Abstract

Polymer flooding has proved an effective technique to improve development efficiency in heterogeneous reservoirs. Previously, operators usually employed continuous injection of large polymer slugs. However, problems existed including premature injection profile reversal during development, ineffective circulation of polymer solution in low-permeability zones, and excessive polymer consumption in the late development stage. The paper proposed a combination method, named as polymer-alternating-water (PAW), to solve the issues of traditional polymer flooding. The characteristic of this method is injecting water slugs between polymer slugs during the polymer flooding process. At present, research on the PAW technique is limited, with the operational parameters, oil recovery mechanisms, and applicability under various reservoir conditions remaining unclear. In this work, a numerical polymer flooding model is developed using the commercial CMG-STARS reservoir simulation module to investigate the oil displacement performance of PAW. Numerical simulations are performed to determine the optimal parameters for maximizing oil recovery factor. The results indicated compared with continuous polymer flooding, PAW shows multiple peaks in daily oil production rate, with a significantly decreased decline rate, resulting in a 1.47% increase in recovery factor. Under different reservoir conditions including mean permeability, heterogeneity, and crude oil viscosity, PAW can achieve further improvements on the basis of continuous polymer flooding. Polymer adsorption and injection concentration significantly impact the recovery factor, requiring further optimization for field applications. In this study, better polymer flooding performance was achieved when the number of alternating cycles of PAW was 2, and the injected alternating water slug volume was 50%. This study contributes to a deeper understanding of the key mechanisms and parameters in PAW enhanced oil recovery process, thereby providing guidance for the further optimization and field application of this technique.

Similar content being viewed by others

Introduction

In the development of conventional oil reservoirs, multiple production stages are typically encountered, including primary recovery, secondary recovery, and potentially tertiary recovery (Thomas 2008). Despite the advancement of reservoir development and well production technologies, a significant amount of oil (up to two-thirds) remains trapped in the pore spaces of the reservoir rock (Niu et al. 2020). The primary reasons include challenges like reservoir heterogeneity, sweep and displacement efficiency, as well as rock–fluid interaction properties (Samba and Elsharafi 2018).

Enhanced oil recovery (EOR), often referred to as tertiary recovery, is employed to extract residual oil from reservoirs subsequent to primary and secondary recovery phases. It mainly includes techniques, such as steam flooding, miscible flooding, and chemical flooding. These EOR methods have different applicability based on the underlying mechanisms to address specific challenges (Syed et al. 2022). Polymer flooding, employed to enhance oil recovery in the context of chemical flooding, has undergone extensive research and practical application. Research on EOR indicates that 11% of global EOR projects involved chemical flooding. Within chemical flooding technologies, polymer flooding accounts for over 77% of the projects, while polymer/surfactant binary flooding represents 23% (Rellegadla et al. 2017).

Polymer flooding stands as an established oil recovery method, extensively implemented in both onshore and offshore oil reservoirs (Song et al. 2022). Despite initial field trials taking place in the USA, China currently spearheads the largest scale field trials and commercial applications of polymer flooding (Guo et al. 2022b). Figure 1 depicts the distribution of polymer flooding projects across China (Hill et al. 2020). According to recent surveys, China has over 170 polymer flooding projects, with Daqing oil field accounting for 93 of the oil field blocks involved in commercial production (Guo et al. 2022a). Recent research indicates that polymer flooding can elevate the recovery rate by 15.5% beyond waterflooding in certain Daqing blocks, culminating in a final recovery rate of 59.7% (Longde et al. 2021). Considering that the average recovery factor across all oil fields is approximately one-third of the geological reserves, this underscores the significant practical value of polymer flooding in oil field applications (Guo et al. 2023).

Polymer flooding in China (Hill et al. 2020)

Polymers can considerably alter the viscosity ratio of the displacing fluid system, resulting in a lowered viscosity index of the same system. The decreased relative permeability of the water phase can induce fluid diversion, thereby enhancing sweep efficiency (Mohsenatabar Firozjaii and Saghafi 2020). Nevertheless, the continuous injection of polymer solutions solely into the injection well presents some challenges. First, the high viscosity of polymers makes it challenging to achieve the desired injection rate due to the limited surface injection capacity into the reservoir (Zhong et al. 2017). Additionally, polymer adsorption onto rock surfaces can have a negative impact on the flow and injection capabilities of the displacing fluid. The factors influencing polymer adsorption in the reservoir encompass polymer type and concentration, molecular weight, rock permeability, flow rate, salinity, temperature, and the presence of clay minerals (Park et al. 2015). Overall, polymer adsorption is a critical factor that restricts the economic feasibility of polymer flooding as it affects rock permeability, the viscosity of injected polymer solutions, and subsequently, the oil recovery process (Agi et al. 2018). Hence, the injection of water slugs between polymer slugs (Fig. 2) promotes the desorption of adsorbed polymers from the rock surface, aiding the subsequent injection of polymer slugs. Moreover, PAW improves percentage of water injected in the low-permeability layers and enhances reservoir sweep efficiency (Sapniwat and Srisuriyachai 2017).

