Abstract

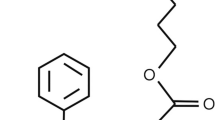

During drilling operation in gas shales, the high capillary force leads to drilling fluid filtration continuously, which eventually results in severe wellbore instability, reservoir damage, and other problems. To solve this urgent problem, in this study, CaCO3 nanoparticles (NPs) enhanced nano-drilling fluid is developed to reduce the drilling fluid permeation into the shale matrix by sealing. In addition, the sealing nanoparticles can be removed by acid washing to restore reservoir permeability. The size distribution of CaCO3 nanoparticles is determined based on the pore size distribution of the shale matrix. The dispersion evaluation experiments are conducted to select and optimize the type of CaCO3 nanoparticles and dispersion agents. A specially designed pressure transmission experiment is used to evaluate the effects of CaCO3 nanoparticle concentration and rock/fluid contact time on the degree of shale matrix sealing by measuring the matrix shale liquid permeability before and after sealing, and the shale liquid permeability as a function of contact time, respectively. Finally, scanning electron microscope technique is used to explore the sealing mechanism of the CaCO3 nanoparticles enhanced nano-drilling fluid on the shale matrix surface. Results show that 10–40 nm hydrophobic CaCO3 nanoparticles and cetyl trimethyl ammonium chloride are the optimal nano-additive and dispersion agent, respectively. When the optimal nanoparticle concentration is 1%, the reduction rate of the shale matrix permeability reaches up to 95.5%. Moreover, the mechanisms of the nanoparticles seal the matrix pores are discovered: (i) A single nanoparticle can seal the shale matrix pore which has a size similar to the nanoparticle size by plugging method; (ii) Several nanoparticles come together and can seal the shale matrix pore which has a diameter greater than nanoparticle size by bridging method. Finally, after washing by 15% HCl for 30 min, the nano-drilling fluid sealing effect can be removed effectively. This research shows that the NPs could be used as a temporary filtrate reducer in drilling operation of gas shales. In particular, the detailed application mechanism of nano-drilling fluids in shale drilling is presented. The experimental research methods and fundamental data provide significant practical guidelines for the development of new NP enhanced drilling fluids.

Similar content being viewed by others

References

Abrams A (1977) Mud design to minimize rock impairment due to particle invasion. J Pet Technol 29(05):586–592

Al-Malki N, Pourafshary P, Al-Hadrami H, Abdo J (2016) Controlling bentonite-based drilling mud properties using sepiolite nanoparticles. Pet Explor Dev 43(4):717–723

Amer A, Carter B, Hudson E II, Du H, Judd C (2016) Revisiting the ideal packing theory with a novel particle size measurement approach. In: Paper presented at the SPE Asia pacific oil & gas conference and exhibition. Society of Petroleum Engineers, Perth. https://doi.org/10.2118/182487-MS

Aston MS, Elliott GP (1994) Water-based glycol drilling muds: shale inhibition mechanisms. In: Paper presented at the European petroleum conference. Society of Petroleum Engineers, London. https://doi.org/10.2118/28818-MS

Chellappah K, Aston MS (2012) A new outlook on the ideal packing theory for bridging solids. In: Paper presented at the SPE international symposium and exhibition on formation damage control. Society of Petroleum Engineers, Lafayette. https://doi.org/10.2118/151636-MS

Dai Jinxing HS, Yan L, Fengrong L (2010) Significant advancement in natural gas exploration and development in china during the past sixty years. Oil Gas Geol 31(6):689–698

Darley HC (1972) Stabilization of hard shaly formations with alkali metal silicate. Google Patents

Fakoya MF, Shah SN (2017) Emergence of nanotechnology in the oil and gas industry: emphasis on the application of silica nanoparticles. Petroleum 3(4):391–405

Hoxha BB, Oort EV, Daigle H (2017) How do nanoparticles stabilize shale? In: Paper presented at the SPE international conference on oilfield chemistry. Society of Petroleum Engineers, Montgomery. https://doi.org/10.2118/184574-MS

Montilva JC, Van Oort E, Brahim R, Quintero L, Dye W, McDonald M, Trenery JB, Luzardo JP (2007) Using a low-salinity high-performance water-based drilling fluid for improved drilling performance in Lake Maracaibo. In: Paper presented at the SPE annual technical conference and exhibition. Society of Petroleum Engineers, Anaheim. https://doi.org/10.2118/110366-MS

