Abstract

The article is dedicated to the development of processes for (oligo)alkylation of petroleum fractions rich in aromatic hydrocarbons, with α-olefins (hexene-1, octene-1, decene-1) in the presence of ionic-liquid catalytic systems and the study of the properties of the products obtained. Alkylation reactions were carried out in the presence of chloroaluminate ionic liquids; for the first time a (nano)metal-polymer composite (NMPC) was used in the catalytic system as a modifier, and zinc chloride (ZnCl2) was used in the catalytic system as a component and the results were compared. It has been shown that these ionic liquid catalytic systems (ILCS) are suitable for (oligo)alkylation reactions and the use of these additives in their composition will lead to efficient alkylation. The products obtained were analyzed by IR-, NMR- spectroscopy, fluorescent indicator adsorption methods, and size exclusion chromatography. It was shown that these petroleum fractions rich in aromatic hydrocarbons can be used as alkylation components, and depending on the composition of the ILCS, it is possible to regulate the molecular, thermophysical and other characteristics of the products obtained based on them. The alkylated products obtained have been tested as plasticizing additives in polyolefin composites.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

The alkylation of aromatic hydrocarbons with α-olefins is of great importance in laboratory synthesis and industrial production. Despite traditional homogeneous catalysts such as AlCl3, HF, H2SO4 are being used in this process and demonstrate high activity, their non-eco-friendly and corrosive abilities, non-reusability, and the difficulty of separation of products from catalyst create problems. On the other hand, heterogeneous catalysts demonstrate shortcomings, such as inferior activity and selectivity and weak regeneration ability.

In this context, ionic liquids (IL) which were added to the principles of “Green Chemistry” have recently been increasingly employed because of their advantages such as their alternative solvent and catalytic ability, the similarity with organic compounds and metal–organic catalysts, and easy separation ability from the reaction product. So they were investigated individually ([emim][PF6], [emim][SbF6], [emim][Cl-AlCl3], [bmim]Cl-FeCl3, [bmim][Al2Cl6Br], [Et3NH][Cl-FeCl3], [Et3NH][Cl-AlCl3], [BuPy][Br–AlCl3]) and as supported and grafted (grafted the [((EtO)3Si)3 C3C1im] + cation on silica and [((EtO)3Si)3 C3C1im][FeCl4] IL grafted on MCM-41, immobilized the Sc(OTf)3 in the ionic liquids such as [emim][SbF6], [bmim][PF6], [bmim][SbF6]) in alkylation processes [23, 27, 28, 31]. The articles of recent years confirm that ionic liquids make a great interest in various petrochemical and alkylation processes [20, 29, 36].

Mainly chloroaluminate IL have been used in alkylation processes. This IL has the ability to be used in combination with metal salts and oxides, to be supported to various surfaces [23, 30]. Chunsheng et al. [22] obtained lubricants by alkylation of benzene with decene-1 and oligomerization of decene-1 in the presence of [Et3NH] [Cl-AlCl3] ionic liquid. The alkylation products consisted mainly of pentamer, tetramer of dialkylbenzene and decen-1. The obtained products had a high viscosity index (114–164), low freezing point (minus 48–minus 62 °C), medium molecular weight (425–620) [22]. Alkylation of toluene with tri-butyl chloride was carried out in the presence of [Et3NH] [Cl-AlCl3]. As a result, 82.5% selectivity of p-tertiary evidence was obtained. IL has been used 5 times and has been retained its original catalytic activity [21]. Sun Xuewen et al. [35] studied the catalytic mechanism of AlCl3/butyl-methylimidazolium chloride IL in the alkylation of benzene with 1-dodecene by the isotope exchange method. The proposed catalytic mechanism was confirmed by analysis of ionic liquid before and after reaction and of the alkylation product of deuterated benzene (C6D6) with 1-dodecene [35]. Friedel–Crafts alkylation reaction of substituted benzenes with CCl4 was carried out in the presence of ionic liquids. The influence of Lewis acidity of ionic liquids has been investigated on the conversion of the alkylation process. The probable mechanism of this reaction has been proposed by NMR spectroscopy [34].

One of the unique features of IL is its accordance with the majority of different substances including (co)polymers. Polymers because of their different structures are widely used in different fields, also as carriers. It is shown that there are halogen atoms in the majority of IL. Despite the advantages of IL, a certain amount of halogen atoms can enter to target product. Therefore, to avoid these processes different polymer surfaces were used. These surfaces combine with halogen or other atoms via different physicochemical bonds. This method proves to be valuable not only in the reuse process but also ecologically [18, 23, 27, 28, 31]. On the other hand, considering the high cost of IL, many efforts have been made to reduce the used amount of IL focusing attention towards the supported ionic liquid systems (SILS) and modifiers. Scholars have shown that to impregnate and add some components as modifiers onto IL give positive results. First of all, it was possible to develop new catalytic materials that allowed to considerably simplify the recycling procedures. In addition, the possibility to adopt the “release and catch” concept for such systems allowed reaching considerable catalytic activity comparable to that of corresponding homogeneous catalysts or at least with a higher activity than a “pure” heterogeneous catalyst. Furthermore, IL, thanks to their low vapor pressure, can remain in the liquid state on the support material at the reaction condition, allowing both liquid and gas-phase applications [18].

Currently, alkylation products (AP) are being used in petrochemistry and organic synthesis fields as additives for oil and fuels, important intermediate compounds in the synthesis of drugs and insecticides, surfactants, additives in the spice industry, sulfonates with surface activity, in the grinding of ores, as cleaners, painters and emulsifiers. At the same time, they are being used as a basic component in nanotechnology. It is possible to create ecologically and economically efficient new technologies by applying of IL in these processes.

