Abstract

A thermoresponsive system of a nanoemulsion-based gel with favorable characteristics to enhanced oil recovery (EOR) application is presented. A full factorial design study with different formulations of thermosensitive nanoemulsion-based gels was performed to assess the influence of the oil chain length, concentration of polyethylene glycol (PEG 400) and concentration of oil on the rheological behavior of the system. A formulation with low viscosity at room temperature and high viscosity at the temperature of the oil extraction well was presented. Hexane (6-carbon chain), capric acid (10-carbon chain) and isopropyl myristate (17-carbon chain) were used in concentrations of 5%, 10%, 15% and 20% wt%, also varying the concentration of PEG 400 in 0%, 3%, 6% and 9% wt%. The thermosensitive polymer used was a mixture of Pluronic® F-127 and Pluronic® F-68 6:1 wt% at 4.7% concentration. The surfactants used were Tween 80 and Span 80 (HLB = 13) at 20%. The formulation containing 20% isopropyl myristate (IPM) without the addition of PEG 400 showed a better response, with an increase in viscosity of more than 38 times in relation to its viscosity at 25 °C, and the maximum viscosity was reached at 53 °C. This is a promising formulation for EOR technology.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Enhanced oil recovery (EOR) is a technique that consists in the application of methods that improve the recovery process and increases the amount of crude oil extracted from an oil field. Among the existing methods are chemical, thermal, injection of miscible gas/solvent, ultrasonic vibration, and flooding with microorganisms. The flooding of oil extraction wells with polymers represents one of the chemical processes of EOR. In this process, water-soluble polymers are used to modify rheological properties of displacement fluid, improving the rate of oil mobility and, therefore, the efficiency of the process [5].

Thermosensitive polymers are interesting for EOR application due to the characteristics of their structure. They consist of a hydrophilic main chain with hydrophobic side chains and are considered alternative viscosifying agents for high temperature and high salinity conditions [11, 12]. In these polymers, thermosensitive monomers with low critical solubility temperature (LCST) are incorporated into the main polymer chain. Above the LCST, the formation of physical networks occurs as these monomers rearrange themselves in hydrophobic micro domains, increasing the viscosity of the polymeric solution [12]. The combination of thermosensitive polymers with surfactants in micro and nanoemulsions has been explored mainly in pharmaceutical applications [8, 22, 27, 28], but has great potential for application in EOR, especially due to the ability to achieve ultra-low values of water–oil surface tension [18].

Triblock copolymers of poly(oxyethylene) and poly(oxypropylene) units (PEO–PPO–PEO), commercially available as Pluronics®, are non-ionic, water-soluble materials that undergo thermal gelation in aqueous solution at appropriate concentrations [13, 24]. These polymers exhibit surface active properties, amphiphilic character and are known to form gels in response to temperature increase [13].

Variations in the number of PEO and PPO units provide a wide range of polyols with different physical and chemical properties [24]. Pluronic® F-127 has a PEO–PPO ratio of 7:3 with a molecular weight of 12,500 and is more readily soluble in cold than in hot water [14]. The aggregation behavior of block copolymers is complex in comparison to low-molecular-weight non-ionic surfactants, which occurs over a range of concentrations rather than at a unique critical micelle concentration (CMC). As a result, CMC values reported can be substantially different depending on the experimental conditions and technique used [2].

Schmolka et al. studied a system composed of the non-ionic polymeric surfactant Pluronic® F-127 with the addition of salts and drugs to form a thermosensitive gel suitable for application in burns [22]. Zhao et al. prepared microemulsion-based thermosensitive gels (MBGs) also using the polymer Pluronic® F-127, in combination with a microemulsion system composed of isopropyl myristate (IPM), water and surfactants Span 20 and Tween 20 [28]. They observed that the viscosity of the gels increased, and the gelation temperature decreased with increasing in polymer concentration. In another study conducted by Zhao et al. MBGs were prepared using Pluronic® F-123 in the presence of IPM, Span 20, Tween 20 and water [27]. The results show that the microstructures of the microemulsion drops are maintained in the MBGs.

