Abstract

β-Ga2O3 nanocrystals have been successfully obtained by the high-energy ball milling method. The obtained nanocrystalline powders have been characterized using X-ray diffraction, transmission electron microscopy, energy-dispersive X-ray spectroscopy, and luminescent spectroscopy. X-ray diffraction patterns show a single gallium oxide structure formed in the milling process with a small amount of α-Ga2O3 phase. The grains of irregular shape were identified with the TEM technique. HRTEM images confirmed the formation of the β-Ga2O3 nanocrystals with a size distribution of 50–80 nm. Three luminescence bands peaked at about 2.52, 2.91, and 3.26 eV were observed in photoluminescence spectra. The gradual blue shift of the emission maxima at the excitation in the fundamental absorption edge under the different milling conditions was detected.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Gallium oxide (β-Ga2O3) is wide band gap semiconductor, which has attracted significant interest in the last decade, primarily due to various practical applications in particular in power electronics, photodetectors, gas sensors, electrodes, and many others (Pearton et al. 2018; Higashiwaki et al. 2016; Luchechko et al. 2019). This material is transparent in UV and visible spectral regions and exhibits optimal luminescence efficiency. It is therefore a candidate for the next generation of different devices due to its high thermal and longer-term chemical stability.

Nowadays, various preparation methods for nanostructured materials are known. Numerous studies have been provided on the synthesis and investigations of the characteristics of β-Ga2O3 low-dimensional structures obtained mainly by sol–gel, chemical vapor deposition, and hydrothermal methods (Liang et al. 2001; Gopal et al. 2018; Yu et al. 2020; Rafique et al. 2017; Zhang et al. 2005). This made it possible to develop new materials and expand the areas of gallium oxide applications. The combination of different phases of wide band gap semiconductor materials, especially β-Ga2O3, GaN, SnO2 as well as graphene makes heterogeneous materials with double or/and triple junctions suitable for advanced nano- and micro-sensors, radiation photodetectors, and other devices (Lupan et al. 2015; Ai et al. 2017).

Among these various methods, the high-energy ball milling method is of particular interest, as it is possible to obtain nanomaterials without contamination with chemical components used during the synthesis because the process is performed under solvent-free conditions. This method has been widely exploited for the synthesis of various nanomaterials (Baláž et al. 2013), in particular nanograins, nanocomposites, and nano quasi-crystalline materials. High-energy ball milling is governed by many parameters, such as milling speed, size and size distribution of the balls, dry or wet milling, the temperature of milling, and the duration of milling (Benjamin 1990; Yadav et al. 2012). Β-Ga2O3 has been synthesized using high-energy ball milling in the past (Swamy et al. 2013).

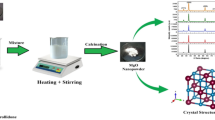

In this work, structural and luminescent properties of β-Ga2O3 powders prepared by high-energy ball milling were investigated using the methods of X-ray diffraction (XRD), transmission electron microscopy (TEM), energy dispersive X-ray (EDX) spectroscopy, and luminescent spectroscopy.

Experimental details

Undoped β-Ga2O3 phosphors were synthesized using a high-energy ball milling method. The high-purity grade Ga2O3 (Sigma Aldrich, 99.999%) was used. The high-energy ball milling process was performed in a Pulverisette 7 Premium line planetary ball mill (Fritsch, Idar-Oberstein, Germany) under the following conditions: air atmosphere, 15 tungsten carbide (WC) milling balls (10 mm diameter), ball-to-powder ratio 37, milling speed 300 rpm. The milling time and overall mass of the sample were changed from 1 to 3 h and from 3 to 7 g, respectively (see Table 1), which were the most optimal for obtaining nanomaterials with high luminescence yield.

X-ray diffraction (XRD) patterns were recorded using a D8 Advance X-ray diffractometer (Bruker, Germany) in the Bragg–Brentano geometry, working with a CuKα (λ = 0.15418 nm) radiation. The operating voltage and current were 40 kV and 40 mA, respectively. All samples were scanned in the range from 20° to 50° 2θ with 0.04° step. The microstructure and morphology of obtained nanopowders were visualized using the transmission electron microscopy (S/TEM) FEI Tecnai Osiris microscope equipped with a field emission gun (FEG), operating at an accelerating voltage of 200 kV. Samples were examined in classical transmission (Bright field); high resolution (HRTEM) and selected area diffraction (SAED) modes. A chemical composition mapping was performed by a super energy-dispersive X-ray spectrometer (EDS) coupled with TEM.

