Abstract

We perform an atomic scale simulation of GaAs/GaAs(100) growth, using the Kinetic Monte Carlo (KMC) technique, to investigate some aspects of Gallium and Arsenic surface migration. We show that the interlayer migration rate is smaller for Arsenic than for Gallium. Results suggest that upward diffusion is thermally activated while downward diffusion is kinetically controlled. We also find an oscillatory behavior of the surface diffusion rates during the growth, in close relation to the roughening of the substrate. The surface migration rates are governed by the temperature, but mostly by the Arsenic to Gallium flux ratio. The Gallium average diffusion lengths are estimated to be ~440 nm at 620°C and ~130 nm at 530°C, in agreement with experimental data.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, the development of MBE technique, which produces high quality layers (Jasik et al. 2008) and epitaxial nanostructures, has opened an interest for the analysis of new phenomena such as formation of defects and diffusion of adatoms during thin film deposition. These are the critical steps in manufacturing integrated circuits and MEMS devices (DasGupta and DasGupta 2004; Jung et al. 2005; Oguz and Gallivan 2008). We note that atomistic models have been widely used to study different aspects of the growth, such as surface reconstruction (Lou and Panagiotis 2004), incorporation of atoms from molecular gas phase (Fazouan et al. 2005; Tiedje and Ballestad 2008) and heteroepitaxial growth (Fazouan et al. 2009). But, until now, no sufficient exploration of kinetic models to study the Gallium and Arsenic surface diffusion is available. Experimentally, the surface diffusion of Ga on GaAs(100) surfaces has been investigated using Scanning Tunneling Microscopy (STM) (Yang et al. 1999) and a combination of Reflection High energy Electron Diffraction (RHEED) and Scanning electron Microscopy (SEM) (Yamashiki and Nishinaga 1999). Anisotropy effects have been further examined via pulsed beam deposition technique (Ripalda et al. 2003). On the theoretical side, activation barriers for Ga adatom diffusion have been calculated, using quantum calculations based on the density functional theory (DFT) (Kley et al. 1997). But the kinetics of the diffusing species, on a growing surface out of equilibrium, has not been considered. In this paper, we focus on Kinetic Monte Carlo (KMC) technique to simulate the MBE of GaAs/GaAs in order to analyze the diffusion of Gallium and Arsenic on GaAs(100) surfaces. KMC is able to perform simulations in a wide range of experimental conditions: temperature, pressure and experiment duration. These performances cannot be reached by more accurate models, such as quantum ab initio calculations or molecular dynamics, which have intrinsic limitations, in terms of the above experimental conditions. KMC allows the treatment of multiple atomic scale configurations and the observation of sequential atomic movements, according to the predefined transition probabilities. We have applied the KMC technique to report on the influence of temperature and Arsenic flux on the average diffusion lengths of Ga and As atoms on GaAs(100) surfaces during growth, by introducing a new mechanism of interlayer diffusion. We describe the method in “Description of the method”, starting by the KMC procedure, the surface configurations implemented and the energy model used to evaluate activation barriers. In “Simulation results and discussion”, we present and discuss the results concerning the surface diffusion during growth, in the presence of islands. Finally, “Conclusions” are given.

Description of the method

KMC procedure

The KMC model is based on the sequence of events. Each event represents the occurrence of an elementary atomistic mechanism at a given site of a predefined lattice. In our case, the predefined lattice is a 2D square cell representing the substrate, a (100) surface of GaAs, on which the layer is deposited. The elementary mechanisms taken into account are deposition (arrival on the substrate), evaporation, interlayer and intralayer migrations of species, namely Ga and As atoms and As2 molecules, on the substrate. Each event operates a transition between two configurations of the system with a given probability per unit time. This way, a KMC simulation run reproduces one random path out of all possible paths that may actually occur on a real surface. In this sense, results of a simulation run could be very close to what is experimentally observed. In the following, KMC is used to attribute a time of occurrence to all possible events, i.e., to all atomistic mechanisms on all individual sites. This time is determined using the Poisson probability distribution:

Where \( \lambda_{i} \) is the probability of occurrence of a particular mechanism per unit time, and \( z_{i} \) is a random number uniformly distributed over the interval (0–1). For all thermally activated mechanisms, the \( \lambda_{i} \) are evaluated by the Arrhenius law:

\( \Updelta E_{i} \) is the activation energy associated to the particular mechanism, v is the attempt frequency set at 3 × 1012 s−1, k is the Boltzmann constant and T is the temperature. The activation barriers are determined according to an energy model described later in this section.

