Abstract

The influence of geological and engineering factors results in the complex production characteristics of shale gas wells. The productivity evaluation method is effective to analyze the production decline law and estimate the ultimate recovery in the shale gas reservoir. This paper reviews the production decline method, analytical method, numerical simulation method, and machine learning method. which analyzes the applicable conditions, basic principles, characteristics, and limitations of different methods. The research found that the production decline method can mainly account for the gas well production and pressure data by fitting type curve analysis. The analytical method is able to couple multiple transport mechanisms and quantify the impact of different mechanisms on shale gas well productivity. Numerical simulation builds multiple pore media in shale gas reservoirs and performs production dynamics as well as capacity prediction visually. Machine learning methods are a nascent approach that can efficiently use available production data from shale gas wells to predict productivity. Finally, the research discusses the future directions and challenges of shale gas well productivity evaluation methods.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Shale gas reservoirs have micro-nano scale pore development and ultra-tight reservoir characteristics when compared to conventional reservoirs. The formation develops with complex pore structures and barely has natural productivity. (Jia et al. 2016). Therefore, large-scale fracturing technology is widely used in the production process of shale gas, which makes shale reservoir characteristics more complex and heterogeneous and shows complex flow patterns of cross-scale transport (Ma et al. 2020). The following also results in less consistent test pressure and production data for shale gas wells in traditional productivity test well analysis. In order to obtain higher gas production efficiency, analyzing the law of gas well production decline, timely economic adjustment and deployment of the development plan, and more accurate estimated ultimate recovery (EUR) are all required. Therefore, how to accurately evaluate and analyze shale gas well productivity has become the focus of research.

At present, shale gas well productivity evaluation methods are mainly divided into production decline analysis method, analytical method, numerical simulation, and machine learning method.

For production decline analysis, many scholars proposed different empirical formulas and derivative methods (Arps 1945; Ilk et al. 2008; Valko 2009; Valko and Lee 2010; Duong 2011; Hu et al. 2018; Li et al. 2019a, b; Manda and Nkazi 2020), such as Arps, PLE, SEPD, YM-SEPD, etc. The empirical method analyzes the law of production decline based on the characteristics of the type curve and effectively predicts the single-well productivity and estimates ultimate recovery. With the change in the gas well production regime, modern production decline analysis that is applicable to variable pressure and production conditions has emerged. The objective has been extended from a single gas well production analysis to a double-parameter analysis of production and pressure. The production decline analysis method has been expanded by introducing the material balance pseudo-time and normalized pseudo-pressure functions, which have been widely used in tight gas reservoirs such as shale gas (Fetkovich 1980; Blasingame et al. 1991; Agarwal et al. 1999; Mattar and Mcneil 1998; Mattar et al. 2006). However, the limitations of applying the production decline method for shale gas flow stages have also caused some uncertainties in the productivity evaluation results.

As research scholars continue to study shale gas transport laws in the subsurface, the analytical method can better describe the transport mechanisms in different stages of shale gas development. Based on the equivalent continuous media model, many scholars defined the relationship among artificial fractures, secondary extension fractures, natural fractures, inorganic matrix, and organic kerogen matrix in shale reservoirs (Warren and Root 1963; De 1976; Watson et al. 1990; Wu et al. 2009; Swami and Settari 2012; Urban et al. 2017; Guo and Yang 2019; Mohamed et al. 2021). They discovered the existence of gas–water two-phase flow, trilinear, and five-linear flow patterns between different flow regions (Bello and Wattenbarger 2010; Brown et al. 2009; Ozkan et al. 2010; Brohi et al. 2011; Ozkanet et al. 2011; Stalgorova and Mattar 2012a, b; Yin et al. 2015; Zhang et al. 2015; Fan and Ettehadtavakkol 2016; Su et al. 2016a, b; Zeng et al. 2019; Liu et al.2020; Behmanesh et al. 2021). The flow coupling laws between multiple media were described mathematically by the mass transfer control equation, which considered the typical flow mechanisms such as Knudsen diffusion, molecular surface diffusion, adsorption–desorption, Klinkenberg effect, high-speed non-Darcy effect, Darcy flow, effective stress sensitivity (Carlson and Mercer1991; Wang et al.2015; David Obembe et al. 2017; Phan et al. 2018; Sun et al.2019; Zhong and Leung 2019; Hassan et al. 2020; Zeng et al. 2021). Thereby establishing an analytical model describing the cross-scale transport of shale gas was developed. Under the Laplace space, the analytical solution is expressed by combining the initial and boundary conditions of the gas reservoir using the separation variable method, such as Laplace transforms and Green's function. The prediction and evaluation of parameters such as single-well productivity and EUR are obtained by curve-fitting and data analysis (Civan 2010; Ali and Sheng 2015; Gu et al. 2016; Duan et al. 2018; Li et al. 2020; Wang et al. 2019; Bo et al. 2020; Jia et al. 2020a, b). However, due to the many idealized assumptions in the analytical model, the analytical method cannot accurately reflect the complex flow mechanisms and development laws of shale gas in the actual formation.

