Abstract

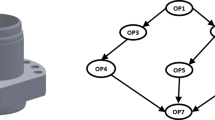

Remanufacturing is a practice that postpones the product ‘end-of-life’ by returning the properties or features of a new product to a used product. Such a process represents an efficient circular economy strategy to extend product life, reducing its environmental footprint. However, remanufacturing systems must overcome distinct challenges related to information uncertainties about quantity and conditions of used products. Current strategies to address these issues include smart approaches towards smart remanufacturing systems. However, remanufacturing architectures must manage the negative effects on operations derived from the used product’s deterioration and return rate variability, as well as remanufactured products demand fluctuations. This study contributes to address this issue by a Reconfigurable Cellular Remanufacturing Architecture that is integrated in a business strategy towards smart sustainable remanufacturing. The design process is based on a multi-objective optimization model that minimizes the grouping cost, the workload balancing cost, the investment cost, the makespan cost and the reconfigurable cost. A customized version of the well-known multi-objective evolutionary non-dominated sorting genetic algorithm II (NSGA2), a mono-objective genetic algorithm (GA-mo) and a GAMS model were implemented to obtain the potential architecture’ configurations for an explanatory case study based on real-world industrial and random data, respectively. Two procedures to identify the best architecture were also considered. A sensitivity analysis is presented to illustrate the robustness of the proposed model. Managerial insights illustrate about solution methods, and best architecture selection. Practical implications also are provided to offer useful options for practitioners.

Similar content being viewed by others

Data availability

The GAMS model and case study data are available in https://github.com/cmm14art/art_rcra_case_study.

References

Ellen MacArthur Foundation: towards circular economy. https://www.ellenmacarthurfoundation.org/assets/downloads/publications/Ellen-MacArthur-Foundation-Towards-the-Circular-Economy-vol.1.pdf. Accessed 7 May 2022

Matsumoto M, Yang S, Martinsen K, Kainuma Y (2016) Trends and research challenges in remanufacturing. Int J Precision Eng Manuf - Green Technol 3:129–142. https://doi.org/10.1007/s40684-016-0016-4

Karvonen I, Jansson K, Behm K, Vatanen S, Parker D (2017) Identifying recommendations to promote remanufacturing in Europe. J Remanuf 7:159–179. https://doi.org/10.1007/s13243-017-0038-2

Russell J, Nasr N (2019) Value-retention processes within the circular economy. Remanufacturing in the circular economy: operations, engineering and logistics. Wiley Online Books, pp 1–29. https://doi.org/10.1002/9781119664383.CH1

Bulmuş SC, Zhu SX, Teunter R (2013) Capacity and production decisions under a remanufacturing strategy. Int J Prod Econ 145:359–370. https://doi.org/10.1016/J.IJPE.2013.04.052

Saidani M, Yannou B, Leroy Y, Cluzel F (2020) Dismantling, remanufacturing and recovering heavy vehicles in a circular economy—technico-economic and organisational lessons learnt from an industrial pilot study. Resour Conserv Recycl 156:104684. https://doi.org/10.1016/j.resconrec.2020.104684

Chaowanapong J, Jongwanich J, Ijomah W (2018) The determinants of remanufacturing practices in developing countries: evidence from Thai industries. J Clean Prod 170:369–378. https://doi.org/10.1016/j.jclepro.2017.09.134

Tolio T, Bernard A, Colledani M, Kara S, Seliger G, Duflou J, Battaia O, Takata S (2017) Design, management and control of demanufacturing and remanufacturing systems. CIRP Ann Manuf Technol 66:585–609. https://doi.org/10.1016/j.cirp.2017.05.001

Toxopeus ME, Haanstra W, Van Gerrevink MR, Van Der Meide R (2017) A case study on industrial collaboration to close material loops for a domestic boiler. Procedia CIRP 61:52–57. https://doi.org/10.1016/j.procir.2016.11.246

Kurilova-Palisaitiene J, Sundin E, Poksinska B (2018) Remanufacturing challenges and possible lean improvements. J Clean Prod 172:3225–3236. https://doi.org/10.1016/j.jclepro.2017.11.023