Photoluminescence characterization of the samples was carried out on SM 2203 spectrofluorometer at room temperature. More details about the used experimental techniques are described in the works (Kravets et al. 2019; Luchechko et at. 2020a).

Results and discussion

The present experiments were set up in such a way to show whether milling time or changing overall mass will significantly alter the phase composition, and subsequently the photoluminescence properties.

XRD patterns for the samples obtained under different milling conditions are shown in Fig. 1. All diffraction peaks are in good agreement with the data for β-Ga2O3 reported by (Liang et al. 2001; Lupan et al. 2015; Yu et al. 2020) and in card of Powder Diffraction Standards. Dominant diffraction peaks of (402), (202), (111), and (311) crystallographic planes are located at about 30.4, 31.7, 35.2, and 38.4° 2 theta positions and correspond to the monoclinic β-phase of gallium oxide. Besides the main β-Ga2O3 phase, a small amount of additional α-Ga2O3 phase was revealed in all samples, which means a phase transformation takes place during milling. This phenomenon has been reported to occur for many different phases like CaCO3 (Baláž 2021; Baláž et al. 2015), PbO (Dachille and Roy 1960) or ZnS (Baláž 2008). The content of α-Ga2O3 phase seems to be quite similar for all three samples, thus it cannot be stated whether its formation is favored by either longer milling time (sample G3) or using the lower sample mass (sample G1).

Figure 2 shows the TEM image of the typical β-Ga2O3 powder (G1). It can be seen that G1 powder consists of agglomerated particles with an average particle diameter of about 60–90 nm (Fig. 2a). The TEM images of samples G2 and G3 were very similar. The atomic-scale HRTEM image in Fig. 2b revealed that the formed β-Ga2O3 nanocrystals possess a good crystallinity with an interplanar distance of about ~ 0.27 nm. This distance corresponds to the (\(\overline{1 }11\)-) crystallographic plane of β-Ga2O3 with a monoclinic structure (Bae et al 2018).

The selected electron diffraction pattern of G1 powders is shown in Fig. 3. This figure demonstrates typical patterns with sharp reflections of the monoclinic β-phase of gallium oxide. As there are isolated dots (not concentric rings), it seems that the crystallinity of the sample is quite good.

The HAADF-STEM image of β-Ga2O3 grains for sample G1 is shown in Fig. 4a. The observed grains of irregular shape are a common feature after mechanically obtaining powders by high-energy ball milling (Baláž 2008). Figure 4 also shows the typical EDS mapping of the G1 sample. The results of elemental mapping of Ga (Fig. 4b) and O (Fig. 4c) show that both elements are homogeneously distributed in the sample, and they perfectly match each other.

The photoluminescence spectra of β-Ga2O3 powders treated under different milling conditions are shown in Fig. 5. According to the literature, undoped β-Ga2O3 powders should exhibit luminescence upon excitation with light from the area of fundamental absorption edge (the wavelength range 230–265 nm) or in front of the absorption edge (the band 280 nm) (Villora et al. 2003). As can be seen in Fig. 5, the photoluminescence band of β-Ga2O3 powders is broad and extends from 350 to 700 nm with a maximum of emission at about 425 nm. There is a shift of this emission maximum in the region of larger wavelengths when the excitation wavelength of powders was changed from 250 to 280 nm. Moreover, as can be seen from Fig. 5a, the change in milling conditions also leads to a shift of the emission maximum of G1-G3 powders to the shorter wavelengths at the excitation of 250 nm. The use of lower mass and shorter milling time (sample G1) results in luminescence at a greater wavelength, whereas longer milling with a higher amount of sample (G3) shows the luminescence maximum at a shorter wavelength. However, the position of the maximum does not change when changing the milling conditions of powders excited at 280 nm (Fig. 5b). As the α-Ga2O3 phase does not show any emission in the visible spectral region, its presence will not be considered in the text below.

