Abstract

The oxidation of benzylic alcohols in the machine of microwave (Discover, CEM-SP1245 model, USA) by the composite material type Cr-(MCM41/ZSM5) with high crystallinity, exchanged at low content of chromium has dramatically reduced the reaction times and have high conversion rates and high yields compared to conventional heating. Ketones were obtained for only 10 min of reaction. The composite materials used containing both micropore and mesopore structures are stable for this type of reaction. The method uses composite materials Cr (50-MCM41/ZSM5) as the catalyst system and t-BuOOH as the stoichiometric terminal oxidant. The reactions carried out by the microwave and made without the use of an organic solvent, because, the substrates are mixed directly or, in our case, the subtract is mixed with silica which is inactive in the reaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The oxidation of primary and secondary alcohols to the corresponding carbonyl compounds is a fundamental reaction in organic synthesis (Sheldon and Korchi 1981; Ley and Martin 1991). Such transformations are most frequently accomplished by the use of Cr(IV)-based reagents in amounts ranging from stoichiometric to large excess (Cainelli and Cardillon 1984). Problems in the use of Cr(IV) complexes as oxidation reagents often crop up due to the lack of selectivity in oxidations, safety hazards associated with the use of large quantities of toxic chromium compounds and the need of aqueous acidic or basic conditions for reactions of chromate salts. In attempt to circumvent these problems, attention has been focused recently on the use of transition metal incorporated zeolites (e.g., TS1, VS1, etc.).

The first example of a redox molecular sieve was titanium silicalite-1(TS-1) developed by Enichem workers (Taramasso et al. 1983; Clerici 1991; Clerici et al. 1991; Romano et al. 1990) which proved to be active catalyst for selective oxidations with 30 % aqueous H2O2 in the liquid phase under mild conditions. Examples of oxidative transformations catalysed by TS-1 include the hydroxylation of olefins and aromatics (Thangaray et al. 1990), and the selective oxidation of primary alcohols to aldehydes and secondary alcohols to ketones (Esposito et al. 1984). The success of TS-1 stimulated the investigation of broad range of metal-substituted molecular sieves as oxidation catalysts, e.g., ZrS-1 for the hydroxylation of benzene to phenol with H2O2 (Dongare et al. 1991), cobalt-substituted aluminophosphates (CoAPOs) as catalysts for the oxidation of cyclo-hexane with O2 (Czarnetzki 1989), vanadium-substituted aluminophosphates (VAPOs) as olefin epoxidation catalysts (Haanepen and Van Hooff 1992; Rigutto and van Bekkum 1993), chromium-substituted silicalite 1 (CrS-1) for the oxidation of alkyl aromatics, alcohols, and allylic oxidation of olefins (Chen et al. 1995; Lempers and Sheldon 1996) and exchanged CrZSM5 for oxidation of secondary and primary benzylic alcohols to the corresponding organic components(ketones, aldehydes) (Lounis 2006). More recent developments include the incorporation of redox metals into the framework of mesoporous molecular sieves, such as MCM-41 (Zhang et al. 1996). One aspect which is generally overlooked in the euphoric rush to develop new catalytic systems is the stability and, hence the true heterogeneity of these materials under oxidising conditions.

On the other hand, the fine chemical industry is confronted with market inquiries of increasing molecular complexity, notably in the area of advanced pharmaceutical intermediates. To respond positively to such inquiries, it needs broadly applicable synthetic methods that are effective under mild conditions and that fulfil economic and environmental constraints. With respect to alcohol oxidation, very few currently available methods meet with the above methods. The use of the microwave technology can reduce the reaction times and energy consumption, and may lead to an increase in yields and selectivity in some cases (Gronnow et al. 2005).

However, the microwave as non-conventional source of energy was largely accepted to carry out organic synthesis; this was supported by the increase in numbers of publications in these last years, with the general availability of the new instruments of microwaves. A great number of examples of reactions were described in the organic synthesis (Strauss and Trainor 1995).

The reactions carried out by the microwave and made without the use of an organic solvent, because, the substrates are mixed directly or, in our case, the subtract is mixed with silica which is inactive in the reaction.

We report here a simple and efficient method for the oxidation of secondary alcohols to ketones under mild reaction conditions using the new instrument microwave discover as source of energy. The method uses composite materials Cr (50-MCM41/ZSM5) as the catalyst system and t-BuOOH as the stoichiometric terminal oxidant. The oxidation reaction was carried out free from solvents.

