Abstract

A heterogeneous spent soda effluent generated from Tunisian petroleum refineries has been filtrated and separated in four solid fractions with a particle diameter of 160 to 100, 100 to 40, 40 to 16 and 16 to 10 µm and the fifth one with diameters < 10 µm obtained after total evaporation of the remained filtrate. Spectroscopic characterizations of the condensed phases by means of X-ray induced photoelectron and IR absorption, as well as pH-metry, potentiometry and stationary voltammetry at Ag2S/Ag electrode studies of the filtrate, show that the whole of the separated fractions contain Na2S, NaHS, C2H5SNa, Na2S2O3, Na2SO3 and methyl, ethyl and propyl mercaptans.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

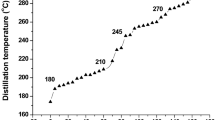

To comply with the standards, gasoline and LPG (liquefied petroleum gas) fraction resulting from the distillation of petroleum must be free of sulfur compounds, such as H2S, mercaptans R-SH (R: CH3–, C2H5– …) and disulfides. To eliminate them, the action of NaOCl or by Cl2 is an essential step [1], leading to the generation of organochlorine compounds, environmentally harmful. The use of H2O2 as a washing solution entails additional costs due to the decomposition of the hydrogen peroxide caused by the transition metals [2]. Although the caustic soda washing of these fractions in Fig. 1 is a well-adapted and economical method, it is highly polluting [3, 4]. The waste solution is very far from the standards of rejection; consequently, its storage constitutes a crucial and important problem, especially if its composition is not well known. Our aim in this work consists to determine the chemical composition of soda waste solution generated from the contact of aqueous sodium hydroxide with hydrocarbon streams in Tunisian petroleum refineries.

Materials and methods

Samples of soda ash were supplied from one of the underground storage basins of the Tunisian refinery station. HCl (37%), AgNO3 (99.5%), Na2S (60%) and K2SO4 (99.9%) were purchased from PROLABO. C2H5SH (99%) and NH4OH (25%) were purchased from ACROS. FTIR-ATR characterizations were performed using a Perkin-Elmer Spectrum 100 FT-IR Spectrophotometer. XPS spectra were recorded using an electron spectrometer with a nonmonochromatized Al–Kα radiation source of 200 W (15 kV) and a hemispheric electron analyzer equipped with nine Channeltron electron multipliers. After the survey, spectra were obtained, and higher resolution scans were performed at pass energy of 1.12 eV. The intensities of the different contributions were obtained by integrating each peak after eliminating the S-shaped baselines and adjusting the experimental curves to a combination of Lorentz (30%) and Gaussian (70%) lines. All the binding energies were compared to that of the line of the C1s of 284.4 eV, obtaining values with a precision of ± 0.2 eV. The elemental analysis was performed using a Carlo Erba EA1108 device equipped with an autosampler.

Cyclic voltammetry experiments were carried out in a conventional three-electrode cell under N2 atmosphere. The working electrode was Ag2S/Ag sphere (Radiometer), and a platinum wire was used as the counter electrode as well as sulphate electrode (se). Potentials were measured against Saturated Calomel Electrode (SCE) immersed in the same electrolyte through a Luggin capillary. Cyclic voltammograms were recorded at a constant sweep rate. A Methrohm Millivoltmeter Mettler Toledo-MP 220 was used for the pH-metric measurement, the constant sweep rate is 0.2 mL/min. Gran's method allows us to accurately determine the equivalence points of the obtained curves [5].

Results and discussion

Samples of approximately 1023 g of soda ash were vacuum filtrated using 4 glass frits with porosities comprised between 160 and 10 µm, leading to four solide samples, namely S1, S2, S3 and S4 and a homogeneous filtrate. From this filtrate, a volume of 10 mL leads to solid (S5), after total evaporation. Table 1 illustrates the solid mass and porosities. IR characterisations were undertaken for S1, S2, S3, S4 and S5. For technical reasons, solid S4 has been excluded from XPS analysis. While the remained filtrate was titrated using the pH-metric and potentiometric techniques and studied by means of the voltamperometric approach.