Zampieri and Moreno (2013) conducted multiple sets of laboratory core tests to compare the oil recovery performance between PF (polymer flooding) and PAW. Their ultimate findings indicate that, in the majority of cases, injecting polymer solutions can postpone water breakthrough, and the oil recovery factor is further enhanced with PAW compared to PF.

Tuncharoen and Srisuriyachai (2018) conducted a sensitivity analysis using numerical simulation software to determine the optimal engineering parameters for PAW and maximize the recovery factor. The results indicated that in the alternating process, the size of the water slug should be smaller than 5% of the polymer slug’s size, and the concentration of the polymer slug should remain consistent. Additionally, the best injection effect was achieved when the alternating cycle was repeated twice. Compared to PF, this approach resulted in a 0.65% increase in oil recovery.

Pan et al. (2020) conducted a dual-tube experiment to study the long-term PF and PAW in addressing the issues of decreased injection capacity and excessive polymer consumption in the late stage of a heavy oil field in the southern Bohai Bay. The results demonstrated that PAW could further improve the polymer flooding performance. It increased the water intake in low-permeability layers, adjusted the water intake profile, effectively suppressed profile reversal during polymer injection, and enhanced the displacement efficiency of medium- and low-permeability oil reservoirs. As a result, the oil recovery in heterogeneous reservoirs was improved. In 2016, PAW was implemented in the target reservoir, leading to a 20% increase in injection rate, a 30% increase in daily oil production, and an 8% decrease in water cut. During the injection process, polymer consumption was reduced by 50%, and operational costs decreased by 85%, resulting in significant economic benefits.

At present, there are relatively limited researches on PAW in terms of laboratory experiments, numerical simulations, and field applications. The underlying mechanisms of how PAW enhances oil recovery and its applicability under different reservoir conditions have not been well understood yet. This study aims to investigate the oil displacement mechanisms of PAW, and assess its applicability under different reservoir conditions through numerical simulations. The rest of the paper was organized as follows: Section “Reservoir model and fluid properties” constructs the representing reservoir model and defines the fluid properties; Section “Numerical simulation study of PAW” compares the performance of PF and PAW with numerical simulation; Section “Feasibility study of PAW under different reservoir and fluid conditions” studies the feasibility of PAW under different reservoir and fluid conditions; Section “Sensitivity analysis” presents a sensitivity analysis of PAW; Section “Conclusions” concludes the paper.

Reservoir model and fluid properties

This study utilized the commercial numerical simulation software CMG with the STARS module. The model grid size was 51 × 51 × 7, with each grid dimension measuring 10 m × 10 m × 3 m. The reservoir length, width, and thickness were 510 m, 510 m, and 21 m, respectively. The reservoir was located at a depth of 1830 m underground and was uniformly distributed. The injection and production wells follow a five-spot pattern within the reservoir, with one injector well located at the center and four producer wells at each corner. The reservoir model is shown in Fig. 3. Figure 4 shows the horizontal permeability in the X direction, with the Y direction having the same horizontal permeability values. The vertical permeability in the Z direction is 0.1 times that of the X direction. Based on the permeability classification criteria, the reservoir is divided into high-permeability layers (Layers 1–4), medium-permeability layers (Layers 5–6), and a low-permeability layer (Layer 7). Table 1 presents the main characteristic parameters of the reservoir model and fluid properties.