The composite materials used as catalyst were molecular sieves with a bimodal pore size distribution, combining the advantages of both the microporous and the mesoporous materials. This twofold molecular sieve might have potential applications in adsorption and catalysis for bulky molecules (Meynen et al. 2007). For instance, these materials proved to be also active for solid acid catalysts (Ordomsky et al. 2007). From catalytic point of view, the composite materials Cr-(50-MCM41/ZSM5) prepared by our research were investigated on the oxidation reaction of the benzylic alcohols.

Experimental section

The chemicals

The chemicals used for the syntheses were colloidal solution of silica (Ludox HS40, dupont, 40 % SiO2, 60 % H2O), tetrapropylammonium bromide (TPABr (97 %, Aldrich) cetyltrimethylammonium bromide (CTMA Br) (98 %, Fluka), sodium aluminate NaAl2O3 (65 % Al2O3, 27 % Na2O, Aldrich), sodium hydroxide (98 %, Fluka) and deionised water.

The products of exchange are the salts of chromium nitrate (>99 %, Aldrich), the deionised water and the MeNH2 (40 wt % in water, Fluka).

The catalyst preparation

A synthesis procedure described earlier (Karlsson et al. 1999) was modified for mixtures of the C6[C6H13(CH3)NBr] and C14[C14H29(CH3)3NBr] templates/surfactants. The concentrations of ammonium were scaled according to: C6 (wt) + C14 (wt) = 100 %, where C6 (wt) = 50 % and C14 (wt) = 50 %.

A synthesis of the composite materials Al MCM41/ZSM5 was obtained by two-step procedure:

Solution A

The mixture of the template agents was dissolved in water under magnetic stirring at room temperature for 15 min.

Solution B

For the preparation of aluminosilicate material, aluminate sodium used as source of Al was added to sodium hydroxide and subsequently dissolved in water at 50 °C for 10 min. Then, a solution of silica ludox (40 % SiO2, 60 % H2O) was added to the previous solution under stirring with magnetic stirrer at room temperature for 15 min.

The solution B was poured onto the solution A drop-wise under continuous stirring for 24 h at room temperature. The gel of the surfactants/silica mixture obtained has the following composition: SiO2, 0.01 Al2O3, 0.20 Na2O and 700 H2O. The (C6 + C14):SiO2 molar gel ratio was maintained at 0.4

Finally, the gel mixture was transferred into the tubes of glass Pyrex sealed by Teflon ribbon to avoid the loss of material during heating. The tubes were placed vertically into beakers and were introduced into the drying oven. Then, the gel was crystallised at the temperature of 120 °C under static conditions and atmospheric pressure for 4 days. The resulting solids were recovered by filtration, completely washed with distilled water three to four times and then dried to 100 °C overnight. The calcination of the as-synthesised materials was carried out at 500 °C with heating rate of 3 °C/min in air for 6 h to remove the template molecules. The obtained solid is denoted by 50-(MCM-41/ZSM-5).

The cationic exchange of the 50-(MCM-41/ZSM-5) by chromium ions was obtained by the following procedure: 1 g of the calcined product was ion exchanged in 100 ml of a solution of 0.5 M NaCl for 24 h at ambient temperature and pH 5–6, this initial Na+ ion exchange was followed by a second (24 h) under gentle agitation in fresh solutions to obtain Na-50(MCM41/ZSM5).

The Na-50(MCM-41/ZSM-5) samples were subsequently exchanged with Cr3+ ions, again with 1 g solid in 40 ml solution of 0.1 M Cr(NO3)2. The chromium ion exchanges were done under stirring at 50 °C for 3 h. The pH control was employed throughout all ion exchanges and the pH value was adjusted to the desired range (5–6) by adding MeNH2 (40 wt % in water) before introducing the solid. The final solid was recovered by filtration, washed several times with de-ionised water and dried (150 °C, 5 h) before being analysed by various characterisations. The chromium-exchanged composite material obtained is denoted by Cr-(50-MCM-41/ZSM-5).

Catalyst characterisation

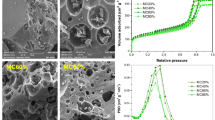

The Cr-(50-MCM-41/ZSM-5) was characterised by powder X-ray diffraction using a Philips PW 1801/29 diffractometer with CuKα radiation. The similarity of the intensity of the main peaks of Cr-(50-MCM-41/ZSM-5) and (50-MCM-41/ZSM-5) spectra indicated that the alteration of the structure in the course of the ion exchanges is not significant (Figs. 1, 2).

Specific surface area measurements were obtained from volumetric nitrogen adsorption using ASAP 2010 instrument. Nitrogen adsorption measurements were performed at liquid nitrogen temperature. The BET surface area measured was 560 m2/g.