Hashemnejad et al. synthesized a nanoemulsion-base thermoresponsive gel through a low-energy cost process, with application in cosmetics and pharmaceuticals [8]. The oil used was isopropyl myristate (IPM), along with surfactants Tween 80 and Span 80 (HLB = 13), a mixture of Pluronic® F-127 and F-68 in low concentrations (4.7%) and cosurfactant polyethylene glycol (PEG 400). They stated that the rearrangement of Pluronic® molecules as the temperature rises can be affected by hydrophobic regions, including oil droplets in the nanoemulsion and the central hydrophobic structure of the micelles of surfactants Tween 80 and Span 80 [8]. As the temperature rises, Pluronic®’s PPO segments are adsorbed at the interface of the oil droplets, as these segments become more hydrophobic. They observed that there is no transition from liquid to gel in the absence of oil, which suggests that the adsorption of Pluronic® copolymers at the droplets interface is a fundamental step for the thermosresponsive behavior of the system [8].

Previous experiments demonstrated that the displacement of micro and nanoemulsions in the porous medium improve oil recovery [4, 6, 9, 16, 17, 29]. There has been numerous studies that investigate the use of polymers in EOR [3, 5, 10, 15, 21, 25, 26], however, a formulation of a flooding fluid with physical–chemical and rheological characteristics that are optimal for EOR application (a fluid with low surface tension able to deliver high increase in viscosity at temperatures around 60 °C with liquid-like behavior at room temperature) is yet to be presented.

The aim of the present work is to develop an optimized formulation of a thermoresponsive nanoemulsion-based gel suitable for EOR application. The studies were carried out by tuning the concentrations of cossurfactant polyethylene glycol 400 (PEG 400) and oil, and the chain length of the oil in the presence of a mixture of known thermoresponsive triblock copolymers. This study was based on a formulation proposed by Hashemnejad et al. which was developed aiming to achieve properties suited for cosmetics and pharmaceutical applications [8].

Experimental

Materials

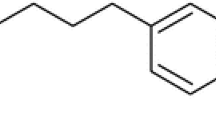

Cosurfactant polyethylene glycol 400 (PEG 400), oils n-hexane and isopropyl myristate (IPM) and surfactant Tween 80 were all analytical grade and were purchased from Synth (Brazil). Capric acid 99.5%, Span 80 (analytical grade) and block polymers Pluronic® F-127 and Pluronic® F-68 were purchased from Sigma-Aldrich (Germany).

Methods

Sample preparation

The thermoresponsive nanoemulsion-based gels were made through a low-energy process described elsewhere [8]. Concisely, the preparation of the samples consists in mixing a determined amount of oil and a determined amount of PEG 400 with surfactants Tween 80 and Span 80 (HLB = 13) at 20% wt% at room temperature, then adding ultrapure water dropwise into the mixture under stirring. Last, a mixture of Pluronic® F-127 and Pluronic® F-68 (6:1 wt%), previously solubilized in cold ultrapure water at 23.3% wt%, is added into the mixture under stirring at 4.7% wt%.

Experimental factorial design

A full factorial experiment was designed and analyzed using the software MiniTab 19.1.1. To verify the influence of the factors on the rheological behavior of the system, the concentration of PEG 400 (%PEG), the concentration oil (%Oil) and oil chain length (CL) were evaluated. The concentration of PEG 400 added to the formulation varied in 0%, 3%, 6% and 9% (wt%) and the concentration of oil varied in 5%, 10%, 15% and 20% (wt%). The oils studied were n-hexane (6-carbon chain), capric acid (10-carbon chain) and isopropyl miristate (IPM) (17-carbon chain). The responses monitored were viscosity of the system at 25 °C, temperature at which there was a peak in viscosity (peak temperature), increase in viscosity from room temperature and particle size. The experiments were carried out in randomized run order to avoid bias.

Rheology and particle size

The rheology of the samples was analyzed using a Brookfield R/S plus rotational rheometer equipped with a Searle-type concentric cylinder geometry CC25, shear rate of 20 s−1 and temperature ramp from 5 °C to 70 °C. Particle size was analyzed by dynamic light scattering (DLS) on a Particulate Systems NanoPlus equipment, after diluting the samples to 3.5% wt% with ultrapure water.

