Abstract

Hydraulic fracturing of shale reservoirs is one of the important technologies in the oil and gas industry. To ensure the safe operation of oil and gas recovery, it is important to study the shale-fluid interactions on the geomechanical behavior of shale. This study investigated the effect of fracturing fluid treatment on the mechanical and elastic properties of the Mowry Shale formation, Wyoming, USA. Cylindrical Mowry Shale specimens with a diameter of 12.5 mm collected from the United States Geological Survey (USGS) and School of Energy Resources (SER) of the University of Wyoming were treated with brine and brine + stimulation fluid for one month each at pressures of 9 and 11.7 MPa and temperatures of 96 and 66 °C, respectively. Triaxial compression experiments were conducted on the specimens. Results showed that all Mowry Shale specimens experienced an increase in maximum volumetric strain with the increase in effective confining pressure (Pd). Regardless of aging fluids, the maximum deviatoric stress (Δσd) of most Mowry Shale specimens increases with the increase in Pd. At a lower Pd, the USGS specimen aged with brine and stimulation fluid exhibits higher maximum Δσd than those aged with brine only. However, at a higher Pd, the USGS specimen aged with brine exhibits a higher maximum Δσd. SER specimens aged with brine and stimulation fluid exhibit higher maximum Δσd values than those aged with brine for all three Pd values. Regardless of the aging fluids, most USGS specimens experience a brittle failure mode, while SER specimens aged with brine and stimulation fluid experienced a more ductile behavior.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Shale reservoirs have gained more attention as a source of energy because of the rise in energy demand (Wang et al. 2016). Horizontal drilling and hydraulic fracturing of shale reservoirs have greatly helped the oil and gas industry (Ma et al. 2016). When doing hydraulic fracturing, a large amount of fracturing fluid is injected into the reservoir to create/expand fractures (Karakul 2018). Fracturing fluids can interact with rocks and potentially affect their physical and mechanical properties (Lin et al. 2019). Many studies have been conducted to investigate this issue. Khalil et al. (2017) showed that core flooding using a 15%HCl solution made the Eagle Ford shale samples more permeable, and increasing the injection pressure decreased the breakthrough time. Using an inclined direct shear experiment, Abousleiman et al. (2010) observed that fractured shale samples from the Persian Gulf flooded with water-based drilling mud showed 23 and 11% lower strength under confining pressures of 6.89 and 13.79 MPa, respectively, compared to the samples flooded with mineral oil.

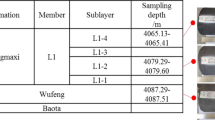

Many studies have investigated the effect of fracturing fluid on shale using triaxial compression experiments, mostly reporting a deterioration in shale’s mechanical and elastic properties (Akrad et al. 2011; Yang et al. 2023). After seven days of being immersed in fracturing fluid, Longmaxi Shale samples showed an almost 100% decrease in strength under triaxial compression conditions (Bai et al. 2020). From the same study, 85% and 54% decreases in elastic modulus and Poisson’s ratio, respectively, were also reported. Smaller percentages of decrease were reported in another study (Zhong et al. 2019), where after ten days of treatment, fracturing fluid decreased the elastic moduli of Longmaxi and Wufeng shale samples by 20 and 7%, on average, respectively. A long treatment duration of twelve months did not seem to have a very severe effect on the compressive strength and elastic modulus of Niutitang black shale samples subjected to acidic fracturing fluid as the decreases were 29 and 32.2%, respectively (Lyu et al. 2022). On the other hand, the decrease in strength after 5 days of immersion in the fracturing fluid was 47% for Chongqing shale samples from triaxial compression tests under a confining pressure of 50 MPa and temperature of 80 °C (Hou et al. 2018).

From uniaxial compression tests, 68% decrease in uniaxial compressive strength (UCS) and 75% decrease in the elastic modulus was reported for Eagle Ford shale samples after being soaked in fracturing fluid for 72 h (Lai et al. 2016). On the comparison of the effect of different fluids on shale properties, the UCS values of Mancos shale samples decreased by 57, 47, and 41% after exposure to water, dodecyl trimethyl ammonium bromide (DTAB), and sodium dodecyl benzene sulfonate (SDBS) surfactants, respectively (Aderibigbe & Lane 2013).

An experimental study on the effect of treatment duration with fracturing fluid on the mechanical behavior of Longmaxi shale samples under triaxial compression tests was completed by Zhao et al. (2023). In their study, the peak compressive strengths of samples soaked in fracturing fluid at 130 °C and under 90 MPa for 3, 15, and 45 days decreased 55%, 47%, and 35%, respectively. A similar trend was reported on the elastic modulus. They attributed the higher strengths at 15 and 45 days to the precipitated flocculent and the dissolved minerals in the pores, and rock compaction from the confining pressure.

