Abstract

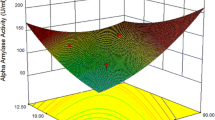

A newly isolated amylolytic strain was identified as Bacillus cereus spH1 based on 16S and 16-23S gene sequencing (Accession numbers OP811441.1 and OP819558, respectively), optimization strategies, using one variable at time (OVAT) and Plackett–Burman design, were employed to improve the alpha-amylase (α-amylase) production. Condition inferred revealed that the optimal physical parameters for maximum enzyme production were 30 °C, pH 7.5, and 12 h of incubation, using tryptone, malt extract, orange (Citrus sinensis) peels, crab (Portunus segnis) shells, calcium, and sodium chloride (NaCl) as culture medium. The full factorial design (FFD) model was observed to possess a predicted R2 and adjusted R2 values of 0.9788 and 0.9862, respectively, and it can effectively predict the response variables (p = 0). Following such efforts, α-amylase activity was increased 141.6-folds, ranging from 0.06 to 8.5 U/mL. The ideal temperature and pH for the crude enzyme activity were 65 °C and 7.5, respectively. The enzyme exhibited significant stability, with residual activity over 90% at 55 °C. The maltose was the only product generated during the starch hydrolysis. Moreover, the Bacillus cereus spH1 strain and its α-amylase were used in the treatment of effluents from the pasta industry. Germination index percentages of 143% and 139% were achieved when using the treated effluent with α-amylase and the strain, respectively. This work proposes the valorization of agro-industrial residues to improve enzyme production and to develop a green and sustainable approach that holds great promise for environmental and economic challenges.

Similar content being viewed by others

Data Availability

All the relevant data have been provided in the manuscript. Links to the submitted sequences: Bacillus cereus strain H1 16S ribosomal RNA gene, partial sequence: https://www.ncbi.nlm.nih.gov/nucleotide/OP811441.1?report=genbank&log$=nuclalign&blast_rank=1&RID=TZEBW479016; Bacillus cereus 16S-23S ribosomal RNA intergenic spacer and 23S ribosomal RNA gene, partial sequence: https://www.ncbi.nlm.nih.gov/nucleotide/OP819558.1?report=genbank&log$=nuclalign&blast_rank=1&RID=TZEPY6CJ013.

References

Abd-Elaziz AM, Karam EA, Ghanem MM et al (2020) Production of a novel α-amylase by Bacillus atrophaeus NRC1 isolated from honey: purification and characterization. Int J Biol Macromol 148:292–301. https://doi.org/10.1016/j.ijbiomac.2020.01.120

Abd-Elhalim BT, Gamal RF, El-Sayed SM, Abu-Hussien SH (2023) Optimizing alpha-amylase from bacillus amyloliquefaciens on bread waste for effective industrial wastewater treatment and textile desizing through response surface methodology. Sci Rep 13:19216. https://doi.org/10.1038/s41598-023-46384-6

Afrisham S, Badoei-Dalfard A, Namaki-Shoushtari A, Karami Z (2016) Characterization of a thermostable, cacl 2 -activated and raw-starch hydrolyzing alpha-amylase from Bacillus licheniformis AT70: production under solid state fermentation by utilizing agricultural wastes. J Mol Catal B Enzym 132:98–106. https://doi.org/10.1016/j.molcatb.2016.07.002

Ahmed SA, Mostafa FA, Helmy WA, Abdel-Naby MA (2017) Improvement of bacterial α-amylase production and application using two steps statistical factorial design. Biocatal Agric Biotechnol 10:224–233. https://doi.org/10.1016/j.bcab.2017.03.004

Ali EH, El-Nagdy MA, Al-Garni SM et al (2017) Enhancement of alpha amylase production by Aspergillus flavus AUMC 11685 on mandarin (Citrus reticulata) peel using submerged fermentation. Eur J Biol Res 7(3):154–64

Alonazi M, Karray A, Badjah-Hadj-Ahmed AY, Ben Bacha A (2020) Alpha amylase from Bacillus pacificus associated with brown algae Turbinaria ornata: cultural conditions, purification, and biochemical characterization. Processes 9:16. https://doi.org/10.3390/pr9010016

Amin K, Tranchimand S, Benvegnu T et al (2021) Glycoside hydrolases and glycosyltransferases from hpyerthermophilic archea: insights on their characteristics and applications in biotechnology. Biomolecules 11:1557. https://doi.org/10.3390/biom11111557

Anupama A, Jayaraman G (2011) Detergent stable, halotolerant α-amylase from Bacillus aquimaris vitp4 exhibits reversible unfolding. Int J Appl Biol Pharm Technol 2:366–376

Awasthi MK, Sarsaiya S, Wainaina S et al (2021) Techno-economics and life-cycle assessment of biological and thermochemical treatment of bio-waste. Renew Sustain Energy Rev 144:110837. https://doi.org/10.1016/j.rser.2021.110837