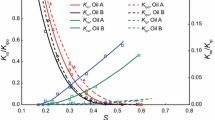

Rock adsorption and polymer viscosity are two important parameters for polymer flooding. As lack of polymer test, polymer viscosity and adsorption were assumed in this simulation. Figure 5 shows three correlations between polymer concentration and polymer adsorption. For Function 1, the maximum adsorption is 0.16 gmol/m3; for Function 2, the maximum adsorption is 0.21 gmol/m3; and for Function 3, the maximum adsorption is 0.26 gmol/m3. The correlation between polymer viscosity and polymer concentration is shown in Fig. 6 (Li and Schechter 2014). Furthermore, in this simulation, it is assumed that the residual resistance factor of the polymer is 2, and the inaccessible pore volume of the polymer is 0.8 (Tuncharoen and Srisuriyachai 2018).

Numerical simulation study of PAW

The numerical simulation of PF and PAW is conducted when the water cut reaches 90% during waterflooding. The injection rate is set at 0.1 PV/a. In the numerical simulation for PF, 0.6 PV of polymer is continuously injected, followed by the resumption of waterflooding. In the numerical simulation for PAW, 0.3 PV of polymer is injected, followed by 0.15 PV of water, and then another 0.3 PV of polymer is injected before resuming waterflooding.

The simulation results showed that the final recovery for WF (waterflooding) was 41.52%. For PF, the final recovery was 55.07%, and for PAW, the final recovery was 56.54%. The increase in recovery compared to WF is 13.55% for PF and 15.02% for PAW. When comparing the two injection methods, PAW achieved a 1.47% higher ultimate recovery compared to PF (Fig. 7).

Analyzing the daily oil production curves and water cut curves for PF and PAW, it was observed that PAW generated two peaks in daily oil production (Fig. 8). The rate of decline in daily oil production was slower in PAW, and the corresponding water cut experienced two lower points, indicating a more effective water cut reduction that lasted longer during the entire simulation process (Fig. 9).

During the injection of the polymer solution into the reservoir, the polymer tends to be adsorbed onto the rock surfaces. Due to the differences in interlayer permeability, the volume of polymer solution entering each layer varies significantly, ultimately resulting in different polymer adsorption densities on the rock surfaces. Comparing the adsorbed polymer density distribution in the each layer for both PF and PAW, the results indicate the following:

-

(1)

After polymer injection, the polymer density at the center of the high-permeability layer (Layer 1) is 2.28 kg/m3 for PF and 1.68 kg/m3 for PAW;

-

(2)

At the center of the middle-permeability layer (Layer 4) is 1.70 kg/m3 for PF and 1.50 kg/m3 for PAW;

-

(3)

At the center of the low-permeability layer (Layer 7) is 1.12 kg/m3 for PF and 0.81 kg/m3 for PAW.

It is observed that PAW exhibits significantly lower polymer adsorption density in all layers compared to PF (Figs. 10, 11, and 12).

The difference in polymer adsorption density on the rock surfaces in different layers results in varying percentage of water injected at different layers, directly affecting the variation of water saturation at each layer. Comparing the water saturation distribution after PF and PAW at different layers, the results show that the water saturation at the center of the high-permeability layer (Layer 1) decreases from 0.59 to 0.53 (Fig. 13). The water saturation at the center of the medium-permeability layer (Layer 4) increases from 0.45 to 0.50 (Fig. 14). The water saturation at the center of the low-permeability layer (Layer 7) increases from 0.39 to 0.44 (Fig. 15).

Comparing the percentage of water injected in different layers for PF and PAW, it is observed that in the high-permeability layers (Layers 1 to 4), the cumulative injection proportion decreases from 78 to 70%. In the middle-permeability layers (Layers 5–6), the cumulative injection proportion increases from 18 to 21%. In the low-permeability layer (Layer 7), the injection proportion increases from 4 to 9% (Fig. 16).

Feasibility study of PAW under different reservoir and fluid conditions

The crude oil viscosity

Polymer drive is usually used for reservoir fluids with crude oil viscosities of 10–150 mPa s, and the specific range of applicability is affected by a variety of factors such as reservoir conditions, polymer type, injection concentration, and injection temperature. Before conducting the feasibility study, a total of four (5, 10, 20, and 50 mPa s) crude oil viscosity values were set, and a total of several sets of simulations were tested within the range of polymer concentration of 0–2500 mg/L (Fig. 17), and it can be seen that under the same crude oil viscosity, the larger the polymer-to-crude oil viscosity ratio is, the larger the recovery rate increase is. However, when the viscosity ratio increases to a certain degree, the recovery improvement is no longer obvious. For light crude oil, under the condition of the same viscosity ratio, the increase in the recovery degree when the crude oil viscosity is larger is higher than that when the crude oil viscosity is lower. The optimal polymer injection concentrations for different crude oil viscosities were finally determined as shown in Table 2.

