents theoretical models developed for the prediction of the maximum axial force demands of tie bars of planar composite plate shear walls–concrete filled (C-PSW/CF). In the development of the theory, a previously benchmarked finite element (FE) wall model was used with some modifications. The results from the FE models were used to demonstrate the formation of the tie bar axial force demands, passive lateral confining pressure, concrete confinement, effectively confined concrete core and to develop theoretical models for the prediction of tie bar maximum force demands. The proposed method accounts for various aspects of wall geometry such as horizontal and vertical tie bar spacings, steel plate thickness, and wall thickness. The predictions of the proposed theoretical models were compared with the predictions of FE analyses by performing a parametric study involving C-PSW/CF having different tie bar spacings, plate thickness, wall thickness, and wall depths. Past experimental research available in the literature were used to evaluate the significance of the theoretical model in predicting tie bar maximum axial force demands. Tie bar axial force demand due to the confinement effect is not currently considered in the design of tie bars and there is no theoretical approach in the literature that considers the effect of confinement on the tie bar axial force demand. The theoretical models presented in this study allow the determination of the maximum axial force demands due to the confinement effect on planar C-PSW/CF tie bars without the need for complex and costly numerical analysis.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

AISC (2022). Seismic provisions for structural steel buildings. AISC 341–22, American Institute of Steel Construction, Chicago, IL.

Alzeni, Y., and Bruneau, M. (2014). Cyclic inelastic behavior of concrete filled sandwich panel walls subjected to in plane flexure. Technical Rep. MCEER, 14–009,, Univ. at Buffalo, the State Univ. of New York, Buffalo, NY, MCEER.

Alzeni, Y., & Bruneau, M. (2017). In-plane cyclic testing of concrete-filled sandwich steel panel walls with and without boundary elements. Journal of Structural Engineering, 143(9), 04017115.

Bhardwaj, S. R., Varma, A. H., & Orbovic, N. (2019). Behavior of steel-plate composite wall piers under biaxial loading. Journal of Structural Engineering, 145(2), 04018252.

Booth, P. N., Varma, A. H., Sener, K. C., & Mori, K. (2015). Seismic behavior and design of a primary shield structure consisting of steel-plate composite (SC) walls. Nuclear Engineering and Design, 295, 829–842.

Bowerman, H., Gough, M., & King, C. (1999). Bi-Steel design and construction guide. London: British Steel Ltd Scunthorpe.

Eom, T.-S., Park, H.-G., Lee, C.-H., Kim, J.-H., & Chang, I.-H. (2009). Behavior of double skin composite wall subjected to in-plane cyclic loading. Journal of Structural Engineering, 135(10), 1239–1249.

Epackachi, S., Nguyen, N. H., Kurt, E. G., Whittaker, A. S., & Varma, A. H. (2014). In-plane seismic behavior of rectangular steel-plate composite wall piers. Journal of Structural Engineering, 141(7), 04014176.

Epackachi, S., Whittaker, A. S., Varma, A. H., & Kurt, E. G. (2015). Finite element modeling of steel-plate concrete composite wall piers. Engineering Structures, 100, 369–384.

Harmon, J. R., & Varma, A. H. (2021). Local buckling of steel faceplates anchored to concrete infill in C-PSW/CF. Thin-Walled Structures, 167, 108230.

Kenarangi, H., Kizilarslan, E., & Bruneau, M. (2021). Cyclic behavior of c-shaped composite plate shear walls–Concrete filled. Engineering Structures, 226, 111306.

Kizilarslan, E., Broberg, M., Shafaei, S., Varma, A. H., & Bruneau, M. (2021). Seismic design coefficients and factors for coupled composite plate shear walls/concrete filled (CC-PSW/CF). Engineering Structures, 244, 112766.

Kurt, E. G., Varma, A. H., Booth, P., & Whittaker, A. S. (2016). In-plane behavior and design of rectangular SC wall piers without boundary elements. Journal of Structural Engineering, 142, 04016026.

LSTC. (1998). LS-Dyna, version R8.0. Livermore Software Technology Corporation. CA: Livermore.

LSTC (2013). Keyword User's Manual, Volume II, Material Models, Livermore Software Technology Corporation (LSTC), Livermore, CA, USA.

Malvar, L. J., Crawford, J. E., Wesevich, J. W., & Simons, D. (1997). A plasticity concrete material model for DYNA3D. International Journal of Impact Engineering, 19(9–10), 847–873.

Mander, J., Priestley, M., & Park, R. (1988a). Observed stress-strain behavior of confined concrete. Journal of Structural Engineering, 114(8), 1827–1849.

Mander, J. B., Priestley, M. J., & Park, R. (1988b). Theoretical stress-strain model for confined concrete. Journal of Structural Engineering, 114(8), 1804–1826.