The effect of confining pressure on the mechanical responses of shale samples was studied by some researchers. With the increase in confining pressure from 20 to 30 MPa, the peak strength of the Pierre-1 shale samples increased by 53% (Islam & Skalle 2013). Similarly, an increase in the confining pressure from 20 to 80 MPa increased the peak strength of the marine shale samples from 160 to 300 MPa (or 88%) (Wang et al. 2022). Changes in surface morphology after treatment with fracturing fluid were also investigated in some studies. Tan et al. (2022) showed that after the imbibition with fracturing fluid, the fractal dimension of Niutitang black shale samples increased by 9–30% because of the dissolution, hydrolysis, and hydration processes. Sun et al. (2018) observed a rougher surface on Longmaxi shale samples after 72 h of reaction with slick water, attributed to the dissolution of carbonate.

Mowry Shale has been considered one of the major sources of Cretaceous oil and gas in the northern Rocky Mountains. Hydrocarbons are most abundant in lower Cretaceous reservoirs. Mowry Shale is encountered in Wind River Basin Province, Bighorn Basin, and Powder River Basin, WY. The United States Geological Survey (USGS) estimated that a mean total of 288 million barrels of oil and 74 billion cubic meters of natural gas can be recovered from the upper siliceous Mowry Shale in Wind River Basin Province (Kirschbaum et al. 2019). For the Upper Cretaceous Mowry Shale in the Powder River Basin, the estimated cumulative petroleum production is about 1.2 billion barrels of oil and 62 billion cubic meters of gas (Anna & Cook 2008). It has been reported that significant condensate quantities have been produced and a lesser amount of more valuable oils have been yielded from the unconventional horizontal wells, since 2009 (Goolsby 2010). This undesirable production could be partly attributed to the insensitivity of the Mowry Shale to hydraulic fracturing, resulting in inadequate crack propagation, fewer fractures, and surface area. On the other hand, detailed quantification using high-resolution imaging techniques and mineral characterization reveals that abundant biogenically derived authigenic micro quartz in the Mowry Shale is expected to yield brittle behavior (Milliken & Olson 2017).

Although Mowry Shale has been recognized as an important source rock for oil and gas production, the geomechanical behavior of Mowry Shale has yet to be investigated and understood to overcome the current challenges encountered in unconventional hydrocarbon production (Pish 2014). This paper presents the stress–strain behaviors of Mowry Shale subjected to different effective confining pressures from triaxial compression (TC) experiments. Cylindrical specimens were prepared from Mowry Shale core samples and aged with brine and stimulation fluid. The triaxial compression results are used to quantify the elastic properties (Elastic modulus and Poisson’s ratio), shear strength parameters (cohesion, friction angle), failure modes, and crack stress thresholds. This is the first study of its kind to investigate the mechanical and elastic properties of the Mowry Shale subjected to the stimulation fluid. Also, an innovative experimental method was proposed to prepare and test specimens with a diameter of 12.5 mm and a length of 25 mm in a triaxial compression condition. All the experiments were done at in situ pressure and temperature. The research outcomes will improve our understanding of the effect of aging reactions and rock matrix alteration on geomechanical behaviors.

Geological background

Mowry Shale formation is a Lower Cretaceous biogenic siliceous mudstone covering much of western North America, including the major basins within Wyoming. The Mowry Shale was deposited when much of western North America was covered by the Mowry Sea, which extended from the Arctic to present-day Colorado (Byers & Larson 1979; Davis et al. 1989; Davis 1970). The depositional environment in which the Mowry Shale was deposited favored the production of radiolarians with silica tests, and being restricted from warmer, southern waters restricted carbonate deposition (Davis 1970; Davis et al. 1989). The result of this depositional environment is a shale with characteristically high silica and low carbonate content (Fig. 1). The silica within the Mowry Shale is primarily of biogenic origin; however, there is evidence for mixed detrital and biogenic sourcing (French et al. 2023; Hollon 2014; Milliken & Olson 2017). The Mowry Shale is a prolific hydrocarbon source bed within the Powder River Basin, Wyoming, and as a result, is of interest for direct production (Davis et al. 1989; French et al. 2023; Nixon 1973). Lithologically, the Mowry Shale is a biogenic siliceous mudstone. Facies divisions can vary based on the author but commonly considered factors are bentonite, sand content, laminations, and silica source (biogenic versus detrital) (Davis et al. 1989; Davis 1970; Hollon 2014; Socianu 2016).

(Left) Stratigraphic chart showing the Mowry Shale along with associated formations. Reproduced from (Nixon 1973). Ternary diagram representing XRD mineralogy of the Mowry Shale (Right). Of note is the highly siliceous nature of the formation, with very low carbonate content (United States Geological Survey Core Research Center, 2023)

For this study, two cores were selected based on both their ease of access and the opportunity to evaluate the Mowry Shale’s performance with an immature and late oil maturity end member. These cores were the University of Wyoming School of Energy Resources UW PRB#1 well located near Gillette, Wyoming, and the second Educated Guess 1-11H well located near Sheridan, Wyoming, hosted at the USGS. The UW PRB#1 cores (hereafter SER core) represent a low-maturity sampling and Educated Guess 1-11H cores (hereafter USGS core) represent a more mature sampling. Experimental pressure and temperature conditions were calculated based on the sample depth using a pressure gradient of 0.01 MPa/m and a temperature gradient (T) in °C calculated from Eq. (1):

The temperature gradient was calculated based on bottom hole temperatures and average surface temperatures in northern Wyoming. Both cores were highly fractured parallel to bedding, presumably owing to planes of weakness caused by detrital silt beds. Samples were selected that did not contain visible silt beds and appeared to be homogenous biogenic silica.