From Fig. 18, the following observations can be made. The lower the crude oil viscosity, the higher the oil recovery rates for WF, PF, and PAW methods. When the crude oil viscosity is 5 mPa s, the recovery improvement of PF on the basis of WF is the smallest 13.17%. When the crude oil viscosity is 20 mPa s, the recovery improvement of PF on the basis of WF is the largest 17.28%. In the range of different crude oil viscosities, the recovery improvement of PF on the basis of WF was 13.17–17.28%. When the crude oil viscosity is 20 mPa s, the recovery improvement of PAW over PF is the smallest 1.11%. When the crude oil viscosity is 5 mPa s, the recovery improvement of PAW over PF is the largest 1.92%. In the range of different crude oil viscosities, the recovery improvement of PAW on the basis of PF was 1.11–1.92%. It can be seen that PAW is suitable for reservoirs with different ranges of crude oil viscosity, and all of them can improve the final recovery to some extent on the basis of PF.

Mean permeability

Before conducting the feasibility study, multiple simulations were performed for different reservoir mean permeabilities (50, 100, 200, 600, and 1000 mD) and polymer concentrations ranging from 0 to 2500 mg/L (Fig. 19). It can be observed that, for the same reservoir average permeability (50–200 mD), a higher polymer-to-oil viscosity ratio results in a greater increase in oil recovery. However, after reaching a certain viscosity ratio, the increase in oil recovery becomes less significant. For reservoirs with an average permeability of 1000 mD, the oil recovery continues to increase within the tested polymer concentration range, indicating the potential need for higher polymer concentrations. Under the condition of the same viscosity ratio, the increase of recovery rate appears to increase and then decrease with the increase of the average permeability of the reservoir. The optimal polymer injection concentrations for different reservoir average permeabilities were finally determined as shown in Table 3.

From Fig. 20, the following observations can be made. The greater the average permeability of the reservoir, the higher the WF recovery. When the permeability is 50–600 mD, the larger the average permeability, the higher the recovery of PF and PAW. When the average permeability is 1000 mD, the recovery of PF and PAW decreases, mainly due to the fact that at this time the concentration of the polymer is small, and it is necessary to inject a higher concentration of polymer. The greater the average permeability, the greater the increase in recovery of the PAW over the PF. When the average permeability is 50 mD, the recovery increases by 0.24%, while the recovery increases by 1.88% as the average permeability is 1000 mD. When the permeability changes from 600 to 1000 mD, the recovery of both PF and PAW decreases to some extent. Thus, the use of polymer displacement technology in medium- to high-permeability reservoirs can significantly enhance oil recovery. Moreover, under the same reservoir conditions, PAW can enhance the final oil recovery to a certain extent compared to PF. However, in high-permeability reservoirs, a higher concentration of polymer is required.

Heterogeneous formation

Reservoir heterogeneity is an important aspect of describing reservoir, as interlayer heterogeneity can lead to interlayer interference and affect the microscale displacement efficiency of injected chemicals. Therefore, it is essential to conduct feasibility studies of PAW in reservoirs with different degrees of heterogeneity. The variation in interlayer permeability, especially the horizontal permeability, is a crucial parameter for quantitatively describing interlayer heterogeneity and can be represented using the permeability variation coefficient (VDP).

Before conducting the feasibility study, two sets of heterogeneous reservoir models were established with average permeabilities of 200 mD and 600 mD, and permeability variation coefficients of 0.5, 0.6, 0.7, 0.8, and 0.9. Multiple simulations were performed in the range of polymer concentration from 0 to 2500 mg/L (Fig. 21). It can be observed that when the average permeability is 600 mD, the stronger the reservoir heterogeneity, the better the improvement in oil recovery. Additionally, the optimal polymer injection concentration for different heterogeneous reservoir models is very close, at approximately 2100 mg/L.

From Fig. 22, we can observe the column chart of oil recovery for different heterogeneity cases (WF, PF, and PAW) when the average permeability is 600 mD. The smaller the heterogeneity represented by the permeability variation coefficient, the higher the oil recovery for WF, PF, and PAW. PF shows an oil recovery improvement of 13.59–14.88% compared to WF. PAW shows an oil recovery improvement of 0.93–1.22% compared to PF.

