Abstract

The development of bioactive, multi-functional, and cost-effective nanocomposite filaments for additive manufacturing (AM) is pivotal for the evolution of biomedical and healthcare sectors. Herein, an industrially scalable process is reported, to produce medical grade PA12/AgNP nanocomposites, through in-situ reactive melt-mixing, occurring within the filament extruder. Bactericidal elemental nanoparticles (Ag0) were formed by silver ions (Ag+) reducing from the Silver Nitrate (Ag2NO3) precursor, which was suitably added to the polymer melt. Polyvinyl Alcohol (PVA) was deployed in the compound melt, as a reducing macromolecular agent. The produced nanocomposite filaments were utilized to fabricate samples with Material Extrusion (MEX) AM. A total of sixteen (16) different tests were conducted on filaments and 3D-printed samples to assess their mechanical, rheological, thermal, and antibacterial characteristics, in accordance with international standards. The nanocomposites exhibited a significant mechanical reinforcement of up to 50% compared to PA12. Additionally, the Ag-based nanocomposites demonstrated remarkable antimicrobial behavior in the presence of Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli) microbes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the most emerging fabrication techniques is Additive manufacturing, which offers various advantages, such as shorter lead times, the facilitation of customization, and reduced waste, among others (Dzogbewu et al. 2022; Prashar et al. 2022). The growth in this area raises the demand for materials with specific functionalities for AM to satisfy the requirements of each application (Han and Wei 2022). To achieve that goal, a common approach is through the development of composites that improve the properties of pure polymeric materials (Yin et al. 2022). For instance, in culinary applications, antibacterial activity is desired in food packaging and films (Appendini and Hotchkiss 2002; Dutta et al. 2009). There is also a significant demand for antibacterial activity in medical applications which has been achieved in AM by incorporating metal fillers in the polymer matrices, such as titanium (Billings et al. 2021; Dzogbewu and du Preez 2021), zinc (Ahmed et al. 2021; Chong et al. 2022), copper (Vidakis et al. 2022g, e), and silver (Tzounis et al. 2020; Vidakis et al. 2020) based fillers, which are all metals with known biocidal properties. Silver has been applied in various forms and methods in the literature for enabling antibacterial activity in applications (Shahverdi et al. 2007; Chernousova and Epple 2013; Franci et al. 2015; Balachandar et al. 2022; Huq et al. 2022; Zhang et al. 2022). Silver nanoparticles are one of the commonly used and effective forms of combating bacteria (Deng et al. 2016; Gomaa 2017; Tang and Zheng 2018; Masood et al. 2019). Silver nitrate, which is a salt, is also used in applications such as dentistry (Thangavelu et al. 2021). It has known antibacterial performance (Kumar Pandian et al. 2010; Fouda et al. 2021; Aveledo et al. 2022) but still is usually used along with a reducing agent such as PEG, PVA, and PVP (Chou and Ren 2000; Kim 2007; Sedlarik et al. 2010; Ali et al. 2021) to synthesize and release silver nanoparticles. This is achieved through the reduction process, which is a chemical reaction process occurring during the preparation of the composites. With the presence of the reduction agent, Ag+ is reduced to AgNPs, with an indication of the reduction process being the color change (Badineni et al. 2019). PVA has been used as a reduction agent with silver (Khanna et al. 2005; Pencheva et al. 2012) and silver nitrate (Badineni et al. 2019; Yuan et al. 2020a, b; Ali et al. 2021; Jackson et al. 2021; Osman et al. 2021; Zhao et al. 2022). Hydrogels (Jackson et al. 2021) and films (Bhosale 2023) have been developed, therefore their optical properties have been also investigated (Ali et al. 2021). In these types of research works, commonly used bacteria for testing are one gram-negative and one gram-positive, such as E. coli and S. aureus respectively (Feng et al. 2000; Vu et al. 2018; Access and Pathophysiology 2019). In the literature, the reactive melt mixing approach is frequently employed to execute the chemical reduction procedure. (Brown et al. 1995; Bhattacharyya et al. 2005; Wang et al. 2005; Tanemura et al. 2007; Melendez-Rodriguez et al. 2019; Habeeb Rahuman et al. 2022). In AM, and more specifically in MEX 3D printing, the technique of reactive melt mixing occurs in the thermomechanical filament extrusion procedure (Vidakis et al. 2020). In MEX 3D printing this is the standard procedure that is followed, and the PVA polymer research has focused on drug-related, electrical, and shielding applications (Goyanes et al. 2016; Rigotti et al. 2018; Matijašić et al. 2019; Wei et al. 2020; Yang et al. 2020; Mallakpour et al. 2022).

Various polymeric materials have been used in MEX 3D printing as matrix materials (Fico et al. 2022; Petousis et al. 2023). Polyamides are popular polymers for films (Emadzadeh et al. 2015), in the packaging in culinary applications (Tyuftin and Kerry 2020), and also in the medical field due to the medical grades available (Vidakis et al. 2022h). Medical-grade Polyamides have been evaluated for their performance in AM in the MEX 3D printing technique in unfilled form and in composites (Li et al. 2017; Abdullah et al. 2018; Li Feng et al. 2019; Zhang et al. 2020; Vidakis et al. 2022b; Kam et al. 2023). More specifically, the medical-grade PA12 thermoplastic was utilized as the matrix for the preparation of multi-functional (improvement of properties and introduction of new ones) nanocomposites in MEX 3D printing, using titanium nitride, carbon (Vidakis et al. 2022f) and copper-based additives (Vidakis et al. 2022d, c), and silver-based additives (Vidakis et al. 2022h). The objective was to improve the mechanical behavior of the medical-grade PA12 while simultaneously adding antibacterial characteristics, making the proposed nanocomposites suitable for biomedical and culinary applications.

Herein, multi-functional bioactive nanocomposites were developed employing a medical-grade PA12 matrix material, AgNO3 as the additive, and PVA as the reduction agent to enable the melt mixing chemical reaction and the release of AgNPs in the mixture compound. The aim was to increase the medical-grade PA12 polymer mechanical properties and additionally induce biocidal capabilities in the developed nanocompounds. Given that the nano compounds were appropriate for the MEX 3D printing technique, it is remarkable that a related methodology has not yet been reported in the literature, exploiting the high potential of AM as a manufacturing process. Pure PA12 and PVA were also investigated as control polymers. To extensively characterize the fabricated nanocompounds, sixteen distinct experiments were conducted and the thermal, rheological, mechanical, morphological, and antibacterial properties were evaluated and analyzed. The nanocomposites' biocidal efficacy was proved as opposed to Gram-negative E. coli, as well as Gram-positive S. aureus microbes, according to the literature. The increase in the tensile strength reached 19.8% in comparison with the unfilled PA12 thermoplastic, while the associated increase in the microhardness reached 50%. In the experiments, all the produced nanocomposites demonstrated adequate biocidal activity, especially against the gram-positive S. aureus. The procedure used can be easily scaled up and industrialized, thus making the findings presented valuable for real-life applications. The most important challenges this study had to meet are summarized below:

-

To optimize the composition of the compound in all the characteristics studied, i.e., mechanical, rheological, thermal, and antibacterial.

-

To perform thorough standard antibacterial testing.

-

To improve the mechanical properties in the cases that they were downgraded.

-

To use a process that is conveniently scaled up for industrial use.

Materials and methods

Selected screenshots from the experimental method implemented in the study are presented in Fig. 1. More specifically, Fig. 1a and b present the raw materials formation in proper quantities in glass beakers and their drying process before their use for the composites’ development. Figure 1c shows a picture from the process of the filament’s extrusion, while the associated procedure for drying filament is depicted in Fig. 1d. The fabricated filament endured a quality control procedure to confirm its diameter was suitable for MEX 3D-printing (Fig. 1e). Its tensile strength was experimentally determined (Fig. 1f) also for quality assurance and comparison purposes. The samples were produced in agreement with the relative international standards as depicted in Fig. 1g. Specimens also underwent quality control (Fig. 1h). Then, the mechanical tests were carried out (Fig. 1i) and microscopy techniques were employed to estimate the morphological characteristics (Fig. 1j). Finally, antibacterial tests were carried out using an agar well diffusion process against gram-positive S. Aureus and gram-negative E. coli. To meet these goals with the developed nanocomposites in question, specially designed samples were 3D printed for the tests.