The analysis of X-ray fluorescence give the composition in percentage of the Cr-(50-MCM-41/ZSM-5), from this composition we deduct the concentration of chromium in 1 g of product, in our case we use only 5 mg of product which correspond to 0.05 mmol of chromium.

Catalytic testing

The oxidation of the secondary benzylic alcohols over the Cr-(50-MCM-41/ZSM5) catalysts was performed using the following procedure: amixture of the secondary benzylic alcohol as substrate (1 mmol), 70 % aqueous t-BuOOH (4 mmol) + Cr-(50-MCM-41/ZSM5) (5 mg) was mixed with silica gel (5 mg) and it was introduced into the vessel of 50 ml in the machine of microwave (Discover, CEM-SP1245 model, USA), (300 W), with stirring. The option of agitation consists of an electromagnetic dish located below the floor of the cavity of microwave. Agitation occurs when the magnetic field couples with a bar of agitation in the container.

The reaction conditions were recorded on the machine; the temperature of 100 °C is selected under an atmospheric pressure. The oxidation was done under backward flow without organic solvent; the reactants were poured onto silica gel and mixed intimately prior to be introduced in the machine of microwave. The reaction was stopped after 10 min. The product was recuperated from the machine after 20 min until the temperature reached 20 °C. The option of cooling is composed of valves and ports necessary to direct a gas of cooling (nitrogen or clean air) towards the containers in the cavity of the system. This option will decrease the temperature from 150 to 50 °C in less than 120 s.

We suspect that some t-BuOOH did not react in the course of reaction. In order to eliminate the nonreacted oxidant, we filtered the obtained product of reaction over a small pad of alumina, because alumina breaks t-BuOOH. We used diethyl ether to permit the recuperation of the product from alumina by a vacuum pump.

Results and discussion

Taking into account the analyses carried out by gas chromatography and mass spectrometry (Fig. 3), we noted that the composite material Cr-(50-MCM-41/ZSM5) was selective and efficient catalyst for the oxidation of benzylic alcohols under mild conditions using 70 % t-BuOOH as an oxidant, the best yields were obtained to the oxidation of secondary alcohols to the ketones. Interestingly, unactivated alcohols such as 1-phenyl-1,2-ethanediol and trans 2-phenyl 1-cyclohexanol have been oxidised to the corresponding ketones in satisfactory yield (Table 1).The conversion of benzylic alcohols to the corresponding ketones was obtained for drastic time, only 10 min using the technology microwaves.

The use of bimodal pores Cr-(50-MCM-41/ZSM5) in oxidation of benzylic alcohols is due to the fact that zeolites with small pores ZSM5 (≤5 Å) cannot undergo the oxidation of bulky molecules, such as (trans-2-phenyl 1-cyclohexanol, benzhydrol, etc.).

To determine the recyclability of our material, the oxidation of 1-indanol was chosen as substrate (1 mmol) and was performed under the usual conditions, at the end of reaction, the catalyst was separated from the products by filtration. Before the reuse, the Cr-(50-MCM-41/ZSM5) undergo treatment which consist in putting the zeolite in contact with a solution of NaOH 0.1 M (20 ml) under magnetic agitation at ambient temperature for duration of 15 min to remove the cooked carbonyl compounds deposited on its surface. The composite material was then washed several times with distilled water, dried at 100 °C for 3 h and analysed by powder X-ray diffraction which gave well-defined reproducible patterns (Fig. 4). The reuse of the recycled composite material showed the same activity and selectivity as the new one. The composite material can be exploited several times without any loss of its activity.

Following these results, we try to determine the role of chromium-exchanged composite material in the oxidation of benzylic alcohols. To clarify this issue, two experiments have been carried out. As checking test reaction, the oxidation of benzhydrol was chosen in the usual conditions without catalyst. The reaction was stopped after 10 min; work up led to benzophenone in 10 % yield. The formation of benzophenone is due probably to the oxidation by 70 % aqueous TBHP.