Milios L, Matsumoto M (2019) Consumer perception of remanufactured automotive parts and policy implications for transitioning to a circular economy in Sweden. Sustainability (Switzerland) 11:6264. https://doi.org/10.3390/su11226264

Rizova MI, Wong TC, Ijomah W (2020) A systematic review of decision-making in remanufacturing. Comput Ind Eng 147:106681. https://doi.org/10.1016/j.cie.2020.106681

Abbey JD, Kleber R, Souza GC, Voigt G (2017) The role of perceived quality risk in pricing remanufactured products. Prod Oper Manag 26:100–115. https://doi.org/10.1111/poms.12628

Chinen K, Matsumoto M (2021) Indonesians’ perceptions of auto parts remanufactured in China: implications for global remanufacturing operations. Sustainability (Switzerland) 13:1–16. https://doi.org/10.3390/su13073968

Okorie O, Obi M, Russell J, Charnley F, Salonitis K (2021) A triple bottom line examination of product cannibalisation and remanufacturing: A review and research agenda. Sustain Prod Consum 27:958–974. https://doi.org/10.1016/j.spc.2021.02.013

Mejía-Moncayo C, Kenné J-P, Hof LA (2023) On the development of a smart architecture for a sustainable manufacturing-remanufacturing system: a literature review approach. Comput Ind Eng 180:109282. https://doi.org/10.1016/j.cie.2023.109282

Kerin M, Pham DT (2020) Smart remanufacturing: a review and research framework. J Manuf Technol Manag 31(6). https://doi.org/10.1108/JMTM-06-2019-0205

Bagalagel SM, ElMaraghy W (2022) A Framework for Industry 4.0 Implementation in Circular Economy Manufacturing Systems. In: Andersen AL et al (eds) Towards sustainable customization: bridging smart products and manufacturing systems. CARV MCPC 2021 2021. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-030-90700-6_114

Kerin M, Pham DT (2019) A review of emerging industry 4.0 technologies in remanufacturing. J Clean Prod 237:117805. https://doi.org/10.1016/j.jclepro.2019.117805

Deb K, Pratab S, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NGSA-II. IEEE Trans Evol Comput 6:182–197

Czyzyk J, Mesnier MP, More JJ (1998) The NEOS Server. IEEE Comput Sci Eng 5:68–75. https://doi.org/10.1109/99.714603

Saaty RW (1987) The analytic hierarchy process—what it is and how it is used. Math Model 9:161–176. https://doi.org/10.1016/0270-0255(87)90473-8

Romero GA, Mejía-Moncayo C, Torres JA (2015) Modelos matemáticos para la definición del layout de las celdas de manufactura. Revisión de literatura. Revista Tecnura 19:135–148. https://doi.org/10.14483/udistrital.jour.tecnura.2015.4.a11

Daneshmand M, Noroozi F, Corneanu C, Mafakheri F, Fiorini P (2022) Industry 4.0 and prospects of circular economy: a survey of robotic assembly and disassembly. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-021-08389-1

Garrido-Hidalgo C, Ramirez FJ, Olivares T, Roda-Sanchez L (2020) The adoption of internet of things in a circular supply chain framework for the recovery of WEEE: the case of Lithium-ion electric vehicle battery packs. Waste Manag 103:32–44. https://doi.org/10.1016/j.wasman.2019.09.045

Delpla V, Kenné JP, Hof LA (2021) Circular manufacturing 4.0: towards internet of things embedded closed-loop supply chains. Int J Adv Manuf Technol 118:3241–3264. https://doi.org/10.1007/s00170-021-08058-3

Niu B, Xu H, Chen L (2022) Creating all-win by blockchain in a remanufacturing supply chain with consumer risk-aversion and quality untrust. Transp Res E Logist Transp Rev 163:102778. https://doi.org/10.1016/j.tre.2022.102778

Matenga AE, Mpofu K (2023) Blockchain-based product lifecycle management using supply chain management for railcar remanufacturing. Procedia CIRP 116:486–491. https://doi.org/10.1016/j.procir.2023.02.082

