Abstract

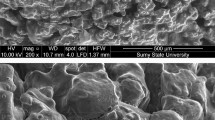

The current paper describes the technological foundations of the porous ammonium nitrate (PAN) convective drying stage in a multistage shelf unit operating as part of a small-sized granulation module. The work consists of two blocks: the theoretical foundations of a multistage shelf dryer operation and the study of the nanoporous PAN structure in the apparatus optimal mode of operation. The main indicator that affects the design of a gravitational shelf dryer is the required residence time of particles (granules) in the zone of contact with the drying agent. On the one hand, this time is determined by the kinetics of the drying process, and, on the other hand, by the hydrodynamic dryer operation mode, the design of the shelves (length, angle of inclination, degree of perforation) and the number of dryer stages. We present a model for calculating the “hydrodynamic” and “kinetic” residence time of PAN granules in the dryer enclosure. Paper demonstrates the features of PAN granules nanoporous structure under conditions when the “hydrodynamic” residence time of PAN granules is less than the “kinetic”, equal to “kinetic” and more than “kinetic”. The results of the research will be used in the development of engineering calculation methods for multistage shelf dryers and regulations for PAN production in devices with active hydrodynamic modes.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Ali K (2015) Design of a spray tower for the granulation of melt. Al-Nahrain J Eng Sci 18(1):111–117

Artyukhov A, Artyukhova N (2018) Utilization of dust and ammonia from exhaust gases: new solutions for dryers with different types of fluidized bed. J Environ Health Sci Eng 16(2):193–204

Artyukhov AE, Ivaniia AV (2017) Obtaining porous ammonium nitrate in multistage and multifunctional vortex granulators. Nauk Visnyk Natsionalnoho Hirnychoho Universytetu 6:68–75

Artyukhov A, Artyukhova N, Krmela J, Krmelova V (2020a) Complex designing of granulation units with application of computer and software modeling: case “Vortex granulator.” IOP Conf Series 776(1):012016

Artyukhov A, Krmela J, Artyukhova N, Ostroha R (2020b) Modeling of the aerodisperse systems hydrodynamics in devices with directional motion of the fluidized bed. Encyclopedia of information science and technology fifth edition. IGI Global, pp 1289–1307

Artyukhova NO (2018) Multistage finish drying of the N4HNO3 porous granules as a factor for nanoporous structure quality improvement. J Nano- Electron Phys 10(3):03030-1–03030-4

Artyukhova N, Krmela J (2019) Nanoporous structure of the ammonium nitrate granules at the final drying: the effect of the dryer operation mode. J Nano- Electron Phys 11(4):04006-1–04006-4

Artyukhova NA, Shandyba AB, Artyukhov AY (2014) Energy efficiency assessment of multi-stage convective drying of concentrates and mineral raw materials. Nauk Visnyk Natsionalnoho Hirnychoho Universytetu 1:92–98

Artyukhova NO, Krmela J, Krmelova V (2022) Experimental–industrial implementation of the technology for producing nanoporous layers on ammonium nitrate: the final drying stage in multistage devices. Appl Nanosci 12:1235–1244

Caiyuan Y, Tao Q, Xizhong W (2004) Heat and mass transfer in process of fluidized bed spray granulation. Chin J Chem Eng 16(6):836–839

Crowe C (2006) Multiphase flow handbook. Taylor and Francis Group, Boca Raton

Gezerman AO (2020) Mathematical modeling for prilling processes in ammonium nitrate production. Eng Rep 2:e12173

Gidaspow D (1994) Multiphase flow and fluidization: continuum and kinetic theory descriptions with applications. Academic Press, San Diego

Hannan Z (2015) wxMaxima for calculus I. Zachary Hannan

Harris FE (2014) Mathematics for physical science and engineering: symbolic computing applications in maple and mathematica. Academic Press

Kudra T, Mujumdar AS (2002) Advanced drying technologies. Marcel Dekker, New York

Litster J, Ennis B (2004) The science and engineering of granulation processes. Springer-Science+Business Media

Marchisio DL, Fox RO (2013) Computational models for polydisperse particulate and multiphase systems. Cambridge series in chemical engineering. Cambridge University Press

Mujumdar AS (2014) Handbook of industrial drying, 4th edn. CRC Press Taylor and Francis Group

Muralidhar P, Bhargav E, Sowmya C (2016) Novel techniques of granulation: a review. Int Res J Pharm 7(10):8–13

Obodiak V, Artyukhova N, Artyukhov A (2020) Calculation of the residence time of dispersed phase in sectioned devices: theoretical basics and software implementation. DSMIE 2019. Lecture notes in mechanical engineering. Advances in Design Simulation and Manufacturing II, pp 813–820

Pabis S, Jayas DS, Cenkowski S (1998) Grain drying: theory and practice. Wiley

Prokopov MG, Levchenko DA, Artyukhov AE (2014) Investigation of liquid-steam stream compressor. Appl Mech Mater 630:109–116

Salman AD, Hounslow MJ, Seville JPK (2006) Granulation. Elsevier Science Ltd, Amsterdam

Sazhin BS, Sazhin VB (2007) Scientific principles of drying technology. Begell House Publishers Inc, Danbury

Sinaiski EG (2010) Hydromechanics: theory and fundamentals. WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim

Srinivasan S (2015) Granulation techniques and technologies: recent progresses. Bioimpacts 5(1):55–63

Stahl H (2004) Comparing different granulation techniques. Pharm Technol Eur 16(11):23–33

Yang WC (2003) Handbook of fluidization and fluid-particle systems. Marcel Dekker, New York

Acknowledgements

This research work had been supported by the Ministry of Science and Education of Ukraine under the project «Technological bases of multistage convective drying in small-sized devices with utilization and heat recovery units», project No. 0120U100476, by the Cultural and Educational Grant Agency of the Slovak Republic (KEGA), project No. 003TnUAD-4/2022.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Artyukhova, N., Krmela, J., Artyukhov, A. et al. Multistage drying of ammonium nitrate with nanoporous structure. Appl Nanosci 13, 5091–5099 (2023). https://doi.org/10.1007/s13204-022-02688-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-022-02688-z