Abstract

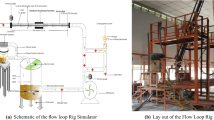

Cuttings lifting to the surface is a special function of drilling muds and it can lead to undue torque and drag, differential pipe sticking and wellbore collapse if this function is not effectively applied. In this study, cuttings lifting to the surface separating facility by water-based mud (WBM) containing enriched polypropylene–nanosilica composite (PP–SiO2 NC) modified by (3-aminopropyl) triethoxysilane (APTES) and those formulated with partially hydrolyzed polyacrylamide (PHPA) were examined. The effect of different annular velocities (66.1, 92.4, 118.8, 138.6, 234.1 ft/min), cuttings diameter (0.5–0.99, 1.0–1.99, 2.0–2.79, 2.8–4.0 mm) and hole inclinations (45°, 60°, 75° and 90°) in a cuttings rig simulator (2.4-in. × 1.2-in., 16-ft. long annulus) with and without pipe rotation were investigated. The results showed that more cuttings were lifted out of the hole with higher concentrations of APTES modified PP–SiO2 NC in WBM than with the PHPA muds, which is due to increased colloidal forces that increase the interaction between the cuttings and the APTES modified PP–SiO2 NC particles. The lifting of cuttings significantly depends on flow rate. The lifting will increase with an increase in the annular velocity and with the whirling motion of the drill pipe with or without enriched PP–SiO2 NC or PHPA. This is because higher flow rate produces larger axial forces to drive the cuttings and reduces the cuttings slip velocity. The recovery of cuttings is most difficult at the hole angle of 45°, due to the decreased in the axial annular velocity with increasing hole deviation. The laboratory results indicate improved lifting ability of the WBM with the presence of the APTES modified PP–SiO2 NC, demonstrating the necessity for its application in a cuttings transport process.

Similar content being viewed by others

Abbreviations

- 10-min:

-

10 min’ gel strength

- 10-s:

-

10 s gel strength

- A-0.4:

-

Base mud + 0.4 ppb PP–SiO2 NC

- A-0.5:

-

Base mud + 0.5 ppb PP–SiO2 NC

- A-0.8:

-

Base mud + 0.8 ppb PP–SiO2 NC

- A-1.2:

-

Base mud + 1.2 ppb PP–SiO2 NC

- API:

-

American petroleum institute

- APTES:

-

(3-aminopropyl) triethoxysilane

- ASTM:

-

American standard testing method

- AV:

-

Apparent viscosity

- B-0.4:

-

Base mud + 0.4 ppb PHPA

- B-0.5:

-

Base mud + 0.5 ppb PHPA

- B-0.8:

-

Base mud + 0.8 ppb PHPA

- B-1.2:

-

Base mud + 1.2 ppb PHPA

- BM:

-

Base mud

- CTE:

-

Cuttings transferring efficiency

- dc :

-

Diameter of drilled cuttings

- ECD:

-

Equivalent circulating density

- FCT:

-

Filter cake thickness

- FL:

-

Filtrate loss volume

- GS:

-

Gel strength

- ID:

-

Outer diameter of the inner drill pipe

- NaOH:

-

Sodium hydroxides

- –NH2 :

-

Amine groups

- NPs:

-

Nanoparticles

- OD:

-

Internal diameter of the outer pipe

- –OH:

-

Hydroxyl groups

- PAC HV:

-

High viscosity polyanionic cellulose

- PE–b–PEG:

-

Poly–ethylene–block poly(ethylene glycol)

- PHPA:

-

Partially hydrolyzed polyacrylamide

- PNCs:

-

Polymer nanocomposites

- PP:

-

Polypropylene

- PP–SiO2 NC:

-

Polypropylene–nanosilica composite

- PV:

-

Plastic viscosity

- ROP:

-

Rate of penetration

- Sand A:

-

0.50–0.99 mm

- Sand B:

-

1.00–1.99 mm

- Sand C:

-

2.00–2.79 mm

- Sand D:

-

2.80–4.00 mm

- SiO2 NP:

-

Nanosilica/silica nanoparticle

- SiO2 :