The process followed herein (a), (b) pure materials preparation, (c), (d) filament’s extrusion and drying, (e), (f) filament mechanical test and quality control, (g), (h) Specimens manufacturing with MEX 3D printing and quality control, (i), (j) mechanical testing and morphological characterization, (k), (l) antibacterial tests

Materials

The matrix material, as mentioned, was a PA12 grade for medical applications. The specific grade used in the study was sourced from its manufacturer (Arkema, Colombes, France). Its specifications from the manufacturer datasheet, are presented in Table 1.

PVA was sourced in pellet form from 3DXtech (Grand Rapids Michigan, United States). These specific PVA pellets are specially developed for the extrusion method employed to produce filament for 3D printing (https://www.3dxtech.com/product/pva-water-soluble-support-pellets/). Silver nitrate (AgNO3) was purchased from its manufacturer, which is Sigma Aldrich, from St. Louis, United States, in salt form (silver-based salt), with a molecular weight of 169.87, 4.350 g/cm3 density, and a melting point of 212 °C. Before its use, it was inspected for its morphology with SEM and its composition with EDS. Both were implemented in a JSM IT700HR SEM field emission (from Jeol Ltd., Tokyo, Japan). Before the observation in the SEM device, specimens were gold-plated. All observations were implemented with 20 kV in a high-vacuum mode.

Reactive filament extrusion and 3D printing

Pure medical-grade PA12 filament and pure PVA filament were prepared as control materials with the extrusion process, using the procured raw materials. PA12 granules were extruded to 3D printing filament, using a 3devo Composer single screw extruder from 3devo, located in Utrecht in the Netherlands. Upon completion, PVA pellets were also turned into MEX 3D printing (1.75 mm in diameter) filament with the same process. The extrusion temperatures are depicted in Table 2 below. These temperatures were selected based on preliminary tests and specifications from the literature (Vidakis et al. 2020). The same extrusion settings used in the PA12 thermoplastic were also used in the composites, for comparison reasons.

The procedure for the preparation of the composites and the concentration of the two additives (silver nitrate salt and PVA reduction agent) were taken from the literature and are explained in detail in the referenced study (Vidakis et al. 2020). Different raw materials mixtures were prepared for each composite composition, with the proper quantities for each material. Each mixture was fed (individually) into the aforementioned filament extruder and corresponding filament compatible with the MEX 3D printing method was prepared for each composite. The procedure was repeated for all composites and corresponding filaments were prepared for each composite. With this procedure, AgNO3 was then added as an enhancement and antibacterial factor in the virgin medical-grade PA12 alongside PVA which was the reduction factor in the composition. Silver nitrate by itself has antibacterial properties (Access and Pathophysiology 2019; Aveledo et al. 2022), but its performance against bacteria depends on its concentration (Kumar Pandian et al. 2010). On the other hand, PVA reacts with silver nitrate, and Ag NPs are released in the composite. This is a chemical reaction known as the reduction process with is often applied and investigated in the literature (Sedlarik et al. 2010; Badineni et al. 2019; Yuan et al. 2020a; Pal et al. 2021) for the production of Ag NPs from silver nitrate (Chou and Ren 2000). Silver NPs are known for their antibacterial performance (Chernousova and Epple 2013; Franci et al. 2015; Balachandar et al. 2022; Huq et al. 2022; Zhang et al. 2022). This process occurs during the mixing of the silver nitrate salt with the PVA reduction agent during the extrusion process (reactive melt mixing) (Brown et al. 1995; Wang et al. 2005; Melendez-Rodriguez et al. 2019; Vidakis et al. 2020). Higher PVA concentration is not recommended since this is a soluble material and it will dissolve when in contact with water, affecting the integrity of the produced parts.

Following these specifications, the acquired experimental results during the study (as explained below), and the literature, two composites were prepared with the medical-grade PA12 as the matrix material, i.e., one with PA12, 5.0 wt. % AgNO3 and 2.5% PVA, and one with PA12, 10.0 wt. % AgNO3 and 5.0% PVA. The filler loading gradually was increased, mechanical tests were carried out and the experiments stopped when the mechanical performance started to constantly decrease in the composites. This outcome in most of the tests of the highest filler loading was attributed to the saturation of the filler, which has a negative effect on the mechanical response of the composites. At the AgNO3 10 wt. % the mechanical properties were decreased, while, at the same time, no significant increase in the antibacterial performance was found. So, now further increase in the filler loading was attempted as it would provide no useful information.

Mixtures with the proper virgin materials quantities were created in separate glass bowls and they were mixed with a high-power blender. Then they were dried (especially PVA is highly hydrophilic) and fed a “Composer”, which is a filament extruder with this commercial model code (from 3DEVO, Utrecht, Netherlands). The specific filament extruder creates filament proper for the MEX 3D-printing technique (1.75 mm), while, due to the geometry of its screw, it is also specially made for material and additive mixing. Four different filaments were prepared in adequate quantities for the specimens manufacturing with 3D printing and the remaining experimental procedures, i.e., pure PA12, pure PVA, PA12/5 wt. % AgNO3/2.5% PVA, and PA12/10 wt. % AgNO3/5% PVA. The four filament batches underwent quality control inspections to ensure that the side surface was smooth without defects and their diameter was suitable for the MEX 3D-printing procedure. The mechanical performance was evaluated in tensile experiments, utilizing an MX2 experimenting device from Imada Inc (from Northbrook, United States). Five specimens were examined from each filament. The tests were performed under normal room conditions. During the tests, in agreement with the associated standard (ASTM D638-02a), A 10 mm/min test speed was applied, after the guidelines of the ASTM D638-02a standard for tensile tests.

Then, the filament was used to manufacture corresponding specimens for the mechanical and antibacterial tests. For the different mechanical tests, five samples were fabricated with each filament (pure material or composite), following the corresponding mechanical test standards, i.e., ASTM D638-02a, ASTM D695-02a, ASTM D790-02, and ASTM D6110-04, for the tensile experiments (3.2 mm thickness type V specimens), compression tests (prismatic objects 12.7 × 12. 7 × 25.4 in mm), flexural experiments (prismatic specimens 64 × 12.7 × 3.2 in mm), and for the impact tests (notched Charpy prismatic samples 122.0 × 12. 7 × 5.0 in mm, respectively). Additionally, for the antibacterial tests, cylindrical specimens (Ø12 × 4 mm) were fabricated. All samples were manufactured using an Intamsys 3D printer, model Funmat-HT (from Shanghai, China). Preliminary testing for the PA12 (medical grade) and the literature were used to optimize the settings used in the 3D-printing process for the prepared composites and the raw PA12 (Vidakis et al. 2023). 3D printing parameters for the raw PVA filament were derived from preliminary tests and the instructions provided in the literature on corresponding commercial filaments (Matijašić et al. 2019).

Thermal characteristics evaluation with thermogravimetric and differential scanning calorimetry

To assess the fillers’ effect on the thermal degradation rate of the PA12 (medical-grade) and to evaluate the overall thermal stability and the response of the nanocomposites prepared herein, TGA, as well as DSC measurements were carried out. TGA was carried out in an apparatus with the model’s name Diamond from Perkin Elmer (Perkin-Elmer, Massachusetts, USA). The temperature cycle followed was from 40 up to 550 °C and 10 °C/min was the temperature increase rate. To carefully manage the selected cooling and heating rates of 15 °C/min, DSC experiments were executed employing a TA Instruments Discovery Series DSC-25 (from TA-Instruments, Delaware, USA) in conjunction with a Refrigerated Cooling System RSC-90. Using high-purity nitrogen gas, the two thermal analysis experiments—DSC and TGA—were carried out in an inert environment.

FTIR and Raman spectroscopy

The Raman Spectrometry was carried out by means of a LabRAM HR-modified Spectrometer (HORIBA, from Kyoto, Japan). Using a 90 mW solid-state laser module with a center wavelength of 532.0 nm, the Raman process was excited. The excitation light was delivered onto the specimen. A 50 × microscopic objective lens was used to collect the Raman signals. 10.6 mm working distance and a 0.5 numerical aperture were selected (LMPlanFL-N by Olympus). (LMPlanFL-N by Olympus). To attenuate the power, a 5% transmittance Neutral Density filter was employed, resulting in a power on the sample at 2 mW. In lateral and axial directions, the laser spot measured about 1.70 μm and 2.0 μm, respectively. The resolution of the Raman spectrum was approximately 2.0 cm−1, achieved by utilizing a grating of grooves 600. Furthermore, the range of the spectral was set from 50 up to 3900.0 cm−1, which was concealed through three optical windows. Each measurement point acquisition period was 10 s, with five accumulations.