The two arrival mechanisms related to Gallium and Arsenic species are not thermally activated. They obey the Maxwell kinetic theory in the gas phase and have the following probabilities of occurrence:

Where Cst is a constant, P is the pressure, S is the elementary 2D cell area and \( M_{\text{Ga,As}} \) is the respective molar masses of Ga and As2 species. In this scheme, the software starts the simulation by establishing two types of calendars, one for the arrivals of Gallium atoms and As2 molecules, which are closely related to the kinetics in the gas phase, and the other for thermally activated mechanisms occurring on the surface. All calendars will be updated at each step, as the surface configuration evolves. As soon as the calendar is up to date, the software calculates all the occurrence times and finds the occurring event, the mechanism and the site, corresponding to the minimum occurrence time. Then, the event occurs, the local configuration is updated and the new configuration implemented. This cycle is repeated up to the experiment duration. Figure 1 shows a schematic view of this procedure.

Surface configurations

In GaAs/GaAs(100) MBE, the Gallium is supplied in atomic specie, while Arsenic is supplied in the As4 or As2 molecular form. As4 desorption measurements show that the incorporation of Arsenic atoms is via dissociative chemisorption of As2 molecules. Actually, the decomposition of As4 leads to physisorbed molecules on the substrate surface, in an intermediate \( {\text{As}}_{2}^{ * } \) state. The final incorporation of Arsenic requires, therefore, two neighboring vacant As sites. The sticking coefficient tends to unity above 620°C and the basic reactions can be presented as (Foxon and Joyce 1975; Foxon and Joyce 1977; Horikoshi et al. 1988; Ghaisas and Madhukar 1986)

On a GaAs(100) surface, adatoms are doubly bonded to the substrate, along a [011] row, and have two dangling bonds left. This configuration is the most stable one on a flat (100) surface, since two dangling bonds are pointing towards each of the adsorption sites. All other neighboring structures will spontaneously relax to this one. Figure 2a shows schematically such a Gallium adatom. Once the single Gallium adatom is adsorbed, it can further migrate towards steps present on the surface and become stabilized by establishing more bonds with the substrate. Obviously, due to the stochastic nature of the growth, well represented in a KMC simulation, Gallium atoms may directly impinge close to the steps and be adsorbed with more than two bonds. This configuration, similar to the one occurring after surface migration, as noted above, is not represented in Fig. 2 to save space. The incorporation of Arsenic requiring two neighboring vacant As sites, these sites might be aligned with the bonds or situated on two adjacent rows. These two configurations are schematically represented on Fig. 2b, c. This type of bonding makes the surface highly anisotropic. Therefore, the migrations of species on GaAs(100) surface are almost uniaxial in [011] direction for Gallium and \( \left[ {0\bar{1}1} \right] \) direction for Arsenic. In compound semiconductors, like GaAs, the interlayer migrations take place over two atomic layers, in order to avoid antisite defects. Since vacancies and overhangs are not allowed in the simulations, the lateral atomic displacement during an interlayer migration is relatively important. That is the reason why the use of an intermediate state, where the migrating atom is in an interstitial position, has been suggested in the literature (Dalla Torre et al. 1998). In this way, the interlayer migration mechanism is performed in two steps. Figure 2d shows schematically such an intermediate position, together with the initial and final positions of the migrating atom.

Figure 3 represents the two-step migration path of a substitutional atom in the third layer (Fig. 3a) down to its final position in the first layer (Fig. 3c), via the interstitial configuration (Fig. 3b). Performing interlayer migrations via this intermediate position allows migrations to positions as far as the fourth nearest neighbors. This results in the multiplication of final substitutional positions. Further, all events being reversible, the two-step mechanism slows down the interlayer diffusion rates. Therefore, the diffusion towards lower layers is no more spontaneous, in agreement with Ehrlich–Schwoebel (ES) effect (Ehrlich and Hudda 1966; Schwoebel and Shipsey 1966). The interstitial position in Fig. 3b is metastable and transforms rapidly into a substitutional configuration.