In the energy coordinates, the luminescence spectrum of the G3 nanopowder was decomposed into three elementary Gaussian curves (Fig. 6). The half-width of the elementary luminescence bands at room temperature was about 0.5 eV. The emission maxima of the elementary bands are located in the UV ~ 3.26 eV (~ 380 nm), blue ~ 2.91 eV (~ 425 nm), and green ~ 2.52 eV (~ 490 nm) regions of the spectrum. The blue luminescence band with a maximum of 2.91 eV was the most intense among the elementary bands. The UV band, the maximum of which is at 3.26 eV at room temperature, has an intensity of approximately 75% of the blue band. The maximum green luminescence band is located in the region of larger wavelengths (~ 490 nm). It should be noted, that the position of the radiation maxima of elementary bands coincides well with the position of the known bands of intrinsic luminescence of β-Ga2O3 crystals (Vasil’tsiv et al. 1988; Binet et al. 1998; Onuma et al. 2013).

Regardless of the milling conditions, all three elementary bands of host luminescence were observed in the investigated gallium oxide powders G1-G3. The relative intensity of the elementary bands' emission changed. The total emission intensity, as well as the intensity of the UV and blue luminescence bands, were the highest in G3 powder, thus it seems that using a higher sample mass and longer milling time seems to be more favorable.

Figure 7 shows the excitation spectra for different gallium oxide powders. For all three samples, the excitation spectrum covers the wavelength range (energies) of the excitation light from 230 to 320 nm (3.8–5.5 eV), extending from the fundamental absorption region (230–270 nm) to the transparency region (270–450 nm). The main excitation maximum is located near the edge of the fundamental absorption of 254 nm (Luchechko et al. 2018). In the region of transparency of gallium oxide in front of the edge of the fundamental absorption is another excitation band at 4.4 eV (280 nm). In addition to the main excitation bands in the longer wavelength region of the spectrum in the energy range of 2.75–3.75 (wavelengths 350–450 nm) a wide low-intensity excitation band of luminescence with a maximum near 350–370 nm is observed. The excitation spectra of luminescence differ in the ranges of 230–300 and 300–400 nm, depending on the milling conditions of powders. The maximum excitation intensity of luminescence is observed for G3 powder at a wavelength of about 254 nm (Fig. 7a). To see the change in the relative intensity of the different excitation bands of G1-G3 powders, the spectra were normalized (Fig. 7b). For powder G1, there is an increase in the relative intensity of the excitation bands at 280 and 365 nm, which are located in the transparency region of gallium oxide.

UV luminescence band of β-Ga2O3 is independent of impurities and only decreases during doping, in particular with Cr3+ ions (Luchechko et al. 2020b; Vasyltsiv et al. 2021). UV luminescence of gallium oxide is characterized by a significant Stokes shift, high quantum yield, broad elementary bands, and decay time of the order of 10–6 s and is most often attributed to radiative recombination of autolocalized excitons or electrons with holes through donor–acceptor pairs (Onuma et al. 2018; Frodason et al. 2020). The autolocalization of excitons occurs as a result of the deformation interaction of electronic excitations with the acoustic oscillations of the lattice. The process of autolocalization is characteristic of phosphors with strong electron–phonon interaction and is highly dependent on temperature. In the case of gallium oxide, the increase in temperature is always accompanied by temperature quenching of UV luminescence. The energy of thermal quenching of UV luminescence coincides with the energy of some of their phonons 0.08 eV and may be due to the thermal destruction of autolocalized states.

The blue luminescence band observed is most often (Vasil’tsiv et al. 1988; Binet et al. 1998; Onuma et al. 2013) attributed to the recombination of electrons with holes through the donor–acceptor pairs. Since the donors and acceptors in gallium oxide can be of different types and different depths (Luchechko et al. 2020c; Usseinov et al. 2021; Vasyltsiv et al. 2021), it can be expected that the position of the maximum radiation can vary from UV to green parts of the spectrum.

With an increase in the intensity of milling, the average size of nanoparticles decreases, and accordingly, the effective surface of grains increases. The main defects that are formed during milling are concentrated precisely on the surface. Such defects are primarily oxygen vacancies and interstitial gallium. The oxygen evaporates into the atmosphere, which leads to the formation of an excess of gallium. Enhancing the number of interstitial gallium ions, which is a shallow donor, leads to an increase in the concentration of donor–acceptor pairs, that are responsible for blue luminescence.