Materials and methods

Mowry Shale specimens were prepared for treatment with fracturing fluid and triaxial testing experiments. Figure 2 shows a flow chart describing the schematic experimental methodology used in this research.

Core sample collection and specimen preparation

Extracting large specimens from shale samples is a difficult task as they can act quite brittle and easily break during the drilling process. Because of this, many studies use nanoindentations or two-scale finite element method to study the behavior of shale (Esatyana et al. 2020, 2021; Sakhaee-Pour & Li 2019). In this research, authors faced the same problem, while drilling, since most of the cores were 76.3 mm in diameter and thin fractured pieces with thicknesses less than 40 mm (Fig. 3a). Hence, considering the required 1:2 ratio of the diameter to the length of a cylindrical specimen, a total of six SER specimens were drilled out from the cores at a depth of 2,320 m using a dry method. The specimens were prepared with a 12.5-mm diameter by 25-mm length as shown in Fig. 3b. USGS rock cores were selected for preparing 12.5-mm diameter specimens at the USGS facility in Denver, CO. The depths of the USGS specimens range from 3,233 m to 3,235 m. A wet wheel saw was used to cut them in length, and both ends of each specimen were grinded so that the side was perpendicular to the ends. Due to the fragility of the USGS Mowry Shale, a total of four USGS specimens were prepared (Fig. 3c).

Treatment of shale specimens

All the Mowry Shale specimens were aged with brine and/or stimulation fluid. Since, the chemical composition of the Mowry Shale formation brine at the SER PRB#1 well is unknown, the chemical composition of the Mowry Shale brine, obtained from USGS was used in this research. The synthetic formation brine was prepared in the lab to mimic the chemical composition shown in Table 1.

The pressure and temperature of shale samples were calculated based on the sample depth using a pressure gradient of 0.01 MPa/m and a temperature gradient calculated from Eq. (1). The temperature gradient was calculated based on bottom hole temperatures and average surface temperatures in northern Wyoming. Namely, 11.7 MPa and 66 °C for SER samples and 9 MPa and 96 °C for USGS samples. Because of limited available chemical composition data on the stimulation fluid, a surrogate was prepared as follows: (1) The original synthetic brine was diluted eightfold down to 0.2 mol/kg; and (2) then, it was acidified with HCl to a pH of 2.8. Before specimen aging, all the shale specimens were saturated with formation brine for four days under vacuum. The relatively long saturation time was intended to make sure these tight rocks were fully saturated with formation brine. Following that, the saturated shale samples were soaked in a transfer vessel, which had been filled with formation brine. Figure 4 shows the structure of the transfer vessel. This vessel consists of two chambers, separated by a well-sealed plug. Specifically, the bottom chamber (inlet) is connected to an ISCO pump to control the pressure by adjusting the DI water volume of the bottom chamber whereas the top chamber (outlet) provides a space for the formation brine and shale rocks. Then the transfer vessel was closed and moved to an oven, in which in situ temperature can be set. Since, temperature, in contrast to pressure, primarily controls water–rock interactions, the pressures of both SER and USGS samples applied in this research were only half of their corresponding in situ values, as their values are not critical for reactivity. In this research, four transfer vessels were used to satisfy different rock treatment conditions: one is for formation brine-SER rock interaction, the second is for formation brine-stimulation fluid-SER rock interaction, a third one is for formation brine-USGS rock interaction, and the last one is for formation brine-stimulation fluid-USGS rock interaction. The formation brine-rock interaction experiment lasted 30 days in total. As for the formation brine-stimulation fluid-rock interaction, the shale specimens were first soaked in formation brine for 15 days. Then, the prepared stimulation fluid was injected into the respective top chamber of the transfer vessel via the ISCO pump, during which another ISCO pump, connecting to the inlet of the transfer vessel, was used to keep the pressure inside the transfer vessel constant (half of in situ pressure value). This formation brine-stimulation fluid-rock interaction process lasted another 15 days. Table 2 shows the detailed treatment conditions of these shale specimens. Subsequently, all the shale specimens were taken out of the transfer vessel, followed by desaturation to prepare geomechanical measurements.

Geomechanics experimental design

Table 3 summarizes the geomechanics experimental conditions for the USGS specimens. The specimen identification system comprised of three parts (from left to right) is described as follows: the rock core source from which the specimen was prepared, treatment fluid (i.e., B denotes aging with brine and BS denotes aging with brine and stimulation fluid), and triaxial compression condition with respect to confining and pore pressures. An in situ temperature of 96 °C was selected for the USGS specimens. Table 4 summarizes the geomechanics experimental conditions for the SER specimens. The same identification system was adopted. An in situ temperature of 66 °C was selected for the SER specimens. Triaxial compression experiments on specimens were conducted using newly retrofitted (to accommodate 12.5-mm diameter specimens) GCTS RTR-1500 equipment (Fig. 5a). The specimen was placed between two holders and protected by a heat shrink jacket to prevent mixing of the confining oil and the pore pressure water during the test. Two linear variable differential transformers (LVDTs) were mounted on a ring installed on the bottom of the setup to record the axial deformations. Three LVDTs mounted on a middle ring were used to record the radial deformations (Fig. 5b). Next, the specimen column was slid into the equipment and the cell wall was then brought down. The cell was filled with oil, which was heated to the target temperature typically within two hours. After this stage, an initial confining pressure of about 2 MPa followed by a small deviatoric stress (about 1 MPa) was applied to the specimen. An initial pore pressure (water) of 0.17 MPa was applied to the specimen. Next, both the confining and pore pressures were ramped to the target values in 5 min, while keeping the deviatoric stress constant. The confining and pore pressures were kept in equilibrium for 5 min before increasing the deviatoric stress at a rate of 0.1% axial strain per minute to failure. Failure would be identified as a decline in the axial stress with the continuous increase in axial strain.

