Abstract

Multi-layer commingle production is a common development technique to improve the overall oil recovery of multi-layer reservoirs. However, this technique is mainly used at low water cut stage. Research on this technique at high water cut stage is comparatively few. Therefore, in order to improve productivity and recovery of wells, feasibility analysis of commingle production of multi-layer reservoirs in the high water cut stage is analyzed. To achieve a good commingle production result, the production layers must be optimized and inter-layer interference must be analyzed and reduced as much as possible. Factors, such as permeability, porosity, viscosity, capillary pressure, gravity, pressure difference, and water cut difference, have impact on commingle production. But it is difficult to consider all these factors. Therefore, according to the geological reservoir characteristics of X Oilfield, a model is established to simulate commingle production process, and the results are compared and analyzed. The interference degree is characterized by seepage resistance. The commingle production effect is evaluated by dimensionless oil increase coefficient, production index, and production index interference coefficient. The results show that the larger the difference of permeability ratio and water cut between multi-layers, the more severe the interlayer interference; dimensionless oil increase coefficients are all positive, it means that commingle production can achieve good oil increase effect even in the high water cut stage; the recommended technical limits for commingle production are that: permeability ratio is less than 5; commingle production timing is that water cut of low permeability layer is higher than 80%. This technique has been applied to X Oilfield, and the oil recovery increased about 2.8%, which confirmed this method feasibility.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Multi-layer commingle production is an important development technique used in field to improve the productivity and the oil recovery of multi-layer reservoirs (Liu et al. 2019; Shi et al. 2006; Jackson and Banerjee 2000). However, multi-layer commingle production is generally used in the early or relatively lower water cut stage in the development process (Cui and Zhao 2010; Hu et al. 2010). Less consideration is given to the effect of multi-layer commingle production in the high water cut stage. As we all know, multi-layer commingle production is commonly used in the early stage of development, and then in the later stage, the layers are finely divided and converted to single-layer production from multi-layer commingle production. This is a common development mode in oilfield development. However, for the target oilfield, due to its national legal requirements, only single-layer production is allowed in the whole development. Therefore, different from regular development we know, when it is in the high water cut stage after decades of single-layer production, whether it is feasible to convert to multi-layer commingle production in the high water cut stage is the focus of our work. It can give us some inspiration for oilfield development to sustain stable production. Therefore, in order to improve the productivity and economic profit within the limited contract period, it is important to comprehensively study on the feasibility of commingle production of multi-layer reservoirs in the high water cut stage.

Multi-layer reservoirs are mostly heterogeneous reservoirs. Due to the heterogeneity among multi-layers in the vertical direction, different layers may have different producing degree when single layer production, resulting in different interlayer interference degree during the multi-layer commingle production process. Significant differences in producing degree and recovery of each layer is the main contradiction that affects the overall oilfield development effect (Yu et al. 2006; Jiang et al. 2022; Xiong et al. 2010). Many factors such as permeability, porosity, viscosity, capillary pressure, gravity, pressure difference, and water cut difference have impact on multi-layer commingle production. Currently, methods of indoor physical simulation experiments and numerical simulations are mostly used to analyze multi-layer commingle production (Wu 2017; Zhang et al. 2014; Kan et al. 2019). Wang Zhibo et al. (2012) use numerical simulation methods to study the interference of positive and negative rhythm reservoirs on the multi-layer commingle production under interlayer or no interlayers situation in the low water cut stage, and found that the permeability ratio is the main factor influencing interlayer interference in the low water cut stage; Cui Chuanzhi et al. (2018) propose the ‘apparent mobility’ to study equivalent permeability of fractured layers in the low-permeability reservoirs, and found that artificial fractures has a significant impact on multi-layer commingle production in the low-permeability reservoirs. Li Yu et al. (2018) use physical simulation methods to analyze that the main controlling factors of interlayer interference during multi-layer commingle production in the low water cut stage are permeability ratio and pressure difference. Liu Lingli et al. (2022) perform a set of multi-layered commingle production simulation experiments, and found that big interlayer pressure difference will cause obvious backflow phenomenon that oil flow from the high-pressure layer to the low-pressure layer in the initial stage and commingle production layer should be have small pressure differences. Currently, research on multi-layer commingle production mainly focuses on the low water cut stage in the early development stage, while less focuses on the high water cut stage in the late development stage. And also it mainly studies on the influence of geological parameters, such as permeability, oil viscosity, oil layer thickness, and inter-layers on commingle production (Huang et al. 2015; Zhao 1983; Mu et al. 2021), without considering the impact of water cut. In the late development high water cut stage, is it feasible to switch from single-layer production to multi-layer commingle production? Further in-depth research is needed.