Characterisation of the solid phases

The solid phases were examined by XPS to analyze their surface compositions. Calibration of C1s from adventitious contamination set at 284.8 eV. Figure 2 shows the photoelectronic spectra of S1, S2, S3, and S5, revealing O1s, C1s and S2p signals. The latter one corresponds to unresolved doublets, indicating the presence of the sulfur element in an oxidized state. With Table 2 we can see those surface compositions and binding energies of S1, S2, S3, and S5; that S1, S2, S3, and S5 are majority constituted by carbon, sodium, oxygen and sulfur elements, which are the basic elements of the removed impurities from gasoline fractions and LPG during their washing by the caustic solution, while silicon, calcium, iron and boron are present as traces.

Figure 3 shows the deconvoluted S2p signals of S1, S2, S3 and S5 leading to A, B, C, D and E bands that the possible attributions are reported in Table 3.

From this table, sulfur in the form of Na2S2O3, Na2SO3, RS2O2R, RSOR, RSO3−, SO42− and S4O62− could be suggested. FTIR characterization was performed to confirm the XPS results. As expected, Fig. 4 that the major of the absorption bands are illustrated in Table 4 shows in addition to the hydroxyl band, from 3700 to 2700 cm−1, H–S band appearing from 2600 to 2400 cm−1. Moreover, a carbonate band is observed at around 1650 cm−1 and could be assigned to the presence of Na2CO3. Besides, a C–S band is observed in the region from 1440 to 1410 cm−1.

Besides, for S1, S2, S3, S4, and S5 the characteristic band's vibration of the CH2–S– group C–S bonds observed from 710 to 630 cm−1, indicating the presence of ethyl mercaptan substrate. Moreover, the appearance of a band around 660 cm−1 which could be linked either to the extensional vibration of the (C–S) bond in the CH3–S– group or to the extension of the (S–S) bond of the disulfides, allows us to deduce that all solids could contain either a salt of methyl mercaptan or a salt of a disulfide or both compounds. S1 also has elongation bands at 541 and 466 cm−1 which correspond to the (S–S) bond characteristic of the polysulfides. The solids S2 and S3 have bands that correspond to the elongation of the (S–H) bond, around 2463 cm−1. Their spectra also show, at around 1650 cm−1, the characteristic band of elongation vibration of the carbonyl group (C = O), as well as the band which is due to the stretching of the (C–S) bond, around 1440 cm−1. Vibration bands due to (S = O) bonds, both in sulfoxide SO2 and sulfate groups SO42 −, are also recorded, respectively, at wavelengths ranging from 1070 to 995 cm−1 and 700 to 600 cm−1. With regard to the solid S4, with the exception of the characteristic band of the S–H bond, we find all the other bands (C–S, S–S, S = O, and C = O) mentioned before. Finally, the solid S5 has all the bands described for the first three solid, this result,, therefore, allows us to assign the same composition as S1, S2, and S3. All of these results are in agreement with that found in XPS, thus confirming the fact that sulfur is present in different oxidized states in all of the solids fractions. These results indicate that the solids contain mainly mercaptans, disulfides and carbonate compounds such as Na2CO3 from the extraction of CO2 from LPG.

Filtrate analysis

It is worth mentioning that the study of the caustic soda effluent filtrate is also an important step. In this context, its pH-metric, as well as potentiometric titrations, have been undertaken.