Reid PI, Elliott GP, Minton RC, Chambers BD, Burt DA (1993) Reduced environmental impact and improved drilling performance with water-based muds containing glycols. In: Paper presented at the SPE/EPA Exploration and Production Environmental Conference. Society of Petroleum Engineers, San Antonio. https://doi.org/10.2118/25989-MS

Rodriguez Pin E, Roberts M, Yu H, Huh C, Bryant SL (2009) Enhanced migration of surface-treated nanoparticles in sedimentary rocks. In: Paper presented at the SPE annual technical conference and exhibition. Society of Petroleum Engineers, New Orleans. https://doi.org/10.2118/124418-MS

Santos H, Olaya J (2002) No-damage drilling: how to achieve this challenging goal? In: Paper presented at the IADC/SPE Asia pacific drilling technology. Society of Petroleum Engineers, Jakarta. https://doi.org/10.2118/77189-MS

Sawdon CA, Brady ME, Cliffe S, James SG (1995) An integrated approach to the development of a water-based mud with oil-based mud performance. In: Paper presented at the SPE/IADC drilling conference. Society of Petroleum Engineers, Amsterdam. https://doi.org/10.2118/29375-MS

Sensoy T, Chenevert ME, Sharma MM (2009) Minimizing water invasion in shales using nanoparticles. In: Paper presented at the SPE annual technical conference and exhibition. Society of Petroleum Engineers, New Orleans. https://doi.org/10.2118/124429-MS

Shangbin C, Yanming Z, Hongyan W, Honglin L, Wei W, Yue L, Wu L, Junhua F (2010) Research status and trends of shale gas in China. Acta Petrolei Sinica 31(4):689–694

Sharma MM, Zhang R, Chenevert ME, Ji L, Guo Q, Friedheim J (2012) A new family of nanoparticle based drilling fluids. In: Paper presented at the SPE annual technical conference and exhibition. Society of Petroleum Engineers, San Antonio. https://doi.org/10.2118/160045-MS

Srivatsa JT, Ziaja MB (2011) An experimental investigation on use of nanoparticles as fluid loss additives in a surfactant-polymer based drilling fluids. In: Paper presented at the international petroleum technology conference. International Petroleum Technology Conference, Bangkok. https://doi.org/10.2523/IPTC-14952-MS

White CC, Chesters AP, Ivan CD, Maikranz S, Nouris R (2003) Aphron-based drilling fluid: novel technology for drilling depleted formations in the North Sea. In: Paper presented at the SPE/IADC drilling conference. Society of Petroleum Engineers, Amsterdam. https://doi.org/10.2118/79840-MS

Zhang T (2014) Dispersion technique and mechanism research of CaCO3 nanoparticles applied in water based frilling fluid. Southwest Petroleum University (in Chinese)

Zhang H, Lu Y, Li K (2016) Temporary sealing of fractured reservoirs using scaling agents. Chem Technol Fuels Oils 52(4):429–433

Zhang H, Zhong Y, She J, Li G (2018) Characterization of shale matrix pore structure via experiment and model. Arab J Geosci 11(12):320

Zhong Y, Kuru E, Zhang H, Kuang J, She J (2018) Effect of fracturing fluid/shale rock interaction on the rock physical and mechanical properties, the proppant embedment depth and the fracture conductivity. Rock Mech Rock Eng 52:1011–1022

Zou C, Dong D, Wang Y, Li X, Huang J, Wang S, Guan Q, Zhang C, Wang H, Liu H, Bai W, Liang F, Lin W, Zhao Q, Liu D, Yang Z, Liang P, Sun S, Qiu Z (2016) Shale gas in China: characteristics, challenges and prospects (II). Pet Explor Dev 43(2):182–196

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51874052 and No. 51704043), Foundation of Sichuan Educational Committee (No. 18TD0015), National Science and Technology Major Project (Grant No. 2016ZX05023-001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Zhong, Y., She, J. et al. Experimental study of nano-drilling fluid based on nano temporary plugging technology and its application mechanism in shale drilling. Appl Nanosci 9, 1637–1648 (2019). https://doi.org/10.1007/s13204-019-01046-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-019-01046-w