Abstract

The thermal behaviour of hay-based activated carbons modified with adsorption nanolayers of ionic polymers were investigated. The anionic and cationic forms of polyacrylamides (PAM) with different contents of ionizable groups were applied. Using spectrophotometry, potentiometric titration, microelectrophoresis, DCS (Differential Centrifugal Sedimentation) and thermal analysis methods, the adsorption and electrokinetic, properties, as well as thermal stability of studied activated biocarbons—PAM systems were established. It was shown that PAM adsorbed amounts on the activated biocarbon surfaces were considerably higher for cationic polyacrylamides than for anionic ones. The conducted TG-DSC-FTIR/MS analysis in helium showed a significant influence of the synthesis conditions on the content of oxygen surface groups of activated biocarbons obtained in conventional or microwave muffle furnace. The measurements carried out in the oxidizing atmosphere for the polymer-modified samples showed similarity to the original materials and were characterized by three main stages of decomposition: dehydration, decomposition of surface functional groups and, at high temperatures—combustion process. The main decomposition products were CO2 and H2O.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Currently, new solutions are being searched, which will enable finding a common ground for a solution of many environmental problems in accordance with the principles of sustainable development. The most important of them are: processes of matter and energy recovery through the management of biodegradable waste, sewage sludge and biodegradable fraction of municipal waste; improvement of soil properties, reduction of the use of fertilizers minerals and plant protection products, limitation of greenhouse gas emissions and carbon sequestration in soil. The application of biochar and activated biochar fits perfectly into this concept.

Biochar is a solid, renewable fuel obtained from various types of biomass in the process of pyrolysis, in which liquid and gas high-energy products are created. Substrates for the production of biochar are a very diverse and numerous group, which can include energy crops (e.g. miscanthus, willow), forest waste (e.g. sawdust, bark), agricultural biomass (e.g. rape, sunflower, corn cobs), sewage sludge, organic fraction of municipal waste, residues from agri-food processing (e.g. post-fermentation oats, rice husks, nut shells, coconut, fruits stones, residues after extraction of plant materials), as well as chicken and cattle manure, algae biomass, a composted fraction of municipal waste etc. (Sanchez et al. 2009; Bird et al. 2011; Song and Guo 2012; Ibarrola et al. 2012; Laine 2012; Wiśniewska et al. 2017).

The beneficial physicochemical properties of biochar, such as e.g. high organic carbon content, significant chemical stability, significantly developed specific surface area and porosity. To increase the adsorption properties of biochars, their activation using chemical and physical methods is used, which leads to the development of their porous structure and the introduction of functional groups to the surface (Kazmierczak-Razna et al. 2017; Szewczuk-Karpisz et al. 2020a, b). These properties allow for activated biocarbons effective usage for: carbon sequestration in soil, composting process optimization, production of organic fertilizers based on biochar, remediation of contaminated soils, improvement of soil structural properties, reduction of groundwater pollution and wastewater purification.

The water-soluble macromolecular compounds (polymers) show excellent stabilization and destabilization abilities towards the solid particles (including biochar and activated biocarbon ones) dispersed in liquid medium (Wiśniewska 2011). For this reason they are widely used in many areas of human activity—in medicine, industry and environmental protection. One of the most important is wastewater treatment, where the properly selected polymer can affect the stability and rheological properties of colloidal systems. Depending on the conditions (solution pH, temperature, composition of the liquid phase) the polymer presence can decrease the aggregates (flocks) stability. As a result, they undergo sedimentation, which allows for their efficient separation.

To accurately plan the adsorption and aggregation possibilities of the polymer, it is necessary to carefully study of the mechanism of macromolecules binding to the solid surface and the nanostructure of their adsorption layer. Among others, the thermal analysis methods, such as TG (thermogravimetry), DTG (differential thermogravimetry) and DSC (differential scanning calorimetry) are very helpful in this respect. Their coupling with the FTIR and QMS spectrometry allows not only determination of thermal degradation of solid systems modified by polymeric adsorption layers, but also characterization of binding mechanism at the solid–liquid interface (Sternik et al. 2019; Wiśniewska et al. 2022).

The aim of the present study was to investigate the thermal behaviour of hay-based activated carbons modified with adsorption nanolayers of ionic polymers. The anionic and cationic forms of polyacrylamides (PAM) with different contents of ionizable groups were selected for study. The application possibilities of activated biocarbons to the polymer removal from aqueous phase are extremely rare reported in the scientific literature (Wiśniewska et al. 2021). For this reason the presented results have an important element of scientific novelty on the mechanisms of polymeric chains adsorption on the surface of carbon materials, and thus the stability mechanism of such a systems. It is extremely important from the point of view of their effective removal from the aqueous phase in wastewater treatment processes.