The measurements for Attenuated total reflectance/Fourier-transform infrared-spectroscopy (absorbance) were executed with the aid of a BrukerVertex-70v FTIR vacuum spectrometer (Billerica, Massachusetts, United States). An A225/Q Platinum ATR unit was included in the apparatus, featuring a single diamond crystal reflection. The specimens’ infrared analysis through measurements of total reflection was performed in a 400–350 cm−1 spectral range. The spectra were encoded with a spacing of 2.0 cm−1 using a Fourier transformation after the interferograms were gathered at a 4.0 cm−1 resolution (with 8 scans), processed using a Blackman Harris function, and Fourier transformed with two separate zero filling levels. Measurements were automatically subtracted from the background signal of a diamond crystal to adjust for noise. The specimens were properly set under the ATR press, whereas the area of the samples and the A225/Q ATR module’s tip was thoroughly cleansed with raw ethanol (by Sigma Aldrich, from Munich, Germany) after each measurement, and allowed for a couple of minutes to dry.

Rheometric experiments

A Rheometer DHR- 20 Discovery Hybrid Rotational from TA-Instruments (from Delaware, USA) was used for the rheometry studies, which includes a parallel plate setup and an Environmental Test Chamber for controlling the temperature. These measurements assess deformation in liquid samples under external force. Tests were executed exceeding the material’s point of melt to make sure liquidity and below its decomposition temperature to prevent decomposition effects. Every point of measurement had a 10 s acquisition time to prevent excessive heating and decomposition. Rotational rheometry tests were accompanied by Melt Flow Rate (MFR) tests to evaluate the materials’ flow rate at a specific temperature under set pressure through a hole with a set diameter and length. Measurements adhered to international standards for MFI, specifically ASTM D1238-13.

Mechanical assessing

The mechanical response of the produced specimens was assessed with corresponding experiments conducted following the respective international standards of ASTM, i.e., D6110-04 for notched-Charpy impact testing, D695-02a for compression test conditions, D790-02 for flexural test conditions, D638-02a for tensile test conditions, and E384-17 for Vickers microhardness quantification. All experiments were performed in room temperature conditions. Tensile and flexural experiments were performed in an MX2 Imada apparatus, the same device in which the filament was tested. Flexural tests were three-point-bending tests and the support structures’ spacing was adjusted to 52.0 mm. Same with the filament, a strain rate of 10.0 mm/min was adjusted, in agreement with the associated standards. Compression tests were conducted in an Instron KN-1200 (from Massachusetts, United States), with a 1.30 mm/min testing speed, in accordance with the standard guidelines. Impact tests were conducted in a machine model MT-220 from Terco (from Kungens Kurva, Sweden). In every experiment, the Charpy hammer was released from a 367.0 mm height. Measurements for the microhardness were made with the Vickers technique on an InnovaTest (model 300, from Maastricht, Netherlands). An indentation load of 200.0 gF was applied, whereas an indentation period of 10 s was set.

Scanning electron microscopy and EDS examination

SEM pictures were taken at the lateral external surface of the 3D-printed specimens, as well as at the broken surface of tensile test objects after they failed the mechanical test. The inspection of the lateral surfaces was intended to assess the samples’ 3D-printing quality, while the examination of the cracked surface was meant to identify the fracture mechanism in the specimens when they failed in the tests and to inspect the samples for possible agglomerations of the additives. EDS was performed on a randomly selected region located in the tensile samples' fracture surface to verify the elements in the composites. Both SEM and EDS studies were performed in the same apparatus, which is a Jeol JSM-IT700HR field emission SEM, and the AgNO3 was examined with the same conditions (, by Jeol Ltd., from Tokyo, Japan, gold-sputtered specimens, high-vacuum mode, 20 kV).

Antibacterial experiments

The biocidal performance of the two compounds prepared herein was assessed with the agar well diffusion method (Balouiri et al. 2016). The procedure followed is often applied and analytically described in the literature (Sedlarik et al. 2010; Vidakis et al. 2023). The composites were tested against two bacteria that are commonly used in such tests in the literature (Feng et al. 2000; Gomaa 2017), i.e., gram-positive S. Aureus and gram-negative E. coli. Petri dishes of a Ø 85.0 mm nominal diameter with the proper nutrient agar for both bacteria (MC2, C 010068 for S. aureus, C 010066 for Chapman and E. coli,), were inoculated with the respective bacteria. The preparation of the solution followed the McFarland 0.5 technique (Leber 2016). The respective 3D-printed samples fabricated for the antibacterial tests were placed inside the Petri dishes. After incubation at 37 °C for a period of 24 h, the developed inhibition zone was evaluated in the Petri dishes using optical instrumentation. Each composite and bacteria had five samples examined, and for each compound and bacterium, the mean value and variation of the IZ were computed. Every 60 degrees in each of the samples examined, the inhibitory zone’s width was measured six times, and the average IZ width was calculated. With this average width, the area of the IZ has been estimated with the assessment that its shape is a perfect circle (the district of the inner circle, which represents the sample, minus the district of the exterior circle of the mean diameter).

Results

AgNO3 examination

The silver nitrate used in the study is presented in Fig. 2a through a SEM image with 100 × magnification. Figure 2b shows the graph produced by EDS and in the inset image, the composition of the salt is presented along with its molecular structure. In the elemental composition, the Ag concentration is the silver nitrate was identified, which was the main purpose for conducting this analysis. Figure 2c shows a 170× magnification image taken with SEM on the specific silver nitrate. Figure 2d shows a higher magnification image of 550 × taken with SEM. The morphology of the salt crystals is evident in the images. They have irregular shapes and sizes, but the expected shape was verified in the SEM images. Figure 2e shows for the Ag element an EDS mapping taken on the area presented in Fig. 2d. Ag was identified in the region examined with a rather uniform spreading on the surface.

Filament quality control and mechanical assessing

The manufactured filament was examined, as mentioned, for the quality of its surface quality with an optical microscope. Figure 3a presents the optical microscope image taken for the raw PA12, while Fig. 3b shows the related image for the PA12/5% AgNO3/2.5% PVA composite, and Fig. 3c the respective image for the PA12/10% AgNO3/5% PVA composite. Apart from the difference in the color of the filaments (pure polymer and composites), which is owed to the reactive melt mixing technique in the composite, a smooth surface without voids or defects is presented and filaments have a rather constant diameter. Below each microscope image, scattered diameter measurements for the corresponding filament are presented in a graph. These measurements were taken from the monitoring feature of the extruder, which captures the filament's accurate diameter in real-time. As shown, measurements are within acceptable deviations for both filaments, with the composite filament diameter measurements having a rather narrower deviation zone.

Study of the filament: filament inspection with optical microscopy and scattered diameter measurements during its production a pure PA12, b PA12/5% AgNO3/2.5% PVA, c PA12/ 10% AgNO3/5% PVA, d tensile test stress vs strain graph, raw polymers and Ag based composites average evaluates and deviation for: e \({\sigma }_{B}^{\mathrm{FILL}}\), f EFILL

The tensile experiment results on the filament are shown in Fig. 3d, e, and f. Figure 3d shows stress (σFILL) vs. strain graphs for a randomly chosen filament fragment from each compound prepared herein. As shown, the introduction of the additives (AgNO3, and PVA) on the PA12 matrix increases its mechanical strength in the tensile test, but makes the samples more brittle, as they fail under considerably lower strain values. Figure 3e shows the average tensile strength values (\({\sigma }_{\mathrm{B}}^{\mathrm{FILL}}\)) achieved by the filaments in the tests and their deviation.

Figure 3f illustrates the associated values for the tensile modulus of elasticity (EFILL). For correlation purposes, the pure PVA filament was also tested, and it achieved the highest mechanical response values among the filaments tested (strength—Fig. 3e, and modulus of elasticity—Fig. 3f). This shows that it can have a strong contribution to the enhancement of the composites’ strength. Still, as mentioned, it cannot be used in high concentrations in the composites, since it dissolves with water. Overall, the fillers increased the mechanical performance of the raw PA12. The \({\sigma }_{\mathrm{B}}^{\mathrm{FILL}}\) of PA12/5% AgNO3/2.5% PVA compound was increased by 20.0% (Fig. 3e) and the tensile modulus of elasticity by 15.3% (Fig. 3f) compared to the unfilled PA12 thermoplastic. It has to be mentioned that the tensile experiments of the filament were not performed following a standard, still, they provide a strong indication of the additives’ effect on the matrix polymer and the produced composites’ mechanical response to the 3D printed parts and samples. The remaining mechanical experiments were performed following international standards and they were performed on 3D-printed constructions which are not 100% solid (Vidakis et al. 2022a).