Therefore, combined reservoir engineering methods and numerical simulation methods, the mechanism of interlayer interference from the perspective of seepage resistance is analyzed first, and then based on the actual geological and development characteristics of X Oilfield, permeability ratio and water cut are selected as main controlling factors to study their influence on multi-layer commingle production, and then the change laws of production index, dimensionless oil increase coefficient and production index interference coefficient are studied before and after commingle production under different permeability ratio and water cut conditions, thus the influence of permeability ratio and water cut on commingle production are analyzed in depth. It lays a theoretical foundation for commingle production of multi-layer reservoirs in high water cut stage of X Oilfield.

Overview of X reservoirs

Oilfield X is a multi-layer sandstone reservoir with strong edge and bottom water energy, and the difference between formation and saturation pressures is large. In the early stage, it is mainly developed with natural energy. Currently, it is collaboratively developed through natural water flooding and artificial water injection. It has three sets of layers, which are A, B, and C. Layer A is the main production layer. It has good physical properties, with an average porosity of 25% and an average permeability of 4000 × 10−3 μm2, which belongs to high porosity and permeability sandstone edge and bottom water reservoir. Compared with A, the physical properties of layer B are relatively poor with porosity of 16%–26% and permeability of (200–2000) × 10−3 μm2. For layer C, the porosity is 16%–22%, and the permeability (400–1000) × 10−3 μm2. Layer B and C reservoirs are medium porosity and permeability sandstone edge and bottom water reservoirs. In this area, most oil is medium viscosity crude oil, the rest are heavy and ultra-heavy crude oil.

Different from domestic and most overseas oilfields that multi-layer commingle production first and then single-layer production, Oilfield X has been producing with single-layer reservoir since it is put into production due to the development policies of the government, and after nearly 50-year single-layer production, the main oil fields are already in the "dual high" development stage that is high recovery and high water cut stage, with a highly dispersed distribution of remaining oil. The water cut of production wells are mostly higher than 90%, and there are more and more low-production and low-efficient wells, it is extremely severe to maintain stable production and achieve efficient development in the future.

Mechanism analysis of interlayer interference

For the target Oilfield X, it is low amplitude structural reservoirs with 3 main layers, and nearly has no difference in reservoir thickness and oil viscosity. Therefore, in the process of mechanism analysis of interlayer interference, 3 layers are extracted to study on the influence of different permeability ratios on interlayer interference. Under those 3 modes, these 3 layers not just represent 3 different layers, but 3 different permeability ratio layers. That means that for more than 3 layer reservoirs, even more than 10 layer reservoirs, this multi-layer commingle production method can also be used in the oilfield, as long as the permeability ratio between different layers meets the technical limit.

In the development process of multi-layer reservoirs, the phenomenon of mutual interference caused by difference of permeability, fluid property, and pressure among different layers during fluid flow is called interlayer interference (Zhou et al. 2017). Many factors such as permeability, porosity, viscosity, capillary pressure, gravity, pressure difference, and water cut difference have impact on multi-layer commingle production. But it is difficult to take all these factors into account when analyze the effect of multi-layer commingle production. Therefore, we mainly analyze the main affecting factors in this paper, and according to Darcy's formula (Q = KAΔP/μL), the main factors affecting production are pressure difference and seepage resistance. In the process of oil–water two-phase non-piston displacement, the permeability, thickness, oil viscosity, relative permeability, etc. are the main factors influencing seepage resistance. Although porosity is neither the main factor of affecting oil production nor taken into account in the mechanism analysis of interlayer interference, it can also be indirect characterized by permeability factor, because in the real oilfield high permeability corresponding to high porosity and low permeability corresponding to low porosity, which means that porosity is indirect analyzed to some extent.