Oduyemi, T., & Wright, H. (1989). An experimental investigation into the behaviour of double-skin sandwich beams. Journal of Constructional Steel Research, 14(3), 197–220.

Polat, E. (2020). Investigation of influence of concrete material models on cyclic inelastic response of a concrete filled composite plate shear wall. Challenge, 6(2), 91–98.

Polat, E., & Bruneau, M. (2017). Modeling cyclic inelastic in-plane flexural behavior of concrete filled sandwich steel panel walls. Engineering Structures, 148, 63–80.

Polat, E., & Bruneau, M. (2018). Cyclic inelastic in-plane flexural behavior of concrete filled sandwich steel panel walls with different cross-section properties. Engineering Journal, American Institute of Steel Construction, 55, 45–76.

Polat, E., Kenarangi, H., & Bruneau, M. (2021). Investigation of tie bars axial force demands in composite plate shear walls—concrete filled. International Journal of Steel Structures, 21(3), 901–921.

Ramesh, S. (2013). Behavior and design of earthquake-resistant dual-plate composite shear wall systems. PURDUE UNIVERSITY.

Razvi, S. R., & Saatcioglu, M. (1999). Analysis and design of concrete columns for confinement. Earthquake Spectra, 15(4), 791–811.

Saatcioglu, M., & Razvi, S. R. (1992). Strength and ductility of confined concrete. Journal of Structural Engineering, 118(6), 1590–1607.

Sener, K. C., & Varma, A. H. (2014). Steel-plate composite walls: Experimental database and design for out-of-plane shear. Journal of Constructional Steel Research, 100, 197–210.

Sener, K. C., Varma, A. H., & Ayhan, D. (2015). Steel-plate composite (SC) walls: Out-of-plane flexural behavior, database, and design. Journal of Constructional Steel Research, 108, 46.

Seo, J., Varma, A. H., Sener, K., & Ayhan, D. (2016). Steel-plate composite (SC) walls: In-plane shear behavior, database, and design. Journal of Constructional Steel Research, 119, 202–215.

Sheikh, S. A., & Uzumeri, S. M. (1982). Analytical model for concrete confinement in tied columns. Journal of the Structural Division, ASCE, 108(12), 2703–2722.

Varma, A. H., Malushte, S. R., Sener, K. C., & Lai, Z. (2014). Steel-plate composite (SC) walls for safety related nuclear facilities: Design for in-plane forces and out-of-plane moments. Nuclear Engineering and Design, 269, 240–249.

Varma, A. H., Shafaei, S., & Klemencic, R. (2019). Steel modules of composite plate shear walls: Behavior, stability, and design. Thin-Walled Structures Thin-Walled Structures, 145, 106384.

Wright, H., Oduyemi, T., & Evans, H. (1991). The experimental behaviour of double skin composite elements. Journal of Constructional Steel Research, 19(2), 97–110.

Wu, Y., Crawford, J. E., and Magallanes, J. M. "Performance of LS-DYNA concrete constitutive models." Proc., 12th International LS-DYNA Users Conference, 3–5.

Xie, M., & Chapman, J. (2006). Developments in sandwich construction. Journal of Constructional Steel Research, 62(11), 1123–1133.

Zhang, K., Varma, A. H., Malushte, S. R., & Gallocher, S. (2014). Effect of shear connectors on local buckling and composite action in steel concrete composite walls. Nuclear Engineering and Design, 269, 231–239.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declares that they have no conflicts of intrest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Finite Element Modeling and Verification

Appendix 1: Finite Element Modeling and Verification

1.1 General

Previously developed finite element (FE) models of C-PSW/CF by Polat and Bruneau (2017) were adopted in this study. In Polat and Bruneau (2017), LS-Dyna (LSTC) was used to develop FE models of the four experimentally tested walls by Alzeni and Bruneau (2017). The developed models accounted for foundation flexibility by explicitly modeling the foundation and produced good predictions of tested walls’ behavior. The focus of the study of Polat and Bruneau (2017) was to numerically replicate the observed hysteretic wall behavior such as wall pinching, flexural stiffness, and ultimate strength, which was successfully achieved by using the smear-crack Winfrith concrete model (available in LS-Dyna). However, the concrete model had limitations in terms of simulation of passive lateral confinement, which is related to concrete lateral expansion under compressive strains and an essential parameter in formation of axial force demands on tie bars. Because of its limited capacity in capturing shear dilation (Wu et al. 2012), another concrete model, namely the KCC model, was adopted. Polat et al. (2021) carried out numerical studies using the KCC model to investigate concrete confinement, passive lateral pressure and tie bar axial force demands. In addition, Polat et al. (2021) and Polat (2020) confirmed, by doing a comparative study between certain concrete models (i.e. Winfrith, KCC and CSCM models, all available in LS-Dyna), that the KCC model can reasonably predict wall strength and account for the confinement effect. The work performed in this section further verifies that the KCC model can reasonably predict wall strength and wall neutral axis and also provides some additional and supplementary work to that reported by Polat et al. (2021).