Conclusions

Monoclinic gallium oxide β-Ga2O3 nanocrystalline powders with a small amount of α-Ga2O3 admixture phase have been successfully obtained using the high-energy ball milling method. XRD, SAED and HRTEM confirmed that the nanocrystals have a monoclinic structure. The α-Ga2O3 phase did not show any influence on the luminescent properties. The gradual blue shift of the emission maximum was observed when using higher sample mass and longer milling time. The relative intensity of the low energy emission band at 2.52 eV decreases under these conditions. The increase in the yield of blue luminescence in milled samples with milling time increasing can be explained by lattice distortion during mechanical processing, which causes the formation of oxygen vacancies and, as a consequence, the formation of excess gallium. The main models for explaining blue emission are DAP luminescence associated with these defects.

Synthesis of β-Ga2O3 nanocrystals by high-energy ball milling is a new way to operate the properties of this material, which gives the possibility to obtain phosphors based on low-dimensional structures.

Data availability

Not applicable.

References:

Ai M, Guo D, Qu Y, Cui W, Wu Z, Li P, Li L, Tang W (2017) Fast-response solar-blind ultraviolet photodetector with a graphene/β-Ga2O3/graphene hybrid structure. J Alloy Compd 692:634–638

Bae HJ, Yoo TH, Yoon Y, Lee IG, Kim JP, Cho BJ, Hwang WS (2018) High-aspect ratio β-Ga2O3 nanorods via hydrothermal synthesis. Nanomaterials 8:594

Baláž P, Achimovičová M, Baláž M et al (2013) Hallmarks of mechanochemistry: from nanoparticles to technology. Chem Soc Rev 42(18):7571–7637

Baláž M, Zorkovská A, Fabián M, Girman V, Briančin J (2015) Eggshell biomaterial: Characterization of nanophase and polymorphs after mechanical activation. Adv Powder Technol 26:1597–1608

Baláž P (2008) Mechanochemistry in minerals engineering. Mechanochemistry in nanoscience and minerals engineering. Springer, Berlin

Baláž M (2021) Environmental mechanochemistry: recycling waste into materials using high-energy ball milling. Springer, Cham

Benjamin JS (1990) Mechanical alloying-a perspective. Met Powder Rep 45:122–127

Binet L, Gourier D (1998) Origin of the blue luminescence of β-Ga2O3. J Phys Chem Solids 59:1241–1249

Dachille F, Roy R (1960) High-pressure phase transformations in laboratory mechanical mixers and mortars. Nature 186:34–71

Frodason YK, Johansen KM, Vines L, Varley JB (2020) Self-trapped hole and impurity-related broad luminescence in β-Ga2O3. J Appl Phys 127:075701

Gopal R, Goyal A, Saini A, Nagar M, Sharma N, Gupta DK, Dhayal V (2018) Sol-gel synthesis of Ga2O3 nanorods and effect of precursor chemistry on their structural and morphological properties. Ceram Int 44:19099–19105

Higashiwaki M, Sasaki K, Murakami H, Kumagai Y, Koukitu A, Kuramata A, Masui T, Yamakoshi S (2016) Recent progress in Ga2O3 power devices. Semicond Sci Technol 31:034001

Kravets O, Zaremba O, Shpotyuk Y et al (2019) Structure, morphology and optical-luminescence investigations of spinel ZnGa2O4 ceramics co-doped with Mn2+ and Eu3+ ions. Appl Nanosci 9:907–915

Liang CH, Meng GW, Wang GZ, Wang YW, Zhang LD, Zhang SY (2001) Catalytic synthesis and photoluminescence of β-Ga2O3 nanowires. Appl Phys Lett 78:3202–3204

Luchechko A, Vasyltsiv V, Kostyk L, Tsvetkova O (2018) Origin of point defects in β-Ga2O3 single crystals doped with Mg2+ Ions. Acta Phys Pol, A 133:811–815

Luchechko A, Vasyltsiv V, Kostyk L, Pavlyk B (2019) Dual-channel solar-blind uv photodetector based on β-Ga2O3. Phys Status Solidi 216:1900444

Luchechko A, Shpotyuk Y, Kravets O, Zaremba O, Szmuc K, Cebulski J, Ingram A, Golovchak R, Shpotyuk O (2020a) Microstructure and luminescent properties of Eu3+-activated MgGa2O4: Mn2+ ceramic phosphors. Journal of Advanced Ceramics 9:432–443

Luchechko A, Vasyltsiv V, Zhydachevskyy Y, Kushlyk M, Ubizskii S, Suchocki A (2020b) Luminescence spectroscopy of Cr3+ ions in bulk single crystalline β-Ga2O3. J Phys D Appl Phys 53:354001