Experimental

Materials

Two activated biocarbons obtained from hay precursor were used in the study as adsorbents. They were obtained from hay (pellets). The raw material was carbonized at 400 ℃ in the nitrogen atmosphere. Next, the obtained material were chemically activated with H3PO4 (wt. ratio 2:1) at 550 ℃ in conventional or microwave muffle furnace (power 1400 W, frequency 2.45 GHz). The activated biocarbon prepared in conventional furnace was marked as AC1, whereas that in microwave furnace as AC2. The detailed characteristics of activated biocarbons was given in the previous manuscript (Szewczuk-Karpisz et al. 2020a, b), but their selected textural and acid–base properties are listened in Tables 1 and 2. The solid textural parameters were determined using the nitrogen adsorption/desorption method (Micromeritics ASAP 2020 analyzer), whereas The acid–base surface properties of the selected materials were examined using the Boehm titration (Boehm 1994).

Anionic and cationic polyacrylamides (AN PAM, CT PAM), delivered by Korona, were used in the experiments as modifiers of solid surface properties. They were characterized by different content of ionizable groups and different weight average molecular weights (\(\overline{{M_{w} }}\overline{{M_{w} }}\)). The detailed characteristics of applied polymers is presented in Table 3. The pKa and pKb values of anionic and cationic polymer samples, respectively, as well as their dissociation degrees In aqueous solution of pH 6 were determined based on the potentiometric titration results (Szewczuk-Karpisz et al. 2020a, b).

Methods

All adsorption measurements were carried out by the static method at pH 6 ± 0.1 and 25 ℃, using NaCl (0.001 mol/dm3) as the supporting electrolyte. The initial polymer concentration was 100 ppm. The concentration of adsorbates was determined spectrophotometrically (Jasco V-530 UV/Vis spectrophotometer) using specific indicators. In the case of AN PAM it was hyamine 1622 and in the case of CT PAM—brilliant yellow (Szewczuk-Karpisz et al 2020a, b). The formed polymer-indicator complexes coloured solution white and yellow, respectively, with maximum of absorbancies at 500 and 495 nm. The suspensions were prepared using 0.02 g of activated biocarbons and 10 cm3 of the solution containing supporting electrolyte and polyacrylamide. The adsorption process lasted 24 h. After this time the solids were centrifuged and the supernatant was collected for further analysis. The PAM adsorbed amounts were determined based on the difference between polymer concentration before and after adsorption process using previously prepared calibration curves.

Using the potentiometric titration method the surface charge density as a function of solution pH (changing in the range 3.5–10) was determined (Wiśniewska et al. 2016). Due to the fact, that both solids surface charge densities were negative in the whole studied pH range, the specification of the points of zero charge (pHpzc) were impossible. It can be concluded only that their values are smaller than 3. The potentiometric titrations of activated biocarbon suspensions without and with PAM in the supporting electrolyte solution (NaCl, 0.001 mol/dm3) were carried at 25 ℃ using NaOH with concentration 0.1 mol/dm3 as a titrant. The titrator Titrino 702 SM (Metrohm) was used. The polymer concentration was 100 ppm.

Thermal properties of samples were determined using the simultaneous thermal analyzer STA 449 F1 Jupiter (Netzsch, Germany). The TG, differential TG (DTG) and differential scanning calorimetry (DSC) curves were recorded over the 30–950 ℃ range at a heating rate of 10 ℃/min in the synthetic air atmosphere (50 cm3/min) using a sensor of thermocouple type S TG-DSC. The samples: mass ~ 20 mg (in helium atmosphere) and mass ~ 7 mg (in air atmosphere) were placed in a alumina crucible. An empty Al2O3 crucible was used as a reference. The gaseous products emitted during decomposition of materials were analyzed by FTIR spectrometer Tensor 27 (Brucker Optik GmbH, Germany) and by QMS 403D Aeölos (Netzsch, Germany) coupling on-line to the thermal analyzer. The data were collected and processed using the NETZSCH Proteus® software, version 6.1.

The samples of activated biocarbons for thermal analysis were collected after adsorption process. They were centrifuged solid without and modified by ionic PAM after adsorption process, dried in the room temperature.

Results and discussion

The adsorption kinetics measurements indicated that, regardless of polyacrylamide ionic character, equilibrium state was reached after 4 h (Szewczuk-Karpisz et al. 2020a, b). The adsorption of polymers was significantly slower than that of simple inorganic ions. This results from complex structure of polymeric compound and possibility of their chains to assume of various conformations at the solid/liquid interface. One polymer chain may interact with several adsorption sites on the activated biocarbon surface. Additionally, the reconformation of previously adsorbed macromolecules occurs (Wiśniewska 2011). The kinetics data were better fitted to the pseudo-second-order model, which pointed out rather on the chemical nature of adsorption.