-

Silica/silicon dioxide

- TEOS:

-

Tetraethyl orthosilicate

- VAmud :

-

Annular mud velocity

- V net :

-

Cuttings net rise velocity

- V slip :

-

Cuttings slip velocity

- WBMs:

-

Water-based muds

- YP:

-

Yield point

- YP/PV:

-

Yield point to plastic viscosity ratio

- ζ–potential:

-

Zeta potential

- ρ c :

-

Density of drilled cuttings

- ρ f :

-

Density of drilling mud

References

Abdollahi M, Pourmahdi M, Nasiri AR (2018) Synthesis and characterization of lignosulfonate/acrylamide graft copolymers and their application in environmentally friendly water-based drilling fluid. J Pet Sci Eng 171:484–494. https://doi.org/10.1016/j.petrol.2018.07.065

Acres RG, Ellis AV, Alvino J, Lenahan CE, Khodakov DA, Metha GF, Andersson GG (2012) Molecular structure of 3-aminopropyltriethoxysilane layers formed on silanol-terminated silicon surfaces. J Phys Chem C 116:6289–6297

Aftab A, Ismail AR, Ibupoto ZH, Zolkifile N (2016) Novel approach for the enhancement of rheological properties of water-based drilling fluids by using multi-walled carbon nanotube, nanosilica and glass beads. J Pet Sci Eng 139:264–275. https://doi.org/10.1016/j.petrol.2016.01.036

Agi A, Junin R, Gbadamosi A (2018) Mechanism governing nanoparticle flow behaviour in porous media: insight for enhanced oil recovery applications. Int Nano Lett 8:1–29. https://doi.org/10.1007/s40089-018-0237-3

Agi A, Junin R, Gbadamosi A, Abbas A, Azli NB, Oseh J (2019) Influence of nanoprecipitation on crystalline starch nanoparticle formed by ultrasonic assisted weak-acid hydrolysis of cassava starch and the rheology of their solutions. Chem Eng Process-Process Intensif 142:1–16. https://doi.org/10.1016/j.cep.2019.107556

API recommended practice 13B-1 (2017) API standard practice for field testing water–based drilling fluids, fifth ed. pp. 1–121

ASTM D4253–00 (2006) Standard test methods for maximum index density and unit weight of soils using a vibratory table. ASTM International, West Conshohocken. https://doi.org/10.1520/D4253-00R06

Azar JJ, Sanchez RA (1997) Important issues in cuttings transport for drilling directional wells. Latin American and Caribbean Petroleum Engineering Conference, pp. 1–4. https://doi.org/10.2118/39020-ms

Bailey WJ, Peden JM, (2000) A Generalized and consistent pressure drop and flow regime transition model for drilling hydraulics. SPE Drill & Completion

Bilgesu HI, Mishra N, Ameri S (2007) Understanding the effect of drilling parameters on hole cleaning in horizontal and deviated wellbores using computational fluid dynamics. SPE-111208-MS. In: Presented at the SPE Eastern Regional Meeting, 17–19 October, Lexington, Kentucky, pp. 1–7. https://doi.org/10.2118/111208-MS

Bizhani M, Corredor CFE, Kuru E (2016) Quantitative evaluation of critical conditions required for effective hole cleaning in coiled-tubing drilling of horizontal wells. SPE Drill Complet 31:188–199. https://doi.org/10.2118/174404-pa

Bloys B, Davis N, Smolen B, Bailey L, Fraser L, Hodder M (1994) Annular velocity for rotary drilling operations. Oilfield Revi Schlumberger 6(2):33–43

Borthakur A, Choudhurry SRD, Sengupta P, Rao KV, Nihalani MC (1997) Synthesis and evaluation of partially hydrolysed polyacrylamide (PHPA) as viscosifier in water-based drilling fluids. Indian J Chem Technol 4:83–88

Bourgoyne AT Jr, Millheim KK, Chenevert ME, Young FS (1991) Applied drilling engineering. Society of Petroleum Engineers, Richardson (Second printing)