As shown in Fig. 23, when the average permeability is 200 mD, the oil recovery increases with the increase of the viscosity ratio. However, after reaching a certain point, there is a slight decrease in the oil recovery. This is mainly because as the polymer concentration increases, the injection capability of the polymer becomes weaker. It is worth noting that the optimal polymer injection concentration is quite similar for different heterogeneity cases, approximately 1200 mg/L.

From Fig. 24, we can observe the column chart of oil recovery for different heterogeneity cases (WF, PF, and PAW) when the average permeability is 200 mD. It indicates that smaller VDP results in higher oil recovery for WF, PF, and PAW. PF exhibits an increase in oil recovery by 12.53–13.36% compared to WF. PAW shows an additional improvement in oil recovery by 0.61–0.78% compared to PF. It can be inferred from the results that PAW can improve the final recovery to a certain extent on the basis of PF under different heterogeneity conditions in medium- and high-permeability reservoirs, and the effect is better in high-permeability reservoirs.

Sensitivity analysis

In this section, sensitivity analyses are performed for polymer adsorption, polymer concentration, number of alternating cycles, and alternating water slug size for the specific scenarios shown in Table 4.

Polymer adsorption

During the polymer injection process, the adsorption of the polymer onto the rock surfaces results in two primary effects. Firstly, it diminishes the polymer concentration within the reservoir. Secondly, it alters the percentage of water injected into various levels of the reservoir, impacting the distribution of the polymer solution. In Fig. 5, three sets of adsorption curves were plotted for numerical simulations of PF and PAW.

In PF and PAW simulations, the decline in polymer adsorption is associated with reduced adsorption density in low-permeability rock (Figs. 25 and 26), leading to increased polymer mobility and a greater proportion of liquid uptake, thereby improving the sweep efficiency of the reservoir. Additionally, as polymer adsorption decreases, the peak oil production increases (Fig. 27), and the improvement in water cut becomes more effective (Fig. 28). This phenomenon is attributed to the loss of flow control exerted by the polymer due to its adsorption on the rock’s surface, which results in reduced polymer adsorption and ultimately higher ultimate recovery (Fig. 29). Furthermore, as the polymer adsorption diminishes, PF shows a more substantial increase in recovery rate compared to WF, and PAW shows an even greater increase compared to PF.

Polymer concentration

Polymers have a notable impact on altering the fluidity ratio of the oil displacement system and reducing its viscosity index. The system’s decreased relative permeability in the water phase induces fluid diversion, thereby increasing the sweep efficiency coefficient. The research comprised three sets of numerical simulations with injection concentrations of 1000 mg/L, 1500 mg/L, and 2000 mg/L, while maintaining a uniform size for the injected polymer slug.

The study found that higher polymer concentrations result in better incremental oil production for both PF and PAW methods, leading to higher peak oil production. Additionally, PAW shows more pronounced double-peak characteristics (Fig. 30) and better water cut improvement effects (Fig. 31) with increasing polymer concentration. At a polymer concentration of 2000 mg/L, the highest recovery rates for PF and PAW are 55.07% and 56.54%, respectively (Fig. 32). However, as the polymer concentration increases, the rate at which PAW improves recovery rate compared to PF diminishes. In practical applications, the concentration of polymer should not be increased indiscriminately. Higher polymer concentrations result in a significant increase in viscosity, leading to higher injection pressures under constant injection rates. Excessive pressure may even cause reservoir rock fracturing, indicating that higher polymer concentrations are not always better in practice.

Number of alternate cycles

In the process of alternate injection, four comparative schemes were established to investigate the influence of the number of alternate cycles on the effectiveness of polymer flooding. These schemes involved alternate cycles of 1, 2, 3, and 4 times, where a single alternate cycle is equivalent to PF.

The research findings revealed that as the number of alternate cycles increased, the polymer’s effective action time extended, leading to a multi-peak distribution and reduced peak values in the daily oil production curve (Fig. 33). Additionally, the water cut curve showed repetitive fluctuations (Fig. 34). At two alternate cycles, the highest recovery rate reached 56.94%. However, with an increase in the number of alternate cycles, the recovery rates showed a varying degree of decline (Fig. 35). The reason for the lower oil recovery when more than 2 cycles are used is that the polymer dosage of each slug becomes too small, which is not sufficient to maintain the effectiveness of the polymer. This results in a relatively lower oil recovery. Overall, the optimal oil displacement effect was achieved when the polymer and water were alternated for two cycles.