As for capillary pressure and gravity, the permeability range of the layers is more than hundreds of millidarcy, not only the higher permeability layer, but also the lower permeability layer, which means that the permeability of the lower permeability layer (400 mD) is just relatively lower than that of higher permeability layers, not real low permeability layer. In such situation, the capillary pressure in the model is just about 0.02 MPa, very small compared with displacement pressure difference (about 14.3 MPa), especially in the high water cut stage, the capillary pressure will become smaller, because it is reduced with water cut increasing. Therefore, in the model the capillary pressure is not taken into account the main affecting factor. And the net pay of the layers are very thin, just about 4 m, and the reservoir belongs to low amplitude structural reservoir, thus the effect of the gravity is quite limit. Also in the mechanism analysis of interlayer interference, we focus on the difference between the layers, therefore the gravity is not considered in the mechanism analysis of interlayer interference.

Therefore, we mainly analyze the influence of pressure difference and permeability ratio and water saturation on production. Because the production is affected by pressure difference and seepage resistance, and the seepage resistance is affected by the permeability ratio and relative permeability, the relative permeability is affected by water saturation. Based on the Buckley Leverett theory (Ma et al. 2021), the relationship between water cut and water saturation can be obtained from the fractional flow equation, and the seepage resistance under different permeability ratio (3, 5, 7, 10) and different water cut conditions (40%, 50%, 60%, 70%, 80%, 90%) can be obtained. Firstly, we establish a calculation model for seepage resistance, and then analyze the changes of seepage resistance under single-layer production and multi-layer commingle production conditions. The phenomenon of backflow will not happen according to the current pressure system and oil production technology of the target reservoir. Finally, we study the interlayer interference with the ratio of seepage resistance between lower permeability and higher permeability layers.

Calculation model for seepage resistance

We establish a double-layer one-dimensional water flooding theoretical model (Liu et al. 2022), assuming that: (1) non-piston water drive oil, existing in an oil–water two-phase zone; (2) no influence of gravity and capillary pressure because of the large displacement pressure difference and thin reservoir, balancing between injection and production; (3) no considering of compressibility of rock and fluid; (4) the flow of oil and water phases obeys Darcy's law.

The motion equation of oil–water two-phase (Zhang et al. 1998) is:

where \(v_{{\text{o}}}\) is oil phase seepage velocity, 10−6 m/s; \(v_{{\text{w}}}\) is water phase seepage velocity, 10−6 m/s; \(v_{{\text{t}}}\) is total seepage velocity, 10−6 m/s; \(\mu_{{\text{o}}}\) is oil viscosity, mPa s; \(\mu_{{\text{w}}}\) is water viscosity, mPa s; \(K\) is absolute permeability, 10−3 μm2; \(K_{{{\text{ro}}}}\) is oil phase relative permeability, dimensionless; \(K_{{{\text{rw}}}}\) is water phase relative permeability, dimensionless; \(Q\) is total flow rate, 10−6 m3/s; \(A\) is seepage cross-sectional area, m2.

where \(\Delta p_{1}\) is pressure drop in oil–water two-phase zone, MPa; \(\Delta p_{2}\) is pressure drop in oil zone, MPa; L is distance from edge to wells, m; \(x_{{\text{f}}}\) is position of oil and water front, m; \(S_{{{\text{wc}}}}\) is irreducible water saturation, dimensionless.

Relative permeability data is a key parameter for calculating seepage resistance. Corey type (Corey 1954) relative permeability curve is used to process relative permeability data.

where \(K_{{{\text{roe}}}}\) is relative permeability corresponding to the end point of oil phase, dimensionless; \(K_{{{\text{rwe}}}}\) is relative permeability corresponding to the end point of water phase, dimensionless; \(n_{{\text{o}}}\) is Corey index of oil phase, dimensionless; \(n_{{\text{w}}}\) is Corey index of water phase, dimensionless; \(S_{{\text{o}}}\) is oil saturation, dimensionless; \(S_{{\text{w}}}\) is water saturation, dimensionless.

Fractional flow equation is:

First derivative of water cut:

Second derivative of water cut:

The seepage resistance before water breakthrough includes two parts: the oil–water two-phase zone and the pure oil zone:

Position of oil and water front:

where \(f_{w}{\prime} (S_{wf} )\) is derivative of distributing rate corresponding to water saturation of water flooding front, dimensionless; \(\phi\)—porosity, dimensionless.

Initially, the cumulative liquid production of the two layers is:

Position of oil and water front:

Seepage resistance of the two layers:

where \(\int_{0}^{{S_{wf} }} {\frac{{f_{w}^{{\prime\prime}} (S_{{\text{w}}} )}}{{\frac{{K_{{{\text{ro}}}} }}{{\mu_{{\text{o}}} }} + \frac{{K_{{{\text{rw}}}} }}{{\mu_{{\text{w}}} }}}}{\text{d}}S_{{\text{w}}} }\)is constant obtained by numerical integration.