Bejaoui S, Ghribi F, Hatira S et al (2017) First investigation in the biochemical analysis of the invasive crab portunus segnis from Tunisian waters. J Am Oil Chem Soc 94:673–682. https://doi.org/10.1007/s11746-017-2987-x

Bhatia SK, Jagtap SS, Bedekar AA et al (2020) Recent developments in pretreatment technologies on lignocellulosic biomass: effect of key parameters, technological improvements, and challenges. Bioresour Technol 300:122724. https://doi.org/10.1016/j.biortech.2019.122724

Bhatt K, Lal S, Srinivasan R, Joshi B (2020) Bioconversion of agriculture wastes to produce α-amylase from bacillus velezensis KB 2216: purification and characterization. Biocatal Agric Biotechnol 28:101703. https://doi.org/10.1016/j.bcab.2020.101703

Bouaziz A, Horchani H, Ben Salem N, Gargouri Y, Sayari A (2011) Expression, purification of a novel alkaline Staphylococcus xylosus lipase acting at high temperature. Biochem Eng J 54(2):93–102

Caliskan Ozdemir S, Coleri Cihan A, Kilic T, Cokmus C (2016) Optimization of thermostable alpha-amylase production from Geobacillus sp. D413. J Microbiol Biotechnol Food Sci 6:689–694. https://doi.org/10.15414/jmbfs.2016.6.1.689-694

Chouchane H, Hoekstra AY, Krol MS, Mekonnen MM (2015) The water footprint of Tunisia from an economic perspective. Ecol Indic 52:311–319. https://doi.org/10.1016/j.ecolind.2014.12.015

Crini G, Lichtfouse E (2018) Advantages and disadvantages of techniques used for wastewater treatment. Environ Chem Lett 17:145–155. https://doi.org/10.1007/s10311-018-0785-9

Deljou A, Arezi I (2016) Production of thermostable extracellular α-amylase by a moderate thermophilic Bacillus licheniformis isolated from Qinarje Hot spring (Ardebil Prov. of Iran). Periodicum Biologorum 118(4):405–416. https://doi.org/10.18054/pb.v118i4.3737

Deshmukh RK, Naik JB (2013) Diclofenac sodium-loaded Eudragit® microspheres: optimization using statistical experimental design. J Pharm Innov 8:276–287. https://doi.org/10.1007/s12247-013-9167-9

Duque SMM, Dizon EI, Merca FE, Flores DM (2016) Optimization of raw-starch-digesting amylase (RSDA) production medium for Enterococcus faecium DMF78. Int Food Res J 23:1280–1288

Elyasi Far B, Dilmaghani A, Yari Khosroushahi A (2020) In silico study and optimization of Bacillus megaterium alpha-amylases production obtained from honey sources. Curr Microbiol 77:2593–2601. https://doi.org/10.1007/s00284-020-02019-x

Embaby AM, Masoud AA, Marey HS et al (2014) Raw agro-industrial orange peel waste as a low-cost effective inducer for alkaline polygalacturonase production from bacillus licheniformis shg10. SpringerPlus 3:327. https://doi.org/10.1186/2193-1801-3-327

Esparza I, Jiménez-Moreno N, Bimbela F et al (2020) Fruit and vegetable waste management: conventional and emerging approaches. J Environ Manag 265:110510. https://doi.org/10.1016/j.jenvman.2020.110510

Farias TC, Kawaguti HY, Bello Koblitz MG (2021) Microbial amylolytic enzymes in foods: technological importance of the bacillus genus. Biocatal Agric Biotechnol 35:102054. https://doi.org/10.1016/j.bcab.2021.102054

Food and Agricultural Organization Statistics (2021). https://www.fao.org/faostat/fr/#home

Hu Q, Wu Q, Dai B et al (2022) Fermentation optimization and amylase activity of endophytic Bacillus velezensis D1 isolated from corn seeds. J Appl Microbiol 132:3640–3649

Industrial enzymes market size, share, growth opportunities (2023) Market-report https://www.marketsandmarkets.com/Market-Reports/industrial-enzymes-market-237327836.html. Accessed 18 Nov 2023a

Iram N, Shakir HA, Irfan M et al (2021) Statistical optimization of amylase production using grape fruit peels in submerged fermentation. Acta Sci Technol 43(1):e50538. https://doi.org/10.4025/actascitechnol.v43i1.50538

Keskin Gündoğdu T, Deniz İ, Çalışkan G et al (2014) Experimental design methods for bioengineering applications. Crit Rev Biotechnol 36:368–388. https://doi.org/10.3109/07388551.2014.973014

Kikani BA, Kourien S, Rathod U (2019) Stability and thermodynamic attributes of starch hydrolyzing α-amylase of Anoxybacillus rupiensis TS-4. Starch-Stärke 72(1–2):1900105. https://doi.org/10.1002/star.201900105