Boyou NV, Ismail I, Sulaiman WRW, Haddad AS, Hussein N, Heah TH, Nadaraja K (2019) Experimental investigation of hole cleaning in directional drilling by using nano-enhanced water-based drilling fluids. J Pet Sci Eng 176:220–231. https://doi.org/10.1016/j.petrol.2019.01.063

Brown NP, Bern PA, Weaver A (1989) Cleaning deviated holes: new experimental and theoretical studies. SPE- 18636-MS. In: Presented at the SPE\IADC Drilling Conference, 28–30 February, New Orleans, pp. 171–179. https://doi.org/10.2118/18636-MS

Burger ED, Munk WR, Wahl HA (1982) Flow increase in the Trans-Alaska Pipeline through use of a polymeric drag reduction additive. J Pet Technol, SPE 9419, presented at 55th Annual Technical Conference and Exhibition, Dallas

Caenn R, Darley HCH, Gray GR (2017) Introduction to drilling fluids. In: Composition and properties of drilling and completion fluids, 7th edn. Gulf Professional Publishing, USA, pp 1–748. ISBN: 978-0-12-804751-4

Chien SF (1972) Annular velocity for rotary drilling operations. Int J Rock Mech Min Sci Geomech Abstr 9(3):403–416. https://doi.org/10.1016/0148-9062(72)90005-8

Cho H, Shah SN, Osisanya SO (2000) A three-layer modeling for cuttings transport with coiled tubing horizontal drilling. Soc Pet Eng, SPE Annual technical conference and exhibition, 1–4 October, Dallas, Texas, pp. 1–14. https://doi.org/10.2118/63269-MS

Duan MQ, Miska S, Yu MJ, Takach N, Ahmed R (2008) Transport of small cuttings in extended reach drilling. SPE Drill Complet 23:258–265. https://doi.org/10.2118/104192-PA

Ek S, Liskola EI, Niinistö L, Vaittinen J, Pakkanen TT, Root A (2004) A NMR study on the surface species of gas-phase-deposited-aminopropylalkoxysilanes on heat-treated silica. J Phys Chem B 108:11454–11463

Elochukwu H, Gholami R, Dol SS (2017) An approach to improve the cuttings carrying capacity of nanosilica based muds. J Pet Sci Eng 152:210–216. https://doi.org/10.1016/j.petrol.2017.03.008

Ercan C, Ozbayoglu ME (2009) PHPA as a frictional pressure loss reducer and its pressure loss estimation. Middle East Drill Technol Conf Exhib. https://doi.org/10.2118/125992

Ernesto F, Corredor R, Bizhani M, Kuru E (2016) Experimental investigation of cuttings bed erosion in horizontal wells using water and drag reducing fluids. J Pet Sci Eng 147:129–142. https://doi.org/10.1016/j.petrol.2016.05.013

Fattah KA, Lashin A (2016) Investigation of mud density and weighting materials effect on drilling fluid filter cake properties and formation damage. J Afr Earth Sc 117:345–357. https://doi.org/10.1016/j.jafrearsci.2016.02.003

Gao ZN, Jiang ZB, Guo K (2012) Study of the hydrolysis of 3-aminopropyltriethoxysilane (KH550) and the surface modification of silica. J B Univ Chem Technol (Nat Sci) 9:7–12

Gbadamosi AO, Junin R, Abdalla Y, Agi A, Oseh JO (2018a) Experimental investigation of the effects of silica nanoparticle on hole cleaning efficiency of waterbased drilling mud. J Pet Sci Eng 172:1226–1230. https://doi.org/10.1016/j.petrol.2018.09.097

Gbadamosi AO, Junin R, Manan MA, Yekeen N, Agi A, Oseh JO (2018b) Recent advances and prospects in polymeric nanofluids application for enhanced oil recovery. J Ind Eng Chem. https://doi.org/10.1016/j.jiec

Gbadamosi AO, Junin R, Manan MA, Augustine A, Oseh JO, Usman J (2019) Synergistic application of aluminum oxide nanoparticles and oilfield polyacrylamide for enhanced oil recovery. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2019.106345