Bettín-Díaz R, Mejía-Moncayo C, Rojas AE (2021) A blockchain-based approach to support an ISO 9001:2015 quality management system. ParadigmPlus 2:17–32. https://doi.org/10.55969/PARADIGMPLUS.V2N2A2

Bressanelli G, Adrodegari F, Perona M, Saccani N (2018) The role of digital technologies to overcome circular economy challenges in PSS business models: an exploratory case study. Procedia CIRP 73:216–221. https://doi.org/10.1016/j.procir.2018.03.322

Acerbi F, Forterre DA, Taisch M (2021) Role of artificial intelligence in circular manufacturing: a systematic literature review. In: 17th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2021, vol 54, no 1. Elsevier B.V., pp 367–372. https://doi.org/10.1016/j.ifacol.2021.08.040

SKF: Improve uptime, efficiency and reliability with AI-driven industrial analytics (2020). https://cdn.skfmediahub.skf.com/api/public/0901d19680ba9a3e/pdf_preview_medium/0901d19680ba9a3e_pdf_preview_medium.pdf#cid-567836. Accessed 7 May 2022

Mejía-Moncayo C, Rojas AE, Mura I (2018) A discrete bacterial chemotaxis approach to the design of cellular manufacturing layouts. Lecture Notes Comput Sci (Including Subser Lecture Notes Artif Intell Lecture Notes Bioinformatics) 10960 LNCS, pp 423–437. https://doi.org/10.1007/978-3-319-95162-1_29

Mejía-Moncayo C, Battaia O (2019) A hybrid optimization algorithm with genetic and bacterial operators for the design of cellular manufacturing systems. IFAC-PapersOnLine 52:1409–1414. https://doi.org/10.1016/j.ifacol.2019.11.396

Papaioannou G, Wilson JM (2010) The evolution of cell formation problem methodologies based on recent studies (1997–2008): review and directions for future research. Eur J Oper Res 206:509–521. https://doi.org/10.1016/j.ejor.2009.10.020

Mejia-Moncayo C, Rojas AE, Dorado R (2017) Manufacturing cell formation with a novel discrete bacterial chemotaxis optimization algorithm. Commun Comput Inf Sci 742:579–588. https://doi.org/10.1007/978-3-319-66963-2

Mejia-Moncayo C, Rojas AE, Kenne J-P, Hof LA (2022) An ant approach to define product families and remanufacturing cells. IFAC-PapersOnLine 55:73–78. https://doi.org/10.1016/J.IFACOL.2022.09.370

Aljuneidi T, Bulgak AA (2017) Designing a cellular manufacturing system featuring remanufacturing, recycling, and disposal options: a mathematical modeling approach. CIRP J Manuf Sci Technol 19:25–35. https://doi.org/10.1016/j.cirpj.2017.04.005

Koren Y, Heisel U, Jovane F, Moriwaki T, Pritschow G, Ulsoy G, Van Brussel H (1999) Reconfigurable manufacturing systems. CIRP Ann Manuf Technol 48:527–540. https://doi.org/10.1016/S0007-8506(07)63232-6

Bortolini M, Galizia FG, Mora C (2018) Reconfigurable manufacturing systems: literature review and research trend. J Manuf Syst 49:93–106. https://doi.org/10.1016/j.jmsy.2018.09.005

Bi ZM, Lang SYT, Shen W, Wang L (2008) Reconfigurable manufacturing systems: the state of the art. Int J Prod Res 46:967–992. https://doi.org/10.1080/00207540600905646

Koren Y, Shpitalni M (2010) Design of reconfigurable manufacturing systems. J Manuf Syst 29:130–141. https://doi.org/10.1016/j.jmsy.2011.01.001

Andersen AL, Brunoe TD, Bockholt MT, Napoleone A, Hemdrup Kristensen J, Colli M, Vejrum Wæhrens B, Nielsen K (2023) Changeable closed-loop manufacturing systems: challenges in product take-back and evaluation of reconfigurable solutions. Int J Prod Res 61:839–858. https://doi.org/10.1080/00207543.2021.2017504