Energy model

The activation barriers determining the temperature-dependent transition probabilities are calculated using a bond breaking model. In this model, pair interactions between first and second nearest neighbor atoms are taken into account. Using values reported in the literature (Thomsen et al. 1987; Peskov 1994; Singh and Bajaj 1985), we set EGa–As = 0.8 eV for nearest neighbor interactions, EGa–Ga = 0.16 eV and EAs–As = 0.2 eV for second neighbor interactions. These values are known to reproduce cohesive and surface energies of GaAs. The total energy of the system is then determined by counting the number of first and second neighbors and adding the corresponding interaction terms. The number of bonds is easily calculated for atoms in substitutional positions. This might seem more complicated for an atom in interstitial position. In fact, we should remind that all migrating atoms are on the substrate surface, where dangling bonds are present. A surface atom in an interstitial position is still bonded to two neighboring atoms with two dangling bonds left (see Fig. 2d). But, these bonds are strongly distorted with respect to their perfect lattice orientations. We, therefore, add a positive strain energy to the negative first neighbor interactions, reducing the binding and, therefore, the stability of the atom in an interstitial position. The strain energy ES takes the bond distortions into account and is calculated using the Valence Force Field approximation (Martin 1970):

\( k_{\theta } = 1.1{\text{ev}} \) is calculated from the elastic constants of the materials. \( \Updelta {{\uptheta}}_{ij} \) is the bonds angle variations with respect to their equilibrium values in the perfect lattice. In our case, the calculated value of Es is 1.5 eV. Although this approximation is crude, its main effect is to accelerate the transition of an atom in interstitial configuration. This acceleration results from the increase of total energy between the substitutional and the interstitial configurations.

To evaluate the activation barriers, we also need the saddle point energies. In the saddle point transition state, the migrating atom is assumed to keep only one bond with one nearest neighbor, all the others being broken as a result of large interatomic distances. This assumption leads to diffusion barriers in the range of 1–2 eV, depending on the local environment, in terms of second nearest neighbors in the initial configuration, in agreement with the previous values determined by DFT calculations (Kley et al. 1997). We can notice that the environment dependence has not a negligible effect on the surface diffusion and should play an important role in the kinetics of migrating species during the growth process.

Simulation results and discussion

We report here the results of Gallium and Arsenic migrations, in terms of number of hops and average diffusion lengths, during GaAs/GaAs(100) growth. A substrate size of (30 × 30) atomic sites, with periodic boundary conditions in both lateral directions, has been used. Up to four atomic layers, at a deposition rate of one atomic layer/sec., have been deposited in each simulation run. This deposition rate corresponds approximately to a Ga partial pressure of 2 × 10−6 torr. Different temperatures, in the range of 530–620°C, and As/Ga flux ratios of 9, 10, and 20, have been considered. The attempt frequency is set equal to 3 × 1012 s−1 for all thermally activated events.

Figure 4 shows the average number of hops, per deposited atom, versus inverse temperature, for As/Ga flux ratio of 9. Results correspond to Ga and As atoms migrating between the first and the third deposited layers. It is noticeable that both the Ga and As interlayer jumps evolves as an exponential form. We can observe, at all temperatures, that the number of As interlayer migrations is much lower than the number of Ga interlayer migrations. This is partly due to lower second neighbor interaction energy between Ga atoms than between As atoms. But, the main reason is related to the kinetics of surface growth, which is governed by the Ga flux. In fact, the dissociative chemisorption of molecular Arsenic slows down its incorporation, while the Ga in atomic form is rapidly incorporated into the substrate and ready to migrate. Looking at Ga interlayer diffusion, the number of upward migrations is lower than the number of downward migrations, because of the larger number of bonds, between second nearest neighbors, in lower layers than in upper layers. Globally speaking, the number of interlayer migrations, per deposited atom, is low for both Ga and As. The reason for this is discussed later in this section. The interlayer diffusion mechanism being thermally activated, their number obviously increases with the temperature, but it is interesting to compare diffusion rates for the two species, Ga and As, present on the surface. We can notice that the ratio of migrations between the two species is almost constant, and independent of the temperature, for downward migrations. This result suggests that downward diffusion is essentially controlled by kinetic effects, such as arrival of atoms on the substrate and the sticking coefficients. On the other hand, the same ratio depends strongly on the temperature for upward migrations. We can, therefore, assume that upward diffusion is governed by the binding energies of the two species to the step edges. This argument is supported by the larger second nearest neighbor interactions between As atoms than between Ga atoms.