In order to improve the accuracy of complex geological characterization and finely characterize the shale gas flow within complex fractures, the discrete fracture grid model (DFM) was developed based on the equivalent multiple media model commonly used in analytical methods (Karimi-Fard et al. 2004). Flow patterns between matrix and fractures can be efficiently characterized by reducing the fracture dimensions and grid dissecting the matrix system (Baca et al. 1984; Moinfar et al. 2011a, 2011b). To reduce the computational cost associated with encrypting the matrix grid and to avoid generating irregular matrix grids along the crack orientation, many scholars proposed the embedded discrete fracture model (EDFM) by embedding the fracture into the structured matrix grid (Cipolla et al. 2009; Huang et al. 2015). Later, the scholars proposed using EDFM to study the complex multiple transport mechanism flow problem of matrix fractures in shale gas reservoirs (Carlson and Mercer 1991; Song et al. 2019). Chen et al. effectively characterized the flow of shale gas between cross-scale media by modeling a complex fracture network with natural fracture-hydraulic fracture coupling. (Chen and Fu 2019; Wachtmeister et al. 2017).

With the continuous integration of artificial intelligence with oil and gas field production sites, machine learning methods are gradually emphasized in the productivity evaluation of shale gas wells. Many scholars have conducted multifactor analysis research on capacity evaluation based on gas well pressure production data. Machine learning algorithms such as back-propagation neural networks and recurrent neural networks are used to effectively solve the problem of low accuracy of theoretical models for shale gas well productivity prediction.

In summary, the empirical model considers the cross-scale transport mechanism of shale gas in multiple media and establishes a reliable theoretical basis for productivity evaluation. However, the model makes many idealized assumptions, and the results are difficult to match the flow characteristics of shale gas in the actual formation. The numerical simulation method refines the characterization of the artificial fracture-natural fracture-matrix pore model. It provides a basis for describing the flow characteristics of shale gas transport cross-scale. However, the models are not highly accurate and require significant computational costs. Artificial intelligence methods can compensate for the drawback of empirical models and effectively analyze the main influencing factors for different productivity characteristics of a shale gas well. However, the problems of algorithm preference, model optimization, and underfitting still need to be solved. This paper composes the basic principles and application of shale gas well productivity evaluation methods and proposes future research directions for each method. The article is expected to better improve the shale gas well productivity evaluation system and provide support for shale gas development evaluation and scale efficiency on production.

Production decline curve analysis method

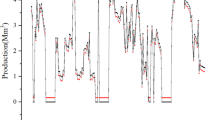

After shale gas wells entered the declining stage, the production decline analysis method was commonly applied to predict gas well productivity and EUR (Terminiello et al. 2020; Liu et al. 2013; Chen et al. 2018a, b). This method is analyzed for gas well production and pressure and does not require many geological and engineering parameters. The reservoir parameters and dynamic reserves are determined by fitting production curves with type curve (Hu et al. 2018; Chen et al. 2018a, b; Li et al. 2019a, b). There are seven main methods for production decline analysis of shale gas wells, including the Arps method, PLE method, SEPD method, Duong method, modified hyperbolic decline method, modern production decline method, and material balance method.