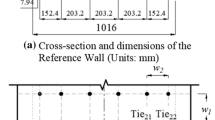

1.2 Overview of the Walls Analyzed

Figure 15 shows the cross-section of the walls (one of which was previously shown in Fig. 2a) that were modeled using FE methods. These walls were referred to NB1 (a) and B2 (b) by Alzeni and Bruneau (2017) and also described by the same name in this study. The elements that make up the wall cross-section and the cross-section dimensions are also shown in Fig. 15. Note that the geometric and material properties for the wall NB1 were previously described in Sect. 3 and are not repeated here. The geometric and material properties for the wall B2 are as follows: The wall B2 had a height of 3048 mm (120 in), and a wall depth of 1235 mm (48.625 in). It had boundary elements that consisted of round HSS columns (HSS 8.625 × 0.322). The steel web plates had a width of 762 mm (30 in) and thickness of 7.94 mm (5/16 in). The web plates were interconnected by circular tie bars with a diameter of 25.4 mm (1 in). The tie bars were spaced at horizontal (w1) and vertical (w2) intervals of 304.8 mm (12 in). The infill concrete had a uniaxial compressive strength of 48.8 MPa (7.08 ksi) (obtained from concrete cylinder tests). The steel web plates and the HSS had a yield strength of 441 MPa (64 ksi) and 386 MPa (56 ksi), respectively.

Element and Material Models

Figure 16 shows the FE model of the wall B2 developed using LS-Dyna R8.0. As illustrated in this Figure, the concrete was modeled using eight-node solid elements (Solid 1) with reduced integration; the steel plates were modeled using four-node fully integrated shell elements (Shell 16), and the tie bars were modeled using two-node beam elements (Beam 1) with Hughes-Liu formulation. The dimension of the solid elements was 25.4 × 25.4x25.4 mm (1 × 1x1 in), the dimension of the shell elements was 25.4 × 25.4 mm (1 × 1 in), and the beam elements had a length of 25.4 mm (1 in). Note that, the same modeling aspects apply to the wall NB1 as well. The interaction between the wall steel surface and concrete was considered by the definition of the surface-to-surface contact model. The automatic_surface_to_surface_mortar contact model available in the program uses an isotropic friction law. A static friction coefficient of 0.3 was used to account friction in the analysis models. (The work substantiating the choice of this contact model is presented by Polat and Bruneau (2017)).

In LS-Dyna, the Mat003 plastic-kinematic material model was used to model the steel material of the plates and the tie bars of the wall. A schematic of the stress–strain behavior of Mat003 is shown in Fig. 17. The bi-linear model shown in this Figure consists of the parameters of the yield strength, σYO; maximum strength, σY1; elastic modulus, E, and; tangent modulus, ET. The material model has an option of kinematic and isotropic hardening (it is defined by the parameter β) and kinematic hardening was used in the analysis. The actual stress–strain curve of the steel material was idealized for use in the analysis as shown in Fig. 18. The steel material properties defined for the wall NB1 are as follows: σYO(WP) = 427 MPa (62 ksi), σYO(HSS) = 317 MPa (46 ksi), E(WP) = 205,463 MPa (29,800 ksi), E(HSS) = 189,605 MPa (27,500 ksi), ET(WP) = 551 MPa ( 80 ksi), ET(HSS) = 344 MPa (50 ksi). The material properties defined for the wall B2 are as follows: σYO(WP) = 441 MPa (64 ksi), σYO(HSS) = 386 MPa (56 ksi), E(WP) = 205,463 MPa (29,800 ksi), E(HSS) = 189,605 MPa (27,500 ksi), ET(WP) = 689 MPa (100 ksi), ET(HSS) = 413 MPa (60 ksi).

The Mat072R3, Karagozian & Case Concrete Model – Release III (KCC), was used to model the concrete of the wall. This model has two options: the complex material definition by user and the parameter generation option (the model parameter generation capability was provided by Release III (LSTC, 2013)). The latter option was preferred here because its convenience of definition of nonlinear behavior of concrete by solely the definition of unconfined compression strength of the concrete. An open-source reference of the material model after Release III is not available. Prior to Release III version of the KCC model, an open-source reference containing the KCC constitutive law is provided by Malvar et al. (1997) (LSTC, 2013). The elastic modulus (Ec) of the concrete is internally calculated and given by \(57000\sqrt{{f}_{c}^{^{\prime}}}\) (in psi). For the wall NB1, fc = 47.8 MPa (6.94 ksi) and Ec = 32,750 MPa (4750 ksi). For the wall B2, fc = 48.8 MPa (7.08 ksi) and Ec = 32,960 MPa (4780 ksi). Other parameters such as concrete tensile strength (taken equal to 10% of fc) and Poisson’s ratio (0.2) were also defined for the KCC model.