Surface tensiometry

Surface tension of the optimized formulation was measured at 25 °C using a DCAT 11 Dataphysics tensiometer. The method used was Wilhelmy plate with plate dimensions of 10 mm × 19.9 mm × 0.2 mm (length × width × thickness). The surface tension measurements were done in triplicate.

Results and discussion

A total of 48 experiments were performed in randomized order to determine the effect of the factors [concentration of PEG 400 (%PEG), concentration of oil (%Oil) and oil chain length (CL)] on four characteristic responses: viscosity of the system (η) at 25 °C, temperature at which the maximum viscosity was reached (peak temperature), maximum increase in viscosity and droplet size (particle size). Table 1 shows the experimental design matrix with factors and the results of the response variables studied. The increase in viscosity of samples with peak temperature below 25 °C is marked as 0% because in EOR the pumping process usually occurs at room temperature, however all samples showed an increase in viscosity somewhere between 5 °C and 70 °C.

The peak temperature should ideally be close to that of the oil wells (approximately 60 °C) to guarantee that the fluid would be at its maximum viscosity during extraction work, increasing the oil displacement in the porous medium [7]. Samples that showed peak temperature between 50 °C and 70 °C (samples 3, 4, 6, 7, 11, 13, 14, 15, 27, 28, 31, 33, 34, 43, 44 and 47) have broadly different compositions. The difference in composition indicates that there is no clear correlation between one factor studied and the peak temperature response. It is likely that two or more factors and their interactions are responsible for tuning the peak temperature property of the system.

The injection of chemical fluids to the oil wells seeks to increase miscibility between the injected fluid and the oil, decrease the interfacial tension to increase wettability of rock surface and increase viscosity of the injected fluid [7]. The highest increase in viscosity of 3836.5% was obtained with sample 15, which has 20% IPM in its composition with no addition of PEG 400. IPM has low toxicity [28] and could be used as a component of a flooding fluid without significant environmental impact. The presence of IPM in concentrations above 15% in sample 15 and other samples which had high increase in viscosity (samples 4, 6 and 14) shows that the presence and characteristics of the oil phase are critical in obtaining a thermoresponsive behavior of the system. The hypothesis is that there is synergistic effect occurring between Pluronic copolymers and the nanoemulsion droplets [8]. The viscosity diagram of sample 15 is displayed in Online Resource 1.

The viscosity at room temperature should be as low as possible to facilitate the pumping of the fluid into the wells. The lowest viscosities at 25 °C were obtained in samples with concentrations of oil lower than 10% (samples 1, 17, 33, 35, 42 and 43), however they did not show a high increase in viscosity nor did they have an adequate peak temperature. The low viscosity at room temperature with lower concentration of oil shows that the oil phase not only is linked to the gelling behavior of the system, but also has a direct influence on the viscosity at 25 °C, increasing the viscosity of the nanoemulsion before any temperature or shear trigger.

Usually, a clear and stable nanoemulsion has its structures (droplets of oil in water or water in oil interacting with the surfactants) in sizes up to 100 nm [7]. All samples formulated with capric acid (CL = 10) had a particle size bigger than 100 nm, indicating that the chain length has a clear influence on particle size property. It also indicates that capric acid could be considered a less suitable oil among the oils studied to produce clear and stable nanoemulsions. Samples formulated with different CL, PEG concentration and oil concentration were able to produce nanoemulsions with particle size up to 100 nm, indicating that other factors and their interactions are also influencing the response.

Analysis of variance (ANOVA) was performed to verify whether the influence of each component of the formulation and their interactions are significant on the responses studied. The results of p-value and F value obtained for all the factors and their interactions are shown in Table 2.

P-value is the probability used to determine if the effect or the interaction of effects in the model is statistically significant. For a 95% confidence level, the p-value should be less or equal to 0.05 for a factor to be considered statistically significant [23]. The degree of significance can be ranked based on F values. The greater the F value, the more significant the factor is, if its p-value is less than 0.05. The results of p-values from ANOVA reported in Table 2 show that all the responses are significantly influenced by at least two factors or interaction of factors. The complexity of the system makes it hard to predict its behavior without a mathematical model associated to each response. Statistical analysis also makes it possible to propose an optimized formulation considering how all the variables and their interactions influence the rheology of the system.

