China is rich in Shale gas resources, and the preliminarily predicted geological resource reserves are about 134 1012 m3, with a technically recoverable reserve of approximately 25·1012 m3. The Weiyuan-Rongxian area has abundant natural gas resources, but its geological conditions are complex, characterized by poor drillability of local formations, deep burial of reservoirs, and uneven horizontal distribution. These complex geological conditions result in low mechanical drilling speed, long drilling cycles, and high drilling costs, posing severe challenges and challenges to drilling engineering. In view of the technical difficulties of oil-based drilling fluid in the deep shale high-pressure fracture formation in this block, this paper has developed a particle size variable nano micron plugging agent CLG-NM suitable for the high-pressure fracture formation in the deep shale gas formation. Its molecular structure was characterized, its nano micron plugging characteristics were evaluated, and its microscopic mechanism was discussed. The research results indicate that the median particle size D50 of the newly developed variable nano micron sealing agent CLG-NM is 89.4 nm. After high-temperature aging at 150°C, the filtration loss of the experimental slurry showed a gradually decreasing trend with the increase of the amount of sealing agent CLG-NM added. When the dosage of sealing agent is 1%, the filtration loss of sand disc sealing is only 4.2 mL, demonstrating strong nano micron sealing performance. On this basis, CLG-NM was applied on-site in the Longmaxi Formation of Well Weiye 32-3HF. Field tests have shown that during the drilling process of the Weiye 32-3HF Longmaxi Formation, there were no complex downhole situations such as well leakage or wellbore instability. The drilling was successfully completed, with a pure drilling time of 42 hours, an average drilling speed of 7.81 m/h, and a density reduction of about 0.08-0.1 g/cm3 compared to the adjacent well.

Similar content being viewed by others

References

Zhu X.Y., Duan H.L., Sun Y.X. Exploration Breakthrough and Significance of Paleogene Continental Shale oil in Gaoyou Sag, Subei Basin [J]. Acta Petrolei Sinica, 2023: 1-17.

Jia C.Z., Zheng M., Zhang Y.F. Unconventional Oil and Gas Resources and Exploration and Development Prospects in China [J]. Petroleum Exploration and Development, 2012, 39(02): 129-136.

Luo P.Y., Li W.Z., Dai F., et al. Strengthening drilling fluid technology for shale gas reservoirs in the Longmaxi Formation, southern Sichuan Basin [J]. Natural Gas Industry, 2023, 43(04): 1-10.

Mohrwestheide T., Reimold W.U., Riller U., et al. Pseudotachylitic Breccia and Microfracture Networks in Archean Gneiss of the Central Uplift of the Vredefort Dome, South Africa [J]. South African Journal of Geology, 2009, 70(9): 604-609.

Bowker K.A. Barnett Shale gas production, Fort Worth Basin: Issues and discussion [J]. AAPG Bulletin, 2007, 91(4): 523-533.

Saleh T.A., Muhammad Nur M. Synthesis of polyacrylic-melamine grafted graphene as efficient inhibitor for shale stabilization in water-based drilling fluid [J]. Materials Today Communications, 2023, 35: 106264.

Yu J.Q., An Y.X., Ma J.Y., et al. Synthesis and performance of high-performance shale plugging agent [J]. Petrochemical Technology, 2022, 51(7): 806-814.

Geng Y., Sun J.S., Cheng R.C., et al. Micro/nano structured oleophobic agent improving the wellbore stability of shale gas wells [J]. Petroleum Exploration and Development, 2022, 49(6): 1252-1261.

Wang J., Luo T.T., Pu K.Y., et al. Oil-based Drilling Fluid Pressure-bearing Plugging Materials Suitable for Fuling Shale Gas Field Reservoir [J]. Materials Reports, 2022, 36(6): 120-124.

Liu H., Sun T., Zhang Y., et al. Design of Oil Shale In-Situ Extraction Heater Structure and Numerical Simulation of the Fracturing Process [J]. Chemistry Technology of Fuels and Oils, 2023, 58: 990-1004.

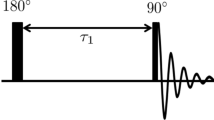

Wang L., Yang J., Peng J., et al. Nuclear Magnetic-Seepage Joint Measurement Experimental Technology and Field Application of Shale Oil Reservoir [J]. Chemistry Technology of Fuels and Oils, 2023, 59: 343-350.

Hosseini S.E., Nowrouzi I., Shahbazi K., et al. An investigation into shale swelling inhibition properties of dodecyltrimethylammonium chloride (DTAC) for water-based drilling fluids [J]. Geoenergy Science and Engineering, 2023, 223: 221465.

Ahmad H.M., Iqbal T., Al Harthi M.A., et al. Synergistic effect of polymer and nanoparticles on shale hydration and swelling performance of drilling fluids [J]. Journal of Petroleum Science and Engineering, 2021, 205: 108763.

He S., Wang W., Zhou J., et al. A Model for Analysis of Wellbore Stability Considering the Effects of Weak Bedding Planes [J]. Journal of Natural Gas Science & Engineering, 2015, 27: 1050-1062.

Cheshomi A., Hajipour G., Hassanpour J., et al. Estimation of uniaxial compressive strength of shale using indentation testing [J]. Journal of Petroleum Science & Engineering, 2017, 151: 24-30.

Tang X.H., Zhu H.Y., Che M.G., et al. Complex fracture propagation model and plugging timing optimization for temporary plugging fracturing in naturally fractured shale [J]. Petroleum Exploration and Development, 2023, 50(1): 152-165.

Ma H., Yang Z., Xie N., et al. Dynamic Analysis Method Research and Application of Shale Gas Horizontal Well [J]. Chemistry Technology of Fuels and Oils, 2021, 57: 289-298.

Pollastro R.M. Total petroleum system assessment of undiscovered resources in the giant Barnett Shale continuous (unconventional) gas accumulation, Fort Worth Basin, Texas [J]. AAPG Bulletin, 2007, 91(4): 551-578.

Civan F., Rai C.S., Sondergeld C.H. Shale-Gas Permeability and Diffusivity Inferred by Improved Formulation of Relevant Retention and Transport Mechanisms [J]. Transport in Porous Media, 2011, 86(3): 925-944.

Dehghanpour H., Shirdel M. A Triple Porosity Model for Shale Gas Reservoirs [C]. SPE 149501, 2011.

Hoelscher K.P., Stefano G.D., Riley M., et al. Application of Nanotechnology in Drilling Fluids [C]. SPE 157031, 2012.

Yang X.Y., Cai J.H., Jiang G.S., et al. Modeling of nanoparticle fluid microscopic plugging effect on horizontal and vertical wellbore of shale gas [J]. Energy, 2022, 239: 122130.

Zhang R.X., Hou B., Tan P., et al. Hydraulic fracture propagation behavior and diversion characteristic in shale formation by temporary plugging fracturing [J]. Journal of Petroleum Science and Engineering, 2020, 190: 107063.

Wu Y., Wang Z., Yan Z., et al. Poly (2-acrylamide-2-methylpropanesulfonic acid) modified SiO2 nanoparticles for water-based drilling fluids [J]. Industrial & Engineering Chemistry Research, 2016, 56(1): 168-174.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 4, pp. 164–169, July – August, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Q. Development and Application of a Novel Nano-Micron Plugging Agent with Core-Shell Structure for Oil-Based Drilling Fluids. Chem Technol Fuels Oils 59, 891–900 (2023). https://doi.org/10.1007/s10553-023-01594-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-023-01594-6