Seepage resistance in oil–water two-phase zone after water breakthrough:

Seepage resistance

(1) Single-layer production.

The changes of seepage resistance during single layer production are shown in Fig. 1. The permeability ratio is 3. According to Fig. 1a, the seepage resistance of the lower permeability layer is greater than that of the higher permeability layer; and with the water cut increasing the seepage resistance of both these two layers decreases; and when the water cut reaches 80%, there is an inflection point in the seepage resistance of the lower permeability layer, and it may be a breakthrough of water flooding front to significantly decrease the seepage resistance in the oil–water two-phase zone. According to Fig. 1b, the seepage resistance ratio of these two layers increases first and then decreases, but always higher than the permeability ratio of 3.

(2) Commingle production.

The changes of seepage resistance ratio between lower permeability and higher permeability layers are shown in Fig. 2. X-axis represents the commingle production timing (water cut) of the lower permeability layer, and Y-axis represents the seepage resistance ratio. Each point represents a commingle production scheme. According to Fig. 2, with the delaying of commingle production timing (water cut increasing of the lower permeability layer), the ratio of seepage resistance between the lower permeability layer and the higher permeability layer decreases, because the seepage resistance of the lower permeability layer decreases when the water cut of the two layers is close; The larger the permeability ratio, the larger the ratio of seepage resistance between the lower permeability layer and the higher permeability layer, the greater the degree of interlayer interference; no matter when to commingle production, the ratio of seepage resistance between the two layers is always greater than the ratio of permeability, which means that interlayer interference will inevitably occur after commingle production to affect the overall development effect. Therefore, it is necessary to analyze the influence of geological and reservoir conditions on multi-layer commingle production.

Interlayer interference mechanism

During commingle production of multi-layer reservoirs, the seepage resistance constantly changes with water flooding, including the changes in each layer and the differences between multi-layer reservoirs:

-

1.

Due to the difference in viscosity between oil and water, the seepage resistance of oil is greater than that of water. In the non-piston water flooding process, as the water flooding front continues to move forward, the oil–water two-phase zone gradually expands, while the oil zone gradually reduces. This results in a decreasing of seepage resistance in the higher permeability layer, the same to the lower permeability layer, during the commingle production of multi-layer reservoirs.

-

2.

Due to the difference in permeability, the seepage resistance of the higher permeability layer is smaller than that of the lower permeability layer, and the moving speed of water flooding front in the higher permeability layer is faster than that in the lower permeability layer, resulting in a faster reduction of seepage resistance in the higher permeability layer than the lower permeability layer. This leads to an increasing difference in seepage resistance between the higher and the lower permeability layer, forming the interlayer interference, during the commingle production of multi-layer reservoirs.

Feasibility analysis of multi-layer commingle production

Based on the analysis of interlayer interference mechanism, we establish a numerical simulation model to analyze the changes of dimensionless oil increase coefficient and production index interference coefficient under different permeability, water cut and pressure difference conditions to further study the feasibility and technical limits of multi-layer commingle production.

Establishment of numerical simulation model

To study the production performance of commingle production of multi-layer reservoirs in X, we establish a double-layer mechanism model with one well injection and one well production to simulate one-dimensional fluid flow. The model parameters are shown in Table 1, and the established model is shown in Fig. 3.

The permeability range of different layers of main oilfields in X is (400–4000) × 10−3 μm2. They have big differences in permeability and water cut, while little difference in pressure difference. The permeability of the lower permeability layer is set to be 400 × 10−3 μm2, and by changing the permeability of the higher permeability layer, the different permeability ratios during multi-layer commingle production are achieved. According to the pressure and depth in different layers, the pressure coefficients are calculated. The pressure coefficient of the upper layer is set to be 0.85, and by changing the pressure coefficient of the lower layer, five pressure coefficient differences are obtained. Therefore, we design 29 sets of numerical simulation schemes considering of permeability ratio, water cut and pressure coefficient difference, shown in Table 2.

Result analysis

(1) Production index.