The evolution of pH = f(VHCl) in Fig. 5 suggest the presence of different basic forms such as S2 −, RS−, CO32−, HS− in addition to hydroxyl ions. Using the method of Gran, lead us to conclude the concentration of basic compounds other than OH− [C] basic compounds = 2.238 mol L− 1. On the basis of the reported titration method, the effluent soda filtrate and two solutions of fresh caustic soda containing Na2S and C2H5SH having a concentration 10–1 mol L− 1 have been studied. Figure 6 shows there are three potential jumps which are located respectively around a volume of reagent titrant of 20 cm3 for the first (− 1235 mV at − 263 mV), 40 cm3 for the second (− 263 and − 107 mV) and 50 cm3 for the last jump (− 107 mV to + 60 mV). The first jump of potential which is quite important is relative to the dosage of the S2 − ions, whereas the second one can be attributed to the dosage of the HS− ions, which gives in the presence of Ag+ ions the AgSH complex, which can be transformed into Ag(HS)2−. In case of a solution containing only ethyl mercaptan, we observe two successive potential jumps, the first which is by far the most important, is due to the jump of potentiometric from − 1.05 V to − 0.075 V, it corresponds to a volume of silver nitrate solution of the order of 7 cm3. Subsequently, a second rather weak jump (≈ 0.050 V) appears after adding a volume of the order of 14 cm3 of the solution, after the second equivalence point the potential stabilizes at − 0.060 V. The intense peak observed is attributed to the assay of the existing C2H5S− anion in the solution. The rather weak peak could be due to the dosage of a more complex form.

The method steps the potentiometric dosage of the filtered washing solution gave three jumps of potential, we locate the first jump of potential, which corresponds to the passage of − 1091 mV to − 245 mV, to 40 cm3 of added solution. While the second jump which is less important (from − 245 mV to − 106 mV), corresponds to a volume of the order of 65 cm3. Finally, the third jump after which the potential stabilizes towards + 84 mV indicating the end of the dosage, appears around 97 cm3.

The comparison of the dosage curve of spent soda, on the one hand to those which correspond to the determination of sodium sulphide and ethyl mercaptans, on the other hand, to the method (UOP209-69 T) [15], allows us to conclude that the spent soda solution contains mainly sodium sulphide Na2S and mercaptans as ethyl mercaptans in the form of salt C2H5SNa. We can also estimate the presence of other mercaptans in the washing solution and which can be determined without being able to distinguish them on the curve of dosage. At the end of the dosage, the characteristic bad smell of the sulphides already present in the spent soda solution disappears completely.

To explain the shape of the curve ΔE = f (VAgNO3) plotted during the determination of the used soda solution, by potentiometry at zero current, we proposed to examine the variation of the current as a function of the potential imposed on a silver electrode covered with a deposit of Ag2S. This was then immersed in a series of three prepared solutions of sodium hydroxide with pH = 13, containing only sodium sulphide for the first, that of ethyl mercaptan for the second, to finally go to the filtrate. The shape of the curve recorded in contact with a solution of Na2S is illustrated in Fig. 6. By going towards the more negative potentials, this one is delimited by a wall of reduction which is manifested by a fairly important decrease of the current starting from a potential of the order of − 1.17 V. This potential barrier is due to the gain of an electron pair by the solid Ag2S of the indicator electrode following the half-reaction:

Towards the most positive potentials, and more precisely towards − 0.3 V, we are witnessing a rather rapid increase in current. This potential barrier corresponds to the loss of an electron by the silver element of the Ag2S/Ag electrode to form, in the presence of ammonia, the Ag(NH3)2+ complex according to the reaction mechanism:

[16]

Moreover, this curve presents two successive waves in oxidation. The first one, located around − 1.17 V, corresponds to the formation of silver sulphide (solid Ag2S), in this case, the silver forming the electrode oxidizes to combine with the sulphide ion which diffuses from the solution to the electrode and limit the current. The reaction mechanism of this step corresponds to the inverse of that of the reduction wall (reaction 1), we can write it as follows:

During this step, we consume the electrode metal that goes in the direction of the formation of Ag2S on the surface of the electrode. Now, the complete recovery of the latter causes the growth of the deposit to stop, since the interface between the two silver/silver sulphide electronic conductors can not be the seat of the electrochemical reaction. Also, we are witnessing a decrease in the current limit of this wave which is quite remarkable in Fig. 7.