Arps method

As a classical method to evaluate the production decline law of gas reservoirs, the Arps method has been widely used in the gas field (Arps 1945). According to the different values of parameter b in the following formula, the Arps decline curve can be divided into three types: exponential, harmonic, and hyperbolic decline curve, and the decline speed is from fast to slow.

The decline rate is defined as:

The relation between rate and time is expressed as:

Firstly, when the Arps method is applied to the production decline analysis of gas wells, the production data must be obtained under the condition of constant pressure. Secondly, the method has the best production fitting effect in the BDF (Boundary defined flow) stage. However, most shale gas wells are in the early stage of unstable linear flow for a long time. The production decline law shows a sharp decline in the initial stage. Therefore, the value of b is often greater than 1, which makes the well productivity prediction value higher and its applicability is limited. However, the Arps method is still widely used and easy to operate in North American shale gas wells in the BDF stage with constant pressure production systems.

Exponential PLE method

It is essential to evaluate the early rapid decline law of shale gas well because there are a lot of nano-scale pores in shale gas reservoirs, which makes it difficult for gas to flow in the matrix so that the shale gas wells rarely reach the quasi-stable flow stage. ILK found a power-law exponent relationship between decline rate and time in the logarithm curve through statistical analysis of a large number of shale gas well production dynamic data (ILK et al. 2008). Based on the exponential decline model of the Arps method, the exponential decline rate D∞ is introduced, and the power-law decline expression is obtained:

The integral of the formula is expressed as:

The PLE model can better match the production data of unstable and boundary quasi-stable flow stages. However, the increase of formula parameters will inevitably bring multiple fitting results, thus increasing the uncertainty of productivity prediction results.

SEPD method and YM-SEPD method

In 2009, Valko et al. proposed the extended exponential production decline method (SEPD) based on the analysis of the power exponential yield decline law, assuming the decline rate D∞ = 0, Di = 1⁄τn under infinite time in the PLE method. (Valko and Lee 2010).

The definition of decline rate is:

The daily production versus time:

The cumulative production versus time:

This method analyzes the production decline of a shale gas well at constant pressure when they have entered the declining stage and have a long production time. However, the SEPD method cannot calculate the production of gas well in the upper and stable production periods. In 2013, Yu and Milosevic et al. proposed the YM-SEPD model. By integrating the yield formula in the SEPD method and taking the logarithm, they drew the curve of dimensionless production (q/q0)-t double logarithm and obtained n and τ values by fitting the straight line. The calculation model of reserves in the whole cycle of the stable production stage and decline stage in a shale gas well was obtained comprehensively (Zhao et al. 2015).

The calculation formula for estimated ultimate reserves (EUR):

Duong method

In 2010, Duong et al. obtained an empirical analysis method for the production decline of a fractured shale gas well by analyzing production data of a large number of shale gas wells in the Barnett shale reservoir. Due to the artificial fracturing technology used in shale gas production, the permeability of fractures is different from that of the matrix, and the contribution of the matrix of productivity is almost negligible. Therefore, the Duong method considers that the shale gas well is in the unstable linear flow stage dominated by fractures for a long time. It is difficult to achieve the quasi-stable flow stage controlled by the matrix. (Duong 2011).

The daily production versus time:

The cumulative production versus time:

The above equation makes a q/Gp-t curve on a double logarithmic curve as a straight line segment with a negative slope, and the cumulative output versus time can also be expressed as:

Duong concluded that shale gas wells generally have an m-value greater than 1. If the m-value is less than 1, the well is likely to be a conventional low-permeability gas reservoir gas well. Since the Duong method cannot analyze the declining law of the stable flow stage, a modified Duong method is proposed by defining the time of the beginning of the proposed stable flow stage and the corresponding initial decreasing rate, which is combined with the Arps method.