Taking the permeability ratio of 3 as an example, the comparison of production index before and after commingle production is shown in Fig. 4. X-axis represents the commingle production timing (water cut of the lower permeability layer), and Y-axis represents the production index. Compared to the sum of production index of each single layer production, the total production index of two-layer commingle production decreases, but higher than that of the higher permeability layer. This indicates that although the production capacity of two-layer commingle production is lower than the sum of that of each single layer production respectively, it is higher than that of the higher permeability layer, that is, within a certain period of time, we can increase the total oil production by commingle production. The later the timing of commingle production (the higher the water cut of the lower permeability layer), the smaller the difference of water cut between the two layers, the closer the production index of single layer production and two-layer commingle production, and the smaller the interlayer interference.

According to the changes of production index, the two layers should have a relatively similar water cut when commingle production.

(2) Dimensionless oil increase coefficient.

Dimensionless oil increase coefficient (βo) is the ratio of the difference between the oil production of commingle production and single higher permeability layer production and the oil production of single higher permeability layer production. The formula is as follows:

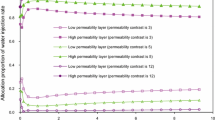

The comparison of dimensionless oil increase coefficient in different commingle production schemes is shown in Fig. 5. X-axis represents the commingle production timing (water cut of the lower permeability layer), and Y-axis represents dimension-less oil increase coefficient. The later the timing of commingle production (the higher the water cut of the lower permeability layer), the smaller the dimensionless oil in-crease coefficient; the larger the permeability ratio, the smaller the dimensionless oil increase coefficient. The dimensionless oil increase coefficients obtained in different schemes are all positive, indicating that it can achieve the oil increase effect by commingle production.

The comparison of the relationship among dimensionless oil increase coefficient, water cut and pressure coefficient difference is shown in Fig. 6. X-axis represents the commingle production timing (water cut of the lower permeability layer), and Y-axis represents dimension-less oil increase coefficient. The later the timing of commingle production (the higher the water cut of the lower permeability layer), the smaller the dimensionless oil in-crease coefficient; the larger the pressure coefficient difference, the larger the dimensionless oil increase coefficient. While under current pressure system, the difference in dimensionless oil increase coefficient after commingle production is less than 25%, which means that it has little impact on the oil increase effect.

According to the changes of the dimensionless oil increase coefficient, it can be seen that it is feasible to switch from single-layer production to multi-layer commingle production in the late development stage when most wells are high water cut.

(3) Production index interference coefficient.

Production index interference coefficient (αo) is the ratio of the difference between the production index of single-layer production and commingle production and the production index of single-layer production. The formula is as follows:

The comparison of production index interference coefficient in different commingle production schemes is shown in Fig. 7. X-axis represents the commingle production timing (water cut) of the lower permeability layer, and Y-axis represents production index interference coefficient. The later the timing of commingle production (the higher the water cut of the lower permeability layer), the smaller the αo, the smaller the interference on production index; the larger the permeability ratio, the larger the αo, the greater the interference on production index, the stronger the inter-layer interference; αo goes to be flat when the water cut of the lower permeability layer is higher than 80%, which indicates that the degree of interlayer interference is weakened; when the permeability ratio is less than 5, the production index interference coefficient decreases significantly as the water cut of the lower permeability layer increases from 40 to 90%; when the permeability ratio is larger than 5, the production index interference coefficient decreases slowly, indicating a relatively strong interlayer interference.

The comparison of the relationship among production index interference coefficient, water cut and pressure coefficient difference is shown in Fig. 8. X-axis represents the commingle production timing (water cut of the lower permeability layer), and Y-axis represents production index interference coefficient. The later the timing of commingle production (the higher the water cut of the lower permeability layer), the smaller the production index interference coefficient; the larger the pressure coefficient difference, the smaller the dimensionless oil increase coefficient. While under current pressure system, the difference in interference after commingle production is less than 15%, which means that it has little impact on the interlayer interference.

According to the changes of the production index interference coefficient, it can be seen that it has a better effect of multi-layer commingle production when the permeability ratio is less than 5 and the water cut of the lower permeability layer is higher than 80%d, and the pressure coefficient difference is less than 0.1.

(4) Application.

Based on the above multi-layer commingle production analysis, recently in the Oilfield X, several wells adopt multi-layer commingle production according to the technical limits we proposed, and development parameters are predicted according to the production performance. The results (Fig. 9.) show that these multi-layer commingle production wells have good incremental oil effect. Recovery is increased by 2.8%, which confirmed this method feasibility.

Conclusions

Based on above multi-layer commingle production analysis, the following conclusions and understandings are obtained:

-

1.