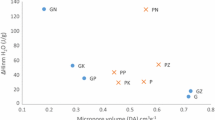

The PAM adsorbed amounts on the examined activated biocarbon surfaces were considerably higher for cationic polyacrylamides than for anionic ones (Fig. 1). The electrostatic interactions between the PAM macromolecules and the solid particles are mainly responsible for this behaviour (Wiśniewska et al. 2020). Under examined pH conditions, namely at pH 6, the surfaces of both activated biocarbons are negatively charged. On the other hand, dissociation of cationic polymers is practically complete (Table 3) and thus CT PAM macromolecules gave a positive charge. In such a situation the electrostatic attraction between adsorbate with cationic character and negatively charged solid surface occurs, which leads to adsorption increase. For anionic polyacrylamides dissociation degree equalled 0.98 (for AN1) and 0.83 (AN2) at pH 6 (Table 3). It means that their molecules contain the negatively charged functional groups repelled electrostatically with the solid surface and the adsorbed amounts of AN PAM are significantly smaller (Fig. 1). Moreover, the higher content of ionizable groups in the polymer chains, the greater PAM adsorbed amounts are observed. This is obvious in the case of CT PAM—CT2 polymer characterized by the higher content of cationic groups show stronger electrostatic attraction with the solid surface and its adsorption reaches the highest level about 33 mg/g.

Surprisingly, for anionic polymers, that one characterized by higher number of anionic groups (AN2) shows larger adsorption on the activated biocarbons (compared to AN1 one). This means, that in the despite the presence of stronger electrostatic repulsion between the polymer and solid particles, the PAM adsorbed amount is higher. This is result of different conformations of macromolecules containing various contents of anionic groups and their dissociation degrees. At pH 6 the dissociation degree of AN2 polymer is uncomplete (contrary to that of AN1 one) and assumes value 0.83. Smaller number of dissociated groups in the AN2 macromolecules contributed to their more coiled structure. In such a situation, more packed polymeric adsorption layer is formed and thus the adsorption level increases.

It should be also noted that ionic polyacrylamides have similar adsorption affinity to both examined activated biocarbons. Microwave heating in the case of AC2 contributed mainly to higher micropore area, which is inaccessible for polymer macromolecules with so high molecular weight.

The industrial use of carbon materials depends largely on their chemical nature and pore structure. Indirectly, these properties are the result of the type of substrates used in production, the conditions of their synthesis and the method of activation. Additionally, the modifier molecules introduced in the sorption process have a significant impact on their useful abilities. One of the techniques often applied to characterize this type of materials are thermal methods (Figueiredo et al. 1999; Szymański et al. 2002; Sternik et al. 2019), allowing not only to determine the thermal stability of materials, but also to assess the surface groups as a supplement to the standard Boehm method.

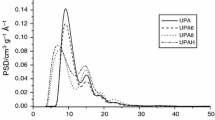

Figure 2 presents the curves obtained during the pyrolysis of activated biocarbon samples in a helium atmosphere. Detailed data are presented in Table 4. Small weight losses at temperatures up to 150 ℃ by about 1.5% are related to the removal process of hygroscopic water and other atmospheric gases that are weakly bound to the surface. In the temperature range from 150 to 410 ℃, the DTG curves contain clear peaks with a minimum of 220 ℃, related to the endothermic decomposition of mainly carboxyl groups present on the adsorbent surface.

Figure 2c shows the changes in the intensities of CO and CO2 signals obtained on the basis of FTIR measurements. As can be seen, within the discussed temperature range, CO2 emissions occur, which confirms the decomposition of COOH groups and is consistent with the literature data (Zhuang et al. 1995, Figueiredo et al. 1999). At higher temperatures, up to approx. 1100 ℃, the weight loss by about 27% is related to the decomposition of subsequent oxygen surface groups. In the temperature range up to about 700 ℃, the rapid increase in the intensity of the CO2 signal is observed and it is probably the result of the decomposition of the lactone surface groups.

In addition, a clear increase in the intensity of the carbon monoxide signal in this range in the case of the AC2 sample proves the decomposition of oxygen groups such as acid anhydrides (CO2 and CO emission) as well as phenolic, hydroquinone and ether groups (CO emission). At higher temperatures, above 700 ℃, the DTG curves show a clear peak with a minimum of ~ 900 ℃, which corresponds to a sharp increase in the CO signal (for both activated biocarbons), probably related to further degradation of ether, phenolic and carbonyl groups. Above 1100 ℃, slight weight losses (approx. 2.5%) are mainly related to the decomposition of pyrone groups (Szymański et al. 2002).