The quasi-stable flow start time is expressed as:

The initial decline rate of the quasi-stable flow stage is:

The production versus time:

Although the modified Duong method extends the fitting range to unstable and quasi-stable flow stages, it is difficult to accurately identify the start time of quasi-stable flow stages, thus causing a deviation in the productivity prediction results.

Modified hyperbolic decline model (MHD)

By analyzing the production law of Barnett shale gas well at constant pressure, Seshadri et al. found that the production decline law of shale gas well showed two stages: hyperbolic decline law in the early stage and exponential decline law in the middle-late stage. Then a modified hyperbolic decline model is proposed by improving the PLE model. By defining the time coefficient m, the fitting problem of b value greater than 1 in the Arps method is solved, and the dimension problem of the PLE method is optimized. (Seshadri and Mattar 2010).

The definition of decline rate is:

By separating variables from the definition of decline rate and integrating the production prediction expression is obtained:

The MHD has clear physical significance and describes the production decline process of shale gas wells. At the beginning of production, the production decline rate is equal to the initial decline rate (D = Di). In the early stage of shale gas production, the hyperbolic decline pattern is followed. In the middle-late production, the decline law is mainly limited by D∞.

Modern production decline methods

The empirical method requires that gas wells must be produced at a constant bottom-hole flow pressure. In the variable bottom-hole flow pressure production system, the empirical method is no longer applicable. However, most gas wells adopt the variable pressure production system in actual production. In addition, due to the compressibility of the gas, the actual production process has both variable pressure and variable production for a single-phase gas well. Blasingame introduced material balance pseudo-time function and normalized pseudo-pressure to make the decline curve suitable for production decline analysis of gas wells under the condition of variable production and pressure (Blasingame et al. 1991; Agarwal et al. 1999).

The basic principle of the method is to use the matter balance pseudo-time parameter to convert the fluid properties. The gas well pseudo-pressure flow equation is transformed into the normalized pseudo-pressure flow equation using normalized pressure parameters. Finally, the application condition of the production decline analysis method is altered from constant pressure to variable pressure. By simplifying the flow equation and fitting it with the actual production data, the actual formation physical parameters are obtained and the productivity can be predicted effectively.

The Blasingame method uses the material balance time and the pseudo-time function to obtain the material balance pseudo-time function and combines the normalized pseudo-pressure to realize the extension of the Fetkovich method.

The pseudo-time function of material balance is defined as:

The normalized pseudo-pressure is defined as:

The Agarwal–Gardner method (A–G) and the Normalized Pressure Integral method (NPI) are also the main methods for production decline analysis. Based on the Blasingame decline analysis method, the A–G added dimensionless parameter relationship in the unstable well test analysis to establish a production decline analysis type curve. This method type curves fitting analysis process is the same as the Blasingame method. This method mainly analyzes the production and time relationship data (Agarwal et al 1999). The difference between the Blasingame method and the A–G method is that the definitions of dimensionless parameters are different, which reduces the multi-solution of the fitting. The type curve of the NPI method changes the dimensionless production of the A–G method to the dimensionless pressure. The horizontal axis of the type curves is still the dimensionless time. The process of type curves fitting analysis of the NPI method is similar to the other two methods.

Flow material balance method (FMB)

Matter proposed the flow material balance method, and concluded that the declining gradient of bottom hole flow pressure is approximately the same as that of the average formation pressure. According to the parallel theory of the material balance curve, the original formation pressure (pi) and the original geological reserves (G) can be obtained by making a material balance relation line parallel to the bottom flow pressure, and the intersection point of the parallel line and the horizontal axis is G (Mattar and Mcneil 1998).

The limitation of the traditional material balance method is that the production of the gas well must be constant. Otherwise, it will bring calculation errors. Matter and Anderson et al. proposed the flow material balance method (FMB) in 2006(Mattar et al. 2006). Material balance pseudo-time function is introduced to adapt to the variable production of the gas well. The limitation is that the gas well must reach the quasi-stable flow stage, otherwise, it is difficult to obtain the accurate geological reserves calculated by the linear relationship.