Haider A, Levenspiel O (1989) Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol 58:63–70

Hale AH, Mody FK (1993) Partially hydrolyzed polyacrylamide (PHPA) mud systems for Gulf of Mexico deep-water prospects. In: SPE International Symposium on oilfield chemistry, 2–5 March, New Orleans, Louisiana. pp. 301–316. https://doi.org/10.2118/25180-MS

Hanks RW (1963) Laminar-turbulent transition for flow in pipes, concentric annuli, and parallel plates. AIChE J 9(1):45–48. https://doi.org/10.1002/aic.690090110

Heshamudin NS, Katende A, Rashid HA, Ismail I, Sagala F, Samsuri A (2019) Experimental investigation of the effect of drill pipe rotation on improving hole cleaning using water-based mud enriched with polypropylene beads in vertical and horizontal wellbores. J Pet Sci Eng 179:1173–1185. https://doi.org/10.1016/j.petrol.2019.04.086

Ismail AR, Mohd Norddin MNA, Latefi NAS, Oseh JO, Issham I, Gbadamosi AO, Agi A (2019) Evaluation of a naturally derived tannin extracts biopolymer additive in drilling muds for high-temperature well applications. J Pet Explor Prod Technol. pp. 1–17. https://doi.org/10.1007/s13202-019-0717-7

Jafarzadeh M, Rahman IA, Sipaut CS (2012) Synthesis of silica–polypyrrole core–shell nanocomposite using in situ γ-aminopropyltriethoxysilane (APTES)-modified nanosilica. Synth Met 162(5–6):466–476

Jain R, Mahto V, Mahto TK (2016) Rheological investigations of water based drilling fluid system developed using synthesized nanocomposite. Korea-Aust Rheol J 28(1):55–65. https://doi.org/10.1007/s13367-016-0006-7

Kadaster AG, Guild GJ, Hanni GL, Schmidt DD (1992) Field applications of PHPA muds, SPE-19531-PA. SPE Drill Eng 7(3):191–199. https://doi.org/10.2118/19531-PA

Kelessidis VC, Bandelis GE (2004) Flow patterns and minimum suspension velocity for efficient cuttings transport in horizontal and deviated wells in coiled-tubing drilling. SPE-81746-PA. SPE Drill Compl 19:213–227. https://doi.org/10.2118/81746-PA

Kök MV, Bal B (2019) Effects of silica nanoparticles on the performance of water-based drilling fluids. J Petrol Sci Eng 180:605–614

Lam C, Jefferies SA, Goodhue KG (2010) Observations on viscosity reduction of PHPA polymer support fluids. Geotech Spec Publ 205:184–189

Lam C, Martin PJ, Jefferis SA (2015) Rheological properties of PHPA polymer support fluids. J Mater Civ Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0001252

Larsen TI, Pilehvari AA, Azar JJ (1997) Development of a new cuttings-transport model for high-angle wellbores including horizontal wells. SPE-25872-PA. SPE Drill Compl 12:129–135. https://doi.org/10.2118/25872-PA

Liao WA, Siems DR (1990) Adsorption characteristics of PHPA on formation solids. In: SPE/IADC Drilling Conference held in Houston, Texas, February 27 March 2. pp. 1–12. https://doi.org/10.2118/19945-ms

Luo Z, Pei J, Wang L, Yu P, Chen Z (2017) Influence of an ionic liquid on rheological and filtration properties of water-based drilling fluids at high temperatures. Appl Clay Sci 136:96–102. https://doi.org/10.1016/j.clay.2016.11.015

Lv Z, Wang Y, Chen Z, Sun L, Wang J, Chen M, Xu Z, Liao Q, Zhou L, Chen X, Li J, Zhou K, Zhou Y, Zeng ZJ, Han ST, Roy VAL (2018a) Phototunable biomemory based on light-mediated charge trap. Adv Sci. https://doi.org/10.1002/advs.201800714

Lv Z, Zhou Y, Han ST, Roy VAL (2018b) From biomaterial-based data storage to bio-inspired artificial synapse. Mater Today 21(5):537–552. https://doi.org/10.1016/j.mattod.2017.12.001