Kini UA, Shettar M, Sharma S et al (2019) Effect of hygrothermal aging on the mechanical properties of nanoclay-glass fiber-epoxy composite and optimization using full factorial design. Mater Res Express 6:065311. https://doi.org/10.1088/2053-1591/ab0d68

Lakshmi SS, Mahesh CH, Gayatri K et al (2020) Statistical optimization of amylase production and its purification from a palm wine isolate Bacillus sp., Q-164. Biocatal Agric Biotechnol 29:101820. https://doi.org/10.1016/j.bcab.2020.101820

Li S-W, He H, Zeng RJ, Sheng G-P (2017) Chitin degradation and electricity generation by Aeromonas hydrophila in microbial fuel cells. Chemosphere 168:293–299. https://doi.org/10.1016/j.chemosphere.2016.10.080

Londoño-Hernandez L, Ruiz HA, Toro CR et al (2020) Advantages and progress innovations of solid-state fermentation to produce industrial enzymes. Microorg Sustain. https://doi.org/10.1007/978-981-15-1710-5_4

Mojumdar A, Deka J (2019) Recycling agro-industrial waste to produce amylase and characterizing amylase–gold nanoparticle composite. Int J Recycl Org Waste Agric 8:263–269. https://doi.org/10.1007/s40093-019-00298-4

Mouna Imen O, Mahmoud K (2015) Statistical optimization of cultural conditions of an halophilic alpha-amylase production by halophilic Streptomyces sp. grown on orange waste powder. Biocatal Agric Biotechnol 4:685–693. https://doi.org/10.1016/j.bcab.2015.08.011

Niyomukiza S, Owino W, Mathara JM et al (2022) Isolation, purification and biochemical characterization of alkaline α-amylase from Bacillus subtilis strain W3SFR5 isolated from kitchen wastes. Appl Food Biotechnol 9:9–19

Nusrat A, Rahman SR (2007) Comparative studies on the production of extracellular α-amylase by three mesophilic Bacillus isolates. Bangladesh J Microbiol 24:129–132. https://doi.org/10.3329/bjm.v24i2.1257

Ojha SK, Singh PK, Mishra S et al (2020) Response surface methodology-based optimization and scale-up production of amylase from a novel bacterial strain, Bacillus aryabhattai KIIT BE-1. Biotechnol Rep 27:e00506. https://doi.org/10.1016/j.btre.2020.e00506

Okino-Delgado CH, Zanutto-Elgui MR, do Prado DZ et al (2019) Enzymatic bioremediation: current status, challenges of obtaining process, and applications. In: Arora P (ed) Microbial metabolism of xenobiotic compounds. Microorganisms for sustainability, vol 10. Springer, Singapore, pp 79–101. https://doi.org/10.1007/978-981-13-7462-3_4

Oueslati W, Zrelli S, Bouchleghem S et al (2019) First study on the interest of the determination of the total volatile basic nitrogen in the blue crab (Portunus segnis) in Tunisia. J New Sci 68:4140–4146

Ousaadi MI, Merouane F, Berkani M et al (2021) Valorization and optimization of agro-industrial orange waste for the production of enzyme by halophilic Streptomyces sp. Environ Res 201:111494. https://doi.org/10.1016/j.envres.2021.111494

Phanphet S, Bangphan S (2021) Application of full factorial design for optimization of production process by turning machine. J Tianjin Univ Sci Technol 54:35–55

Plackett RL, Burman JP (1946) The design of optimum multifactorial experiments. Biometrika 33:305–325. https://doi.org/10.1093/biomet/33.4.305

Rajagopalan G, Krishnan C (2008) Optimization of medium and process parameters for a constitutive α-amylase production from a catabolite derepressed Bacillus subtilis KCC103. J Chem Technol Biotechnol 83:654–661. https://doi.org/10.1002/jctb.1845

Raul D, Biswas T, Mukhopadhyay S et al (2014) Production and partial purification of alpha amylase from Bacillus subtilis (mtcc 121) using solid state fermentation. Biochem Res Int 2014:1–5. https://doi.org/10.1155/2014/568141

Rehman A, Saeed A, Asad W, Kiran T, Baloch MN, Eijaz S (2019) Optimization of physicochemical parameters for maximum amylase production by indigenously isolated Bacillus cereus AS2 strain. Pakistan J Pharm Sci 32(2):889–894

Rivas B, Torrado A, Torre P et al (2008) Submerged citric acid fermentation on orange peel autohydrolysate. J Agric Food Chem 56:2380–2387. https://doi.org/10.1021/jf073388r