In recent years the investigations on the IL have been tested on different petrochemical processes in the Institute of Petrochemical Processes named after acad. Y.H. Mammadaliyev of Azerbaijan National Academy of Sciences [4, 7, 9]. The alkylation of different aromatic hydrocarbons with C6–C12 α-olefins raises a great interest among these research works [1,2,3, 11]. Thus, different fractions rich in aromatic hydrocarbons (liquid fraction obtained via reforming process (RPF), liquid fraction obtained via pyrolysis process (PPF)) were used in the alkylation processes and results obtained have been presented in this article. Chloroaluminate IL and nanometal polymer composites (NMPC) were used as catalytic systems [13,14,15,16, 26].

As mentioned previously, the alkylation process has been more extensively studied in the presence of IL. It is known that IL was first tested in the alkylation process. The importance of the use of ionic liquids in alkylation processes is also confirmed by the industrial processes carried out in their presence. Thus, chloroaluminate ionic liquids and their modified forms with copper salts are widely used in the process of "Ioniklylation", which is currently operating in China [28]. The fact that the importance of alkylation reactions in the presence of ionic liquids for the chemical industry also is being reflected in the dynamically increasing number of patents each year [19, 24, 25, 32, 33]. It is known that the main goal of the research is to create new catalytic systems that allow us to regulate the direction of the reaction to obtain alkylate products with the required structure. Our main goal is to use various modifiers as reaction regulators in a familiar chloroaluminate-type ionic liquid catalytic system, as well. On the other hand, another target of ours is to use an oil fraction rich in aromatic hydrocarbons to make the alkylation process environmentally and economically efficient. It is known that the reforming process is one of the most important petrochemical processes. It is also known that the products are being used to produce high-octane gasoline. On the other hand, this process is being used for the synthesis of individual aromatic hydrocarbons, namely benzene, toluene, and xylenes. Additionally, it is clear that multi-stage rectification and purification processes are carried out to obtain these individual aromatic hydrocarbons. The main purpose of our research was not to use the individual aromatic hydrocarbons obtained as a result of this multi-stage synthesis, but instead to use the fraction obtained directly from the reforming process. We used both aromatic hydrocarbons and RPF to have a comparative investigation. Summarizing our opinion, we should note that the scientific innovation in our research is obtaining new regulated ionic liquid catalytic systems for alkylation processes of C6–C8 aromatic hydrocarbons with C6–C12 olefins and the use of oil fractions rich in aromatic hydrocarbons obtained from the reforming process as a primary component. The results of this research have been presented in the article.

Experimental part

All experimental work on the synthesis of IL used in alkylation processes and catalytic processes was carried out using solvents, which were calcined in an inert environment (nitrogen, argon) with the use of starting reagents purified by distillation or recrystallization before experiments.

The following reactants are used in the research work:

-

I.

Olefin (as an alkylating agent)

Hexene–1 (C6H12), octene–1 (C8H16), decene–1 (C10H24)—(Alfa Aesar/A Johnson Matthew Company (Germany)) used as components in alkylation processes, colorless liquids with specific pungent smell;

-

II.

As catalytic systems

-

(a)

Aluminium chloride (AlCl3) used as a catalyst and component for obtaining IL, colorless trigonal crystals;

-

(b)

Triethylamine hydrochloride (C6H15N × HCl) and pyridinium chloride (C5H5N × HCl) (Alfa Aesar/A Johnson Matthew Company (Germany)) used as a component for synthesizing IL;

-

(c)

(Nano)metal-polymer composite (NMPC) was used in the catalytic system as a modifier. NMPC was obtained by chemical thermolysis, Zn(CH3COO)2 was added onto low-density polyethylene and Zn/ZnO containing composites were prepared on the polymer matrix as a result of thermolysis at 180–200 °C temperature. Zn/ZnO comprised 2% weight in the polymer matrix; [12]

-

(d)

Zinc chloride (ZnCl2) was used as a component in the composition of the ionic liquid. Zinc chloride (ZnCl2), of which nine crystalline forms are known, is colorless or white, and is highly soluble in water;

-

III.

As aromatic hydrocarbons and oil fractions rich in aromatic hydrocarbons

-

(a)

Ortho-, meta-, para-xylenes (C8H10) (Alfa Aesar/A Johnson Matthew Company (Germany));

-

(b)

A liquid fraction obtained from the reforming process (RPF) and liquid fraction obtained from the pyrolysis process (PPF) rich in aromatic hydrocarbons were used as components in alkylation processes. RPF and PPF were separated into narrow fractions (fr.).

RPF

I fr.: 60–80 °C (10.2%); II fr.: 80–92 °C (11.5%); III fr.: 90–110 °C (9.1%); IV fr.: 110–120 °C (11.3%); V fr.: 120–138 °C (19.6%); VI fr.: 138–150 °C (9.7%); VII fr.: 150–172 °C (15.5%); VIII fr.: > 172 °C (4%) fractions. Conditionally, these were called II fr. benzene of reforming fraction (RFB), IV fr. toluene of reforming fraction (RFT), V fr. xylene of reforming fraction (RFX).

PPF

I fr.: 32–80 °C (28%); II: 80–90 °C (14.9%); III: 90–100 °C (10.7%); IV: 100–125 °C (10.5%); V: 125–145 °C (14.5%); VI: 145–200 °C (20.5%) fractions. Conditionally, these were called II–benzene of pyrolysis process (PPB), IV – toluene of pyrolysis process (PPT), V–xylene of pyrolysis process (PPX).