Luchechko A, Vasyltsiv V, Kostyk L, Tsvetkova O, Pavlyk B (2020c) The Effect of Cr3+ and Mg2+ impurities on thermoluminescence and deep traps in β-Ga2O3 crystals. ECS J Solid State Sci Technol 9:045008

Lupan O, Braniste T, Deng M, Ghimpu L, Paulowicz I, Mishra YK, Kienle L, Adelung R, Tiginyanu I (2015) Rapid switching and ultra-responsive nanosensors based on individual shell–core Ga2O3/GaN: Ox@ SnO2 nanobelt with nanocrystalline shell in mixed phases. Sens Actuators, B Chem 221:544–555

Onuma T, Fujioka S, Yamaguchi T, Higashiwaki M, Sasaki K, Masui T, Honda T (2013) Correlation between blue luminescence intensity and resistivity in β-Ga2O3 single crystals. Appl Phys Lett 103:041910

Onuma T, Nakata Y, Sasaki K, Masui T, Yamaguchi T, Honda T, Karamata A, Higashiwaki M (2018) Modeling and interpretation of UV and blue luminescence intensity in β-Ga2O3 by silicon and nitrogen doping. J Appl Phys 124:075103

Pearton SJ, Yang J, Cary PH, Ren F, Kim J, Tadjer MJ, Mastro MA (2018) A review of Ga2O3 materials, processing, and devices. Appl Phys Rev 5:011301

Rafique S, Han L, Lee J, Zheng XQ, Zorman CA, Feng PXL, Zhao H (2017) Synthesis and characterization of Ga2O3 nanosheets on 3C-SiC-on-Si by low pressure chemical vapor deposition. J Vac Sci Technol 35:011208

Swamy AN, Shafirovich E, Ramana CV (2013) Synthesis of one-dimensional Ga2O3 nanostructures via high-energy ball milling and annealing of GaN. Ceram Int 39:7223–7227

Usseinov A, Koishybayeva Z, Platonenko A, Pankratov V, Suchikova Y, Akilbekov A, Zdorovets M, Purans J, Popov AI (2021) Vacancy Defects in Ga2O3: First-Principles Calculations of Electronic Structure. Materials 14:7384

Vasiltsiv VI, Zakharko YM, Rym YI (1988) On the nature of the blue and green luminescence bands of β-Ga2O3. Ukr Fiz Zh 33:1320

Vasyltsiv V, Luchechko A, Zhydachevskyy Y, Kostyk L, Lys R, Slobodzyan D, Jakieła R, Pavlyk B, Suchocki A (2021) Correlation between electrical conductivity and luminescence properties in β-Ga2O3:Cr3+ and β-Ga2O3:Cr, Mg single crystals. J Vac Sci Technol 39:033201

Villora EG, Hatanaka K, Odaka H, Sugawara T, Miura T, Fukumura H, Fukuda T (2003) Luminescence of undoped β-Ga2O3 single crystals excited by picosecond X-ray and sub-picosecond UV pulses. Solid State Commun 127:385–388

Yadav TP, Yadav RM, Singh DP (2012) Mechanical milling: a top down approach for the synthesis of nanomaterials and nanocomposites. Nanosci Nanotechnol 2:22–48

Yu S, Zhang G, Carloni D, Wu Y (2020) Fabrication, microstructure and optical properties of Ga2O3 transparent ceramics. Ceram Int 46:21757–21761

Zhang J, Liu Z, Lin C, Lin J (2005) A simple method to synthesize β-Ga2O3 nanorods and their photoluminescence properties. J Cryst Growth 280:99–106

Acknowledgements

AL acknowledges the support of this work by the International Visgerad Fund (scholarship id number 52110997).YS is grateful to SAIA for financial support within the National Scholarship Program of the Slovak Republic. The financial support of the Slovak Research and Development Agency under contract No. APVV-18-0357 and that of The Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic (project 2/0044/18) are also gratefully acknowledged. The support of COST Action CA18112 MechSustInd (www.mechsustind.eu), supported by the COST Association (European Cooperation in Science and Technology, www.cost.eu) is also acknowledged

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The Authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Luchechko, A., Vasyltsiv, V., Kushlyk, M. et al. Structural and luminescence characterization of β-Ga2O3 nanopowders obtained via high-energy ball milling. Appl Nanosci 13, 5149–5155 (2023). https://doi.org/10.1007/s13204-022-02717-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-022-02717-x