Lv Z, Chen M, Qian F, Roy VAL, Ye W, She D, Wang Y, Xu ZX, Zhou Y, Han ST (2019) Mimicking neuroplasticity in a hybrid biopolymer transistor by dual modes modulation. Adv Func Mater. https://doi.org/10.1002/adfm.201902374

Lyons WC, Carter T, Lapeyrouse NJ (2016) All the formulas you need to solve drilling and production problems. In: Formulas and calculations for drilling, production, and workover, USA. Gulf Professional Publishing, pp. 357–381

Mao H, Qiu Z, Shen Z, Huang ZW (2015) Hydrophobic associated polymer based silica nanoparticles composite with core–shell structure as a filtrate reducer for drilling fluid at ultra-high temperature. J Pet Sci Eng 129:1–15. https://doi.org/10.1016/j.petrol.2015.03.003

Maurya NK, Mandal A (2016) Studies on behavior of suspension of silica nanoparticle in aqueous polyacrylamide solution for application in enhanced oil recovery. Pet Sci Technol 34:429–436. https://doi.org/10.1080/10916466.2016.1145693

McInnes SJ, Voelcker NH (2009) Silicon–polymer hybrid materials for drug delivery. Future Med Chem 1(6):1051–1074. https://doi.org/10.4155/fmc.09.90

Moraveji MK, Sabah M, Shahryari A, Ghaffarkhah A (2017) Investigation of drill pipe rotation effect on cutting transport with aerated mud using CFD approach. Adv Powder Technol 28(4):1141–1153. https://doi.org/10.1016/j.apt.2017.01.020

Omurlu C, Pham H, Nguyen QP (2016) Interaction of surface-modified silica nanoparticles with clay minerals. Appl Nanosci 6(8):1167–1173. https://doi.org/10.1007/s13204-016-0534-y

Oseh JO, Mohd Norddin MNA, Ismail I, Gbadamosi AO, Agi A, Mohammed HN (2019a) A novel approach to enhance rheological and filtration properties of water-based mud using polypropylene–silica nanocomposite. J Petrol Sci Eng 181:106264. https://doi.org/10.1016/j.petrol.2019.106264

Oseh JO, Norddin MNAM, Ismail I, Ismail AR, Gbadamosi AO, Agi A (2019b) Effect of the surface charge of entrapped polypropylene at nanosilica-composite on cuttings transport capacity of water-based muds. Appl Nanosci. https://doi.org/10.1007/s13204-019-01063-9

Ozbayoglu EM, Sorgun M (2010) Frictional pressure loss estimation of water-based drilling fluids at horizontal and inclined drilling with pipe rotation and presence of cuttings. In: SPE oil and gas India conference and exhibition. Mumbai, India, pp. 1–9. http://doi.org/10.2118/127300-MS

Parizad A, Shahbazi K, Tanha AA (2018) SiO2 nanoparticle and KCl salt effects on filtration and thixotropic behavior of polymeric water based drilling fluid: with zeta potential and size analysis. Results Phys 9:1656–1665

Peden JM, Ford JT, Oyeneyin M B (1990) Comprehensive experimental investigation of drilled cuttings transport in inclined wells including the effects of rotation and eccentricity. SPE-20925-MS. In: European Petroleum Conference, pp. 393–404. https://doi.org/10.2118/20925-ms

Prasher R, Song D, Wang J, Phelan P (2006) Measurements of nanofluid viscosity and its implications for thermal applications. Appl Phys Lett 89(13):133108. https://doi.org/10.1063/1.2356113

Qiao B, Wang T-J, Gao H, Jin Y (2015) High density silanization of nano-silica particles using γ-aminopropyltriethoxysilane (APTES). Appl Surf Sci 351:646–654. https://doi.org/10.1016/j.apsusc.2015.05.174

Reynolds O (1883) An experimental investigation of the circumstances which determine whether the motion of water shall be direct or sinuous, and of the law of resistance in parallel channels. Philos Trans R Soc 174:935–982