Chloroaluminate IL was prepared by interacting complex ammonium salts (triethylamine hydrochloride—TEAHX, pyridine hydrochloride–PHX) with AlCl3 taken at molar ratios 1:1.5 ÷ 2. Synthesis of the ILCS and also alkylation processes were carried out in glass reactor dried up in drying oven and in dry nitrogen or argon atmosphere. To that end, the reactor was carefully vacuumed by warming up under nitrogen current before the preparation of the complex catalyst. Then, after cooling to room temperature, the corresponding amine was added to it. Measured quantities of AlCl3 were added onto dried amine hydrochloride (TEAHC or PHC) and the exothermic process was observed within a few minutes. Consequently, yellowish viscous IL was obtained.

It is known that the acidic and basic properties of chloraluminate ionic liquids depend on the molar ratio of cations and anions contained ionic liquids. We noted that to increase the acidity of IL, the amount of AlCl3 has to be taken much more than amine. It is true that when the ratio of AlCl3 to amine is 1:1, the ionic liquid becomes neutral and the efficiency of the reaction decreases. In the alkylation process, 1.7:1 was used as the optimal variant as the ratio of AlCl3 to an amine. It is believed that [Al2Cl7]− or [Al3C10]− anions are available in acidic ILCS presenting high activity only in the TEAHX/AlCl3 > 1.5 or PHX/AlCl3 > 1.5 ratio based on investigated kinetic regularity [8, 17] and only these anion-containing ionic liquids can be active in the processes of alkylation and oligomerization. Before each alkylation and oligomerization process, different types of ILCS are obtained depending on the ratio of the complexes:

Glass reactor dried up in drying oven was carefully vacuumed by warming up under a nitrogen current before preparation of the catalyst. A certain amount of IL and NMPC was added in an inert atmosphere, then fractions with aromatic compositions were added, and finally, olefin was added through a dropping funnel. Experiments were carried out at the temperature of 60 °C for 1–3 h under constant mixing with a stirrer. The molar ratio of aromatic hydrocarbons to α-olefins was 2: 1. It is known that oligomerization occurs faster than alkylation. So, taking this ratio, as well as adding olefin to the drop-by-drop to the reaction medium, allows the reaction to proceed in a more alkylating direction. It is known that ionic liquids are suitable systems for two-phase catalysis. Our processes also take place in two-phase conditions, and the catalyst is separated from the reaction product by layering and filtered. To purify the reaction product from the catalyst, the product obtained is washed off with a 10% solution of the sodium hydrate and then washed off with distilled water until it neutralizes, then were dried up over calcined Al2O3. and stored in calcined A2O3 for 24 h, filtered and rectificated. No other organic solvents are used to clean oligoalkylate products. The recovery of IL is practically complete. The (oligo) alkylate sample is also analyzed and confirmed to contain no IL residues. The IL is washed with an inactive solvent (heptane or hexane), dried in a vacuum, cleaned from the solvent, and stored in an inert gas in a Schlenk flask and reused 3 times. In this case, the yield of (oligo) alkylate and the composition of the product are almost identical. However, after 3 times, the activity starts to decrease, in this case a certain dose of AlCl3 must be added to the IL for reuse. The reaction mixture was fractioned by simple distillation (< 200 °C) and vacuum distillation (> 250 °C) in nitrogen flow and weighed. Along with using of RPF which separates into narrow fractions (RFB, RFT, and RFX), alkylation processes were carried out with direct oil fractions, too. As direct oil fraction, RPFa, the boiling point of which was 38–172 °C, was used. Likewise, RPF, the boiling point of which was 60–145 °C, has been separated from RPFa and used as an alkylated component on alkylation processes.

Methods of analysis

Alkyl products were analyzed by NMR-, IR-, UV- spectroscopy, DSC and exclusion chromatography.

1H NMR spectra were recorded on a Bruker pulsing Fourier spectrometer (Germany) operating at the frequency of 300.18 MHz. Deuterated trichloromethane was used as a solvent.

The obtained AP were performed by IR – spectroscopy on the FT-IR-7600 spectrophotometer of «Lambda Scientific» (Australia). The samples taken for analysis are oily viscous liquids and were measured at room temperature and under atmospheric air conditions, in the range of 400–4000 cm−1 using a diamond support.

The aromatic nature of AP boiled at > 250 °C temperature were determined by UV/Visible spectrophotometer of “Jenway” (China).

Thermodynamic parameters of AP were measured on a Thermo electron Q-20 Differential Scanning Calorimeter (USA) at a heating rate of 20 °C/min in an air and nitrogen atmosphere. The differential thermal analysis (DTA) was performed on Q-1500 D, MOM derivatograph. Analysis processes were carried out at a temperature range of 20 ÷ 500 °C and in an air atmosphere. The rising speed of temperature was 5 °C / min.

Fluorescent Indicator Adsorption (FIA) is the analysis required to separate the hydrocarbon content of the obtained product. The process is carried out by Standhope—Seta 14060–OT (United Kingdom).

Molecular weight distribution (MWD) of obtained products and the parameters were studied by size exclusion chromatography method using high performance “Kovo” (Czech Republic) liquid chromatography with a refractive index detector and UV – spectrophotometric (λ = 254 nm) detector. Two 3.3–150 mm columns packed with the ‘‘Separon-SGX’’ stationary phase with a particle size of 7 mm and a porosity of 100 Ǻ were used. Dimethylformamide was used as an eluent (flow rate of 0.3 ml/min, temperature 20–25 °C). A calibration plot of log M versus VR in the range M = 2–100–102 was obtained using polyethylene glycol standards and transformed into the common dependence of fraction (%) of chains from their molecular weights. Calculations of the average molecular weights and MWD characteristics were made from the data of size exclusion chromatographic analysis following the procedure described in. Average molecular weights (Mw and Mn) were calculated using the following formulas:

where Mi is the molecular weight, corresponding to the ith slice of the chromatogram; ωi is the area fraction of the ith slice.