Results

Confinement stage

Stress–strain response

Figure 6 shows the volumetric strain (εv) versus the effective confining pressure (Pd) of the USGS specimens during the confinement stage of the triaxial compression experiments. Figure 7 shows the εv-Pd responses for the SER specimens. The εv was calculated using Eq. (2) based on the measured radial strain (εr) and axial strain (εa). The Pd was calculated using Eq. (3) as the difference between the confining pressure (Pc) and the pore pressure (Pp).

Figures 6a, 7a show the εv-Pd responses of the specimens treated with brine, while Figs. 6b, 7b show the εv-Pd responses of the specimens treated with brine and stimulation fluid. The Pd starts from around 2 to 3 MPa depending on the specimen toughness and increases to the target Pd as shown in Table 3 and 4. The results show that the εv increases with the increase in Pd for all specimens. The positive increase in εv indicates compression in the specimen during the confining stage. Comparing Figs. 6a, b for the lowest Pd, the USGS-B-TC0 specimen exhibits a lower εv than that of the USGS-BS-TC0 specimen. On the other hand, the USGS-B-TC1 specimen exhibits a higher εv than that of the USGS-BS-TC1 specimen at Pd of 17.2 MPa. The effect of aging with stimulation fluid on the compressibility of USGS specimens in terms of εv cannot be generally concluded.

Figure 7 shows that all SER specimens except SER-B-TC2 experience an increase in maximum εv with the increase in Pd. SER-B-TC2 specimen experiences a lower maximum εv than that of SER-B-TC0 and SER-B-TC1. For all three Pd values, Fig. 7a, b show that SER specimens aged with brine exhibit higher maximum εv values than that of the specimen aged with brine and stimulation fluid.

Bulk Modulus

Bulk Modulus (K) as an indicator of the changes in the volume of the specimen during the confining stage was calculated using Eq. (4) based on the change in effective confining pressure (ΔPd) and change in volumetric strain (Δɛv).

Figure 8 summarizes the bulk modulus (K) of the SER and USGS specimens aged with brine and brine + stimulation fluid. Both SER and USGS specimens under higher Pd exhibit higher bulk moduli. For specimens at low Pd, stimulation fluid reduces the K values. However, stimulation fluid increases the K values of specimens at higher Pd. USGS specimens generally exhibit higher K values than those of the SER specimens.

Axial loading stage

Stress–strain response

Figures 9 and 10 present the deviatoric axial stress (Δσd) versus axial strain (ɛa) and radial strain (ɛr) of USGS specimens and SER specimens, respectively. All plots (a) present the stress–strain results of specimens aged with brine, and plots (b) are for specimens aged with brine and stimulation fluid. Each plot shows the Δσd-ɛr responses on the left and the Δσd-ɛa responses on the right. Positive ɛa indicates axial compression and negative ɛr indicates radial expansion of the shale specimen under the axial loading.

The maximum Δσd of the USGS specimens increases at a higher Pd (Fig. 9). Regarding the effect of aging fluid, USGS-BS-TC0 subjected to a lower Pd has a higher peak Δσd of 221 MPa than 153.8 MPa of USGS-B-TC0. In contrast, USGS-BS-TC1 subjected to a higher Pd exhibits a lower peak Δσd of 286 MPa than 523 MPa of USGS-B-TC1. It is important to note that the Δσd-ɛa-ɛr responses of USGS-B-TC1 are about two times higher than that of USGS-B-TC0 and are questionable unless triaxial experiments can be repeated. USGS-BS-TC0 experiences larger ɛa and ɛr values at the maximum Δσd than those of USGS-B-TC0. Regardless of the aging fluids, all USGS specimens experience a brittle failure mode.

Figure 10 shows the stress–strain responses of the SER specimens. Unlike the USGS specimens, the effect of Pd on the maximum Δσd values of SER specimens is not apparent. Figure 10a shows that SER-B-TC0 and SER-B-TC1 specimens show similar maximum Δσd values of 90.8 MPa and 91.9 MPa, respectively, while SER-B-TC2 exhibits the lowest maximum Δσd of about 70.8 MPa. For SER specimens aged with brine and stimulation fluid in Fig. 10b, SER-BS-TC0 and SER-BS-TC2 show similar maximum Δσd values of about 132.9 MPa and 131.5 MPa, respectively, which are slightly higher than 126 MPa of SER-BS-TC1. Figure 10 shows that SER specimens aged with brine and stimulation fluid exhibit higher maximum Δσd values than those aged with brine for all three Pd values. In addition, stimulation fluid causes the SER specimens to reach the maximum Δσd values at higher axial strains than that of the specimens aged with brine. However, the radial strains of specimens aged with brine and stimulation fluid are lower than those aged with brine. Comparing the post-failure responses in Fig. 10a, b, SER specimens aged with brine and stimulation fluid show a more ductile behavior than those aged with brine. Furthermore, SER specimens generally fail in a more ductile manner, while USGS specimens fail in a more brittle manner.

