Abstract

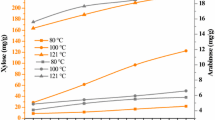

A sequential pretreatment method for hydrolyzing rigid hemicelluloses and cellulose content in the bamboo biomass was investigated in this study. The effects of different parameters, such as nature of biomass, type of acid, acid and biomass concentration, were studied. Under the optimum condition of 5% (v/v) HCl-treated biomass and biomass concentration (8%, w/v), the maximum yield of sugar (619 mg/g of biomass) was obtained. The enzymatic hydrolysis parameter conditions were further optimized by response surface methodology-based central composite method. According to the results, the highest yield of sugar (515 mg/g of biomass) was obtained at hydrolysis temperature 50 °C, biomass concentration 8.9%, w/v, enzyme concentration (199.8 mg/g of biomass) and time 60 h, respectively. The effects of untreated, pretreated and enzymatically hydrolyzed biomass structure and complexity were investigated by field emission scanning electron microscopy and X-ray diffraction techniques.

Similar content being viewed by others

References

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Balat M (2011) Production of bioethanol from lignocellulosic materials via the biochemical pathway: a review. Energy Convers Manage 52:858–875

Banik RM, Santhiagu A, Upadhyay SN (2007) Optimization of nutrients for gellan gum production by Sphingomonas paucimobilis ATCC-31461 in molasses based medium using response surface methodology. Bioresour Technol 98:792–797

Cara C, Ruiz E, Ballesteros M, Manzanares P, Negro MJ, Castro E (2008) Production of fuel ethanol from steam-explosion pretreated olive tree pruning. Fuel 87:692–700

Cardona CA, Sánchez OJ (2007) Fuel ethanol production: process design trends and integration opportunities. Bioresour Technol 98:2415–2457

Cheng KK, Cai BY, Zhang JA, Ling HZ, Zhou YJ, Ge JP, Xu JM (2008) Sugarcane bagasse hemicellulose hydrolysate for ethanol production by acid recovery process. Biochem Eng J 38:105–109

da Costa Sousa L, Chundawat SP, Balan V, Dale BE (2009) ‘Cradle-to-grave’ assessment of existing lignocellulose pretreatment technologies. Curr Opin Biotechnol 20:339–347

Duan X, Zhang C, Ju X, Li Q, Chen S, Liu Z, Wang J (2013) Effect of lignocellulosic composition and structure on the bioethanol production from different poplar lines. Bioresour Technol 140:363–367

Ferreira S, Duarte AP, Ribeiro MHL, Queiroza JA, Dominguesa FC (2009) Response surface optimization of enzymatic hydrolysis of Cistus ladanifer and Cytisus striatus for bioethanol production. Biochem Eng J 45:192–200

Ge L, Wang P, Mou H (2011) Study on saccharification techniques of seaweed wastes for the transformation of ethanol. Renew Energy 36:84–89

Gnansounou E, Dauriat A (2010) Techno-economic analysis of lignocellulosic ethanol: a review. Bioresour Technol 101:4980–4991

Hamzah F, Idris A, Shuan TK (2011) Preliminary study on enzymatic hydrolysis of treated oil palm (Elaeis) empty fruit bunches fibre by using combination of cellulose and b1-4 glucosidase. Biomass Bioenerg 35:1055–1059

Harinder SO, Simranjeet KS, Praveen VV (2012) Statistical, optimization of hydrolysis process for banana peels using cellulolytic and pectinolytic enzymes. Food Bioprod Process 90:257–265

He M-X, Wang J-L, Qin H, Shui Z-X, Zhu Q-L et al (2014) Bamboo: a new source of carbohydrate for biorefinery. Carbohydr Polym 111:645–654

Jin C, Li J, Han S, Wang J, Sun Q (2014) A durable, superhydrophobic, superoleophobic and corrosion-resistant coating with rose-like ZnO nanoflowers on a bamboo surface. Appl Surf Sci 320:322–327

Kim S, Kim CH (2013) Bioethanol production using the sequential acid/alkali-pretreated empty palm fruit bunch fiber. Renew Energy 54:150–155

Kim S, Park JM, Seo J-W, Kim CH (2012) Sequential acid-/alkali-pretreatment of empty palm fruit bunch fiber. Bioresour Technol 109:229–233

Laluce C, Tognolli JO, Oliveira KF, Souza CS, Morais MR (2009) Optimization of temperature, sugar concentration, and inoculum size to maximize ethanol production without significant decrease in yeast cell viability. Appl Microbiol Biotechnol 83:627–637

Miller et al (1959) Use of dinitro-salicylic acid reagent for determination of reducing sugars. Anal Chem 31:426–428

Palmarola-Adrados B, Choteborska P, Galbe M, Zacchi G (2005) Ethanol production from non-starch carbohydrates of wheat bran. Bioresour Technol 96:843–850

Palukurty MA, Telgana NK, Bora HSR, Mulampaka SN (2008) Screening and optimization of metal ions to enhance ethanol production using statistical experimental designs. Afr J Microbiol Res 2:87–94

Piarpuzán D, Quintero JA, Cardona CA (2011) Empty fruit bunches from oil palm as a potential raw material for fuel ethanol production. Biomass Bioenerg 35:1130–1137

Rabelo SC, Carrere H, Maciel FR, Costa AC (2011) Production of bioethanol, methane and heat from sugarcane bagasse in a biorefinery concept. Bioresour Technol 102:7887–7895

Rass-Hansen J, Falsig H, Jorgensen B, Christensen CH (2007) Bioethanol: fuel or feedstock? J Chem Technol Biotechnol 82:329–333

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energy 37:19–27

Sathitsuksanoh N, Zhu ZG, Ho TJ, Bai MD, Zhang YHP (2010) Bamboo saccharification through cellulose solvent-based biomass pretreatment followed by enzymatic hydrolysis at ultra-low cellulase loadings. Bioresour Technol 101:4926–4929

Sievers C, Marzialetti T, Hoskins TJC, Olarte MBV, Agrawal PK, Jones CW (2009) Quantitative solid state NMR analysis of residues from acid hydrolysis of loblolly pine wood. Bioresour Technol 100:4758–4765

Sindhu R, Kuttiraja M, Binod P, Sukumaran RK, Pandey A (2014) Bioethanol production from dilute acid pretreated Indian bamboo variety (Dendrocalamus sp.) by separate hydrolysis and fermentation. Ind Crop Prod 52:169–172

Yamashita Y, Shono M, Sasaki C, Nakamura Y (2010) Alkaline peroxide pretreatment for efficient enzymatic saccharification of bamboo. Carbohyd Polym 79:914–920

Zaldivar J, Nielsen J, Olsson L (2001) Fuel ethanol production from lignocellulose: a challenge for metabolic engineering and process integration. Appl Microbiol Biotechnol 56:17–34

Zhang M, Song X, Deines TW, Pei ZJ, Wang D (2014) A consistency mapping for the effects on enzymatic hydrolysis sugar yield using two sugar yield definitions in cellulosic biofuels manufacturing. Renew Energy 62:243–248

Acknowledgements

The authors acknowledge and thank the Management of SRM University and Director (E&T) for their support in carrying out this research work and also the Department of Chemical Engineering for providing necessary facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Jagannathan, P., Muthukumaran, C. & Tamilarasan, K. A sequential pretreatment of lignocelluloses in bamboo biomass to fermentable sugars by acid/enzymatic hydrolysis. 3 Biotech 7, 260 (2017). https://doi.org/10.1007/s13205-017-0892-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0892-5