Samsuri A, Hamzah A (2011) Water based mud lifting capacity improvement by multiwall carbon nanotubes additive. J Pet Gas Eng 5:99–107

Sanchez RA, Azar JJ, Bassal AA, Martins AL (1999) Effect of drill pipe rotation on hole cleaning during directional-well drilling. SPE J 4:101–108. https://doi.org/10.2118/56406-PA

Sercan G, Volkan A (2018) Drilling and well completion cost analysis of geothermal wells in Turkey. SGP–TR–213. In: Proceedings, 43rd Workshop on Geothermal Reservoir Engineering Stanford University, Stanford, California, 12–14, February. pp. 1–19

Sifferman TR, Becker TE (1992) Hole cleaning in full-scale inclined wellbores. SPE Drill Eng 7:115–120. https://doi.org/10.2118/20422-pa/

Smith J, Bedrov D, Smith GD (2003) A molecular dynamics simulation study of nanoparticle interactions in a model polymer-nanoparticle composite. Compos Sci Technol 63(11):1599–1605. https://doi.org/10.1016/s0266-3538(03)00061-7

Song X, Xu Z, Li G, Pang Z, Zhu Z (2017) A new model for predicting drag coefficient and settling velocity of spherical and non-spherical particle in Newtonian fluid. Powder Technol 321:242–250. https://doi.org/10.1016/j.powtec.2017.08.017

Walker S, Li J (2000) The effects of particle size, fluid rheology, and pipe eccentricity on cuttings transport. SPE-60755-MS. In: Presented at the SPE/ICoTA Coiled Tubing Roundtable, 5–6, Houston, USA, pp. 1–10. http://doi.org/10.2118/60755-MS

Wang Y, Lv Z, Chen J, Wang Z, Zhou Y, Zhou L, Chen X, Han ST (2018a) Photonic synapses based on inorganic perovskite quantum dots for neuromorphic computing. Adv Mater. https://doi.org/10.1002/adma.201802883

Wang Y, Lv Z, Liao Q, Shan H, Chen J, Zhou Y, Zhou L, Chen X, Roy VAL, Wang Z, Xu Z, Zeng YJ, Han ST (2018b) Synergies of electrochemical metallization and valance change in all-inorganic perovskite quantum dots for resistive switching. Adv Mater 30(28):1–10. https://doi.org/10.1002/adma.201800327

Wang Y, Yang J, Wang Z, Chen J, Yang Q, Lv Z, Zhou Y, Zhai Y, Li Z, Han ST (2019) Near-infrared annihilation of conductive filaments in quasiplane MoSe2/Bi2Se3 nanosheets for mimicking heterosynaptic plasticity. Small. https://doi.org/10.1002/smll.201805431

Wei N, Meng Y, Li G, Wan L, Xu Z, Xu X, Zhang Y (2013) Cuttings transport models and experimental visualization of underbalanced horizontal drilling. Math Probl Eng. https://doi.org/10.1155/2013/764782

Okrajni S, Azar J (1986) The effects of mud rheology on annular hole clean-ing in directional wells. Soc Pet Eng SPE Drill Eng pp. 1–12. https://doi.org/10.2118/14178-PA

Yeu WJ, Katende A, Sagala F, Ismail I (2019) Improving hole cleaning using low density polyethylene beads at different mud circulation rates in different hole angles. J Nat Gas Sci Eng 61:333–343. https://doi.org/10.1016/j.jngse.2018.11.012

Acknowledgements

The authors wish to thank the Ministry of Higher Education Malaysia (MOHE) and Universiti Teknologi Malaysia Research Management Centre for funding this project under the Fundamental Research Grant Scheme (FRGS) with reference number FRGS/1/2019/TK05/UTM/02/20.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Rights and permissions

About this article

Cite this article

Oseh, J.O., Mohd Norddin, M.N.A., Ismail, I. et al. Study of cuttings lifting with different annular velocities using partially hydrolyzed polyacrylamide and enriched polypropylene–nanosilica composite in deviated and horizontal wells. Appl Nanosci 10, 971–993 (2020). https://doi.org/10.1007/s13204-019-01163-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-019-01163-6