Density was defined using aqueous alcohol solution in the DMA 4500 M device.

The refraction index was defined by Abbemat 350/350 device.

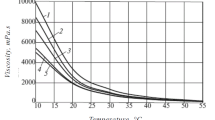

Kinematic viscosity (KV) at the 40 °C; 50 °C və 100 °C temperature on Stabinger SVM device, on ASTM D445 and because of these data were calculated coefficient of viscosity (CV) on ASTM D2270. Physical and chemical data of obtained AP were determined.

Results and discussion

In our study, along with oil fractions rich in aromatic hydrocarbons (RPF and PPF) the alkylation of α-olefins (hexene-1, octene-1, decene-1) with individual aromatic hydrocarbons (mainly xylenes) was carried out in the presence of ILCS and the results were compared. The regularities of the reactions carried out with individual hydrocarbons were also observed in the reactions carried out with RPF and PPF. Moreover, reactions to two-phase catalysis were carried out in this direction. It is known that the reactions occur on the surface of the IL. In this case, a diffusion equilibrium is formed and the reaction continues.[4, 10] In (oligo) alkylation processes, the reaction follows a similar situation. This confirms itself in both cases—when taking both individual hydrocarbons and RPF. The yields of AP are comperable. However, considering the corrosive ability of AlCl3 and because of economical considerations, it has been decided to reduce the amount of AlCl3 and replace a certain ratio of this with ZnCl2. On the other hand, “harder” acid-centered catalytic systems are being replaced by “softer” active centers. The changing of the nature of the active center allows to regulate the molecular parameters of AP. (Table 2) Furthermore, NMPC has been taken as a modifier in the composition of ILCS. In this case, although the yield of AP decreases, it is possible to regulate molecular parameters. The use of NMPC taken as a modifier improves the dispersibility of ILCS according to our investigations. This shows a great impact on two-phased catalytic systems. Moreover, the selectivity of the target product increases. The studies on the IL demonstrate that the investigations carried out in this field are of current interest and have a wide scientific and practical significance. At the same time, the reduction of the used amount of IL and the absence or a strong limitation of IL can contribute to significant consequences from an economical point of view. It was also possible to recycle the catalytic system by recovering the IL phase and reusing it in the next cycles with moderate results. The yields of the products and the conditions of alkylation of a liquid fraction rich in aromatic hydrocarbons and individual aromatic hydrocarbons obtained from the reforming process (RPF) and the pyrolysis process (PPF) with α-olefins based on IL were illustrated in Table 1.

In this table alkylation processes carried out in the presence of pure IL and NMPC has been presented and results of experiments carried out with individual aromatic hydrocarbons and RPF and PPF is compared. It is obvious that individual aromatic hydrocarbons are much more reactive than oil fractions rich in aromatic hydrocarbons (RPF and PPF). This originates from olefins and substances containing iso-structural substituted aromatic hydrocarbons in the oil fractions. So this influences the rate of a chemical reaction and the yield of AP. Likewise, all these opinions were proved by our investigations and the results were presented in Table 1. On the other hand, it is shown from the Table 1 that using RPF without separation into narrow fractions (RFB, RFT, and RFX) increases the yield of AP (> 70% weight) significantly in the concentration of 1–3% AlCl3 and the presence of [(C2H5)3NH]+[Al2Cl7]−, compared to using the narrow fractions of RPF and PPF. After the third re-use of AP 14, the yield of which is 94%, as shown in Table 1, the yield falls to 75%.

According to the results of the analysis, the RPF (80–145 °C) fraction contains up to 60% of aromatic hydrocarbons. It is known that due to the presence of this oil fraction, it contains not only aromatic hydrocarbons but also non-reactive aliphatic hydrocarbons. Of course, when RPF is divided into narrower fractions (RFB, RFT, RFX), they also contain other non-reactive hydrocarbons. Therefore, compared to pure individual hydrocarbons, the yield is reduced in this case. However, when RPF is used directly, it has a synergistic effect due to the presence of various aromatic hydrocarbons, and the yield of AP increases. The yield of AP increases up to 80%. Therefore, economically and ecologically, it is more acceptable to use RPF directly. Our main goal is to use RPF directly, too. Furthermore, because of less viscosity and flowing ability, the use of the TEAHX IL leads to an increase in the yield of AP impressively compared to the PHX IL. But high viscosity of PHX influences to the diffusion factor in alkylation processes.

On the other hand, because of the existence of olefins the use of PPF is not recommended for alkylation processes, therefore a dramatic decrease in the yield of AP (< 35% weight) was observed. During this process mainly oil polymer resin (OPR) (> 70% weight) was obtained through the use of PPX. It has been shown from researches that PPF and their narrow fractions can be recommended in producing OPR.

-

(1)

The definition of AP via spectroscopic methods.