Thermal properties and spectroscopy

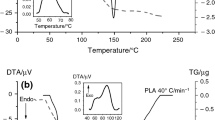

The diagram produced during the TGA for the degradation of the materials is presented in Fig. 4a. As shown, the PVA has a slightly different degradation response. On the other hand, the degradation response of the PA12 matrix is not influenced by the addition of the two fillers, with its curve being almost identical to the graphs of the two composites which differ in the silver nitrate and the PVA loadings. The main difference, as expected, is the weight that persists after the completion of the volumes, due to the presence of the additives in the composites. In the inset graph displayed in Fig. 4a, the remaining weight is presented, and it is in agreement with the filler loadings. Additionally, the TGA showed that the PA12 and the two composites prepared herein start to degrade at temperatures higher than 300 °C. This ensures that the temperatures employed throughout the processes of filament extrusion and MEX 3D printing, maintain the thermal stability of the two composites developed herein and the raw PA12.

The DSC measurements generated the graph in Fig. 4b, displaying the melting (Tm) and glass transition (Tg) temperatures. The PVA matrix exhibits a distinct thermal response, evidenced by the Tg and Tm differences due to its unique polymer chains. In contrast, the pure and composite PA12 matrices' DSC curves, despite variations in AgNO3and PVA loadings, do not impact the material’s Tm and Tg, as demonstrated in Fig. 4b. Furthermore, the Tm verifies that the applied rheometric, and extrusion temperatures used in both filament production, as well as 3D printing, lie within the material's liquid state, promoting homogeneous behavior.

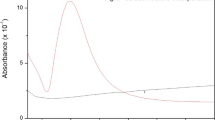

In Fig. 4d the clear Raman spectra from the two raw materials PA12 and PVA can be observed. The associated Raman signals are shown in the next Tables 3 and 4, respectively. They are certified by the literature and show no differences. The incorporation of silver nitrate produces a substantial photoluminescence that encompasses all the Raman signals. As it is confirmed, the photoluminescence is 100× times more intense than the Raman signals from pure materials.

PA12 specimen showed a typical FTIR spectrum (Fig. 4e). Particularly, the absorption peaks of hydrogen-bonded N–H 3305 cm−1, amide-B moderate bond at 30980 cm−1, amide-II band (CO–NH bending, as well as C–N stretching vibration) at 15560 cm−1, amide-V band (N–H bending out of plane) at 6800 cm−1, and amide-VI band (C═O bending out of plane) at 6260 cm−1 are present (Ma et al. 2020). There were no new spectral features resulting from the mixture of the two components. Absorption characteristics are clearly from the mixture of the two pure components.

Figure 4e, f and g present the EDS diagrams for the raw PA12, PA12/5.0% AgNO3/2.5% PVA, and PA12/10.0% AgNO3/5.0% PVA, respectively. No unexpected elements were located in the pure PA12 (Fig. 4e), while the Ag element was located in the two composites and no other elements, which was the expected outcome (Fig. 4f, and g). In the higher Ag concentration composite (PA12/10% AgNO3/5% PVA, Fig. 4g), the Ag peaks are higher in the EDS graph, which is also expected since it indicates a higher loading of the element under the observation region.

Rheometric test results

Figure 5a displays logarithmic curves representing viscosity in relation to the shear rate and the shear stress also in relation to. the shear rate. Viscosity generally decreases for all matrices (raw PA12, pure PVA, and compounds) as applied shear stresses increase, indicating shear thinning behavior. Pure PA12 and PVA matrices exhibit higher viscosity values across the entire range of studied shear rates compared to composites. This can be attributed to the increased lubrication impact of AgNPs on PVA and PA12 chains. AgNPs are able to slip freely in the polymer chains’ melted state because their incompatibility prevents them from forming chemical bonds, which lowers the resistance of polymer chains to applied shear forces. These observations are also evident in the MFR diagram in Fig. 5b, which shows that composites have higher flow rates than raw PA12 and PVA matrices, owing to the lubrication effect of AgNPs.

Mechanical experiments

The 3D printed specimens made with pure PA12, pure PVA, PA12/5.0% AgNO3/2.5% PVA, and PA12/10.0% AgNO3/5.0% PVA tensile experiment findings, are displayed in Fig. 6. Figure 6 depicts the respective findings to the tensile experiments on the filament. The findings indicate a quite analogous trend compared to the corresponding results for the filaments under tensile conditions. PVA achieved the highest values in the experiments among the materials and compounds tested for tensile strength (\({\sigma }_{\mathrm{B}}^{\mathrm{T}}\)—Fig. 6b) and the tensile modulus of elasticity (ET—Fig. 6c). The brittleness of the PA12 thermoplastic significantly increased with the introduction of the additives, as it was revealed on the stress (σT) versus strain curves (Fig. 6a), but the strength and the stiffness of the polymer were also increased. Again, the PA12/5% AgNO3/2.5% PVA compound accomplished the greatest findings among the composites examined, with a raise of 19.8% of the tensile strength (Fig. 6b) and 14.9% (Fig. 6c) of ET in comparison with the unfilled medical-grade PA12 thermoplastic.

Figure 7 shows the corresponding results in the compression tests. Regarding compressive strength (\({\sigma }_{\mathrm{B}}^{\mathrm{C}}\)—Fig. 7b) and the compression modulus of elasticity (EC—Fig. 7c), a similar configuration to the tensile experiments is observed. The PA12/5% AgNO3/2.5% PVA compound accomplished the greatest findings between the composites experimented, with an enhancement of 19.3% in the compressive strength Fig. 7b) and 15.5% (Fig. 7c) in the EC in comparison with the virgin medical-grade PA12 thermoplastic. Again, the PVA polymer presented the greatest performance in the examinations. In the compressive stress σC vs. strain graphs, the outcome differs from the tensile tests (Fig. 7a). The strength and stiffness of the PA12 polymer are presented increased in the graphs, as expected, but the addition of fillers, in this case, does not increase the brittleness of the PA12 polymer, which was not significantly affected in this test. The two composites showed a ductile response, similar to the one of the pure PA12 matrix.

The flexural experiment outcomes are presented in Fig. 8. Similar to previous mechanical tests, the results here show the same trend. The PVA polymer achieved the highest mechanical properties in the flexural experiments. The PA12/5% AgNO3/2.5% PVA compound accomplished the greatest findings between the composites experimented, with a raise of 23.7% in flexural strength (\({\sigma }_{\mathrm{B}}^{\mathrm{F}}\)—Fig. 8b) and an impressive 39.1% in the flexural modulus of elasticity (EF—Fig. 8c) in comparison to the raw PA12 polymer. From the stress σF vs. strain graphs depicted in Fig. 8a, no safe results can be derived regarding how the additives affect the brittleness of the PA12 (medical-grade) polymer. The flexural tests ended at 5% strain, as the corresponding standard (ASTM D790-02) instructs.

The ability of the compounds to absorb energy during the experimental procedures presented above was calculated from the stress over strain diagrams. This is the so-called toughness parameter, and it was computed as the integral (area) of the stress-to-strain diagram (area below the curve). The average values and deviation are presented in Fig. 9., i.e., tensile toughness TT (Fig. 9a), compression toughness TC (Fig. 9b) flexural toughness TF (Fig. 9c), tensile toughness of the filament TFILL (Fig. 9f). Due to the high ductility (high strain before it failed in the experiments) of the unfilled PA12 thermoplastic, its toughness values are high, and the results do not follow the same pattern with the corresponding experimental values. Interestingly, the toughness of the neat PVA plastic in the tensile experiments (3D printed sample and filament) is rather low despite the high strength values of the PVA. In the tensile experiment, the pure PA12 showed higher values than the composites, due to its ductility, as mentioned. In the other tests, the composites showed slightly higher values than the unfilled PA12 thermoplastic, owing to the higher strength values developed by the composites in the tests. More specifically, in the compression and the flexural test, the PA12/5% AgNO3/2.5% PVA compound accomplished, respectively, 9.5% and 4.0% higher toughness, than the unfilled PA12 thermoplastic. In the tensile test for the filaments, the PA12/10% AgNO3/5% PVA composite achieved 4.3% higher toughness, than the raw polymer, still, the difference in the toughness values in this test, with the lower additives’ concentration composite was very close.