Table 3 shows the order of importance of statistically significant factors for each response based on the results from ANOVA in Table 2.

The oil chain length (CL) is the main influence factor on three out of four responses studied and its interaction with %Oil also shows important effect on all four responses. The interaction between CL and %Oil and %Oil alone also have significant influence on all responses studied. That again confirms that the presence and properties of the oil phase are critical in defining the rheological behavior of the system.

The concentration of cosurfactant PEG 400 and its interactions have the least significant influence on the responses in general. Hashemnejad et al. found that an increase in the concentration of PEG 400 lowers the gelation temperature of their nanoemulsion-based system [8]. Prior studies of Pluronic aqueous solutions also showed that the presence of short PEG chains lowers the critical micellization temperature [19, 20]. We were able to obtain a formulation with desired rheological behavior without addition of PEG 400 (sample 15). However, Table 2 and Table 3 show that %PEG and %PEG interactions do have statistically significant influence on the responses, even if they are less significant than the influence of other factors and interactions. The %PEG should, therefore, be considered when doing optimization calculations. The direction and magnitude of the influence of each factor can be verified through the coefficients in the equations of each model adjusted, found in Online Resource 1.

The results of the tests used to assess the adequacy of the models are summarized in Table 4. The coefficient of determination (R2) measures the total variability of the model, however a potential problem with this statistic is that it always increases as factors are added, whether they are significant or not [23]. The adjusted-R2 (R2aj) is a statistic adjusted to the number of factors in the model in a way that it decreases if insignificant factors are added, thus it is preferred to use the adjusted-R2 to evaluate the model adequacy [23]. The predicted-R2 (R2pred) assess if the model is good at making predictions, namely, it determines whether there is an overfitting of the model.

The statistics of adequacy show that the model proposed for η at 25 °C is neither well adjusted for the number of significant factors nor it is a good predictor. This might indicate that there are external factors influencing this response that we are unaware of and were not considered. For the other responses, the values of R2 and R2aj show that the models are well fitted for the data presented (R2 values above 95%) and are reasonably adjusted to the number of significant factors of each model (R2aj values above 87%), indicating that the regression explained the process adequately. The low values of R2 pred for peak temperature and increase in η show that the models are unable to explain the variability in new data well due to overfitting. However, the model proposed for particle size can explain variability of new data effectively, with R2 pred of 95,89%.

Figures 1, 2, 3 and 4 depict the three-dimensional surface plots of the main interaction effects between factors on the responses increase in η, η at 25 °C, peak temperature and particle size, respectively, at a fixed value of the third parameter.

The surface plots in Figs. 1, 2, 3 and 4 show that the samples prepared with capric acid (CL = 10) resulted in systems with larger particles, lower peak temperature, higher viscosity at 25 °C and lower increase in viscosity, which is the opposite of ideal for EOR application. Higher concentrations of oil result in higher increase in viscosity, however it also results in higher viscosity at 25 °C. All four three-dimensional plots showed non-linear surfaces, which justifies the need of adding center points to a two-level full factorial design. Optimization was designed to achieve maximum increase in viscosity, minimum viscosity at 25 °C and maximum peak temperature with α = 0.05, and sample 15 was pointed out with composite desirability of 0.73. The equations of each model adjusted are found in Online Resource 1.

The surface tension of sample 15 at 25 °C was 33.363 ± 0.028 mN/m, being 54% lower than the surface tension of the water at the same temperature. This feature of low surface tension is desirable for EOR application because it improves the wettability of the rocks in the reservoir [18]. The wettability is related to capillarity effects and is critical in determining the affinity of the oil with the reservoir rock and how easily it will be displaced [7].

The emulsion phase inversion technique used to prepare the nanoemulsion is a low-energy easy-to-scale method that makes the use of the technology cost-effective. In contrast to traditional emulsification processes, such as ultrasonication and high-pressure homogenization, this synthesis method offers the feasibility of large scale production [8].