Elastic properties

Figures 11 and 12 present the elastic modulus (E) and Poisson’s ratio (ν) with respect to Pd. A linear line was fitted to the linear part of the stress–strain curve (Figs. 9 and 10) of each specimen and the slope of the line was taken as the E. The ν was calculated by using Eq. (5) using the measured εr and εa of the linear region of the stress–strain responses in Figs. 9 and 10.

Figures 11a, b compare the E and ν values with Pd for the USGS specimens, respectively. Increasing the Pd increases the E of specimens aged with brine from 2.5 to 3.3 GPa, while decreasing the E of specimens aged with brine and stimulation fluid from 2.26 to 2.04 GPa. The stimulation fluid aging results in lower E values than that of the specimens aged with brine. Similarly, the Pd has a positive effect on the ν of the specimens aged with brine and a negative effect on the ν of the specimens aged with brine and stimulation fluid. The impacts of the stimulation fluid on ν depends on the Pd. At low Pd, the ν values of the specimens aged with brine and stimulation fluid are higher at a lower Pd and lower at a higher Pd than those of the specimens aged with brine.

.

Figure 12a, b compare the E and ν values of the SER specimens, respectively. For both aging conditions, increasing the Pd from 4.8 to 11.7 MPa reduces the E but further increase in the Pd from 11.7 to 18.6 MPa increases the E. Stimulation fluid increases the E values, on average by 7.5%, compared to the specimen aged with brine for the Pd range. Regardless of the aging conditions, the ν values of the SER specimens decrease with the increase in Pd. However, the ν values of the specimens aged with brine and stimulation fluid are generally lower than that of the specimens aged with brine.

Major and minor effective principal stresses

Figure 13a, b show the relationships between the major effective principal stress (P′a) and the minor effective principal stress (Pd) for USGS and SER specimens, respectively, aged with brine and brine + stimulation fluid. The P′a can be calculated using Eq. (6) as the summation of Pd and maximum deviator stress (Δσd).

Figure 13a shows that higher Pd increases the P′a of the USGS specimens for both treatment conditions. The USGS specimen treated with brine and stimulation fluid exhibits a slightly higher P'a of 225 MPa at the lowest Pd of 3.4 MPa, but a much lower P'a of 303 MPa at the higher Pd of 17.2 MPa than that of the specimens treated with brine. Figure 13b shows that the P'a values of the SER specimens treated with brine and stimulation fluid increase marginally with Pd. In other words, the P'a values increase from 138 to 150 MPa when the Pd increases from 4.8 to 18.6 MPa. Little to no increase in P'a of the SER specimens treated brine is observed. Generally, the P'a values for all Pd of the SER specimens treated with brine and stimulation fluid are higher than those of specimens treated with brine.

Shear strength parameters

Figure 14a, b present the effective friction angle (φ′) and the effective cohesion (c′) of the USGS and SER specimens, respectively. The φ' can be calculated using Eq. (7) based on the gradient (a) of the linear fitted line of the P'a and Pd relationship shown in Fig. 13. The c′ can be calculated using Eq. (8) based on the y-intercept value (b) of the linear fitted P'a and Pd line and calculated φ′.

Figure 14a shows that the stimulation fluid of the USGS specimens reduces the φ′ from 68 to 0° and increases the c' from 6 to 123 MPa. Figure 14b shows that the stimulation fluid increases the c' from 51 to 66 MPa, while the φ′ remains 0. The results indicate that Mowry Shale does exhibit c' but not the φ′ in providing resistance to shear.

Crack stress thresholds

Three crack stress thresholds are compared against the Pd and treatment conditions. The three crack stress thresholds are 1) crack closure threshold (σcc) when the closure of preexisting cracks occurs during the initial stage of loading, 2) crack initiation threshold (σci) when microfracture and stable crack propagation begins, and 3) crack damage threshold (σcd) when unstable crack growth occurs. The statistical method proposed by Yu et al. (Yu & Ng 2021) was adopted for determining these stress thresholds. Table 5 summarizes the three thresholds and the maximum deviatoric stress (Δσd) for USGS and SER specimens. In a few specimens, some stress thresholds cannot be distinctly determined from the stress–strain responses using the statistical method. The different stress thresholds of USGS specimens at both aging conditions increase with the increase in Pd (i.e., from TC0 to TC1). However, the increase in the stress thresholds with Pd cannot be consistently observed in the SER specimens due to comparable stress–strain responses shown in Fig. 10. The combination of higher Pd (i.e., TC1) and stimulation fluid reduces the stress thresholds of the USGS specimens. Generally, the stimulation fluid tends to increase the stress thresholds of the SER specimens in all Pd conditions. The USGS specimens have higher stress thresholds than those of the SER specimens.