Figure 9d presents the Charpy impact experiments for the pure polymers and the compounds developed herein. As shown, in this experiment, the incorporation of the two fillers decreases the impact strength of the PA12. The PVA polymer shows reduced impact strength and probably this negatively affects the corresponding strength of the composites. The Vickers microhardness measurements (Fig. 9e) show a similar pattern to the previously presented mechanical tests (except the impact test). The PVA polymer has higher values. The composites showed significantly increased microhardness values in comparison with the virgin medical-grade PA12 thermoplastic, with the improvement reaching 53.3% on the PA12/5% AgNO3/2.5% PVA compound, in comparison to the raw PA12.

Morphological classification

The topography of 3D—printed specimens consisted of raw PA12 and the two compounds developed with the PA12 thermoplastic as the matrix material was inspected with SEM and the acquired images are shown in Fig. 10. On the images taken from the sides of the 3D-printed samples (Fig. 10a—raw PA12, Fig. 10d—PA12/5.0% AgNO3/2.5% PVA, Fig. 10g—PA12/10% AgNO3/5% PVA), a perfect 3D printing structure, without voids or defects, uniform layer thickness and fusion, is presented for the unfilled PA12 polymer. The fillers' introduction to the matrix material worsens the 3D-printing quality. The additive concentration increase in the compounds further worsens the fusion among the layers, and the shape of the strands in the layers and voids are present in the sample.

SEM photographs at a 30× magnification on the side samples face, SEM pictures at a 30% magnification at the fracture samples area, and SEM pictures at a 150× magnification of 150× at the fracture samples area, respectively, presented for (a), (b), (c) raw PA12, (d), (e), (f) PA12/5% AgNO3/2.5% PVA, (g), (h), (i) PA12/10% AgNO3/5% PVA

The corresponding tensile experiment samples fracture surface pictures are presented at two magnifications, i.e., 30× (Fig. 10b—pure PA12, Fig. 10e—PA12/5% AgNO3/2.5% PVA, Fig. 10h—PA12/10% AgNO3/5.0% PVA), and 150 × (Fig. 10c—pure PA12, Fig. 10f—PA12/5% AgNO3/2.5% PVA, Fig. 10i—PA12/10.0% AgNO3/5.0% PVA). As shown, pure PA12 has a clear ductile response with great deformations present in the cracked surface (Fig. 10b, and c). The addition of AgNO3 and PVA in the matrix significantly reduces the ductility of the specimens, making them more brittle (Fig. 10e, and f), with reduced deformation of the fracture surface observed. This effect is increased by further increasing the concentration of the additives in the composites, with the higher fillers loading composite having an even more brittle behavior (Fig. 10h, and i).

Biocidal performance

The developed IZ after the agar well diffusion tests are presented in Fig. 11. The pure PA12 specimens were the control samples. As expected, no IZ was developed with these specimens for both bacteria (Fig. 11a—E. coli, Fig. 11e—S. aureus). The two composites developed IZ, indicating their biocidal capabilities against the two bacteria tested. The IZ was wider at the higher additives loading composite for both bacteria (Fig. 11c—E. coli, Fig. 11g—S. aureus). Figure 11d shows the calculated area of the IZ developed in the samples tested against E. coli. Figure 11h shows the corresponding calculated area of the IZ developed in the samples tested against S. aureus. This indicated that increasing the concentration of the additive improves the biocidal behavior of the compounds for both bacteria. Also, the biocidal behavior against S. aureus was more efficient than towards E. coli. In the literature, there are studies stating that AgNPs are more efficient against S. aureus than E. coli (Shahverdi et al. 2007), while there are also studies that report the opposite (Vu et al. 2018), and others that report no significant differences in the effect of silver on these two bacteria (Feng et al. 2000). So, the outcome differs, probably due to the testing conditions and parameters.

Discussion

Herein, the reactive melt mixing procedure was employed for the preparation of the multi-functional nanocomposites, which was validated by the change in the hue of the composites in comparison with the raw PA12 (yellow to brown, pure PA12 was white, as shown in the images of the study). This color change indicates that a chemical response appeared throughout the extrusion of the filament, as the literature reports (Brown et al. 1995; Wang et al. 2005; Vidakis et al. 2020). The composites developed were abundantly characterized for their rheological, morphological, thermal, antibacterial, and mechanical performance in sixteen different tests. This vigorous effort aimed to analytically report their properties and ensure their stability and performance, which were proven through the reported experimental results.

The mechanical test findings are outlined in the spider-form graph presented in Fig. 12. In the graph the performance of the PVA polymer in the mechanical tests is also included. Still, since PVA was not a matrix material in the study, its performance was not compared with the remaining mechanical test results in Fig. 12. The spyder graph depicts the performance of the pure PA12, the pure PVA, and the PA12/AgNO3/PVA composites. The mechanical properties derived from the experimental procedure are presented (average value from the five samples assessed in each mechanical test) of each compound and the pure materials. The grey shaded area depicts the pure PA12 performance in each mechanical property. On the right side, these properties are presented in a list and the compound that achieved the highest response in each mechanical property is indicated. Each compound is presented with a different color according to the legend provided in the figure. On the right side, it is shown that the PA12/5% AgNO3/2.5% PVA compound had the greatest reaction to the greatest extent of the mechanical tests. So, this is the recommended composite among the composites tested when mechanical reinforcement is the priority. Still, this composite had inferior antibacterial properties, compared to the PA12/10.0% AgNO3/5.0% PVA composite. According to the requirements of each application, a balance concerning mechanical reinforcement and antibacterial behavior should be attained.

In the literature, the reported mechanical performance of the 3D-printed PVA polymer is reported to be lower than the mechanical performance reported herein (Rigotti et al. 2018; Yang et al. 2020). Such differences can be attributed to non-identical PVA grades and 3D printing conditions, which can affect the 3D-printed parts’ mechanical performance. Still, PVA was not the matrix material in the study. It was used, as mentioned, as a reduction agent. Regarding PA12, which was the matrix material in the study, in 3D printing Alumina and Zirconia have been introduced as fillers for composites development for biomedical applications (Nakonieczny et al. 2021). In the aforementioned study, the introduction of the fillers led to inferior mechanical performance, still, the additives rendered the composites compatible with biomedical applications. To achieve a similar effect silver-doped antibacterial nanopowder was used as an additive in the same medical-grade PA12 polymer in MEX 3D printing (Vidakis et al. 2022h). A 27% increase was achieved in the tensile tests, compared to the 19.8% achieved in the current research. Interestingly, the antibacterial behavior reported by (Vidakis et al. 2022h) agrees with the current findings, with the biocidal activity being more intense towards S. aureus than E. Coli. Cuprous oxide has also been tested as an additive in medical-grade PA12 polymer in MEX 3D printing, as a reinforcement and biocidal agent (Vidakis et al. 2022c). In this study, a 28% increase was achieved in the tensile tests, compared to the 19.8% achieved in the current study. The antibacterial performance achieved by the Cuprous oxide filler was similar to that of the findings reported herein and again the biocidal activity was more intense as opposed to S. aureus than E. Coli, as in the current research. The development of nanocomposites with binary inclusions, i.e., titanium nitride (TiN) as a reinforcement agent and cuprous oxide or copper as an antibacterial agent, using again a medical-grade PA12 polymer in MEX 3D-printing has been documented (Vidakis et al. 2022d). The nanocomposite with TiN as a filler achieved a 45% increase in tensile strength, compared to the unfilled PA12 thermoplastic. The compound having TiN and cuprous oxide as fillers, to enable also antibacterial properties in the nanocomposite, achieved a 28% increase in the tensile experiments, compared to the 19.8% achieved in the current study. The corresponding compound having TiN and copper as fillers, which also showed biocidal activity, achieved a 24.5% increase in the tensile experiments, compared to the 19.8% achieved in the current study. The nanocomposite with TiN and cuprous oxide showed better antibacterial performance than the corresponding one with TiN and copper. Again, the biocidal activity was more intense towards S. aureus than E. Coli, as in the current research. Comparing the biocidal behavior of the silver nitrate to that of cuprous oxide and copper in (Vidakis et al. 2022d), silver nitride (AgNP after the reactive melt mixing procedure) was more effective against the two bacteria tested.