The IR – spectroscopy of samples obtained as a result of AP has observed the following absorption bands: 691 cm−1 and 725 cm−1 deformation pendulum vibration of C – H bond which belong to aromatic hydrocarbons; 1033 cm−1 and 1079 cm−1 flat deformation pendular vibration of C-H bond; 1803 cm−1, 1860 cm−1 and 1943 cm−1 common deformation pendular vibration of C-H bond; deformation (1494 cm−1) and valent (3026 cm−1) pendular vibration of C-H bond of the aromatic ring; 1603 cm−1 valent pendular vibration of C=C bond of the aromatic ring; deformation (1380 cm−1, 1456 cm−1) and valent (2870 cm−1, 2920 cm−1) pendular vibration of C-H bond of methyl groups. IR spectrums of a heavy faction of AP (Tboil. > 250 °C) are similar and appropriate to their substituted aromatic hydrocarbons. It should be noted that, substituted groups in the aromatic chain are also isostructural and absorption bands of these groups prove this opinion by IR – spectroscopy (1304 cm−1). Some IR–spectroscopies of RPF and AP obtained based on RPF results were illustrated in Fig. 1.

RPF, and based on it, the obtained AP were analyzed comparatively by UV–spectroscopy. It has been shown that high intensity and 2 characteristic absorption bands of mononuclear aromatic hydrocarbons (basically benzene, toluene and xylene) were observed in 198 nm and 200 nm regions in UV spectra of RPF. Likewise, intensive peaks were observed in 201 nm and 204 nm regions in UV spectra of AP. Thus, hypsochromatic shifts were observed because of RPF.

The results of the definition of the structural parameters of products by 1H NMR spectroscopy method, which were obtained from the alkylation of RPF with C6–C12 α-olefins are consistent with the data of IR spectral analysis. In 1H NMR spectra of all synthesized AP the resonant absorption band of the protons of methyl (0.98 ppm), methylene (1.28–1.3 ppm) and methine (1.4–1.7 ppm), corresponding to the chemical shift of the protons in the alkyl group, appears. In the 1H NMR spectra weak bands of protons of the methylene groups (5.0—5.5 ppm) with CH=CH2, and vinylene (4.5—5.7 ppm) CH=CH groups appear, indicating a small number of double bonds in the composition of the products obtained. At the same time, multiple signals corresponding to the substituted aromatic rings were observed in 6.8–7.9 ppm region. The triplet bands corresponding to the aromatic rings were observed in 1H NMR spectra of AP in 7.39 ppm, 7.29 ppm and 7.16 ppm regions. It has been determined that the state of bands and integral dependence belong to a different alternative phenyl group, so 7.39 ppm corresponded to ortho-substituted, 7.29 ppm corresponded to meta-substituted and 7.16 ppm corresponded to para-substituted. It is shown from Fig. 2 that the nature of multiplet signals belonging to aromatic hydrocarbons of RPF and AP have been changed.

As mentioned above, according to the 1H NMR images of AP 18 (Fig. 2b) and AP 28 (Fig. 2c) aromatic hydrocarbon signals are present at 7.39, 7.29 and 7.16 ppm. They differ from each other because of the nature of multiplet signals. This means that the addition of NMPC to the catalytic system has some effect on the direction of the reaction, and the structure of the aromatic product changes to some extent during alkylation process.

Thus, the results of IR-, UV- and NMR- spectra indicate the presence of alkyl aromatic compounds in the heavy fraction of AP (Tboil > 250 °C).

Depending on the rise of temperature, change in the speed of heat flux in the DSC curves were observed. It can be seen from the DSC curve of RPF that an endothermic peak with an initial temperature (Ti) – 99.00 °C, maximal temperature (Tm) – 125.61 °C and last temperature (Tl) – 137.16 °C was observed. This process corresponds to the boiling temperature of RPF and its enthalpy (ΔH) is 59.03 J/g. Additionally, an endothermic peak belonging to RPF was observed in the DSC curve of the product obtained in the alkylation of RPF with decene-1. AP is stable about 227.20 °C and Ti = 266 °C, Tm = 290.16 °C, Tl = 325 °C; ΔH = 42,99 J/g. An exothermic peak was observed in the DSC curve of the product obtained in the alkylation of RPF with hexene − 1, AP is stable about 153.24 °C and Ti = 236.5 °C, Tm = 247.50 °C, Tl = 265 °C; ΔH = 15.22 J/g. Additionally, exothermic peak was observed in the DSC curve of AP obtained in the alkylation of RFT with hexene-1, AP is stable about 172.73 °C and Ti = 215.43 °C, Tm = 250.79 °C, Tl = 305.75 °C; ΔH = 76,74 J/g. The DSC researchers of AP (> 250 °C) defined that, obtained products are generally thermostable around 190 °C. The results have been illustrated in Fig. 3.

It is known that molecular characterizations are some of the important data to obtain various products, including AP. For AP according to the size exclusion chromatography, the following parameters were determined Mw = 302–1372; Mn = 260–1125; Mw/Mn = 1.05–1.28. Also an average numeral functionality (fn) was calculated based on molecular data of the obtained reaction products. According to the value of the fn it was determined that alkylate products with di- and tri-(oligo)alkyl aromatic fragments and oligomeric macromolecules without aromatic rings were obtained in the process. Thus it can be reasonably assumed that the following types of macromolecules are formed in the studied reaction: I–Ar- (Ol)n; II–Ar- (Ol)n-Ar; III–(Ol)n. The formation of the Ar-(Ol)n-Ar structure in these processes is presumed based on the analysis of exclusion chromatography. Based on the molecular parameters of (oligo) alkylates, their average numeral functionality (fn) was determined for aromatic fragments. When the average numeral functionality for aromatic groups is higher than one (fn ≥ 1), it can be assumed that the AP also contains fractions with functionality fn = 2, in other words, dimeric and tetrameric oligomeric chains with two aromatic finite fragments type–Ar- (Ol)n-Ar, where n = 2–4. These data change, when is used various ILCS. We assume that when both the alkylation and oligomerization processes take place at the same time, the double bond in the substituent is exposed to re-alkylated and this structure can be formed. Molecular characterizations of obtained AP were illustrated in Table 2. The names of the AP correspond to Table 1.