Yao X, Zhou J, Lin Y, Li Y, Yu H, Liu Y (2019) Smart manufacturing based on cyber-physical systems and beyond. J Intell Manuf 30:2805–2817. https://doi.org/10.1007/s10845-017-1384-5

Napoleone A, Macchi M, Pozzetti A (2020) A review on the characteristics of cyber-physical systems for the future smart factories. J Manuf Syst 54:305–335. https://doi.org/10.1016/j.jmsy.2020.01.007

Brunoe TD, Andersen AL, Nielsen K (2019) Changeable manufacturing systems supporting circular supply chains. In: 52nd CIRP Conference on Manufacturing Systems (CMS), Ljubljana, Slovenia, June 12–14, 2019. Procedia CIRP, vol 81. Elsevier B.V., pp 1423–1428. https://doi.org/10.1016/j.procir.2019.05.007

Eguia I, Lozano S, Racero J, Guerrero F (2011) A methodological approach for designing and sequencing product families in reconfigurable disassembly systems. J Ind Eng Manag 4:418–435. https://doi.org/10.3926/jiem.2011.v4n3.p418-435

Ponis S, Aretoulaki E, Maroutas TN, Plakas G, Dimogiorgi K (2021) A systematic literature review on additive manufacturing in the context of circular economy. Sustainability 13:6007

Fan X, Zhang Z, Jin X, Yuan W, Guo N (2010) TTechnology of reconfigurable multi-process combined machining for remanufacturing. 2010 International Conference on E-Product E-Service and E-Entertainment, ICEEE2010. https://doi.org/10.1109/ICEEE.2010.5661040

HooshyarTelegraphi A, Bulgak AA (2021) A mathematical model for designing a reliable cellular hybrid manufacturing-remanufacturing system considering alternative and contingency process routings. SN Appl Sci 3:356. https://doi.org/10.1007/s42452-021-04315-y

Mejía-Moncayo C, Kenné J-P, Hof LA (2021) A hybrid architecture for a reconfigurable cellular remanufacturing system. In: Dolgui A, Bernard A, Lemoine D, von Cieminski G, Romero D (eds) Advances in production management systems. Artificial intelligence for sustainable and resilient production systems. Springer International Publishing, Cham, pp 488–496

Gen M, Lin L, Zhang H (2009) Evolutionary techniques for optimization problems in integrated manufacturing system: state-of-the-art-survey. Comput Ind Eng 56:779–808. https://doi.org/10.1016/j.cie.2008.09.034

Acknowledgements

The authors would like to acknowledge the financial support of the Natural Sciences and Engineering Research Council of Canada (NSERC) under the Discovery Grant (RGPIN-2018-05292 and RGPIN-2019-05973).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Genetic algorithms NSGA2 and GA-mo

This study implements in Matlab 2021a two genetic algorithms to solve the proposed multi-objective model, both share the same solutions coding and operators. The first is a customized version of NSGA2 [20], and the second is a mono-objective genetic algorithm that uses weighted factors as goal programming.

NSGA2 starts randomly generating the initial population, and a set of non-dominated solutions was obtained. These solutions fed the next iteration step as part of the initial population, which was then completed randomly. Following this incremental solution process, the final iteration provided the best last non-dominated solutions. Here, the NSGA2 and GA-mo were run with the following parameters: number of individuals = 100, generations = 100, iterations = 1000, crossover probability = 0.9, and the mutation probability = 0.1.

Coding solutions

The customization of NSGA2 starts by defining a hybrid data structure for the solutions codification. Similarly, the generation of the initial population, crossover, and mutation processes were customized.

The decision variables \({X}_{ik, }{Y}_{jk}, {Z}_{ijl}\) and \({W}_{pjj{\prime}k}\), described in the mathematical model, were coded in variable Var as a set of four vectors:

The first vector, VarX, is defined by a binary structure that contains the rows of the \({X}_{ik,}\) matrix.

The second vector, VarY, contains the number of the product family or cell k to which each product j was assigned, according to the solution codification based on the cell number exposed by Gen et al. [52] This data structure allows to directly manage Eq. (13), which ensures that each product j is only assigned to a single family or cell k.