Discussion

During the hydrostatic condition, an increase in Pd increased the maximum εv because the higher Pd mobilizes the deformation of granular particles and distortion of cementation. Specimens aged with brine + stimulation fluid showed higher peak strength than that of specimens aged with brine. Based on the results reported in the literature, in most cases, the strength of the shale specimens decreases after treatment with acidic fracturing fluid (Hou et al. 2018; Zhong et al. 2019; Bai et al. 2020). However, the pH of the solution is not the only factor affecting the posttreatment strength of the specimens. For instance, the strength of the continental shale after treatment with fracturing fluid was shown (Yang et al. 2023) to be dependent on the levels of clay minerals in the specimens. Specimens with lower clay contents showed smaller decreases in strength, compared to the untreated specimens. Even though the results of the present study are contradictory to most cases in the literature, one study (Lyu et al. 2022) reported a 5.8% increase in the strength of shale specimens after one month of soaking in an acidic solution, compared to the strength of 15 days. It is believed that the dissolution of the minerals created mineral particles that blocked and filled the original pores of the specimens and increased their post-treatment strength. However, this conclusion has been made based on a limited number of experiments and to firmly conclude the effect of fracturing fluid on the strength of Mowry Shale, future studies are needed. The results show that using the aforementioned fracturing fluid does not decrease the strength of the Mowry Shale. This is important because a decrease in the rock's strength can increase proppant embedment, lower the fracture conductivity, decrease well stability, reduce production rate, and increase operational costs (Acosta et al. 2020; Barati & Liang 2014; Pagels et al. 2013). Future research can be conducted on more Mowry shale specimens from different depths, on longer treatment duration, at different levels of acidity of fracturing fluids, and exposure to drilling muds.

Conclusions

Mowry shale specimens were collected from PRB#1 well prepared by the School of Energy Resources (SER) at the University of Wyoming (referred to as SER specimens) and Educated Guess 1-11H well from the United States Geological Survey (USGS) (referred to as USGS specimens). A series of 12.5-mm diameter shale specimens were prepared from the core samples, and the specimens were aged with brine and brine + stimulation fluids accordingly. Triaxial compression experiments were conducted on these specimens according to in situ pressure and temperature conditions. The stress–strain results and mechanical properties are presented and discussed in this paper. The following conclusions are drawn from this study:

-

(1)

All Mowry Shale specimens experience an increase in volumetric strain (εv) with an increase in effective confining pressure (Pd).

-

(2)

Specimens under higher Pd exhibit higher bulk moduli (K). For specimens at low Pd, stimulation fluid reduces the K values. However, stimulation fluid increases the K values of specimens at higher Pd.

-

(3)

Regardless of aging fluids, the maximum deviatoric axial stress (Δσd) of most Mowry Shale specimens increases with the increase in Pd. Generally, specimens aged with brine and stimulation fluid showed higher strength than the specimens aged with brine only.

-

(4)

For the USGS specimens, the stimulation fluid aging results in lower elastic modulus (E) values than those aged with brine. On the other hand, for the SER specimens, stimulation fluid increases the E values, on average by 7.5%, from those aged with brine.

-

(5)

The impact of the stimulation fluid on Poisson’s ratio (ν) of the USGS specimens depends on the Pd. For the SER specimens, the ν values of the specimens aged with brine and stimulation fluid are generally lower than that of the specimens aged with brine.

-

(6)

The USGS specimen treated with brine and stimulation fluid exhibits a slightly higher major effective principal stress (P'a) at the lowest Pd, but a much lower P'a at the higher Pd than those treated with brine. Generally, the P'a values for all Pd of the SER specimens treated with brine and stimulation fluid are higher than those of specimens treated with brine.

-

(7)

The stimulation fluid of the USGS specimens reduces the effective friction angle (φ′) and increases the effective cohesion (c'). Similarly, the stimulation fluid increases the c' of the SER specimen, while the φ′ remains 0.

-

(8)

The stress thresholds of USGS specimens at both aging conditions increase with the increase in Pd, while the increase in the stress thresholds with Pd cannot be consistently observed in the SER specimens. The combination of higher Pd and stimulation fluid reduces the stress thresholds of the USGS specimens.

Abbreviations

- B:

-

Aged with brine

- BS:

-

Aged with brine and stimulation fluid

- SER:

-

School of energy resources

- TC:

-

Triaxial compression

- USGS:

-

United States geological survey

- a :

-

The gradient of the linear fitted line of the P′a and Pd relationship

- b :

-

Y-intercept of the linear fitted P′a and Pd line

- c′ :

-

Effective cohesion (MPa)

- E :

-

Elastic modulus (GPa)

- K :

-

Bulk Modulus (GPa)

- P′ a :

-

Major effective principal stress (MPa)

- P c :

-

Confining pressure (MPa)

- P d :

-

Effective confining pressure/Minor effective principal stress (MPa)

- P p :

-

Pore pressure (MPa)

- T :

-

Temperature (°C)

- ΔPd :

-

Changes in effective confining pressure (MPa)