Regularities are followed for both yields and molecular parameters. The yield was 90% for individual hydrocarbons and 80% for RPF. The data have been illustrated in Table 1 and in the diagram. According to the exclusion chromatography, for individual hydrocarbons Mw–345–780, Mn–286–630, Mw/Mn–1.11–1.24, for oil fraction Mw–355–1372, Mn–281–1125, Mw/Mn–1.05–1.22. The results have been presented in Table 2. The regularity of the reaction refers mainly to these parameters. As individual hydrocarbons, we have taken benzene (80,1 °C), toluene (1106 °C) and xylenes (o–xylene—144 °C, m-xylene–139 °C, p-xylene–138 °C) in our research, and accordingly, as an oil fraction the boiling point of RPF rich in aromatic hydrocarbons, is 80–145 °C. The boiling point of the oil fraction is close to the boiling point of individual aromatic hydrocarbons. Molecular parameters were regulated depending on the reaction conditions and the selection of the optimal composition of ILCS. The results prove that, is possible to obtain important petrochemical alkyl aromatic products with preassigned properties and structures in the presence of ILCS in the future.

Fluorescent Indicator Adsorption (FIA) was used to more accurately study the hydrocarbon content of the obtained AP and to determine the effect of the composition of ILCS on it. FIA analysis is considered informative for more accurate study of the composition of (oligo) alkylates. The results are presented in Table 3.

According to the results of FIA analysis, the addition of NMPC and ZnCl2 orient the process in a more alkylating direction. In this case, the composition of the reaction product changes and becomes more homogeneous. No paraffin was found in these samples.

It is known that along with the process of alkylation of aromatic hydrocarbons with α-olefins, oligomerization of α-olefins also occurs. Because of this issue, the term ‘(oligo)alkylation’ has been used by academician A.H.Azizov in the early 80s [5, 6, 10]. To lead the process more to the direction of alkylation, the amount of aromatic hydrocarbons is taken more than the olefins. In our research, we also have taken the molar ratio of aromatic hydrocarbon to olefins as 2:1. Using ZnCl2 and NMPC in the catalytic system can change the direction of the reaction. To replace a certain ratio of AlCl3 with ZnCl2 causes the reaction to be carried out in a “softer” condition. It is known that Fridel-Crafts alkylation occurs very rapidly in the presence of more reactive AlCl3. IL plays an important role and leads to regulate the direction of this reaction. It is known that reactions occur on the surface of IL. In this case, a diffusion equilibrium is formed and the reaction continues. We have conducted this research in our previous work. More research on oligomerization has also been conducted on the probable mechanism.

It is known that in these processes, along with alkylation in the presence of IL, oligomerization of olefins (dimerization, trimerization, etc.) occurs. In each case, 100% conversion of the olefin is observed. Olefin is used for both alkylation and oligomerization. Obviously, the obtained (oligo) alkylates have a boiling point above 250 °C. According to the result of various analyses, the olefins determined in these samples are clearly higher olefins. The presence of higher α-olefins has been determined by many analytical methods:

-

1.

The signal intensity of CH2 groups in a long aliphatic chain increases according to 1H NMR.

-

2.

The signal intensity of CH2 groups in the long aliphatic chain increases according to IR—spectral analysis.

-

3.

According to the exclusion chromatographic analysis, oligomeric macromolecules without aromatic rings were obtained in the process. It is known that 2 detectors have been used in this method. The first detector measures the refraction of the total product (both oligomeric and alkylaromatic compounds), and the second detector measures ultraviolet signals (obviously, it especially determines alkylaromatic compounds). A comparison of these two indicators shows that along with aromatics, oligomeric products are also obtained in the product.

-

4.

FIA analysis shows that along with aromatic hydrocarbons, the total product contains higher olefins.

It should be noted that, compared to individual aromatic hydrocarbons, there are specificities of RPF for alkylation processes. Comparative analysis of the alkylating process with RPF rich in aromatic hydrocarbons and individual aromatic hydrocarbons was studied and similar results were achieved (Fig. 4). It has been proven that alkylation process can be carried out in the presence of ionic liquid catalytic systems and modifiers using direct oil fractions. As ILCS, TEAHC IL (IL synthesized from triethylamine hydrochloride and AlCl3), PHC IL (IL synthesized from pyridinium chloride and AlCl3), TEAHC IL+ZnCl2 and PHC IL+ZnCl2 were used. The diagram illustrates the comparative analysis of alkylation process of α-olefins carried out with individual aromatic hydrocarbons and RPF in the presence of different catalytic systems.

As mentioned above, the chief value of alkyl aromatic components lie in their wide range of applications. One of them is the use of AP as an additive for various oils and polymer composites. To find a valuable application field for the obtained AP, some of their properties have been studied. The physical and chemical parameters of the obtained alkylates were also compared. According to some analysis results, the viscosity indices of obtained APs (Tboil. > 250 °C) were between 51–96.3, freezing points between minus 62 °C–minus 45 °C, densities between 0.8681 and 0.8686 and refraction indices between 1.4906 and 1.4964. It has been determined that because of their low freezing temperature, the obtained AP can be used as valuable petrochemical products in refrigeration and lubrication systems.