The production decline curve analysis methods in shale gas wells are summarized in Table 1.

Analytical methods

The analytical method is a reliable method to evaluate the productivity of shale gas wells without production decline data in the flowback stage or the beginning of production. Based on the continuum model, a mass transfer diffusion equation is established to describe the cross-scale flow law and multiple flow mechanism coupling of shale gas in the reservoir. In the Laplace space, the analytical solution is obtained by using the separation variable method, Laplace transform, and Green's function, combined with the initial conditions and boundary conditions of the gas reservoir. The accuracy of the productivity prediction model was evaluated by the type curve fitting. Through the literature investigation, it is found that the basic principles of analytical methods for shale gas productivity evaluation are mainly developed from the following three aspects, including the multi-scale media model and the domain division, the sequence of gas transport in multiple domains and the multiple physics in the shale gas production. The following is a detailed description of the development status.

Multi-scale media model and domain division

The characterization of the shale reservoir is the basis of the analytical method. Due to the low permeability, low porosity, and ultra-tight shale reservoir, artificial fracturing technology is necessary to exploit more shale gas, which also results in the distribution characteristics of multi-scale media coupling in shale reservoirs, as shown in Fig. 1.

The dual-media model is widely used in the characterization of porous media (Warren and Root 1963; De 1976; Su et al. 2016a, b). It is found that the porous media is mainly composed of fractures and matrix, which is also a widely recognized and adopted continuum model. Later, the fracture and matrix were divided in detail. Many researchers believed that the dual media model could not characterize the complex geological environment of the shale reservoir (Wu et al. 2009; Gu et al.2016; Hu et al. 2019), so the triple pore media model was adopted to describe the reservoir, and the fractures were divided into artificial. Swami and Gao proposed that shale kerogen pores, as the porous media that can be self-generated and self-stored, are a non-ignorable part of the multi-media model (Swami and Settari 2012; Gao et al. 2017). Zeng divided the shale matrix into the inorganic matrix and the organic kerogen (Zeng et al. 2019, 2021). A quadruple pore media model of the artificial fracture-micro fracture-inorganic matrix-kerogen pores was proposed. With the application of the analytical method of productivity evaluation, new understandings have been gained on the construction of the shale continuum model. Many scholars believed that the fracturing fluid in artificial fractures can expand and connect the micro-fractures (David Obembe et al. 2017; Guo and Yang 2019; Zhong et al. 2019). Therefore, the micro-fractures can be divided into the connected secondary fractures and the closed natural fractures. Li divided the shale matrix into the modified area and the unmodified area and believed that there were not only inorganic matrix and organic kerogen in the modified area but also a large number of secondary fractures developed as a channel for the shale gas transportation (Li et al. 2020).

The sequence of gas transport in multiple domains

The analytical method is considered to meet the migration characteristics of the linear flow when describing the flow law of shale gas in multiple media. It is difficult for the shale gas wells to reach the radial flow stage because of the tight pore-throat structure of the matrix and the strong heterogeneity of the reservoir. In the flowback stage, due to the pressure difference between the initial formation pressure and the bottom hole flow pressure, shale gas presents a linear gas–water two-phase flow in artificial fractures, which meets Darcy's law (Liu et al. 2020; Behmanesh et al.2021). As the pressure drops, the free gas in the secondary fracture will gradually enter the artificial fracture, realizing the bilinear flow stage between the secondary fracture-artificial fracture and the artificial fracture-wellbore (Bello and Wattenbarger 2010; Brohi et al.2011). With the gas well continues to produce, Ozkan and Brown concluded that adsorbed gas in the inorganic matrix and kerogen pores in the unmodified area would enter the fracture pores in the modified area, showing A trilinear flow pattern (Brown et al.2009; Ozkan et al. 2010, 2011; Zhu and Ma 2018), as shown in Fig. 2. Stalgorova and Yin believed that there was still an unmodified area between the two artificial fractures, and the shale gas flow in the area was earlier than the flow in the unreformed area outside the pressure fracture spread boundary (Stalgorova and Mattar 2012a, b; Yin et al. 2015; Zhu et al. 2018). Therefore, the five linear flow modes of the wellbore-artificial fracture, artificial fracture-secondary fracture, modified matrix area-secondary fracture, unmodified matrix area-modified matrix area, and unmodified matrix area-secondary fracture were proposed, as shown in Fig. 2.