At around − 0.60 V, we observe a rather complex variation of the anode current, which could be attributed to the diffusion of HS− ions towards the electrode to react with the silver of the electrode following the half reaction:

when assaying this solution with AgNO3 0.1 mol L− 1, the voltammetric study at the solid electrode of Ag2S/Ag, allows us to see, as soon as the ten first milliliters of the titrant reagent, the disappearance of the two oxidation waves due to the diffusion of ions S2− and HS−. As dosing progresses, we observe the variation of the potential at zero current (Ei= 0) which becomes more and more positive.We can deduce as qualitative predictions from this voltammetric study, that the potential at zero current undergoes a first jump from the first quantity of reagent titrant added (10 cm3), it then passes from − 1.17 V/at − 0.29 V. Subsequently, there is a second and a third potential jump since it goes respectively to − 0.1 V then 0.6 according to the volumes of Ag added. These variations seem quite comparable to those obtained during the potentiometric assay Fig. 6.

In Fig. 8, we have illustrated the potential current curve that characterizes the electrochemical behavior of an Ag2S/Ag solid electrode in the presence of a basic solution of ethyl mercaptan,[C2H5SH] = 10−3 mol L− 1, which we have prepared in our laboratory. On this curve we can see the presence of the reduction wall to − 1.13 V which is due to the reaction:

On the other hand, and since the solution is free of sulphide ions, the curve does not present the wave that we observed during the study of the Na2S solution:

which corresponds to the silver oxidation in the presence of S2 − ions. Subsequently, there is a fairly complex variation of the current as a function of the potential, especially with the appearance of a rather large peak to − 0.920 V. This behavior could be attributed to adsorption, and/or decomposition and/or oxidation of C2H5SH on the surface of the electrode. Such electrochemical processes, known by mercaptans, have been described in the literature [17, 18]. We have shown the curves i = f (E) recorded at each addition of 10 mL of titrant reagent. According to these, we note the disappearance of all the waves observed before the assay. Moreover, and although these curves have fairly complex paces, which may originate electrochemical behavior of adsorption, oxidation or decomposition of mercaptans, we can distinguish, when adding a quantity of reagent to the other, a variation of the potential at zero current. This one shows a look quite similar to that observed in potentiometry (Fig. 6), although the second potential-jump was not recorded.

In Fig. 9 we have shown the curve i = f (E) obtained by voltammetry at an Ag2S/Ag electrode in contact with the filtrate of spent soda, and whose pH was set at a value equal to 13. The latter presents a rather complex variation of intensity as a function of potential. The current passes by a peak then it decreases. This leads us to suggest the intervention of several rather complex electrochemical phenomena, such as oxidation reactions, adsorption or decomposition that the filtrate can manifest on the surface of the electrode. The recorded curve leads us to think that the content of the solution considered sulphide can only be important.

The determination of the washing solution with AgNO3 0.2 mol L− 1, which is followed by voltammetry, made it possible to draw the curves i = f (E) of Fig. 9. This shows quite different trends with, in particular, the disappearance of the peak of anodic currents to − 1.2 V that we observed just before the assay and which correspond to S2− ions. We are also witnessing the disappearance of the anode wave due to HS− ions, which should be located near − 0.6 V to 50 cm3 of added solution.

The curves of the curves i = f (E) are quite complex and difficult to interpret, although their evolutions present rather remarkable differences from one addition to the other of the titrant reagent. However, it seemed useful to determine the potential at zero current for the different dosage stages. This shows two jumps of potential whose volumes are quite close, since the first corresponds to addition between 80 and 90 cm3, while the second appears when the volume is located around an average value of 100 cm3. The curve shows a fairly similar appearance to that observed in potentiometry (Fig. 5). Indeed, although the determination of zero current potentials is not precise enough, at least two jumps of potentials are recorded.

All these results, obtained at the end of the study of the filtered solution of spent soda, show the presence of the S2 −, HS− ions as well as the mercaptans as sulfur-containing entities.

Nevertheless, it would be interesting to resume the voltammetric study at different stages of the assay by improving the operating conditions. In particular, using a solid electrode Ag2S/Ag rotating, replacing the magnetic stirring of the solution used in all of these studies.