Furthermore, the obtained AP have been tested as a plasticizer additive in the composition of polyolefin composites. The thermophysical properties of various polyolefins and compositions based on AP were determined. In each case, a drop in the melting point of the initial polyolefin matrix down to 20–30 °C has been determined. It should be noted that in this circumstance the rheological properties of the polymer composite can be improved and easily processed. The composition of composites was determined by IRS, SEM, DSC, TQ, RFA and other methods. It has been shown that different polyolefin-AP composites can be used as different polymeric materials, including phase transition materials in the future [16]. The plasticizing effect of alkylate in the product was the same when we use recovered IL in the next alkylation.

Conclusion

In summary, according to the comparative analysis of the alkylating process with RPF rich in aromatic hydrocarbons and individual aromatic hydrocarbons and obtained close results, the alkylation process can be carried out in the presence of ILCS using direct oil fractions. Ionic fluids are accepted ecologically and economically and can be reused successfully in these processes. This is shown that technological schemes can be created by doing a few changes (such as alkylation device related to reforming device) based on these processes in the future. The chosen catalytic systems contribute to regulating thermophysical, physicomechanical, molecular properties, etc. of obtained samples and acquiring alkylate products. Because of their low freezing temperature, obtained AP can be used as a valuable petrochemical product in refrigeration and lubrication systems. AP has been tested as a plasticizer additive, polyolefin-AP composites can be used as different polymeric materials, including phase transition materials in the future.

References

Aliyeva RV, Mamedova EM (2015) Oliqomerizasiya fraksii C3–C4 kataliticheskoqo krekinqa v prisutstvii ionno–jidkostnix i polimernikh kataliticheskikh sistem. Pyataya mejdunarodnaya konferensiya–shkola po khimii i fiziko khimii oliqomerov, 1–6 iyun, Volqoqrad, Rossiya, 72 (In Russian)

Aliyeva RV, Mamedova EM, Seidova KhG, Karayeva EM, Klalil KhS, Azizbeyli EI (2016) (Oliqo)alkilrovanie benzola i toluola C6–C12 α-olefinami v prisutstvii ionno – jidkostnix kataliticheskikh sistem. Prioriteti mirovoy nauki: eksperiment I nauchnaya diskussiya. X Mejdunarodnaya Nauchnaya Konferensiya Severniy Charlston, Yujnaya Karolina, SShA, 17–18 fevralya, 8–13. (In Russian)

Aliyeva RV, Mammadova YM, Bagirova ShR, Yusifov YH, Gasimova LKh (2017) Thermophysical properties of (oligo)alkylate products obtained in the presence of ionic liquids. In: 6th Rostocker International Conference: Thermophysical Properties for Technical Thermodynamics”, 17–18 July, Rostock, Germany.

Azizov AG, Asadov ZG, Akhmedova GA (2010) Ionnie jidkosti i ikh primenenie. Elm, Baku

Azizov AH (2009) Some aspects of organometallic catalysis of oligomerization and polymerization processes. Elm, Baku

Azizov AV (2010) Studies in the field of metal-cationic and carbocationic catalysis of oligomerization and polymerization prosesses ( selected papers). Elm, Baku

Azizov AH, Aliyeva RV, Seidova KhH (2013) Oligoalkylnaphtenic (C6–C12) oils obtained in the presence of Ti-containing ionic-liquid catalysts. Green Sustain Chem 3:18–26. https://doi.org/10.4236/gsc.2013.34A004

Azizov AH, Aliyeva RV, Seidova KhH, Jafarov RP et al (2014) Kinetic regularities of oligomerization of decene-1 in the presence of the ionic liquid of chloraluminate type. Am J Chem Mater Sci 1(3):18–23

Azizov AH, Aliyeva RV, Seidova KhH et al (2015) Oligomerization and alkylation decene-1 in the presense chloroaluminate ionic liquids. Am J Chem Appl 2(3):21–26

Azizov AH, Aliyeva RV, Kalbaliyeva ES, Ibrahimova MJ (2010) Selective synthesis and the mechanism of formation of the oligoalkylnaphthenic oils by oligocyclization of 1-hexene in the presence of ionic-liquid catalysts. Appl Catal A 375(1):70–77. https://doi.org/10.1016/j.apcata.2009.12.019

Azizov AG, Aliyeva RV, Mamedova EM, Bagirova ShR, Seidova KhG (2016) (Oliqo)alkilirovanie fraksii Bakinskikh neftey C6–C12 α-olefinami v prisutstvii ionnikh jidkostey. Aktualniye problemi neftekhimii, V Rossiyskaya konferensiya, 18–21 oktyabrya, Zveniqorod, Rossiya, pp 165–166 (In Russian)

Aliyeva RV, Azizov AH, Gehremanov NT ve b. (2011) Metal—polimer nanokompozitlerin alinma usulu, Azerbayjan patenti İ2011 0058 (In Azerbaijani)

Babashova YM, Eliyeva RV, Bagirova ShR, Seyidova KhH, Gasimova LKh (2018) Trietilammonium xloraluminat ion mayesi ishtirakinda alinan (oliqo)alkilatlarin DSK vasitesile tedqiqi. Elmi Kheberler Ganja 3(26):28–34 (In Azerbaijani)

Babashova YM, Veliyeva FM, Eliyeva RV, Ezizbeyli HR, Khelil KhS (2018) Aromatik karbohidrogenlerin α-olefinlerle ion mayeleri ishtirakinda alkilleshme proseslerinin optimallashdirilmasi Elmi eserler. Azerb Tekhniki Univ 4:93–100 (In Azerbaijani)

Babashova YM (2020) (Oligo)alkylates obtained in the presence of ionic liquids. Process Petrochem Oil Refin 21(3):326–333