A numerical simulation model is established to simulate commingle production process in the high water cut stage. The results show that seepage resistance of each layer decreases, and the reduction rate in higher permeability layer is faster than that in lower permeability layer, resulting in difference in seepage resistance between different layers;

-

2.

Main affecting factors are selected to characterize interlayer interference and commingle production effect in the high water cut stage. The results show that under different situations, dimensionless oil increase coefficient are all positive, and the oil increase effect is obvious, indicating the feasibility of multi-layer commingle production in the high water cut stage;

-

3.

The technical limits for the commingle production of multi-layer reservoirs in the high water cut stage in X Oilfield is that the permeability ratio is less than 5, and the water cut of the lower permeability layer is higher than 80%, and the pressure coefficient difference is less than 0.1.

-

4.

Based on above analysis, several wells in Oilfield X adopt multi-layer commingle production according to the technical limits we proposed. The results show that these multi-layer commingle production wells have good incremental oil effect. Recovery is increased by 2.8%, which confirmed this method feasibility.

Abbreviations

- \(A\) :

-

Seepage cross-sectional area, m2

- \(f_{w}{\prime} (S_{wf} )\) :

-

Derivative of distributing rate corresponding to water saturation of water flooding front, dimensionless

- \(K\) :

-

Absolute permeability, 10−3 μm2

- \(K_{ro}\) :

-

Oil phase relative permeability, dimensionless

- \(K_{rw}\) :

-

Water phase relative permeability, dimensionless

- \(K_{roe}\) :

-

Relative permeability corresponding to the end point of oil phase, dimensionless

- \(K_{rwe}\) :

-

Relative permeability corresponding to the end point of water phase, dimensionless

- L :

-

Distance from edge to wells, m

- \(n_{o}\) :

-

Corey index of oil phase, dimensionless

- \(n_{w}\) :

-

Corey index of water phase, dimensionless;

- \(Q\) :

-

Total flow rate, 10−6 m3/s

- \(S_{o}\) :

-

Oil Saturation, dimensionless

- \(S_{w}\) :

-

Water Saturation, dimensionless

- \(S_{wc}\) :

-

Irreducible water saturation, dimensionless

- \(v_{o}\) :

-

Oil phase seepage velocity, 10−6 m/s

- \(v_{w}\) :

-

Water phase seepage velocity, 10−6 m/s

- \(v_{t}\) :

-

Total seepage velocity, 10−6 m/s

- \(x_{f}\) :

-

Position of oil and water front, m

- \(\mu_{o}\) :

-

Oil viscosity, mPa s

- \(\mu_{w}\) :

-

Water viscosity, mPa s

- \(\Delta p_{1}\) :

-

Pressure drop in oil–water two-phase zone, MPa

- \(\Delta p_{2}\) :

-

Pressure drop in oil zone, MPa

- \(\phi\) :

-

Porosity, dimensionless

References

Corey AT (1954) The interrelation between gas and oil relative permeabilities. Prod Mon 19(1):38–41

Cui CZ, Zhao XY (2010) Method for calculating production indices of multilayer water drive reservoirs. J Pet Sci Eng 75(1):66–70

CuiWu CZ (2018) Layer recombination technique for waterflooded low-permeability reservoirs at high water cut stage. J Pet Explor Prod Technol 8:1363–1371. https://doi.org/10.1007/s13202-018-0439-2

Hu DD, Tang W, Chang YW, et al. (2010) A study for redevelopment trends after polymer flooding and its field application in La-sa-xing oilfield. In: International oil and gas conference and exhibition in China, 8–10 June 2010, Beijing, China. (SPE 130903)

Huang S, Kang B, Cheng L et al (2015) Quantitative characterization of interlayer interference and productivity prediction of directional wells in the multilayer commingled production of ordinary offshore heavy oil reservoirs. Pet Explor Dev 42(4):488–495. https://doi.org/10.11698/PED.2015.04.10

Jackson RR, Banerjee R (2000) Advances in multilayer reservoir testing and analysis using numerical well testing and reservoir simulation. In: SPE annual technical conference and exhibition, 1–4 Oct 2000, Dallas, Texas. (SPE62917).