This test is made to confirm the role played by chromium in the case of oxidation of benzylic alcohols, we have taken composite materials non exchanged with chromium and we have also chosen one alcohols (benzhydrol) in the list of substracts which we have already used. The reaction was stopped after 10 min. Work up led to benzophenone in 23 % yield. The acid activity of the solid catalyst and the presence of 70 % aqueous TBHP as oxidant led to the formation of ketone in poor yields. It is clear from these data that the effect of chromium in this type of reaction is predominant. The team of Muzart and that of Sheldon have worked for more than two decades on the effectiveness and the role of transition cations and more particularly, chromium in the oxidation reactions of benzylic alcohols (Muzart 1987, 1989, 1990, 1992, 1993a, b; N’ait Ajjou et al. 1994). On the basis of literature, the team of Muzart which worked in homogeneous chromium catalyst in liquid phase; they interested on the interactions of the TBHP with transitions metals (Boitsov et al. 2001). This team proposed that the catalysed oxidation of alcohols and activated methylenes implies the formation of complex tert-butyl peroxychromic (A) which plays the true role of oxidising species. The reaction of alcohols with (A) leads to the formation of complex alkoxy of chromium (tert-butyl peroxychromic). However, an intramolecular isolation of hydrogen by group tert-butyloxy releases ketone and the species (R: t-Bu).

The interaction of TBHP with transitions metals in the heterogeneous catalyse in liquid phase was undertaken by the team of Sheldon (Chen et al. 1995; Lempers and Sheldon 1996; Sheldon et al. 1994a, 1994b). The mechanism of Sheldon implies firstly the addition of alcohol to oxo-chromic (VI) catalyst to give complexes of alkoxy-oxochromic (B). However, an elimination of hydrogen from B led to the formation of ketone with an occurrence reduction of CrVI to CrIV.

In our case, the oxidation of benzylic alcohols by heterogeneous chromium catalyst occurs in solid phase; the chromium exchanged is within the pores of composite material, in the third state, and counterbalances the negative charge of the structure. However, the interaction of the molecule TBHP with the CrIII into the pores of composite material leads to the oxidation of chromium to the sixth state (CrVI). Further research on the mechanism of this reaction and the scope of exchanged chromium composite material and related redox molecular sieves as solid catalyst for various solid phase oxidations is in progress.

Conclusions

Generally, these reactions are made in homogeneous medium with chromium oxides of high concentrations (the team of Muzart works with contents of chromium oxide which are 0.5 mmol); these reactions are made in the presence of organic solvents such as toluene or dichloromethane. At the end of the reactions, these oxides are dissolved and can be regenerated. In our case, we worked with solid catalysts. The content of chromium is very low, only 0.05 mmol. The catalyst is regenerated and can be used several times without affecting its activity, and also the reactions are carried out without using the organic solvent. We can show that Cr-(50-MCM-41/ZSM5) is an excellent recyclable solid catalyst for the selective oxidation of benzylic alcohols to the corresponding carbonyls compounds using 70 % aqueous TBHP as oxidant.

The technology of microwaves can reduce the reaction times and the energy consumption, and can lead to an increase in the outputs and selectivity of the oxidative reactions.

References

Boitsov S, Songstad J, Muzart J (2001) Chromium(VI) oxide/tert-butyl hydroperoxide interactions: evidence for a tert-butylperoxychromium complex and its role in the catalytic oxidation of alcohols. J Chem Soc Perkin Trans 2:2318

Cainelli G, Cardillon G (1984) Chromium oxidations in organic chemistry. Springer, New York

Chen JD, Lempers HEB, Sheldon RA (1995) Ti-Al-β and CrAPO-5 as heterogeneous catalysts for selective oxidations in the liquid phase. Colloid Surf A Physicochem Eng Aspects 101:137

Clerici MG (1991) Oxidation of saturated hydrocarbons with hydrogen peroxide, catalysed by titanium silicalite. Appl Catal 68:249

Clerici MG, Bellussi G, Romano U (1991) Synthesis of propylene oxide from propylene and hydrogen peroxide catalyzed by titanium silicalite. J Catal 129:159

Czarnetzki K (1989) Characterisation and modification of zeolites and related molecular sieves. PhD thesis, Eindhoven University of technology, The Netherlands p 116

Dongare MK, Singh P, Moghe PP, Ratnasamy PP (1991) Synthesis, characterization, and catalytic properties of [Zr]-ZSM-5. Zeolites 11:690

Esposito A, Neri C, Buonomo F (1984) Process for oxidizing alcohols to aldehydes and/or ketones, US Patent No. 4480135

Gronnow MJ, White RJ, Clark JH, Macquarrie DJ (2005) Energy efficiency in chemical reactions: a comparative study of different reaction techniques. Org Proc Res Dev 9:516

Haanepen MJ, Van Hooff JHC (1992) In: Tagungsbericht 9204 proceedings of the DGMK conference selective oxidations in petrochemistry, p 227

Chen JD, Haanepen MJ, VanHooff JHC, Sheldon RA (1995) CrAPO-catalyzed oxidations of alkylaromatics and alcohols with TBHP in the liquid phase (redox molecular sieves, part 8) in Stud.Surf.Sci.Catal 84:973