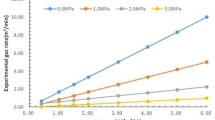

Multiple physics in shale gas production

It is crucial to describe the porosity and permeability parameters of the multiple shale media in the analytical method, and several unique transport mechanisms for shale reservoirs should be considered. Many scholars believed that the gas–water Darcy flow or high-speed non-Darcy flow generally existed in artificial fractures with different construction parameters. According to (Tian et al. 2014; Zhang et al. 2017; Jiang et al. 2020), shale gas presents slip flow or transition flow in the micro-fractures due to the capillary force and the flow friction in fracture pores of secondary fractures. For the question of shale gas storage state, Carlson and Sun suggested that the free and adsorbed gas coexist in shale inorganic matrix and organic kerogen, and are influenced by the dual factors of pressure and temperature (Carlson and Mercer 1991; Sun et al. 2019). As the fracture pore pressure decreases continuously, the desorption of adsorbed gas on the matrix pore surface occurs and fits the isothermal adsorption model. For the problem of the adsorption state of deep shale gas, Duan proposed an isothermal adsorption equation of high temperature and high pressure for characterization (Duan et al. 2018). In addition, the double diffusion phenomenon of shale gas is also the focus of gas well productivity evaluation (Jia et al.2019). One type of diffusion is the directional surface diffusion of free gas occurring from the matrix into the fracture, and the other diffusion is the Knudsen diffusion of free gas and desorption in the case root, caused by the smaller pore size of the kerogen compared to the matrix pore size (Jia et al. 2020a, b). Due to the difference in spatial scale in different porous media, Knudsen numbers of shale gas flow in pore space are different, which is reflected in the coupling of multiple transport mechanisms in the various media. Figure 3 shows the relation curve between the proportion of multiple transport mechanisms and the Knudsen number.

The curve between the proportion of multiple flow mechanisms and Knudsen number (Noorishad and Mehran 1982)

In addition to the transport mechanisms already described, each porous media is also affected by pressure sensitivity (Jia et al. 2020a, b; Monteagudo and Firoozabadi 2004). Zeng and Jia found that with the decrease of pore pressure and the increase of effective stress, the shale porosity and permeability parameters gradually deteriorated. In the analytical method of productivity evaluation (Dershowitz et al. 2000; Zeng et al. 2019, 2021; Jia et al. 2019, 2020a, b), the isothermal compression coefficient theory describes the effect of effective stress on shale gas well productivity (Zhong and Leung 2019; Li et al. 2020).

In summary, the analytical method is one of the mainstream methods for the productivity evaluation of shale gas wells. The mass transfer diffusion equation can better describe the cross-scale transport law of the shale gas and couple the transport mechanism of shale gas in the multiple porous media. However, there are certain assumptions in the model building, and these idealized parameters cannot accurately characterize the actual situation of shale gas in the reservoir. Hence, the optimization of the analytical model is still a vital issue to evaluate the size of shale gas productivity accurately.

Numerical simulation methods

Considering the complex reservoir structure of shale gas reservoirs after artificial fracturing, the analytical method cannot accurately reflect the characteristics of the matrix-fracture system. The advantage of numerical simulation methods is to construct a more accurate characterization of the actual reservoir. Based on the results of fine geological modeling, petrel modeling results, and existing production history data, numerical simulation models for shale gas wells are established to fit the history of gas wells to obtain the productivity prediction index of gas wells. The discrete fracture network model, as the preferred simulation basis, has begun to be widely used in numerical simulation models for shale gas wells.