Conclusions

In current work, full factorial design technology was used to determine the significant parameters, investigate the interaction among them and optimize conditions to formulate a thermoresponsive nanoemulsion-based gel suitable for EOR application. Despite the complexity of the system, it was possible to adjust mathematical models that fitted the presented data well for three out of four responses studied. A proposed model was also able to explain variability of new data effectively for particle size, with R2 pred of 95,89%. A formulation containing 20% IPM was able to reach an increase in viscosity of 3836.54% at 53 °C compared to its viscosity at 25 °C of 520 mPa.s. It also presented surface tension of 33.363 ± 0.028 mN/m at 25 °C, 54% lower than the surface tension of water at the same temperature.

The core-flooding experiments and stability in the presence of salts are yet to be evaluated, still the formulation proposed shows great potential for EOR application. We presented a clear and stable nanoemulsion-based gel with liquid-like behavior at room temperature, high increase in viscosity with increase in temperature, low surface tension and environmentally friendly formulation. The system presented could be used as a flooding fluid in oil recovery since its physical–chemical properties favor room temperature pumping, wettability of the rocks, miscibility with oil and with displacement fluid and enhanced fluid displacement. The rheological characteristics of the optimal formulation presented can also be tuned using the statistical models proposed in this study without the need of numerous time and resource consuming bench experiments.

References

Abidin AZ, Puspasari T, Nugroho WA (2016) (2012) Polymers for enhanced oil recovery technology. Procedia Chem 4:11–16. https://doi.org/10.1016/j.proche.2012.06.002

Bohorquez M et al (1999) A study of the temperature-dependent micellization of pluronic F127. J Colloid Interface Sci 216(1):34–40. https://doi.org/10.1006/jcis.1999.6273

Cao PF, Mangadlao JD, Advincula RC (2015) Stimuli-responsive polymers and their potential applications in oil-gas industry. Polym Rev 55(4):706–733. https://doi.org/10.1080/15583724.2015.1040553

Castro Dantas TN et al (2014) Implementing new microemulsion systems in wettability inversion and oil recovery from carbonate reservoirs. Energy Fuels 28(11):6749–6759. https://doi.org/10.1021/ef501697x

Chen Q et al (2013) Thermoviscosifying polymer used for enhanced oil recovery: rheological behaviors and core flooding test. Polym Bull 70(2):391–401. https://doi.org/10.1007/s00289-012-0798-7

Daghlian Sofla SJ, Sharifi M, Hemmati Sarapardeh A (2016) Toward mechanistic understanding of natural surfactant flooding in enhanced oil recovery processes: the role of salinity, surfactant concentration and rock type. J Mol Liq 222:632–639. https://doi.org/10.1016/j.molliq.2016.07.086

Dantas TNC et al (2019) Microemulsions and nanoemulsions applied to well stimulation and enhanced oil recovery (Eor). BJPG 12(4):251–265. https://doi.org/10.5419/bjpg2018-0023

Hashemnejad SM et al (2019) ‘Thermoresponsive nanoemulsion-based gel synthesized through a low-energy process. Nat Commun 10(1):1–10. https://doi.org/10.1038/s41467-019-10749-1

Hosseini-Nasab SM et al (2016) ‘A new chemical-enhanced oil recovery method? Colloids Surf 507:89–95. https://doi.org/10.1016/j.colsurfa.2016.07.087

Iglauer, S. et al. (2004) Alkyl polyglycoside surfactants for improved oil recovery’, Proceedings—SPE Symposium on improved oil recovery, 2004-April (December 2018). https://doi.org/10.2523/89472-ms

Kamal MS et al (2015) Review on polymer flooding: rheology, adsorption, stability, and field applications of various polymer systems. Polym Rev 55(3):491–530. https://doi.org/10.1080/15583724.2014.982821

Kamal MS, Sultan A (2017) Thermosensitive water soluble polymers: a solution to high temperature and high salinity reservoirs. Soc Petrol Eng 2017:2115–2130

Al Khateb K et al (2016) In situ gelling systems based on Pluronic F127/Pluronic F68 formulations for ocular drug delivery. Int J Pharm 502(2):70–79. https://doi.org/10.1016/j.ijpharm.2016.02.027

Lenaerts V et al (1987) Temperature-dependent rheological behavior of Pluronic F-127 aqueous solutions. Int J Pharm 39(1–2):121–127. https://doi.org/10.1016/0378-5173(87)90206-7