Regarding the 3D-printing value of the composites, as it was presented in the side surface SEM images, it should be mentioned that all specimens were 3D-printed with the same settings to be able to have comparable results. From the rheological measurements, it was found that the addition of silver nitrate and the PVA in the PA12 matrix significantly reduces the viscosity in the composites. Therefore, these defects can be attributed to the reduced rheological properties of the composites in comparison with the unfilled PA12 polymer. This instructs that in the composites the 3D printing settings should differ, and especially the temperatures used should have been raised, to achieve 3D-printing quality similar to that of the pure PA12. 3D printing settings required optimization for the composites as well. Different 3D printing settings between the compounds would make the experimental results in the mechanical tests non-comparable. Nevertheless, despite the non-optimum 3D printing settings in the composites, their mechanical response in the experiments was still increased compared to the unfilled PA12 thermoplastic, as presented above.

Conclusions and future perspectives

The challenges of the study were confronted, and the hypothesis investigated was proven. The composites developed were fully characterized by performing sixteen different tests and their derived properties were evaluated and analyzed in the study. Silver nitrate induced multi-functional characteristics to the medical-grade PA12, by enhancing the mechanical behavior and enabling antibacterial properties on the composites developed. Such multi-functional composites have the potential for bio-related uses in the medical and culinary field, exploiting the benefits of MEX 3D printing. The role of PVA as a reduction agent was verified. Reactive melt mixing during the extrusion process released silver nanoparticles and thus produced nano-scale composites with silver nitrate salt. The compound with 5.0 wt. % AgNO3 and 2.5 wt. % PVA dominated the mechanical tests with its response while having a sufficient antibacterial performance at the same time. As anticipated, the increase of the concentration of the additive in the composite increases the biocidal activity of the composite but reduces the mechanical response of the composite. The produced composites’ biocidal activity was more intense towards the gram-positive S. aureus than the gram-negative E. coli microorganism. In future work, different reduction agents can be examined, the concentration of the additive can be additionally optimized, and further antibacterial tests and cytotoxicity tests can be performed.

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

Abbreviations

- AgNO3 :

-

Silver nitrate

- AM:

-

Additive manufacturing

- C, F, FILL, T:

-

Refers to compression, flexural, filament, and tensile test properties respectively

- DSC:

-

Differential scanning calorimetry

- E. coli :

-

Escherichia coli

- EDS:

-

Energy dispersive spectroscopy

- IZ:

-

Inhibition zone

- M-H:

-

Microhardness

- MEX:

-

Material extrusion

- NPs:

-

Nanoparticles

- PA:

-

Polyamide

- PEG:

-

Polyethylene glycol

- PVA:

-

Polyvinyl alcohol

- PVP:

-

Polyvinylpyrrolidone

- S. aureus :

-

Staphylococcus aureus

- SEM:

-

Scanning electron microscopy

- Tg:

-

Glass transition temperature

- TGA:

-

Thermogravimetric analysis

- wt. %:

-

Weight-to-weight concentration

References

Abdullah AM, Rahim TNAT, Hamad WNFW et al (2018) Mechanical and cytotoxicity properties of hybrid ceramics filled polyamide 12 filament feedstock for craniofacial bone reconstruction via fused deposition modelling. Dental Mater 34:e309–e316. https://doi.org/10.1016/j.dental.2018.09.006

Access O, Pathophysiology C (2019) Antimicrobial effect of zinc oxide and silver nitrate nanoparticles against S. aureus, A. baumannii and P. aeruginosa. 4–7

Ahmed W, Siraj S, Al-Marzouqi AH (2021) Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials. Polymers (basel) 13:1523

Ali HE, Abd-Rabboh HSM, Awwad NS et al (2021) Photoluminescence, optical limiting, and linear/nonlinear optical parameters of PVP/PVAL blend embedded with silver nitrate. Optik (stuttg) 247:167863. https://doi.org/10.1016/j.ijleo.2021.167863

Appendini P, Hotchkiss JH (2002) Review of antimicrobial food packaging. Innovat Food Sci Emerging Technol 3:113–126. https://doi.org/10.1016/S1466-8564(02)00012-7

Aveledo R, Aveledo A, Lago N et al (2022) Antibacterial activity of silver nitrate on Pseudomonas aeruginosa bacteria using Calvet calorimetry. J Therm Anal Calorim 148:1639–1646. https://doi.org/10.1007/s10973-022-11603-1

Badineni V, Maseed H, Arla SK et al (2019) Effect of PVA/PVP protective agent on the formation of silver nanoparticles and its photocatalytic and antimicrobial activity. Mater Today Proc 36:121–125. https://doi.org/10.1016/j.matpr.2020.02.002

Balachandar R, Navaneethan R, Biruntha M et al (2022) Antibacterial activity of silver nanoparticles phytosynthesized from Glochidion candolleanum leaves. Mater Lett 311:131572. https://doi.org/10.1016/j.matlet.2021.131572

Balouiri M, Sadiki M, Ibnsouda SK (2016) Methods for in vitro evaluating antimicrobial activity: a review. J Pharm Anal 6:71–79. https://doi.org/10.1016/j.jpha.2015.11.005

Bhattacharyya AR, Pötschke P, Häußler L, Fischer D (2005) Reactive compatibilization of melt mixed PA6/SWNT composites: mechanical properties and morphology. Macromol Chem Phys 206:2084–2095. https://doi.org/10.1002/macp.200500231

Bhosale S (2023) Opto-electrical characteristics of silver nitrate-doped polyvinyl alcohol films. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.01.087

Billings C, Cai C, Liu Y (2021) Utilization of Antibacterial Nanoparticles in Photocurable Additive Manufacturing of Advanced Composites for Improved Public Health. Polymers (basel). https://doi.org/10.3390/polym13162616

Brown MWR, Johnson AF, Coates P (1995) Reactive Extrusion of Polymers. Eng Plastics 8:406–409

Chernousova S, Epple M (2013) Silver as Antibacterial Agent: Ion, Nanoparticle, and Metal. Angewandte Chemie International Edition 52:1636–1653. https://doi.org/10.1002/anie.201205923

Chong WJ, Shen S, Li Y et al (2022) Additive manufacturing of antibacterial PLA-ZnO nanocomposites: benefits, limitations and open challenges. J Mater Sci Technol 111:120–151. https://doi.org/10.1016/j.jmst.2021.09.039

Deng H, McShan D, Zhang Y et al (2016) Mechanistic Study of the Synergistic Antibacterial Activity of Combined Silver Nanoparticles and Common Antibiotics. Environ Sci Technol 50:8840–8848. https://doi.org/10.1021/acs.est.6b00998

Dutta PK, Tripathi S, Mehrotra GK, Dutta J (2009) Perspectives for chitosan based antimicrobial films in food applications. Food Chem 114:1173–1182. https://doi.org/10.1016/j.foodchem.2008.11.047

Dzogbewu TC, du Preez WB (2021) Additive manufacturing of titanium-based implants with metal-based antimicrobial agents. Metals (basel) 11:1–12. https://doi.org/10.3390/met11030453

Dzogbewu TC, Fianko SK, Amoah N et al (2022) Additive manufacturing in South Africa: critical success factors. Heliyon 8:e11852. https://doi.org/10.1016/j.heliyon.2022.e11852

Emadzadeh D, Lau WJ, Rahbari-Sisakht M et al (2015) Synthesis, modification and optimization of titanate nanotubes-polyamide thin film nanocomposite (TFN) membrane for forward osmosis (FO) application. Chem Eng J 281:243–251. https://doi.org/10.1016/j.cej.2015.06.035

Feng QL, Wu J, Chen GQ et al (2000) A mechanistic study of the antibacterial effect of silver ions on Escherichia coli and Staphylococcus aureus. J Biomed Mater Res 52:662–668

Feng Li, Wang Y, Wei Q (2019) PA12 Powder Recycled from SLS for FDM. Polymers (basel) 11:727

Fico D, Rizzo D, Casciaro R, Esposito Corcione C (2022) A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers (basel) 14:465

Fouda A, Abdel-Maksoud G, Saad HA et al (2021) The efficacy of silver nitrate (Agno3) as a coating agent to protect paper against high deteriorating microbes. Catalysts 11:1–18. https://doi.org/10.3390/catal11030310