- Δɛ v :

-

Changes in volumetric strain (MPa)

- Δσ d :

-

Deviatoric axial stress (MPa)

- ε :

-

Strain

- ε a :

-

Axial strain

- ε r :

-

Radial strain

- ε v :

-

Volumetric strain

- ν :

-

Poisson’s ratio

- σ cc :

-

Crack closure threshold (MPa)

- σ cd :

-

Crack damage threshold (MPa)

- σ ci :

-

Crack initiation threshold (MPa)

- φ′:

-

Effective friction angle (°)

References

Abousleiman YN, Hoang SK, Tran MH (2010) Mechanical characterization of small shale samples subjected to fluid exposure using the inclined direct shear testing device. Int J Rock Mech Min Sci 47(3):355–367. https://doi.org/10.1016/j.ijrmms.2009.12.014

Acosta JC, Dang S, Curtis M, Sondergeld C, Rai C (2020) Fracturing fluids effect on mechanical properties in shales. In unconventional resources technology conference, 20–22 (1383–1396). Unconventional Resources Technology Conference (URTEC).

Aderibigbe AA, Lane RH (2013) SPE-164102-MS Rock/Fluid Chemistry Impacts on Shale Fracture Behavior. http://onepetro.org/SPEOCC/proceedings-pdf/13OCS/All-13OCS/SPE-164102-MS/1583954/spe-164102-ms.pdf/1

Akrad O, Miskimins J, Prasad M (2011) The effects of fracturing fluids on shale rock mechanical properties and proppant embedment. http://onepetro.org/SPEATCE/proceedings-pdf/11ATCE/All-11ATCE/SPE-146658-MS/1666607/spe-146658-ms.pdf/1

Anna LO, Cook TA (2008) Assessment of the mowry shale and niobrara formation as continuous hydrocarbon systems, powder river basin, Montana and Wyoming (2008–1367). US Geological Survey.

Bai J, Kang Y, Chen Z, You L, Chen M, Li X (2020) Changes in retained fracturing fluid properties and their effect on shale mechanical properties. J Nat Gas Sci Eng. https://doi.org/10.1016/j.jngse.2020.103163

Barati R, Liang JT (2014) A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J Appl Polym Sci 131(16)

Byers CW, Larson DW (1979) GEOLOGIC NOTES paleoenvironments of Mowry Shale (Lower Cretaceous). West Cent Wyoming AAPG Bull 63(3):354–361. https://doi.org/10.1306/C1EA5611-16C9-11D7-8645000102C1865D

Davis JC (1970) Petrology of cretaceous Mowry Shale of Wyoming. AAPG Bull 54(3):487–502. https://doi.org/10.1306/5D25C9B3-16C1-11D7-8645000102C1865D

Davis HR, Byers CW, Pratt LM (1989) Depositional mechanisms and organic matter in Mowry Shale (Cretaceous). Wyoming AAPG Bulletin 73(9):1103–1116. https://doi.org/10.1306/44B4A546-170A-11D7-8645000102C1865D

Esatyana E, Sakhaee-Pour A, Sadooni FN, Al-Kuwari HAS (2020) Nanoindentation of shale cuttings and its application to core measurements. Petrophysics 61(05):404–416

Esatyana E, Alipour M, Sakhaee-Pour A (2021) Characterizing anisotropic fracture toughness of shale using nanoindentation. SPE Reservoir Eval Eng 24(03):590–602

French KL, Birdwell JE, Lillis PG (2023) Geochemistry of the cretaceous Mowry Shale in the wind river basin. Wyoming GSA Bull 135(7–8):1899–1922. https://doi.org/10.1130/B36382.1

Goolsby, J. (2010). Horizontal drilling in mature fields. 4th Annual Wyoming CO2 Conference, The Wyoming Enhance Oil Recovery Institute.

Hollon ZG (2014) Elemental chemostratigraphy and reservoir properties of the Mowry Shale in the Bighorn and Powder River Basins, Wyoming, USA. Colorado School of Mines. Elemental chemostratigraphy and reservoir properties of the Mowry Shale in the Bighorn and Powder River Basins, Wyoming, USA - ProQuest

Hou Z, Gutierrez M, Wang A, Almrabat A, Yang C (2018) Mechanical properties and brittleness of shale with different degrees of fracturing-fluid saturation. In Curr Sci 115(6):1163–1173

Islam MA, Skalle P (2013) An experimental investigation of shale mechanical properties through drained and undrained test mechanisms. Rock Mech Rock Eng 46(6):1391–1413. https://doi.org/10.1007/s00603-013-0377-8

Karakul H (2018) Effects of drilling fluids on the strength properties of clay-bearing rocks. Arab J Geosci 11:1–11

Khalil RE, Mansour A, Gamadi T (2017) SPE-187478-MS An experimental study of acid matrix treatment performance on shale core samples. http://onepetro.org/SPELRBC/proceedings-pdf/17LRBC/2-17LRBC/D022S010R003/1291954/spe-187478-ms.pdf/1

Kirschbaum MA, Finn TM, Schenk CJ, Hawkins SJ (2019) Lithologic descriptions, geophysical logs, and source-rock geochemistry of the US Geological Survey Alcova Reservoir AR–1–13 Core Hole, Natrona County, Wyoming. US Geological Survey. (2019–5123). US Geological Survey.

