Abstract

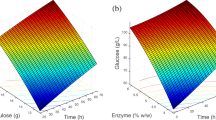

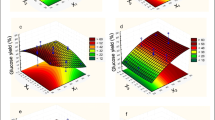

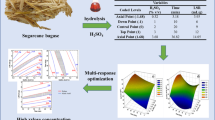

In this study, comparative evaluation of acid- and alkali pretreatment of sweet sorghum bagasse (SSB) was carried out for sugar production after enzymatic hydrolysis. Results indicated that enzymatic hydrolysis of alkali-pretreated SSB resulted in higher production of glucose, xylose and arabinose, compared to the other alkali concentrations and also acid-pretreated biomass. Response Surface Methodology (RSM) was, therefore, used to optimize parameters, such as alkali concentration, temperature and time of pretreatment prior to enzymatic hydrolysis to maximize the production of sugars. The independent variables used during RSM included alkali concentration (1.5–4%), pretreatment temperature (125–140 °C) and pretreatment time (10–30 min) were investigated. Process optimization resulted in glucose and xylose concentration of 57.24 and 10.14 g/L, respectively. Subsequently, second stage optimization was conducted using RSM for optimizing parameters for enzymatic hydrolysis, which included substrate concentration (10–15%), incubation time (24–60 h), incubation temperature (40–60 °C) and Celluclast concentration (10–20 IU/g-dwt). Substrate concentration 15%, (w/v) temperature of 60 °C, Celluclast concentration of 20 IU/g-dwt and incubation time of 58 h led to a glucose concentration of 68.58 g/l. Finally, simultaneous saccharification fermentation (SSF) as well as separated hydrolysis and fermentation (SHF) was evaluated using Pichia kudriavzevii HOP-1 for production of ethanol. Significant difference in ethanol concentration was not found using either SSF or SHF; however, ethanol productivity was higher in case of SSF, compared to SHF. This study has established a platform for conducting scale-up studies using the optimized process parameters.

Similar content being viewed by others

References

Bjerre AB, Olesen AB, Fernavist T (1996) Pretreatment of wheat straw using combined wet oxidation and alkaline hydrolysis resulting in convertible cellulose and hemicellulose. Biotechnol Bioenergy 49:568–577

Damisa D, Ameh J, Umoh VJ (2008) Effect of chemical pretreatment of some lignocellulosic wastes on the recovery of cellulase from Aspergillus niger AH3 mutant. Afr J Biotech 7:2444–2450

de Freitas Gomes JH, Júnior ARS, de Paiva AP, Ferreira JR, da Costa SC, Balestrassi PP (2012) Global criterion method based on principal components to the optimization of manufacturing processes with multiple responses. Strojniški vestnik J Mech Eng 58(5):345–353

Dhaliwal SS, Oberoi HS, Sandhu SK, Nanda D, Kumar D, Uppal SK (2011) Enhanced ethanol production from sugarcane juice by galactose adaptation of a newly isolated thermotolerant strain of Pichiakudriavzevii. Bioresour Technol 102(10):5968–5975

El-Abyad MS, El-Refai AH, El-Diwany AI, Sallam LA, Allam RF (1992) Effect of some fermentation parameters on ethanol productions from beet molasses by Saccharomyces cerevisiae Y–7. Bioresour Technol 42(3):191–195

Ferreira S, Duarte AP, Ribeiro MH, Queiroz JA, Domingues FC (2009) Response surface optimization of enzymatic hydrolysis of Cistus ladanifer and Cytisus striatus for bioethanol production. Biochem Eng J 45(3):192–200

Gharpuray MM, Lee YH, Fan LT (1983) Structural modification of lignocellulosics by pretreatment to enhance enzymatic hydrolysis. Biotechnol Bioeng 25:157–172

Gould JM (1985) Studies on the mechanism of alkaline peroxide delignification of agricultural residues. Biotechnol Bioeng 27(3):225–231

Joglekar AM, May AT (1987) Product excellence through design of experiments. Cereal Foods World 32(12):857

Li J, Li S, Han B, Yu M, Li G, Jiang Y (2013) A novel cost-effective technology to convert sucrose and homocelluloses in sweet sorghum stalks into ethanol. Biotechnol Biofuels 6:174

Liu JZ, Weng LP, Zhang QL, Xu H, Ji LN (2003) Optimization of glucose oxidase production by Aspergillus niger in a benchtop bioreactor using response surface methodology. World J Microbiol Biotechnol 19(3):317–323

Mamma D, Chistakopoulos P, Koullas D, Kekos D, Macris BJ, Koukios E (1995) An alternative approach to the bioconversion of sweet sorghum carbohydrates to ethanol. Biomass Bioenerg 8(2):99–103

Oberoi HS, Babbar N, Sandhu SK, Dhaliwal SS, Kaur U, Chadha BS, Bhargav VK (2012) Ethanol production from alkali-treated rice straw via simultaneous saccharification and fermentation using newly isolated thermotolerant Pichia kudriavzevii HOP-1. J Ind Microbiol Biotechnol 39(4):557–566

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74(1):17–24

Sánchez C (2009) Lignocellulosic residues: biodegradation and bioconversion by fungi. Biotechnol Adv 27(2):185–194

Sandhu SK, Oberoi HS, Dhaliwal SS, Babbar N, Kaur U, Nanda D, Kumar D (2011) Ethanol production from Kinnow mandarin (Citrus reticulata) peels via simultaneous saccharification and fermentation using crude enzyme produced by Aspergillus oryzae and the thermotolerant Pichia kudriavzevii strain. Ann Microbiol 62:655–666

Sharma SK (2000) Saccharification and bioethanol production from sunflower stalks and hulls. Ph.D thesis, Punjab Agricultural University, Ludhiana, India

Shen F, Hu J, Zhang Y, Liu MLY, Saddler JN, Liu R (2012) Ethanol production from steam-pretreated sweet sorghum bagasse with high substrate consistency enzymatic hydrolysis. Biomass Bioenergy 41:157–164

Tébéka IR et al (2009) Hydrolytic activity of free and immobilized cellulose. Langmuir 25(3):1582–1587

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no potential conflict of interest.

Rights and permissions

About this article

Cite this article

Lavudi, S., Oberoi, H.S. & Mangamoori, L.N. Ethanol production from sweet sorghum bagasse through process optimization using response surface methodology. 3 Biotech 7, 233 (2017). https://doi.org/10.1007/s13205-017-0863-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-017-0863-x