Jiang B, Cheng S, Kang B et al (2022) Productivity evaluation method of multi-layer sandstone reservoir based on dynamic prediction of interlayer interference. Pet Geol Recover Effic 29(02):124–130. https://doi.org/10.13673/j.cnki.cn37-1359/te.2022.02.015

Kan L, Wang W, Ao W et al (2019) Experimental study on interlayer interference of general water injection in offshore oilfields. Contemp Chem Ind 48(10):2227–2230. https://doi.org/10.13840/j.cnki.cn21-1457/tq.2019.10.013

Li Yu, Peng H, Wang X (2018) Study on evaluation and solution of interlayer interference problem. Shandong Chem Ind 47(08):114–116. https://doi.org/10.19319/j.cnki.issn.1008-021x.2018.08.041

Liu G, Meng Z, Luo D (2019) Experimental evaluation of interlayer interference during commingled production in a tight sandstone gas reservoir with multi-pressure systems. Fuel 262(11):116557

Liu LL, Wang JJ, Su P et al (2022) Experimental study on interlayer interference of coalbed methane reservoir under different reservoir physical properties and pressure systems. J Petrol Explor Prod Technol 12:3263–3274. https://doi.org/10.1007/s13202-022-01513-1

Liu X, Nie C, et al. (2022) Calculation and evaluation software for reservoir seepage resistance.

Ma Z, Shi Y, Li Y et al (2021) Calculation method of seepage resistance for prediction of interlayer interference in multilayer reservoirs. Pet Geol Recover Effic 28(03):104. https://doi.org/10.13673/j.cnki.cn37-1359/te.2021.03.013

Mu P, Wang S, Tan J et al (2021) Theoretical Study on quantitative characterization of interlayer interference in multi-layer commingled production. J Power Energy Eng 09(04):21–29

Shi CF, Du QL, Zhu LH et al (2006) Research on remaining oil distribution and further development methods for different kinds of oil layers in Daqing oilfield at high water-cut stage. In: SPE Asia Pacific oil & gas conference and exhibition, 11–13 Sept 2006, Adelaide, Australia. (SPE101034)

Wang Z, Huang A, Wei J (2012) Numerical simulation on interlayer interference of thin and interbed reservoirs. J Oil Gas Technol 34(9):247–250

Wu Y (2017) Experimental research on interlayer interference of thin interbed reservoirs by 3-D physical simulation. Res Explor in Lab 36(01):25–29

Xiong Yu, Lu Z, Li Y et al (2010) Research on technical limits of multi-layer producer for oilfield in high water cut stage. Spec Oil Gas Reserv 17(01):61–63

Yu H, Wang W, Rong Na et al (2006) Rule of interlayer interference in various water cut periods of Shengtuo oilfield. Pet Geol Recover Effic 04:71–73

Zhang J, Lei G, Zhang Y (1998) Seepage Mechanics. Pet Univ Press 1998:148–160

Zhang K, Lu R, Zhang L et al (2014) Start-up pressure and interlayer interference of multi-layer commingled production. Pet Geol Oilfield Dev in Daqing 33(06):57–64. https://doi.org/10.3969/j.issn.1000-3754.2014.06.011

Zhang Xu FN (2002) Impact of Vertical Heterogeneity on well productivity in multilayered low-permeable reservoir. Spec Oil Gas Reserv 9(4):39–41

Zhao Y (1983) Discussion on interlayer interference of water injection wells. Pet Explor Dev 1:68–73

Zhou W, Li Q, Geng Z et al (2017) Mathematical simulation study on interlayer interference in commingled production. J Southwest Pet Univ (sci Technol Ed) 39(06):109–116. https://doi.org/10.11885/j.issn.1674-5086.2016.0820.01

Acknowledgements

The authors would like to express our thanks for the financial support from The National Science and Technology Major Projects (No. 2022-FW-077).

Funding

This study was funded by The National Science and Technology Major Projects (No. 2022-FW-077).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This material is the author’s own original work, which has not been previously published elsewhere. The paper is not currently being considered for publication elsewhere. The paper reflects the author’s own research and analysis in a truthful and complete manner. The publication of this manuscript does not engage in or participate in any form of malicious harm to another person or animal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, X., Qi, H., Liu, J. et al. Feasibility analysis of commingle production of multi-layer reservoirs in the high water cut stage of oilfield development. J Petrol Explor Prod Technol (2024). https://doi.org/10.1007/s13202-024-01773-z

Accepted:

Published:

DOI: https://doi.org/10.1007/s13202-024-01773-z

Keywords

- High water cut wells

- Commingle production of multi-layer reservoirs

- Seepage resistance

- Interlayer interference

- Production index interference coefficient