Karlsson A, Stocker M, Schmidt R (1999) Composites of micro- and mesoporous materials: simultaneous syntheses of MFI/MCM-41 like phases by a mixed template approach. Microporous Mesoporous Mater 27:181

Lempers HEB, Sheldon RA (1996) Allylic oxidation of olefins to the corresponding a,ß-unsaturated ketones catalyzed by chromium aluminophosphate-5. Appl Catal A Gen 143:137

Ley SV, Martin A (1991) Oxidation of activated C-H bonds adjacent to heteroatoms: oxidation adjacent to oxygen of alcohols by chromium reagent. In: Trost BM, Fleming I (eds) Comprehensive organic synthesis, vol 7. Pergamon, Oxford, p 251

Lounis Z et al (2006) Chromium-exchanged zeolite (CrE-ZSM-5) as catalyst for alcohol oxidation and benzylic oxidation with t-BuOOH. Appl Catal A Gen 309:270

Meynen V, Cool P, Vansant EF (2007) Synthesis of siliceous materials with micro- and mesoporosity. Microporous Mesopor Mater 104:26

Muzart J (1987) Practical chromium VI oxide-catalyzed benzylic oxidations using 70% tert butylhydroperoxide. Tetrahedron Lett 28:2133

Muzart J (1989) Bimetallic oxidation catalysts: oxidations with tert-butylhydroperoxide mediated by bis-(tributyltin oxide) dioxochromium (VI). J Synth Commun 19:9

J Muzart (1990) Chromium(VI)-catalyzed oxidation of para-substituted phenols by t-butyl hydroperoxide. J Chem Res (S) 96

Muzart J (1992) Chromium-catalyzed oxidations in organic synthesis. J Chem Rev 92:113

Muzart J (1993) Silyl ethers as protective groups for alcohols: oxidative deprotection and stability under alcohol oxidation conditions. Synthesis 1993:11

Muzart J, N’ait Ajjou A (1993) Highly efficient chromium-catalyzed oxidation of secondary benzylic alcohols by aqueous 70 % tert-butyl hydroperoxide. Synthesis 8:785

N’ait Ajjou A, Muzart J, Savelon L, Guillaumet G (1994) Chromium-assisted oxidations. A simple and efficient oxidation of oxazolopyridylcarbinols by aqueous tert-butyl hydroperoxide. Synthesis: 359

Ordomsky VV, Murzin VY, Monakhova YV, Zubavichus YV, Knyazeva EE, Nesterenko NS, Ivanova II (2007) Nature, strength and accessibility of acid sites in micro/mesoporous catalysts obtained by recrystallization of zeolite BEA. Microporous Mesoporous Mater 105:101

Rigutto MS, van Bekkum H (1993) Vanadium site in VAPO-5: characterization and catalytic properties in liquid-phase alkene epoxidation and benzylic, oxidation. J Mol Catal 81:77

Romano U, Esposito A, Maspero F, Neri C, Clerici MG (1990) Selective oxidation with Ti-silicalite. Stud Surf Sci Catal 55:33

Sheldon RA, Korchi JK (1981) Metal-catalyzed oxidations of organic compounds. Academic, New York, p 152

Sheldon RA, Chen JD, Dakka J, Neeleman E (1994a) Recyclable catalysts for liquid phase oxidations. Stud Surf Sci Catal 83:407

Sheldon RA, Chen JD, Dakka J, Neeleman E (1994b) Redox molecular sieves as heterogeneous catalysts for liquid phase oxidations. Stud Surf Sci Catal 82:515

Taramasso M, Perego G, Notari B (1983) Preparation of porous crystalline synthetic material comprised of silicon and titanium oxide. US Patent No. 4410501

Thangaray A, Kumar R, Ratnasamy P (1990) Studied the oxidation of benzene by hydrogen peroxide to phenol and benzoquinone as catalyzed by various zeolites and molecular sieves. Appl Catal 57:L1

Trainor RW, Strauss CR (1995) L’évolution des micro-ondes assisté en chimie organique. Aust J Chem 48:1665

Zhang W, Wang J, Tanev PT (1996) Catalytic hydroxylation of benzene over transition-metal substituted hexagonal mesoporous silica. J Chem Commun: 979

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Lounis, Z., Boumesla, N. & Bengueddach, A.E.K. Oxidation of benzylic alcohols over Cr (MCM-41/ZSM-5) assisted by microwaves. Appl Petrochem Res 2, 45–50 (2012). https://doi.org/10.1007/s13203-012-0007-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-012-0007-5