Figure 5 illustrates the number of intra and inter layer of Ga migrations (lm), as a function of time, for different temperatures and As/Ga flux ratios. For this purpose, we use the conventional expression:

Where N is the total number of Ga hops and L i is the length of an intra and interlayer Ga hop.

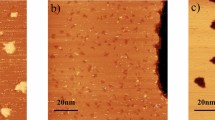

Three observations can be made. First, comparing Figs. 4 and 5, it can be easily seen that the number of intralayer migrations, i.e., migrations on flat parts of the surface, is much larger than the number of interlayer migrations. We should emphasize that the hopping distance is of lc = a/\( \sqrt {\mathbf{2}} \) = 0.39 nm, where a is the GaAs lattice parameter. This observation results from the combination of several mechanisms, all related to the layer by layer growth mode of GaAs. Indeed, in this growth mode, the terraces are large and the probability of atoms being close to the terrace boundaries, and to have the opportunity of undergoing interlayer diffusion, is low. On the other hand, the retardation of downward diffusion, due to ES effect mentioned earlier, slows down this type of interlayer diffusion. The situation is worse for upward diffusion, which is almost completely inhibited by the relatively large binding energy of migrating atoms to the edges of the already formed clusters. One expects, therefore, a low roughness of the deposited film, all over the growth process. This can be seen on Fig. 6 which shows the evolution of this roughness versus time. We notice that the film roughness is always lower than one atomic layer while, in the MBE of GaAs, two atomic layers, respectively Ga and As, are deposited simultaneously to form the compound semiconductor.

The second observation is related to the oscillatory behavior of the diffusion rates. Starting at its maximum value, at the beginning of the growth on a perfect substrate, the diffusion rate decreases gradually down to a minimum after 1 s. deposition, before increasing again. The first maximum is a consequence of the large flat area available to the migrating Ga atoms, which increases their diffusion rates. The oscillation period is 2 s. that corresponds to the growth of two atomic layers, i.e. one layer of Ga and one layer of As. We can deduce that the diffusion rate follows closely the formation of islands on the surface or, similarly, the evolution of the surface roughness. This is clearly seen on Fig. 6 where the diffusion rates and the roughness are plotted together. We can also notice that the initial maximum value of the diffusion rate, at the beginning of the growth, is not totally recovered after 2 s. deposition. This result reflects the fact that the layer by layer growth mode is not perfect and that a residual roughness is still observed after the growth of two atomic layers. Extrapolation of this result to multiple layer growth explains the oscillation modes observed experimentally (Eckstein et al. 1987). It is known that GaAs deposition follows a 2D growth mode (Vladimir and Hee 2003). The physical parameters, such as those represented in Figs. 5 and 6, remain therefore oscillatory for long deposition times, before reaching a stationary state characteristics of surface termination equilibrium. Large computing times are needed to reproduce such stationary states which are beyond the scope of this paper.

Finally, we observe that the diffusion rate decreases when the As/Ga flux ratio increases. Indeed, the high rate of As incorporation stabilizes the Ga islands, at their boundaries, forbidding detachment of Ga atoms from the islands. In other words, Ga diffusion is enhanced in the absence of Arsenic population on the surface. This result is also in agreement with the experimental observations using atomic – resolution scanning tunneling microscopy technique (Itoh et al. 1998).