The third vector, VarZ, contains the number of type i workplaces required to manufacture product i.

The fourth vector, VarW, contains numbers between 0 and 1, which represent the relative position among the products to determine the production sequences \({W}_{pjj{\prime}k}\), as is described next.

The decodification of the variable \({W}_{pjj{\prime}k}\), requires more steps than the previously described ones. This process starts with the vector VarW that store the rows of the matrix \({d}_{pj}^{W}\), where each row presents a period p and each column presents a product j. In a next step, for each period of dWpj, the values which belong to each product family were identified using variable Yjk, hence defining dtemp. Then, in a following step, the obtained values were classified in ascending order to identify the production sequence for each product family in each period. Finally, using this information, the full Wjj′p matrix was defined.

The model constrains were managed using data structure, and penalization and solution correction operators as described in the following. The constrains described as the model Eqs. (12), (13) and (14) were managed using a penalization strategy. Here, each model constraint is verified in a prior step to calculate the objective function for each solution. If a solution is not in agreement with a constraint, a penalization factor is increased. Finally, the objective related to this constraint is then multiplied by the penalization factor.

In addition, two solution correction operators were implemented to fulfil the constraints described in Eqs. (12) to (14). After the solution decoding process, if a solution did not fulfil the constraints Eqs. (12) and (13), workplace i was assigned to the cell or family belonging to product j.

Initial population

The initial population brings the seeds from it starts optimization process to NSGA2-RCRSA, based on solutions coded as Var = (VarX,VarY ,VarZ,VarW), which was implemented according to two strategies. The first strategy defined the population randomly, and the second one followed a heuristic process. For each VarX vector position, a random number a was generated, if a ≤ 0.5 V arX = 1, otherwise VarX = 0. For each position of VarY and VarZ a random integer ranging from 1 to mc was generated. Finally, VarW was generated as a random vector. This strategy allowed to explore the search space; however, it could not be optimized. Hence, for half of the population, the second strategy was implemented. First, a base V arY was defined, where a product j that is processed in a workplace i was assigned to the same cell or product family. Second, to balance the workload and to reduce the makespan in scheduling, VarZ adopts the values of the balanced workplaces \(=\lceil\frac{{t}_{ijl}^{op}}{{t}_{j}^{c}}\rceil\), which approximates the ideal number of workplaces i to balance topijl. Finally, the random values are assigned to VarW trying to be near to the ideal production sequences.

Reproduction

The algorithms use sexual reproduction as a mechanism to exchange information among individuals for improving the population. In this way, this process allows the population’s evolution, providing the features of the best adapted individuals of the current generation to the next one [20]. This process starts with parents’ selection, which in this study was realized through a binary tournament.

A crossover process was conducted after parent selection. During this process, the information of the parents was exchanged. For VarX, VarY, and VarZ a crossover with a single cross point was implemented, as shown in the following example:

For this example, the cross point is the third position, hence as a result two children are obtained:

Given that V arW is a real vector, its crossover is implemented as a random weighted average of the two parents to generate a child:

where α is a random weighted factor.

The last reproduction process is mutation. It allows exploring the search space to generate tiny random changes to some individuals. This mutation is an essential feature of evolutionary algorithms which helps to avoid local optimal solutions. The mutation process was applied to randomly selected individuals (GA-mo) or dominated by others (NSGA2). For each element of an individual vector, a random number was generated, and if less than the mutation probability the element was mutated. In the case of VarX, if the element is ”1”, its value is changed to ”0” and vice-versa. VarY and VarZ were mutated increasing or decreasing the selected element by one unit. If the element value was ”1”, it can only be increased. Finally, VarW is mutated multiplying the element by a random factor that can increase or decrease its value.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mejía-Moncayo, C., Kenné, JP. & Hof, L.A. A Reconfigurable Cellular Remanufacturing Architecture: a multi-objective design approach. Jnl Remanufactur (2024). https://doi.org/10.1007/s13243-024-00139-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13243-024-00139-2