The obtained activated carbons were modified with anionic polyacrylamide containing 12% (AN1) and 40% (AN2) carboxyl groups as well as with cationic polyacrylamide containing 15% (CT1) and 25% (CT2) of quaternary amine groups. The TG, DTG and DSC curves obtained during their heating in the air atmosphere are presented in Fig. 3. In the case of unmodified activated biocarbon samples (black line), three main stages of decomposition can be distinguished. The first of them, in the temperature range up to 150 ℃ with a weight loss of about 1.5%, as in the case of the previously discussed pyrolysis, is associated with the endothermic dehydration process, as evidenced by clear peaks in the DTG curves and in the MS spectra of water (Fig. 4a and c). In the next stage, up to 400 ℃, the slight peaks in the DTG curves of both materials, associated with small weight losses (0.98% and 2.54%, respectively, for AC1 and AC2) are observed. They appear mainly as the result of the decomposition of the oxygen surface groups with the acidic character, as well as water molecules removal from active sites (Sternik et al. 2019). This is evidenced by the peaks in the MS spectra of water (m/z = 18; Fig. 4a and d) and an increase in the carbon dioxide signal (m/z = 44; Fig. 4b and d). At higher temperatures, exothermic processes with weight losses of 69.27 and 61.84% and peaks with a minimum of 517.7 and 541 ℃ on the DSC curves (for AC1 and AC2, respectively) occurs, which is associated with the oxidation reactions of and CO2 emission.

In the case of thermal analysis of samples modified with polyacrylamide, three stages similar to those occurring in the case of unmodified materials were observed. Detailed analysis of obtained parameters are summarized in Table 4. As it results from the presented analyses, a slight increase in weight loss was observed for the modified biocarbon samples in the temperature range 150–400 ℃, which confirms the modification effect, despite the quite low polyacrylamide adsorption (Fig. 1). According to the literature data, the main decomposition products during the pyrolysis of polyacrylamides are amides, imides, nitriles, ketones, aldehydes and acrylamide oligomers (Tutaş et al. 1991; Kitahara et al. 2012; Fu et al. 2021). In the case of the oxidizing atmosphere, the main gaseous products identified by mass spectrometry were NH3, CH4, NO, H2O, CO2 and NO2 (Steudel et al. 2019). In the case of this study, due to the small amount of adsorbed modifier, only the presence of the main combustion products, i.e. water and carbon dioxide, was found. At the same time, in most cases, an increase in the combustion enthalpy was observed for materials modified with ionic polyacrylamide.

Conclusions

Based on the adsorption, electrokinetic and thermal stability results it can be stated that ionic polyacrylamide modified surface properties of both activated biocarbons. Higher adsorbed amount of cationic polyacrylamide on the solid surface is observed (electrostatic attraction of positively charged PAM mac macromolecules with the negatively charged solid surface—more pronounced in the case of CT PAM with higher content of cationic groups). AN PAM characterized by higher content of anionic groups shows larger adsorption on the activated biocarbons surface due to more coiled conformation assumption and more packed polymeric adsorption layer formation. The TG-DSC studies showed a slight influence of adsorbed polymer macromolecules on the thermal stability of activated biocarbon in the examined systems. In addition, thermogravimetric measurements confirmed the presence of the modifier on the solid surface, which was manifested by an increase in weight loss in the temperature range of 150–400 ℃.

References

Bird MI, Wurster CM, de Paula Silva PH, Bass AM, de Nys R (2011) Algal biochar—production and properties. Biores Tech 102:1886–1891

Boehm HP (1994) Some aspects of the surface chemistry of carbon blocks and another carbons. Biochar 32:759–769

Figueiredo JL, Pereira MFR, Freitas MMA, Orfao JJM (1999) Modification of the surface chemistry of activated carbons. Carbon 37:1379–1389

Fu X, Yang Q, Zhang Y (2021) Thermal decomposition behavior and mechanism study of cationic polyacrylamide. J Therm Anal Cal 146:1371–1381

Ibarrola R, Shackely S, Hammond J (2012) Pyrolysis biochar systems for recovering biodegradable materials: a life cycle carbon assessment. Waste Manag 32:859–868

Kazmierczak-Razna J, Nowicki P, Wiśniewska M, Nosal-Wiercińska A, Pietrzak R (2017) Thermal and physicochemical properties of phosphorus-containing activated carbons obtained from biomass. J Taiwan Inst Chem Eng 80:1006–1013