Conclusions

The analysis of the content of the spent soda solution discharged by a petroleum refining station located in Tunisia required at the first stage of the work, separation by vacuum filtration, the solid phase of the liquid effluent solution. In a second step, we subjected the recovered solid and the filtrate to an analysis by various techniques such as X-ray induced photoelectron spectroscopy (XPS), IR absorption spectroscopy, PH-metry, potentiometry, and stationary voltammetry. These techniques show that solids (S1, S2, S3, S4, and S5) and liquid (the filtrate of spent soda) phases essentially contain carbon, sulfur, sodium and oxygen under various chemical combinations (Na2S, NaSH, C2H5SNa, Na2S2O3, Na2SO3, RS2O2R, RSOR); R is an alkyl group. All these compounds, contained in the rejected effluent, are undesirable because they constitute a source of pollution with harmful effects on the ecosystem.

References

Desodorization of effluents loaded with sulfur compounds by washing with hydrogen peroxide. Application to deodorisation of waste water treatment plants - OpenGrey [WWW Document], n.d. URL https://www.opengrey.eu/item/display/10068/879997 Accessed 10.15.20

Féliers C, Patria L, Morvan J (2001) A. Laplanche (2001) hydrogen peroxide in physico-chemical deodorizaton: the role of wash solution composition in H2O2 action. Rev Sci Eau 14:3

Li J, Li X, Liu Y, Zhang J (2016) Removal of mercaptans from light oils using ionic liquids-NaOH aqueous solution as extractants. Chin J Chem Eng 25:171

YW Gong, HX Liu, XN Cheng (2010) Petrol Sci Technol 28

Gran G (1952) Determination of the equivalence point in potentiometric titrations Part II Analyst. Anal Chem 77:661–670. https://doi.org/10.1039/AN9527700661

Siriwardane RV, Cook JM (1986) J Colloid Interface Sci 114

Littlejohn D, Chang SG (1995) J Electron Spectros Related Phenom 71

D. Briggs, M.P (1983) Practical Surface Analysis: By Auger and X-ray Photo-electron Spectroscopy 533

Holm R, Storp S (1976) Surface analysis of Ni/Al alloys by X-ray photoelectron spectroscopy. J Electron Spectros Related Phenom 8:139

CD Wagner, WM Riggs, LE Davis, JF Moulder, Handbook of X-ray photoelectron spectroscopy.

Brion D (1980) Photoelectron spectroscopic study of the surface degradation of FeS2, CuFeS2, ZnS and PbS in air and in water. Appl Surf Sci 5:133

RM Silverstein, GC Bassler, TC Morrill, Spectrometric identification of organic compounds, third édition.

Huanc CK, Konn PF, n.d. Infrared Study Of The Carbonate Minerals. Miiler and Wilkins.

NIST XPS Database, Selected Element Search Menu [WWW Document], n.d. URL https://srdata.nist.gov/xps/selEnergyType.aspx Accessed 10.15.20

Potentiométric analysis of used caustic solution. UOP Method 209–69T

F.Brénon-Audat, F.Rafflegeau, D. Prévoteau , Chimie inorganique et générale, 127.

Zhang J, Lever ABP, Pietro WJ (1995) Can J Chem 73(7):1072–1077

AN Radin, V Danyushevskii, Ya VS Bodganov, VI Kadentsev, LI Lafer et al. (1985) Bull Acad Sci USSR Div Chem Sci (Engl.Transl.) 34:1652–1655.

Acknowledgements

I warmly thank Mr. M.Rzaigui for hosting me in his lab, my co-supervisor Salma Besbes Hentati and to all the technicians of the science faculty of Bizerte. To be used for life science journals + articles with biological applications.

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors have participated in (a) conception and design, or analysis and interpretation of the data; (b) drafting the article or revising it critically for important intellectual content; and (c) approval of the final version. This manuscript has not been submitted to, nor is under review at, another journal or other publishing venue. The authors have no affiliation with any organization with a direct or indirect financial interest in the subject matter discussed in the manuscript. The following authors have affiliations with organizations with direct or indirect financial interest in the subject matter discussed in the manuscript.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Souilhi, A., Hentati, S.B. & Rzaigui, M. Characterization of the Tunisian petroleum refineries caustic effluent. Appl Petrochem Res 11, 39–47 (2021). https://doi.org/10.1007/s13203-020-00257-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-020-00257-5