Lai B, Liang F, Zhang J, Li L, Liu H, Al-Muntasheri G (2016) Fracturing fluids effects on mechanical properties of organic rich shale. ARMA US Rock Mechanics/Geomechanics Symposium, ARMA-2016.

Lin C, Kang YL, You LJ, Yan XP, Chen Q (2019) Effect of fluid exposure on mechanical properties of organic-rich shale and field applications. Proc Int Field Explor Dev Conf 2017. https://doi.org/10.1007/978-981-10-7560-5_158

Lyu Q, Wang K, Hu C, Dick JM, Shi J, Tan J (2022) Experimental study on the mechanical properties of shale after long-term of immersion in fracturing fluids with different pH. Rock Mech Rock Eng 55(8):5047–5061. https://doi.org/10.1007/s00603-022-02918-4

Ma T, Chen P, Zhao J (2016) Overview on vertical and directional drilling technologies for the exploration and exploitation of deep petroleum resources. Geomech Geophys Geo-Energy Geo-Resour 2:365–395. https://doi.org/10.1007/s40948-016-0038-y

Milliken KL, Olson T (2017) Silica diagenesis, porosity evolution, and mechanical behavior in siliceous mudstones, Mowry Shale (Cretaceous), Rocky Mountains, USA. J Sediment Res 87(4):366–387

Nixon RP (1973) Oil source beds in cretaceous Mowry Shale of northwestern interior United States. AAPG Bull 57(1):136–161. https://doi.org/10.1306/819A4250-16C5-11D7-8645000102C1865D

Pagels M, Willberg DM, Edelman E, Zagorski W, Frantz J (2013) Quantifying fracturing fluid damage on reservoir rock to optimize production. In SPE/AAPG/SEG Unconventional Resources Technology Conference (URTEC-1578948). URTeC.

Pish T (2014) Regional spotlight: powder river basin. Oil Gas Investor 32:1

Sakhaee-Pour A, Li W (2019) Two-scale geomechanics of shale. SPE Reservoir Eval Eng 22(01):161–172

Socianu AL (2016) Geochemical insights into the distribution of organic matter in the Mowry Shale. Southern Powder River Basin, Wyoming [MS Thesis]: Laramie, Wyoming, University of Wyoming.

Sun Z, Zhang H, Wei Z, Wang Y, Wu B, Zhuo S, Zhao Z, Li J, Hao L, Yang H (2018) Effects of slick water fracturing fluid on pore structure and adsorption characteristics of shale reservoir rocks. J Nat Gas Sci Eng 51:27–36. https://doi.org/10.1016/j.jngse.2017.12.030

Tan J, Hu C, Lyu Q, Feng G, Chen S (2022) Experimental investigation on the effects of different fracturing fluids on shale surface morphology. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2022.110356

United States Geological Survey Core Research Center (2023)

Wang H, Ma F, Tong X, Liu Z, Zhang X, Wu Z, Li D, Wang B, Xie Y, Yang L (2016) Assessment of global unconventional oil and gas resources. Pet Explor Dev 43(6):925–940. https://doi.org/10.1016/S1876-3804(16)30111-2

Wang L, Guo Y, Zhou X, Yang G, Yang C, Xiao J (2022) Mechanical properties of marine shale and its roof and floor considering reservoir preservation and stimulation. J Pet Sci Eng. https://doi.org/10.1016/j.petrol.2022.110194

Yang H, Wang L, Yang C, Guo W, Bi Z, Guo Y (2023) Experimental investigation on different effects of fracturing fluids on mechanical properties and failure mechanism of continental shale. Int J Rock Mech Min Sc. https://doi.org/10.1016/j.ijrmms.2023.105362

Yu H, Ng K (2021) New systematic method to determine elastic constants and crack propagation thresholds of brittle rocks under triaxial compression. Geotech Geol Eng 39(5):3931–3945. https://doi.org/10.1007/s10706-021-01737-8

Zhao G, Guo Y, Wang L, Chang X, Yang H, Guo W, Wu X, Yang C (2023) Experimental study on mechanical, brittleness, and fracture behavior of deep shales subjected to fracturing fluid-shale interactions at reservoir temperature and in-situ stress conditions. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-023-03555-1

Zhong Y, Kuru E, Zhang H, Kuang J, She J (2019) Effect of fracturing fluid/shale rock interaction on the rock physical and mechanical properties, the proppant embedment depth and the fracture conductivity. Rock Mech Rock Eng 52(4):1011–1022. https://doi.org/10.1007/s00603-018-1658-z

Acknowledgements

The authors would like to acknowledge the funding support from the School of Energy Resources of the University of Wyoming.

Funding

The researh was funded by the School of Energy Resources of the University of Wyoming.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the co-authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dabbaghi, E., Ng, K., Kou, Z. et al. Experimental investigation to understand the effect of fracturing fluid on the geomechanical behavior of mowry shale. J Petrol Explor Prod Technol 14, 1505–1519 (2024). https://doi.org/10.1007/s13202-024-01788-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-024-01788-6