It should be noted that modeling strength degradation was not within the scope of the study here. Therefore, analysis models did not consider material damage in their formulations required to simulate observed damage in testing (i.e.; fracture initiation and propagation, which was the cause of the strength degradation observed in the experimental hysteretic curves (Alzeni & Bruneau, 2017)).

1.3 Comparison of Inelastic Cyclic Wall Response

The walls shown in Fig. 15a-b were analyzed under cyclic displacement with the same loading history as the experimental walls. It should be noted that the experimental walls had a base footing and, therefore, base flexibility. However, FE models were developed excluding the experimental setup due to the time it takes for the numerical solution and numerical convergence issues of the wall containing the experimental setup. (The typical analysis duration of the wall model including the experimental set-up (e.g., wall base footing, strong floor, etc.) is about 60 h using 12-core dedicated processors and using the implicit solution procedure of LS-Dyna). Note that, base flexibility has influence on wall stiffness and axial strain demands of the wall parts at certain drift ratios. For example, at certain drift ratios, axial strain demands of the wall parts of the fixed-base wall are always larger than that of the wall with base flexibility. In other words, same strain values occur at larger drift levels for the wall with base flexibility than the fixed-base wall. If the wall axial strain demands can be matched, as it is done here, a comparison for walls neutral axes can be made.

Figure 19a-b compares the wall base shear (lateral force) versus drift ratio of the fixed-base FE model of the walls: a) NB1, and; b) B2, with the measured values of the tested specimens. The FE models using the KCC material model successfully captured the ultimate strength of the walls tested. Since the KCC model does not simulate the opening and closing of cracks in concrete, the pinching effect observed in the hysteresis of the tested walls could not be captured.

Figure 20a–b compares the neutral axes of the fixed base FE models of the walls: a) NB1, and; b) B2, with the measured values of the tested specimens. Given that the developed FE models were not exact replicate of the tested walls (i.e., base footing of the wall was not accounted) minor differences in results are acceptable. Because the FE models’ base flexibilities were different than the tested walls, the neutral axes were compared at different drift levels but at approximately the same values of axial strain demands. For example, for the wall NB1, axial strain history values measured at 0.40% and 1.80% drift ratio for the tested wall were obtained approximately at 0.20% and 0.90% drift ratio for the numerical wall. For the wall NB1 (Fig. 20a), the neutral axes obtained for the FE model match reasonably with those obtained experimentally. Note that for the FE model at 0.9% drift, the strain results, within the range of −200 mm to −600 mm of the cross-section depth, show some difference. This is attributed to inability of the KCC model in simulating crack opening. Consequently, this resulted in less strain on the steel plate of the FE model compared to the actual axial strain demands. For the wall B2 (Fig. 20b), the neutral axes obtained for the FE model at 0.36% drift matches reasonably with the test at 0.56% drift, whereas the predicted neutral axis of the FE model at 1.0% drift differs by approximately 70 mm (2.75 in) from that of the tested at 2.0% drift. Given that the developed FE models were not an exact replicate of the tested walls the small differences in the results were deemed acceptable.

Figure 21 shows the axial stress distribution of the wall NB1 for the: a) steel plates, and b) concrete at selected wall drift ratios of 0.4%, 0.9%, 1.8%, 2.4%, and 3.6%. Note that average axial stress values across the wall thickness were reported for the concrete. (Note also that axial stress values for the concrete core (the part of the concrete inside the HSS) were not included in the Figure). In this Figure, Fy-WP is the yield strength of the steel wep plate, Fy-HSS is the yield strength of the HSS, and fc’ is the unconfined uniaxial compressive strength of the concrete. The location of the wall neutral axis for each drift level can also be measured in this Figure and seen to be consistent with that shown in Fig. 20a. Figure 21b shows the level of confinement of the concrete under increasing wall drifts. For example, the obtained average axial stress value at 2.0% drift ratio is about −92 MPa (−13.3 ksi) compared to −47.6 MPa (6.9 ksi) unconfined compressive strength of the concrete.

According to the above comparative study, there was reasonable agreement between the FE models of the walls and the experimental results. The performance of the developed FE models with the considered material properties were deemed to be satisfactory in terms of the work carried out in this paper.

Rights and permissions

About this article

Cite this article

Polat, E. Theoretical Models for Tie Bar Maximum Axial Force Demand in Composite Plate Shear Walls–Concrete Filled. Int J Steel Struct 22, 1108–1125 (2022). https://doi.org/10.1007/s13296-022-00625-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13296-022-00625-y