Saha SP, Mazumdar D (2019) Optimization of process parameter for alpha-amylase produced by bacillus cereus Amy3 using one factor at a time (OFAT) and central composite rotatable (ccrd) design based response surface methodology (RSM). Biocatal Agric Biotechnol 19:101168. https://doi.org/10.1016/j.bcab.2019.101168

Salem K, Elgharbi F, Ben Hlima H et al (2020) Biochemical characterization and structural insights into the high substrate affinity of a dimeric and ca2+ independent Bacillus subtilis α-amylase. Biotechnol Prog 36(4):e2964. https://doi.org/10.1002/btpr.2964

Salem K, Jabalera Y, Puentes-Pardo JD, Vilchez-Garcia J, Sayari A, Hmida-Sayari A, Jimenez-Lopez C, Perduca M (2021) Enzyme storage and recycling: nanoassemblies of α-amylase and xylanase immobilized on biomimetic magnetic nanoparticles. ACS Sustain Chem Eng 9(11):4054–4063

Sarmiento F, Peralta R, Blamey JM (2015) Cold and hot extremozymes: industrial relevance and current trends. Front Bioeng Biotechnol. https://doi.org/10.3389/fbioe.2015.00148

Sharif S, Shah AH, Fariq A et al (2023) Optimization of amylase production using response surface methodology from newly isolated thermophilic bacteria. Heliyon 9(1):e12901. https://doi.org/10.1016/j.heliyon.2023.e12901

Shaukat M (2022) Determination and optimization of crude extracellular amylase extracted from different Bacillus species. Pakistan J Sci 73(1):1–12. https://doi.org/10.57041/pjs.v73i1.633

Soares MR, Matsinhe C, Belo S et al (2013) Phytotoxicity evolution of biowastes undergoing aerobic decomposition. J Waste Manag 2013:1–8. https://doi.org/10.1155/2013/479126

Sundarram A, Murthy TPK (2014) α-amylase production and applications: a review. Appl Environ Microbiol 2:166–175

Suresh PV, Kudre TG, Johny LC (2017) Sustainable valorization of seafood processing by-product/discard. In: Singhania R, Agarwal R, Kumar R, Sukumaran R (eds) Waste to wealth. Energy, environment, and sustainability. Springer, Singapore, pp 111–139. https://doi.org/10.1007/978-981-10-7431-8_7

Tiwari SP, Srivastava R, Singh CS, Shukla K, Singh RK, Singh P et al (2015) Amylases: an overview with special reference to alpha amylase. J Global Biosci 4(1):1886–1901

Tripathi N, Hills CD, Singh RS, Atkinson CJ (2019) Biomass waste utilisation in low-carbon products: harnessing a major potential resource. npj Clim Atmos Sci 2:35. https://doi.org/10.1038/s41612-019-0093-5

Uygut MA, Tanyildizi MŞ (2016) Optimization of alpha-amylase production by bacillus amyloliquefaciens grown on orange peels. Iran J Sci Technol Trans A Sci 42:443–449. https://doi.org/10.1007/s40995-016-0077-

Venugopal V (2021) Valorization of seafood processing discards: bioconversion and bio-refinery approaches. Front Sustain Food Syst 5:611835. https://doi.org/10.3389/fsufs.2021.611835

Wu X, Wang Y, Tong B et al (2018) Purification and biochemical characterization of a thermostable and acid-stable alpha-amylase from Bacillus licheniformis B4423. Int J Biol Macromol 109:329–337. https://doi.org/10.1016/j.ijbiomac.2017.12.004

Yassin SN, Jiru TM, Indracanti M (2021) Screening and characterization of thermostable amylase-producing bacteria isolated from soil samples of Afar Region, and molecular detection of amylase-coding gene. Int J Microbiol 2021:1–14. https://doi.org/10.1155/2021/5592885

Acknowledgements

This work is part of a doctoral thesis by Bouthaina Ben Hadj Hmida, whose research was financially supported by the Ministry of Higher Education and Scientific Research (Tunisia) through a grant to the Laboratory of Biochemistry and Enzymatic Engineering of Lipases-Engineering National School of Sfax- University of Sfax-Tunisia.

Author information

Authors and Affiliations

Contributions

BBHH: Data curation, Formal analysis, Investigation, Methodology, Writing—Original Draft. SBM and AF: Investigation, Methodology, Writing — Review & Editing. AS and AH-S: Conceptualization, Writing — Review & Editing, Supervision, Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not applicable.

Consent to Publish

All authors have consent to publish the paper.

Consent to participate

All authors have consent to participate in the study.

Statement of informed consent

The research does not involve human participants and animal experiments.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ben Hadj Hmida, B., Ben Mabrouk, S., Fendri, A. et al. Optimization of newly isolated Bacillus cereus α-amylase production using orange peels and crab shells and application in wastewater treatment. 3 Biotech 14, 119 (2024). https://doi.org/10.1007/s13205-024-03962-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-024-03962-3