Kitahara Y, Okuyama K, Ozawa K, Suga T, Takahashi S, Fujii T (2012) Thermal decomposition of acrylamide from polyacrylamide, time-resolved pyrolysis with ion-attachment mass spectrometry. J Therm Anal Cal 110:423–429

Laine J (2012) Perspective of the preparation of agrichars using fossil hydrocarbon coke. Renew Sustain Energy Rev 16:5597–5602

Sanchez ME, Lindao E, Margaleff D, Martinez O, Moran A (2009) Pyrolysis of agricultural residues from rape and sunflower: production and characterization of bio-fuels and biochar soil management. J Anal Appl Pyrolys 85:142–144

Song W, Guo M (2012) Quality variations of poultry litter biochar generated at different pyrolysis temperatures. J Anal Appl Pyrolys 94:138–145

Sternik D, Wiśniewska M, Nowicki P (2019) Thermal degradation of peat-based activated carbons covered with mixed adsorption layers of PAA polymer and SDS surfactant. Thermochim Acta 676:71–83

Steudel A, Friedrich F, Lieske W, Baille W, König D, Schuhmann R, Emmerich K (2019) Simultaneous thermal analysis of cationic, nonionic and anionic polyacrylamide. Heliyon 5:e02973

Szewczuk-Karpisz K, Nowicki P, Sokołowska Z, Pietrzak R (2020a) Hay-based activated biochars obtained using two different heating methods as effective low-cost sorbents: Solid surface characteristics, adsorptive properties and aggregation in the mixed Cu(II)/PAM system. Chemosphere 250:126312

Szewczuk-Karpisz K, Wiśniewska M, Nowicki P, Oleszczuk P (2020b) Influence of protein internal stability on its removal mechanism from aqueous solutions using eco-friendly horsetail herb-based engineered biochar. Chem Eng J 388:124156

Szymański GS, Karpiński Z, Biniak S, Świątkowski A (2002) The effect of the gradual thermal decomposition of surface oxygen species on the chemical and catalytic properties of oxidized activated carbon. Carbon 40:2627–2639

Tutaş M, Sağlam M, Yüksel M (1991) Investigation of pyrolysis products of polyacrylamide by pyrolysis—gas chromatography. J Anal Appl Pyrolys 22:129–137

Wiśniewska M (2011) A Review of temperature influence on adsorption mechanism and conformation of water soluble polymers on the solid surface. J Dispers Sci Tech 32:1605–1623

Wiśniewska M, Chibowski S, Urban T (2016) Adsorption properties of the nanozirconia/anionic polyacrylamide system -effects of surfactant presence, solution pH and polymer carboxyl groups content. Appl Surf Sci 370:351–356

Wiśniewska M, Nosal-Wiercińska A, Ostolska I, Sternik D, Nowicki P, Pietrzak R, Bazan-Wozniak A, Goncharuk O (2017) Nanostructure of poly(acrylic acid) adsorption layer on the surface of activated carbon obtained from residue after supercritical extraction of hops. Nanoscale Res Lett 12:2

Wiśniewska M, Fijałkowska G, Szewczuk-Karpisz K, Sternik D (2020) Aggregation and thermal properties of nanostructured montmorillonite covered with mixed adsorption layers of cationic polyacrylamide and hazardous lead(II) ions. Appl Nanosci 10:5499–5510

Wiśniewska M, Nowicki P, Szewczuk-Karpisz K, Gęca M, Jędruchniewicz K, Oleszczuk P (2021) Simultaneous removal of toxic Pb(II) ions, poly(acrylic acid) and Triton X-100 from their mixed solution using engineered biochars obtained from horstail herb precursor – impact of post-activation treatment. Sep Purif Tech 276:119297

Wiśniewska M, Sternik D, Nowicki P, Chibowski S, Medykowska M, Gęca M, Szewczuk-Karpisz K (2022) Adsorption, viscosity and thermal behaviour of nanosized proteins with different internal stability immobilised on the surface of mesoporous activated biocarbon obtained from the horsetail herb precursor. Appl Nanosci 12:1323–1336

Zhuang QL, Kyotany T, Tomita A (1995) Dynamics of surface oxygen complexes during carbon gasification with oxygen energy. Fuels 9:630–634

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, I state that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wiśniewska, M., Sternik, D., Nowicki, P. et al. Study of thermal decomposition of hay-based activated biocarbons modified with nanolayers of ionic polyacrylamide. Appl Nanosci 13, 5049–5056 (2023). https://doi.org/10.1007/s13204-022-02678-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-022-02678-1