Li X et al (2017) Comparative studies on enhanced oil recovery: thermoviscosifying polymer versus polyacrylamide. Energy Fuels 31(3):2479–2487. https://doi.org/10.1021/acs.energyfuels.6b02653

Liu D et al (2010) A new fracturing fluid with combination of single phase microemulsion and gelable polymer system. J Petrol Sci Eng 73(4):267–271. https://doi.org/10.1016/j.petrol.2010.07.008

Nandwani SK et al (2017) Study on interfacial properties of Imidazolium ionic liquids as surfactant and their application in enhanced oil recovery. Colloids Surf 516:383–393. https://doi.org/10.1016/j.colsurfa.2016.12.037

Pal N et al (2019) Gemini surfactant/polymer/silica stabilized oil-in-water nanoemulsions: design and physicochemical characterization for enhanced oil recovery. J Petrol Sci Eng 183:106464. https://doi.org/10.1016/j.petrol.2019.106464

Pandit NK, McGowan R (1998) Gelation of pluronic® F127-polyethylene glycol mixtures: relationship to PEG molecular weight. Drug Dev Ind Pharm 24(2):183–186. https://doi.org/10.3109/03639049809085605

Pragatheeswaran AM, Chen SB (2013) Effect of chain length of PEO on the gelation and micellization of the pluronic F127 copolymer aqueous system. Langmuir 29(31):9694–9701. https://doi.org/10.1021/la401639g

Sarsenbekuly B et al (2017) Study of salt tolerance and temperature resistance of a hydrophobically modified polyacrylamide based novel functional polymer for EOR. Colloids Surf 514(66):91–97. https://doi.org/10.1016/j.colsurfa.2016.10.051

Schmolka IR (1972) Artificial skin I. Preparation and properties treatment of burns. J Biomed Mater Res 6:571–582

Seyed Shahabadi SM, Reyhani A (2014) ‘Optimization of operating conditions in ultrafiltration process for produced water treatment via the full factorial design methodology. Sep Purif Technol 132:50–61. https://doi.org/10.1016/j.seppur.2014.04.051

Vadnere M et al (1984) Thermodynamic studies on the gel-sol transition of some pluronic polyols. Int J Pharm 22(2–3):207–218. https://doi.org/10.1016/0378-5173(84)90022-X

Wever DAZ et al (2013) Comb-like thermoresponsive polymeric materials: synthesis and effect of macromolecular structure on solution properties. Polymer 54(21):5456–5466. https://doi.org/10.1016/j.polymer.2013.07.039

Wever DAZ et al (2013) Polymer molecular architecture as a tool for controlling the rheological properties of aqueous polyacrylamide solutions for enhanced oil recovery. Ind Eng Chem Res 52(47):16993–17005. https://doi.org/10.1021/ie403045y

Zhao X et al (2012) Rheological properties and microstructures of thermo-sensitive microemulsion-based gels. Advanc Mater Res 557–559:1009–1012

Zhao XY et al (2007) Preparation of temperature-sensitive microemulsion-based gels formed from a triblock copolymer. Colloids Surf 307(1–3):100–107. https://doi.org/10.1016/j.colsurfa.2007.05.006

Zhao Z, Lü G (2010) Visco-elastic properties of VES diverting acid for carbonate reservoirs. Chin J Chem Eng 18(3):511–514. https://doi.org/10.1016/S1004-9541(10)60251-0

Funding

The authors would like to thank Petrobras (Brazil) for financial support.

Author information

Authors and Affiliations

Contributions

NCD: formal analysis, investigation, writing—original draft preparation. MHAZ: project administration, investigation, writing—reviewing and editing. KLG: conceptualization, supervision. LAO: funding acquisition. AMO: conceptualization, supervision, funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

We know of no conflicts of interest associated with this publication, and there has been no significant financial support that could have impacted its results.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dalibera, N.C., Zanin, M.H.A., Guimaraes, K.L. et al. Optimized formulation of thermoresponsive nanoemulsion-based gel for enhanced oil recovery (EOR) application. Appl Petrochem Res 11, 155–163 (2021). https://doi.org/10.1007/s13203-021-00269-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-021-00269-9