In Fig. 7, we have illustrated the average diffusion length of Ga as a function of temperature. The As/Ga flux ratio is taken equal to 9 and 4 atomic layers have been grown in 3 s. As expected, it is seen that the number of migration, being thermally activated, increases with increasing temperature. We estimate from this figure, that the diffusion length along the surface is ~440 nm at 620°C and ~130 nm at 530°C, in fair agreement with experimental data (Lopez and Nomura 1995; Shen and Nishinaga 1993). These results suggest that our simulation are predictive for the determination of diffusion lengths, at least in the (530–620°C) temperature range.

Conclusion

In this article, we have illustrated the atomic layer deposition of GaAs/GaAs(100), using the KMC technique. The objective was to investigate some aspects of Ga and As interlayer diffusion. The original point used here is the introduction of atoms in interstitial configurations, as intermediate states for the migration between layers, which is performed in two steps. Our simulations reveal that the number of migrations is smaller for Arsenic than for Gallium. Comparing the migration rates for the two species, we conclude that upward diffusion is governed by the binding energies of species to step edges, and are therefore temperature dependent, while the downward diffusion is controlled by kinetic effects. We have shown that the Ga intralayer migration rates oscillates during the growth process, in close relationship to the roughening of the growing surface. We also have shown that the peak values of Ga diffusion lengths are controlled by both the temperature and the As/Ga flux ratio. The Ga diffusion lengths along the surface are estimated to be around 440 nm at 620°C and 130 nm at 530°C, in perfect agreement with experimental data.

References

Dalla Torre J, Djafari Rouhani M, Malek R, Esteve D, Landa G (1998) Beyond the solid on solid: an atomic dislocation formation mechanism. J Appl Phys 84:5487. doi:10.1063/1.368312

DasGupta N, DasGupta A (2004) Semiconductor devices: modeling and technology, Prentice-Hall, New Delhi

Eckstein JN, Webb L, Weng SL, Bertness KA (1987) Photoemission oscillations during epitaxial growth. Appl Phys Lett 51:18331835. doi:10.1063/1.98485

Ehrlich G, Hudda FG (1966) Atomic view of surface self-diffusion: Tungsten on Tungsten. J Chem Phys 44:1039. doi:10.1063/1.1726787

Fazouan N, Atmani E, Djafari-Rouhani M, Esteve A (2005) Monte Carlo growth and in situ characterisation for Alx Ga1-x As heteroepitaxy. Comput Mater Sci 33:382–387. doi:10.1016/j.commatsci.2004.12.056

Fazouan N, Atmani E, Djafari-Rouhani M (2009) A Monte Carlo investigation of growth and characterization of heteroepitaxial. Thin Solid Films 517:6260–6263. doi:10.1016/j.tsf.2009.02.097

Foxon CT, Joyce BA (1975) Interaction kinetics of As4 and Ga on 100 GaAs surface using modulated molecular beam technique. Surf Sci 50:434–450. doi:10.1016/0039-6028(75)90035-7

Foxon CT, Joyce BA (1977) Interaction kinetics of As2 and Ga on GaAs(001) surfaces. Surf Sci 64:293–304. doi:10.1016/0039-6028(77)90273-4

Ghaisas SV, Madhukar A (1986) Role of surface molecular reactions in influencing the growth mechanism and the nature of nonequilibrium surface: a Monte Carlo study of molecular- beam epitaxy. Phys Rev Lett 56:1066–1069. doi:10.1103/PhysRevLett.561066

Horikoshi Y, Kawashima M, Hamaguchi H (1988) Migration enhanced epitaxy of GaAs and AlGaAs. Jpn J Appl Phys 27:169–179. doi:10.1143/JJAP27.169

Itoh M, Bell GR, Avery AR, Jones TS, Joyce BA, Vvedensky DD (1998) Island nucleation and growth on reconstructed GaAs(100) surfaces. Phys Rev Lett 81:633–636. doi:

Jasik A, Wnuk A, Wojcik-Jedlinska A, Jakieta R, Muszalski J, Strupinski W, Bugajski M (2008) The influence of the growth temperature and interruption time on the crystal quality of InGaAs/GaAs QW structures grown by MBE and MOCVD methods. J Cryst Growth 310:2785–2792. doi:10.1016/j.jcrysgro.2008.02.018