Franci G, Falanga A, Galdiero S et al (2015) Silver Nanoparticles as Potential Antibacterial Agents. Molecules 20:8856–8874

Gatin E, Iordache S-M, Matei E et al (2022) Raman Spectroscopy as Spectral Tool for Assessing the Degree of Conversion after Curing of Two Resin-Based Materials Used in Restorative Dentistry. Diagnostics 12:1993

Gomaa EZ (2017) Silver nanoparticles as an antimicrobial agent: a case study on Staphylococcus aureus and Escherichia coli as models for gram-positive and gram-negative bacteria. J Gen Appl Microbiol 63:36–43. https://doi.org/10.2323/jgam.2016.07.004

Goyanes A, Kobayashi M, Martínez-Pacheco R et al (2016) Fused-filament 3D printing of drug products: Microstructure analysis and drug release characteristics of PVA-based caplets. Int J Pharm 514:290–295. https://doi.org/10.1016/j.ijpharm.2016.06.021

Habeeb Rahuman HB, Dhandapani R, Narayanan S et al (2022) Medicinal plants mediated the green synthesis of silver nanoparticles and their biomedical applications. IET Nanobiotechnol 16:115–144. https://doi.org/10.1049/nbt2.12078

Han Z, Wei K (2022) Multi-material topology optimization and additive manufacturing for metamaterials incorporating double negative indexes of Poisson’s ratio and thermal expansion. Addit Manuf 54:102742. https://doi.org/10.1016/j.addma.2022.102742

Huq MdA, Ashrafudoulla Md, Rahman MM et al (2022) Green synthesis and potential antibacterial applications of bioactive silver nanoparticles: a review. Polymers (Basel) 14:742. https://doi.org/10.3390/polym14040742

Jackson J, Burt H, Lange D et al (2021) The design, characterization and antibacterial activity of heat and silver crosslinked poly(Vinyl alcohol) hydrogel forming dressings containing silver nanoparticles. Nanomaterials 11:1–19. https://doi.org/10.3390/nano11010096

Kam M, İpekçi A, Şengül Ö (2023) Investigation of the effect of FDM process parameters on mechanical properties of 3D printed PA12 samples using Taguchi method. J Thermoplast Compos Mater 36:307–325. https://doi.org/10.1177/08927057211006459

Khanna PK, Singh N, Charan S et al (2005) Synthesis and characterization of Ag/PVA nanocomposite by chemical reduction method. Mater Chem Phys 93:117–121. https://doi.org/10.1016/j.matchemphys.2005.02.029

Kim JS (2007) Reduction of silver nitrate in ethanol by poly(N-vinylpyrrolidone). J Ind Eng Chem 13:566–570

Kumar Pandian SR, Deepak V, Kalishwaralal K et al (2010) Mechanism of bactericidal activity of silver nitrate—a concentration dependent bi-functional molecule. Braz J Microbiol 41:805–809. https://doi.org/10.1590/S1517-83822010000300033

Leber AL (2016) Preparation of routine media and reagents used in antimicrobial susceptibility testing. In: Clinical Microbiology Procedures Handbook. pp 5.20.1.1–5.20.3.10

Li H, Zhang S, Yi Z et al (2017) Bonding quality and fracture analysis of polyamide 12 parts fabricated by fused deposition modeling. Rapid Prototyp J 23:973–982. https://doi.org/10.1108/RPJ-03-2016-0033

Liu, X. B., Y. B. Zou, W. T. Li, GPC and WJC (2006) Kinetics of thermo-oxidative and thermal degradation of poy(D,L-lactide) (PDLLA) at processing temperature. Polym Degrad Stab 91:3259–3265

Luiz BKM, Amboni RDMC, Prates LHM et al (2007) Influence of drinks on resin composite: evaluation of degree of cure and color change parameters. Polym Test 26:438–444. https://doi.org/10.1016/j.polymertesting.2006.12.005

Ma N, Liu W, Ma L et al (2020) Crystal transition and thermal behavior of Nylon 12. E-Polymers 20:346–352. https://doi.org/10.1515/epoly-2020-0039

Makarem M, Lee CM, Kafle K et al (2019) Probing cellulose structures with vibrational spectroscopy. Cellulose 26:35–79. https://doi.org/10.1007/s10570-018-2199-z

Mallakpour S, Tabesh F, Hussain CM (2022) A new trend of using poly(vinyl alcohol) in 3D and 4D printing technologies: process and applications. Adv Colloid Interface Sci 301:102605. https://doi.org/10.1016/j.cis.2022.102605

Masood N, Ahmed R, Tariq M et al (2019) Silver nanoparticle impregnated chitosan-PEG hydrogel enhances wound healing in diabetes induced rabbits. Int J Pharm 559:23–36. https://doi.org/10.1016/j.ijpharm.2019.01.019

Matijašić G, Gretić M, Vinčić J et al (2019) Design and 3D printing of multi-compartmental PVA capsules for drug delivery. J Drug Deliv Sci Technol 52:677–686. https://doi.org/10.1016/j.jddst.2019.05.037

Melendez-Rodriguez B, Torres-Giner S, Aldureid A et al (2019) Reactive melt mixing of poly(3-hydroxybutyrate)/rice husk flour composites with purified biosustainably produced poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Materials. https://doi.org/10.3390/ma12132152

Nakonieczny DS, Kern F, Dufner L et al (2021) Alumina and Zirconia-Reinforced Polyamide PA-12 Composites for Biomedical Additive Manufacturing. Materials 14:6201

Osman IM, Abdalla MD, Elfaki AH et al (2021) Effects of additive and gamma irradiation on the structural and optical properties of polyvinyl alcohol doped with silver nitrate. Glob Sci J 9(6):1780–1792

Pal N, Banerjee S, Roy P, Pal K (2021) Cellulose nanocrystals-silver nanoparticles-reduced graphene oxide based hybrid PVA nanocomposites and its antimicrobial properties. Int J Biol Macromol 191:445–456. https://doi.org/10.1016/j.ijbiomac.2021.08.237

Pencheva D, Bryaskova R, Kantardjiev T (2012) Polyvinyl alcohol/silver nanoparticles (PVA/AgNps) as a model for testing the biological activity of hybrid materials with included silver nanoparticles. Mater Sci Eng C 32:2048–2051. https://doi.org/10.1016/j.msec.2012.05.016

Peris-Díaz MD, Łydżba-Kopczyńska B, Sentandreu E (2018) Raman spectroscopy coupled to chemometrics to discriminate provenance and geological age of amber. J Raman Spectrosc 49:842–851. https://doi.org/10.1002/jrs.5357

Petousis M, Vidakis N, Mountakis N et al (2023) On the substantial mechanical reinforcement of Polylactic Acid with Titanium Nitride ceramic nanofillers in material extrusion 3D printing. Ceram Int. https://doi.org/10.1016/j.ceramint.2023.02.001

Prashar G, Vasudev H, Bhuddhi D (2022) Additive manufacturing: expanding 3D printing horizon in industry 4.0. Int J Interactive Design Manufact (IJIDeM). https://doi.org/10.1007/s12008-022-00956-4

Resta V, Quarta G, Lomascolo M et al (2015) Raman and Photoluminescence spectroscopy of polycarbonate matrices irradiated with different energy 28Si+ ions. Vacuum 116:82–89. https://doi.org/10.1016/j.vacuum.2015.03.005

Rigotti D, Fambri L, Pegoretti A (2018) Polyvinyl alcohol reinforced with carbon nanotubes for fused deposition modeling. J Reinf Plast Compos 37:716–727. https://doi.org/10.1177/0731684418761224

Sedlarik V, Galya T, Sedlarikova J et al (2010) The effect of preparation temperature on the mechanical and antibacterial properties of poly(vinyl alcohol)/silver nitrate films. Polym Degrad Stab 95:399–404. https://doi.org/10.1016/j.polymdegradstab.2009.11.017

Sen CK, Ren CY (2000) Synthesis of nanosized silver particles by chemical reduction method. Mater Chem Phys 64:241–246. https://doi.org/10.1016/S0254-0584(00)00223-6

Shahverdi AR, Fakhimi A, Shahverdi HR, Minaian S (2007) Synthesis and effect of silver nanoparticles on the antibacterial activity of different antibiotics against Staphylococcus aureus and Escherichia coli. Nanomedicine 3:168–171. https://doi.org/10.1016/j.nano.2007.02.001