Alternating water slug size

In the process of alternate injection, five comparative schemes were established to investigate the influence of the injected water slug size on the effectiveness of polymer flooding. This was achieved by varying the injection time of water in each cycle, thus altering the size of the injected water slug. The comparative schemes included polymer slug sizes of 0%, 5%, 10%, 20%, 50%, and 100%, with 0% denoting continuous polymer injection.

The research findings indicate that during the injected water slug phase, as the size of the injected water slug increases, the daily oil production shows a more pronounced decrease with a reduction in the peak value (Fig. 36). Additionally, there is a greater increment in the water cut, along with an increase in the lowest water cut value (Fig. 37). When the injected water slug size is 5% of the polymer slug, the recovery rates of both PAW and PF are equal. This is attributed to the limited polymer desorption caused by the small size of the injected water slug. However, as the injected water slug size exceeds 5% of the polymer slug, the longer desorption time of the polymer adsorbed on the rock surface leads to an increased polymer injection capacity, resulting in higher recovery rates. At 100% injected water slug size, the recovery reaches its peak at 56.02%. Nevertheless, the rate of improvement is limited, and the process takes longer. Considering all factors, the injected water slug size at 50% of the polymer slug exhibits a more favorable oil displacement effectiveness (Fig. 38).

Conclusions

In this paper, the injection method of polymer-alternating-water (PAW) was proposed on the basis of polymer flooding (PF), and the oil repulsion mechanism of PAW was studied through the comparison of PF and PAW. Furthermore, a feasibility assessment of PAW was conducted across varying crude oil viscosities, reservoir average permeabilities, and reservoir heterogeneity levels. Additionally, the effects of polymer adsorption, polymer concentration, alternating cycle count, and size of alternating water slugs on PAW were elucidated. The ensuing conclusions can be summarized as follows:

-

(1)

In reservoir conditions with medium to high permeability, the oil rate curve of PAW shows a distinctive multi-peak pattern, showing a considerable decrease in the rate of oil rate decline. Compared to PF, the recovery experiences an increase of 1.47%. Furthermore, the injection of PAW leads to a higher liquid absorption proportion in the middle and low-permeability layers, resulting in an enhanced degree of reservoir sweep.

-

(2)

Under different reservoir conditions, including permeability, heterogeneity, and crude oil viscosity, PAW has the potential to increase the recovery rate compared to PF.

-

(3)

The impact of polymer adsorption and concentration on the recovery rate is significant, requiring further optimization in practical field applications.

-

(4)

Under medium- to high-permeability reservoir conditions, with a number of alternate cycles of 2 and an alternating water slug size set at 50% of the polymer slug, the final recovery rate is higher for PAW.

In summary, this study emphasizes the innovation of the PAW. This technique offers a novel approach to reservoir development, addressing issues present in traditional methods. It holds significant potential for widespread application and provides valuable guidance for practical reservoir development.

Abbreviations

- K h :

-

Horizontal permeability

- K v :

-

Vertical permeability

- PAW:

-

Polymer-alternating-water

- PF:

-

Polymer flooding

- PV:

-

Pore volume

- VDP:

-

Dykstra–Parsons permeability variation coefficient

- WF:

-

Waterflooding

- EOR:

-

Enhanced oil recovery

References

Agi A, Junin R, Gbonhinbor J, Onyekonwu M (2018) Natural polymer flow behaviour in porous media for enhanced oil recovery applications: a review. J Pet Explor Prod Technol 8:1349–1362. https://doi.org/10.1007/s13202-018-0434-7

Guo H, Lyu X, Meng E, Xu Y, Zhang M, Fu H, Zhang Y, Song K (2022a) CCUS in China: challenges and opportunities. In: Presented at the SPE improved oil recovery conference, SPE, Virtual, Day 3 Wed, April 27, 2022, p D031S031R002. https://doi.org/10.2118/209468-MS

Guo H, Lyu X, Xu Y, Liu S, Zhang Y, Zhao F, Wang Z, Tang E, Yang Z, Liu H, Song K (2022b) Recent advances of polymer flooding in China. In: Presented at the SPE conference at Oman petroleum & energy show, SPE, Muscat, Oman, Day 2 Tue, March 22, 2022, p D022S042R002. https://doi.org/10.2118/200084-MS

Guo H, Wang Z, Dang S, Wen R, Lyu X, Liu H, Yang M (2023) What is learned from polymer flooding practices in offshore reservoirs?. In: Presented at the offshore technology conference, OnePetro. https://doi.org/10.4043/32314-MS