Jung MYL, Kwok CTM, Braatz RD, Seebauer EG (2005) Interstitial charge states in boron—implanted silicon. J Appl Phys 97:063520. doi:10.1063/1.1829787

Kley A, Ruggerone P, Scheffler M (1997) Novel diffusion mechanism on the GaAs(001) surface: the role of Adatom–Dimer interaction. Phys Rev Lett 79/26:5278–5281. doi:10.1103/PhysRevLett.79.5278

Lopez M, Nomura Y (1995) Surface diffusion length of Ga adatoms in molecular-beam epitaxy on GaAs(100)–(110) facet structures. J Cryst Growth 150:68–72. doi:10.1016/0022-0248(95)80182-C

Lou Y, Panagiotis DC (2004) Feedback control of surface roughness of GaAs (0 0 1) thin films using kinetic Monte Carlo models. Comput Chem Eng 29:225–241. doi:10.1016/j.compchemeng.2004.07.006

Martin RM (1970) Elastic properties of ZnS structure semiconductors. Phys Rev B 1:4005–4011. doi:10.1103/PysRevB.1.4005

Oguz C, Gallivan MA (2008) Optimization of a thin film deposition process using a dynamic model extracted from molecular simulations. Automatica 44:1958–1969. doi:10.1016/j.automatica.2007.11.017

Peskov NV (1994) Computer simulation of Ga migration in molecular-beam epitaxial growth of GaAs. Surf Sci 306:227–232. doi:10.1016/0039-6028(94)91200-9

Ripalda JM, Bone PA, Howe P, Jones TS (2003) Morphological anisotropy during migration enhanced epitaxy of GaAs(001). Surf Sci 540:L593–L599. doi:10.1016/S0039-6028(03)00798-2

Schwoebel RL, Shipsey EJ (1966) Step motion on crystal surface. J Appl Phys 37:3682. doi:10.1063/1.1707904

Shen XQ, Nishinaga T (1993) Arsenic Pressure dependence of the surface diffusion in molecular beam epitaxy on (111)B-(001) Mesa-etched GaAs substrates studied by in situ scanning microprobe reflection high-energy electron diffraction. Jpn J Appl Phys 32:L1117–L1119. doi:10.1143/JJAP.32.L1117

Singh J, Bajaj KK (1985) Theoretical studies of the intrinsic quality of GaAs/AlGaAs interfaces grown by MBE: Role of kinetic processes. J Vac Sci Technol B3:520–523. doi:10.1116/1.583166

Thomsen M, Ghaisas SV, Madhukar A (1987) Examination of the nature of lattice matched III-V semiconductor interfaces using computer molecular beam epitaxial growth I, AC/BC interfaces. J Cryst Growth 84:79–97. doi:10.1016/0022-0248(87)90115-1

Tiedje T, Ballestad A (2008) Atomistic basis for continuum growth equation: Description of morphological evolution of GaAs during molecular beam epitaxy. Thin Solid Films 516:3705–3728. doi:10.1016/j.tsf.2007.11.015

Vladimir IT, Hee SP (2003) Growth mode transitions in molecular epitaxy of GaAs (001). Thin Solid Films 428:170–175. doi:10.1016/s0040-609(02)01189-6

Yamashiki A, Nishinaga T (1999) Arsenic pressure dependence of incorporation diffusion length on (001) and (110) surfaces and inter-surface diffusion in MBE of GaAs. J Cryst Growth 198/199:1125–1129. doi:10.1016/S0022-0248(98)01135-X

Yang H, LaBella VP, Bullock DW, Ding Z, Smathers JB, Thibado PM (1999) Activation energy for Ga diffusion on the GaAs(0 0 1)-(2x4) surface: an MBE-STM study. J Cryst Growth 201/202:88–92. doi:10.1016/S0022-0248(98)01296-2

Open Access

This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Amrani, A., Djafari Rouhani, M. & Mraoufel, A. A Monte Carlo investigation of Gallium and Arsenic migration on GaAs(100) surface. Appl Nanosci 1, 59–65 (2011). https://doi.org/10.1007/s13204-011-0008-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-011-0008-1