Stuart BH (1996) Temperature studies of polycarbonate using Fourier transform Raman spectroscopy. Polym Bull 36:341–346. https://doi.org/10.1007/BF00319235

Tanemura K, Koike T, Komatsu S et al (2007) A new method for thin silver coating reaction using Ag2O and polyethylene glycol 400. Chem Lett 36:782–783. https://doi.org/10.1246/cl.2007.782

Tang S, Zheng J (2018) Antibacterial Activity of Silver Nanoparticles: Structural Effects. Adv Healthc Mater 7:1–10. https://doi.org/10.1002/adhm.201701503

Thangavelu L, Adil AH, Arshad S et al (2021) Antimicrobial Properties of Silver Nitrate Nanoparticle and Its Application in Endodontics and Dentistry: A Review of Literature. J Nanomater. https://doi.org/10.1155/2021/9132714

Tyuftin AA, Kerry JP (2020) Review of surface treatment methods for polyamide films for potential application as smart packaging materials: surface structure, antimicrobial and spectral properties. Food Packag Shelf Life 24:100475. https://doi.org/10.1016/j.fpsl.2020.100475

Tzounis L, Bangeas PI, Exadaktylos A et al (2020) Three-dimensional printed polylactic acid (PLA) surgical retractors with sonochemically immobilized silver nanoparticles: the next generation of low-cost antimicrobial surgery equipment. Nanomaterials. https://doi.org/10.3390/nano10050985

Vidakis N, Petousis M, Velidakis E et al (2020) Three-Dimensional Printed Antimicrobial Objects of Polylactic Acid (PLA)-Silver Nanoparticle Nanocomposite Filaments Produced by an In-Situ Reduction Reactive Melt Mixing Process. Biomimetics 5:42. https://doi.org/10.3390/biomimetics5030042

Vidakis N, David CN, Petousis M et al (2022a) Optimization of key quality indicators in material extrusion 3D printing of acrylonitrile butadiene styrene: The impact of critical process control parameters on the surface roughness, dimensional accuracy, and porosity. Mater Today Commun 34:105171. https://doi.org/10.1016/j.mtcomm.2022.105171

Vidakis N, Petousis M, Kechagias JD (2022b) Parameter effects and process modelling of Polyamide 12 3D-printed parts strength and toughness. Mater Manuf Processes 37:1358–1369. https://doi.org/10.1080/10426914.2022.2030871

Vidakis N, Petousis M, Michailidis N et al (2022c) Development and Optimization of Medical-Grade MultiFunctional Polyamide 12-Cuprous Oxide Nanocomposites with Superior Mechanical and Antibacterial Properties for Cost-Effective 3D Printing. Nanomaterials. https://doi.org/10.3390/nano12030534

Vidakis N, Petousis M, Mountakis N et al (2022d) Trilateral Multi-Functional Polyamide 12 Nanocomposites with Binary Inclusions for Medical Grade Material Extrusion 3D Printing: The Effect of Titanium Nitride in Mechanical Reinforcement and Copper/Cuprous Oxide as Antibacterial Agents. J Funct Biomater. https://doi.org/10.3390/jfb13030115

Vidakis N, Petousis M, Papadakis VM, Mountakis N (2022e) Multifunctional Medical Grade Resin with Enhanced Mechanical and Antibacterial Properties: The Effect of Copper Nano-Inclusions in Vat Polymerization (VPP) Additive Manufacturing. J Funct Biomater. https://doi.org/10.3390/jfb13040258

Vidakis N, Petousis M, Velidakis E et al (2022f) Multi-functional polyamide 12 (PA12)/ multiwall carbon nanotube 3D printed nanocomposites with enhanced mechanical and electrical properties. Adv Compos Mater 31:630–654. https://doi.org/10.1080/09243046.2022.2076019

Vidakis N, Petousis M, Velidakis E et al (2022g) Investigation of the Biocidal Performance of Multi-Functional Resin/Copper Nanocomposites with Superior Mechanical Response in SLA 3D Printing. Biomimetics. https://doi.org/10.3390/biomimetics7010008

Vidakis N, Petousis M, Velidakis E et al (2022h) Medical-Grade Polyamide 12 Nanocomposite Materials for Enhanced Mechanical and Antibacterial Performance in 3D Printing Applications. Polymers (basel). https://doi.org/10.3390/polym14030440

Vidakis N, Petousis M, Velidakis E et al (2023) Multi-functional medical grade Polyamide12/Carbon Black nanocomposites in material extrusion 3D printing. Compos Struct. https://doi.org/10.1016/j.compstruct.2023.116788

Vu XH, Duong TTT, Pham TTH et al (2018) Synthesis and study of silver nanoparticles for antibacterial activity against Escherichia coli and Staphylococcus aureus. Adv Nat Sci Nanosci Nanotechnol. https://doi.org/10.1088/2043-6254/aac58f

Wang H, Qiao X, Chen J et al (2005) Mechanisms of PVP in the preparation of silver nanoparticles. Mater Chem Phys 94:449–453. https://doi.org/10.1016/j.matchemphys.2005.05.005

Wei C, Solanki NG, Vasoya JM et al (2020) Development of 3D Printed Tablets by Fused Deposition Modeling Using Polyvinyl Alcohol as Polymeric Matrix for Rapid Drug Release. J Pharm Sci 109:1558–1572. https://doi.org/10.1016/j.xphs.2020.01.015

Yang L, Chen Y, Wang M et al (2020) Fused Deposition Modeling 3D Printing of Novel Poly(vinyl alcohol)/Graphene Nanocomposite with Enhanced Mechanical and Electromagnetic Interference Shielding Properties. Ind Eng Chem Res 59:8066–8077. https://doi.org/10.1021/acs.iecr.0c00074

Yin X, Han L, Liu H et al (2022) Recent Progress in 1D Nanostructures Reinforced Carbon/Carbon Composites. Adv Funct Mater 32:2204965. https://doi.org/10.1002/adfm.202204965

Yuan B, Guo J, Bai S (2020a) In situ thermally induced reduction of silver nitrate by polyvinyl alcohol to prepare a three-dimensional porous Ag substrate with excellent adsorption and surface-enhanced Raman scattering properties. J Mater Chem C Mater 8:6478–6487. https://doi.org/10.1039/d0tc00772b

Yuan B, Yang S, Wang M et al (2020b) Preparation of Ag foam catalyst based on in-situ thermally induced redox reaction between polyvinyl alcohol and silver nitrate with supercritical CO2 foaming technology. Polymer (guildf) 206:122858. https://doi.org/10.1016/j.polymer.2020.122858

Zhang X, Fan W, Liu T (2020) Fused deposition modeling 3D printing of polyamide-based composites and its applications. Compos Commun 21:100413. https://doi.org/10.1016/j.coco.2020.100413

Zhang W, Ye G, Liao D et al (2022) Recent Advances of Silver-Based Coordination Polymers on Antibacterial Applications. Molecules 27:7166

Zhao BA, Cai WF, Pu KB et al (2022) Electrochemical deposition of flower-like nanostructured silver particles with a PVA modified carbon cloth cathode. RSC Adv 12:21793–21800. https://doi.org/10.1039/d2ra02495k

Zimmerer C, Matulaitiene I, Niaura G et al (2019) Nondestructive characterization of the polycarbonate—octadecylamine interface by surface enhanced Raman spectroscopy. Polym Test 73:152–158. https://doi.org/10.1016/j.polymertesting.2018.11.023

Zou HT, Yi CH, Wang LX, HTL, WLX (2009) Thermal degradation of poly(lactic acid) measured by thermogravimetry coupled to Fourier transform infrared spectroscopy. J Therm Anal Calorim 97:929–935

Acknowledgements

The authors would like to thank the Institute of Electronic Structure and Laser of the Foundation for Research and Technology-Hellas (IESL-FORTH) and in particular Ms. Aleka Manousaki for taking the SEM images presented in this work, and the Photonic Phononic and Meta-Materials Laboratory for sharing the Raman Instrumentation.

Funding

Open access funding provided by HEAL-Link Greece. This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, analysis, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results. Journal policies have been reviewed and accepted by all authors.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vidakis, N., Petousis, M., Michailidis, N. et al. Medical grade polyamide 12 silver nanoparticle filaments fabricated with in-situ reactive reduction melt-extrusion: rheological, thermomechanical, and bactericidal performance in MEX 3D printing. Appl Nanosci 14, 69–88 (2024). https://doi.org/10.1007/s13204-023-02966-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-023-02966-4