Abstract

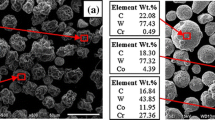

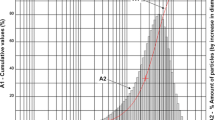

The erosion wear of the thermal barrier coating (TBC) application created by the ceramic topcoat effect on the substrate material and the high-temperature resistance has been researched in the study. Solid particle erosion effect has an important role in high-temperature applications such as energy conversion plants, gas turbines, and jet engine blades. In these applications where the ambient temperature varies and high-temperature effect is important, the deformation resistance is an important criterion in TBC’s produced with atmospheric plasma spray (APS) and high-velocity oxy fuel (HVOF) methods as a result of the angular impact of the particles at certain velocities. In addition, its presence has an important impact in the adhesion effect between the substrate material and the ceramic top coating. In line with all these related criteria, the results of erosion wear in which the significance of the studies is gradually increasing will contribute to the fatigue failure of these coatings. To perform solid particle erosion experiments under high-temperature conditions (300 °C air temperature), experimental parameters were determined as three different erosive particle impact angles (30°, 60° and 90°) and fixed particle impact velocity (~ 50 m/s) with using constant particle size (200 µm Al2O3). As a result of the experiments, the erosion rates under the effect of temperature were determined depending on the angular and velocity variations of different coating methods. In the interpretation of the results, comments were made on the erosion rate variability using the effects of porosity, hardness, and surface roughness.

Similar content being viewed by others

References

Birks N, Meier GH, Pettit FS (2006) Introduction to the high temperature zoxidation of metals. Cambridge University Press, Cambridge

Cernuschi F, Lorenzoni L, Capelli S, Guardamagna C, Karger M, Vaßen R, Von Niessen K, Markocsan N, Menuey J, Giolli C (2011) Solid particle erosion of thermal spray and physical vapour deposition thermal barrier coatings. Wear 271:2909–2918

Cernuschi F, Guardamagna C, Capelli S, Lorenzoni L, Mack D, Moscatelli A (2016) Solid particle erosion of standard and advanced thermal barrier coatings. Wear 348:43–51

Chen W, Wu X, Marple B, Nagy D, Patnaik P (2008) TGO growth behaviour in TBCs with APS and HVOF bond coats. Surf Coat Technol 202:2677–2683

Clarke DR, Oechsner M, Padture NP (2012) Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull 37:891–898

Clarke CR (2018) Thermal Barrier Coatings for Gas Turbines, Hong Kong University of Science and Technology

Curry N (2014) Design of thermal barrier coating systems, University West

Curry N, VanEvery K, Snyder T, Susnjar J, Bjorklund S (2015) Performance testing of suspension plasma sprayed thermal barrier coatings produced with varied suspension parameters. Coatings 5:338–356

Darolia R (2013) Thermal barrier coatings technology: critical review, progress update, remaining challenges and prospects. Int Mater Rev 58:315–348

Demirci M (2020) Investigation of solid particle erosion wear behaviour of thermal barrier coatings at high temperature, Mechanical Engineering, Konya Technical University, Graduate School of Education

Demirci M, Bagci M (2021) Alternative system design for high temperature solid particle erosion wear problem. Tribol Lett 69:23

Diamond S (2000) Mercury porosimetry: an inappropriate method for the measurement of pore size distributions in cement-based materials. Cem Concr Res 30:1517–1525

Hutchings I, Shipway P (2017) Tribology: friction and wear of engineering materials, Butterworth-Heinemann

Kleis I, Kulu P (2007) Solid particle erosion: occurrence, prediction and control, Springer Science & Business Media

Kumar V, Kandasubramanian B (2016) Processing and design methodologies for advanced and novel thermal barrier coatings for engineering applications. Particuology 27:1–28

Mehboob G, Liu M-J, Xu T, Hussain S, Mehboob G, Tahir A (2020) A review on failure mechanism of thermal barrier coatings and strategies to extend their lifetime. Ceram Int 46:8497–8521

Meng G-H, Zhang B-Y, Liu H, Yang G-J, Xu T, Li C-X, Li C-J (2018) Vacuum heat treatment mechanisms promoting the adhesion strength of thermally sprayed metallic coatings. Surf Coat Technol 344:102–110

Mikijelj B, Varela J (1991) Equivalence of surface areas determined by nitrogen adsorption and by mercury porosimetry. Am Ceram Soc Bull 70:829–831

Miller RA (1997) Thermal barrier coatings for aircraft engines: history and directions. J Therm Spray Technol 6:35

Novak R (1994) Coating development and use: case studies, Presentation to the Committee on Coatings for High-Temperature Structural Materials, National Materials Advisory Board, National Research Council, Irvine, California, 18–19

Ruff A, Ives L (1975) Measurement of solid particle velocity in erosive wear. Wear 35:195–199

Schmitt MP, Rai AK, Zhu D, Dorfman MR, Wolfe DE (2015) Thermal conductivity and erosion durability of composite two-phase air plasma sprayed thermal barrier coatings. Surf Coat Technol 279:44–52

Siebert B, Funke C, Vaβen R, Stöver D (1999) Changes in porosity and Young’s Modulus due to sintering of plasma sprayed thermal barrier coatings. J Mater Process Technol 92–93:217–223

Song Y, Zhou C, Xu H (2008) Corrosion behavior of thermal barrier coatings exposed to NaCl plus water vapor at 1050° C. Thin Solid Films 516:5686–5689

Stecura S (1978) Effects of compositional changes on the performance of a thermal barrier coating system. [yttria-stabilized zirconia coatings on gas turbine engine blades]

Vaßen R, Traeger F, Stöver D (2004) Correlation between spraying conditions and microcrack density and their influence on thermal cycling life of thermal barrier coatings. J Therm Spray Technol 13:396–404

Wang S-S, Liu G-W, Mao J-R, He Q-G, Feng Z-P (2010) Effects of coating thickness, test temperature, and coating hardness on the erosion resistance of steam turbine blades. J Eng Gas Turbines Power 132:022102

Wang DS, Tian ZJ, Yang B, Shen LD (2012) Preparation and solid particle erosion behaviors of plasma-sprayed and laser-remelted ZrO2–7wt.% Y2O3 thermal barrier coatings, applied mechanics and materials, Trans Tech Publ pp. 191–197

Wang D, Tian Z, Shen L, Liu Z, Huang Y (2014) Effects of laser remelting on microstructure and solid particle erosion characteristics of ZrO2–7wt% Y2O3 thermal barrier coating prepared by plasma spraying. Ceram Int 40:8791–8799

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Demirci, M., Bagci, M. Erosion of ceramic coating applications under the influence of APS and HVOF methods. Appl Nanosci 12, 3409–3415 (2022). https://doi.org/10.1007/s13204-022-02691-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-022-02691-4