Babashova YM (2020) Neft fraksiasindan alinan (oligo)alkilatlar ve poliolefinler esasinda kompozitlerin istilik-fiziki xasselerinin tedqiqi. J Azerb Oil Ind 04:61–66. https://doi.org/10.37474/0365-8554/2020-4-61-66 (In Azerbaijani)

Bordoloi A, Devassy BM, Niphadkar PS, Joshi PN, Halligudi SB (2006) Shape selective synthesis of long chain linear alkyl benzene (LAB) with AlMCM-41/Beta zeolite composite catalysts. J Mol Catal A 253:239–244. https://doi.org/10.1016/j.molcata.2006.03.045

Campisciano V, Giacalone F, Gruttadauria M (2017) Supported ionic liquids: a versatile and useful class of materials. Chem Rec 17:1–22. https://doi.org/10.1002/tcr.201700005

Aduri P, Parasu VU, Kotra V, Sakhalkar M et al (2019) Ionic liquid compound for catalysis of chemical reactions, CA 2909562A1

Chabakova AK, Shepetova EV, Abdurakhmanovaq NM (2018) İonnie jidkosti v orqanicheskom cinteze. Uspekhi Sovrem estestv 12(1):216–226. https://doi.org/10.17513/use.37000

Chen H, Guohua L, Xin X, Yanli W, Jiajia X (2013) Et3NHCl-AlCl3 ionic liquids as catalyst for alkylation of toluene with 2-chloro-2-methylpropane. China Pet Process Petrochem Technol 15(1):54–60

Chunsheng LV, Yan Z, Yunfei X et al (2012) Synthesis of high performance lubricating oil with alkylation of decene and benzene catalyzed by ionic liquid. Acta Pet Sin 28(6):1025–1030. https://doi.org/10.3969/j.issn.1001-8719.2012.06.022

De Castro C, Sauvage E, Valkenberg MH et al (2000) immobilised ionic liquids as lewis acid catalysts for the alkylation of aromatic compounds with dodecene. J Catal 196:86–94. https://doi.org/10.1006/jcat.2000.3004

Martins, Des Plaines SC, et al (2019) Alkylation process using Phosphonium—Based Ionic Liquids, EP 2 864 277 B1

Driver M, Campbell CB, Harris TV (2015) Method for producing alkylated aromatic compound using acidic ionic liquid catalyst, JP 5748406B2

Memmedova YM, Eliyeva RV, Garayeva EM (2017) Aromatik karbohidrogenlerin ion maye tipli kompozit katalitik sistemlerin ishtirakinda (oliqo)alkilleshme prosesleri. Sumgayit Dovlet Univ Elmi Kheberler 17(4):31–37 (In Azerbaijani)

Mohammad A, Inamuddin D (2012) Green solvents II: properties and application of ionic liquids. Springer Science Business Media Dordrecht, Berlin

Olivier-Bourbigou H, Magna L, Morvan D (2010) Ionic liquids and catalysis: recent progress from knowledge to applications. Appl Catal A 373:1–56. https://doi.org/10.1016/j.apcata.2009.10.008

Patra T, Ahamad S, Upadhyayula S (2015) Highly efficient alkylation of phenol with tert-butyl alcohol using environmentally benign Bronsted acidic ionic liquids. Appl Catal A 506:228–236. https://doi.org/10.1016/j.apcata.2015.08.031

Qiao C, Yonghong C, Quanhui G (2008) Benzene alkylation with long chain olefins catalyzed by ionic liquids: a review. Front Chem Eng China 2(3):346–352. https://doi.org/10.1007/s11705-008-0045-9

Skoda-Földes R (2014) The use of supported acidic ionic liquids in organic synthesis. Molecules 19(7):8840–8884. https://doi.org/10.3390/molecules19078840

Liu et al (2015) Alkylation method using Ionic Liquids as catalyst, US 9,096.487 B2

Riley et al (2016) Benzene alkylation using acidic Ionic Liquids, US 2016/0009612 A1

Xinyu L, Wang W, Sun Y, Zhao Q, Qiu T (2019) Ionic liquids catalyzed friedel-crafts alkylation of substituted benzenes with CCl4 toward trichloromethylarenes. Catal Lett 149:665–671. https://doi.org/10.1007/s10562-018-2633-8

Xuewen S, Suoqi Z (2011) Revealing the catalytic mechanism of an ionic liquid with an isotope exchange method. Pet Sci 8:495–501. https://doi.org/10.1007/s12182-011-0167-4

Zazybin AG, Rafikova Kh, Yu V, Zolotareva D, Dembitsky VM, Sasaki T (2017) Metal-containing ionic liquids: current paradigm and applications. Russ Chem Rev 86(12):1254–1270. https://doi.org/10.1070/RCR4743

Acknowledgements

This work was performed within the "Polymerization catalysts" laboratory of the Institute of Petrochemical Processes named after acad. Y.H.Mammadaliyev of Azerbaijan National Academy of Sciences. We gratefully acknowledge to prof. Ph.D. B.M.Aliyev, Ph.D. S.F.Ahmedbeyova, L.Kh.Gasimova, S.A Alizadeh, R. Alizadeh for their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors state that there are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Aliyeva, R.V., Babashova, Y.M., Khamiyev, M.J. et al. The alkylation of oil fractions rich in aromatic hydrocarbons with C6, C8 and C10 α - olefins in the presence of ionic liquids catalytic systems. Appl Petrochem Res 11, 65–77 (2021). https://doi.org/10.1007/s13203-020-00258-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-020-00258-4