Hill LB, Li X, Wei N (2020) CO2-EOR in China: a comparative review. Int J Greenh Gas Control 103:103173. https://doi.org/10.1016/j.ijggc.2020.103173

Li W, Schechter DS (2014) Using polymer alternating gas to maximize CO2 flooding performance. In: Presented at the SPE energy resources conference, OnePetro. https://doi.org/10.2118/SPE-169942-MS

Longde S, Tongwen J, Fenglan W, Xiaolin W, Kai L, Hang J, Peihui H (2021) Thoughts on the development life of oilfield. Acta Pet Sin 42:56. https://doi.org/10.7623/syxb202101005

Mohsenatabar Firozjaii A, Saghafi HR (2020) Review on chemical enhanced oil recovery using polymer flooding: fundamentals, experimental and numerical simulation. Petroleum 6:115–122. https://doi.org/10.1016/j.petlm.2019.09.003

Niu J, Liu Q, Lv J, Peng B (2020) Review on microbial enhanced oil recovery: mechanisms, modeling and field trials. J Pet Sci Eng 192:107350. https://doi.org/10.1016/j.petrol.2020.107350

Pan G, Zhang L, Huang J, Li H, Qu J (2020) Twelve years field applications of offshore heavy oil polymer flooding from continuous injection to alternate injection of polymer-water. In: Presented at the offshore technology conference Asia, OTC, Kuala Lumpur, Malaysia, Day 4 Thu, November 05, 2020, p D041S038R001. https://doi.org/10.4043/30277-MS

Park H, Han J, Sung W (2015) Effect of polymer concentration on the polymer adsorption-induced permeability reduction in low permeability reservoirs. Energy 84:666–671. https://doi.org/10.1016/j.energy.2015.03.028

Rellegadla S, Prajapat G, Agrawal A (2017) Polymers for enhanced oil recovery: fundamentals and selection criteria. Appl Microbiol Biotechnol 101:4387–4402. https://doi.org/10.1007/s00253-017-8307-4

Samba MA, Elsharafi MO (2018) Literature review of water alternation gas injection. J Earth Energy Eng 7:33–45. https://doi.org/10.25299/jeee.2018.vol7(2).2117

Sapniwat S, Srisuriyachai F (2017) Effects of polymer adsorption and desorption on polymer flooding in waterflooded reservoir. Int J Res Sci 3:1–5. https://doi.org/10.24178/ijrs.2017.3.3.01

Song K, Tao J, Lyu X, Xu Y, Liu S, Wang Z, Liu H, Zhang Y, Fu H, Meng E, Liu M, Guo H (2022) Recent advances in polymer flooding in China. Molecules 27:6978. https://doi.org/10.3390/molecules27206978

Syed FI, Dahaghi AK, Muther T (2022) Laboratory to field scale assessment for EOR applicability in tight oil reservoirs. Pet Sci 19:2131–2149. https://doi.org/10.1016/j.petsci.2022.04.014

Thomas S (2008) Enhanced oil recovery: an overview. Oil Gas Sci and Technol Rev IFP 63:9–19. https://doi.org/10.2516/ogst:2007060

Tuncharoen W, Srisuriyachai F (2018) Evaluation of polymer alternating waterflooding in multilayered heterogeneous waterflooded reservoir. In: MATEC web of conferences, vol 171, p 04001. https://doi.org/10.1051/matecconf/201817104001

Zampieri M, Moreno R (2013) Water injection, polymer injection and polymer alternating water injection for enhanced oil recovery: a laboratory study. In: Presented at the proceedings of the international conference on offshore mechanics and Arctic engineering—OMAE. https://doi.org/10.1115/OMAE2013-10243

Zhong H, Zhang W, Fu J, Lu J, Yin H (2017) The performance of polymer flooding in heterogeneous type II reservoirs—an experimental and field investigation. Energies 10:454. https://doi.org/10.3390/en10040454

Funding

The funding was provided by simulation test of different chemical combination flooding effect in medium- and high-permeability reservoirs (Grant No. RIPED-2022-CL-1472).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the co-authors, the corresponding author wishes to confirm that there are no known conflicts of interest associated with this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dong, Z., Pan, X., Li, W. et al. Using polymer-alternating-water to maximize polymer flooding performance. J Petrol Explor Prod Technol (2024). https://doi.org/10.1007/s13202-024-01782-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13202-024-01782-y