The fracture matrix network model includes a logarithmic grid encryption model and a discrete fracture grid model. The latter is divided into the discrete fracture model (DFM) and the embedded discrete fracture model (EDFM). Both models reduce the dimensionality of the fracture, and the DFM couples the unstructured matrix grid with the reduced dimensional fracture through the mass transfer control equation, which in turn can describe the transport law between a single fracture and adjacent fractures or matrixes (Urban et al. 2017). The EDFM regularizes the unstructured matrix grid on the basis of DFM and embeds the fracture system into the matrix system for calculation, solving the problem of high computational cost due to the encrypted grid. The adoption of the regular structured grid dissection method not only improves the computational speed but also better matches the actual situation of the complex development of the multi-scale fractures and matrix in the reservoir.

Discrete fracture model

Noorishad proposed the concept of a discrete fracture model to study the fluid flow between the matrix and fractures (Noorishad and Mehran 1982). Later, Carlson developed a discrete fracture network model for shale gas (Carlson and Mercer 1991). This model better reflects the strongly inhomogeneous phenomenon of the shale gas reservoirs compared with the analytical model. Li proposed a fully implicit multidimensional discrete fracture medium algorithm on the finite volume method (Li and Lee 2008). Based on the fluid exchange law within the matrix-fracture system, a variable relationship between matrix and fracture was established, and the discrete fractures were dimensionally reduced by this method. Dershowitz suggested that the anisotropy of fractured reservoirs can be more accurately characterized by mixing the dual-media model and the discrete-fracture model (Dershowitz et al. 2000), and described different mixing methods of the dual-media model and the discrete-fracture model. Karimi-Fard proposed a spatial discretization of the discrete fracture model using unstructured grid technique, where the fractures in two and three dimensions can be downscaled into the lines and faces, and the fracture lines and faces are used as constrained boundaries for the unstructured grid dissection (Karimi-Fard et al. 2004), as shown in Fig. 4. The unstructured grid can concisely perform the grid dissection, and at the same time, the model can effectively simulate fluid flow in the matrix grids, fractures, and intersecting fractures, so it is the current grid dissection method that should be more widely used in the discrete fracture models.

Under the condition that the spatial distribution pattern of the fracture network is known, the discrete fracture model is more accurate in characterizing the flow pattern of the cross-scale transport. However, more complex cross section microfracture systems require more unstructured meshing, which greatly increases the calculation cost. In order to improve the computational efficiency, the embedded discrete fracture model EDFM is proposed by optimizing the meshing method of the matrix system and improving the coupling method between the matrix and fracture.

The embedded discrete fracture model

Lee classified the natural fractures according to the different fracture scales (Lee et al. 2000). The equivalent permeability tensor of the matrix grid containing short fractures is calculated by the analytical method. The size of large fractures is larger than that of a matrix grid, and the distribution of large fractures has a significant effect on the direction of fluid flow. Therefore, the discrete fracture model is used for explicit processing to embed the large fractures into the matrix grid. Based on the embedded discrete fracture model, the calculation method of geometric conductivity between large fracture and bedrock mesh is given. This model fully considers the properties of fractures and matrix grids.

Moinfar embedded the large fractures into the matrix grid by explicitly processing the discrete fracture model (Moinfar et al. 2011a, 2011b). The calculation of the conduction coefficient between the large fractures and the matrix grid was proposed to fully consider the nature of the fractures and the matrix grid. By comparing the embedded discrete fracture model with the two-medium model, Moinfar found that the EDFM more accurately describes the heterogeneity of fractured reservoirs. (Moinfar et al. 2013). In order to characterize vertical or inclined 3D fractures, an embedded discrete fracture model for gas reservoir simulation software was established to make the model more accurate in simulating actual fracture development. Later, a numerical simulation method based on the EDFM model considered shale matrix, natural fracture network, and artificial fractures subject to pressure sensitivity. Sangnimnuan developed an embedded model of flow-solid coupling considering the multiple transport mechanisms of the shale gas multiple media (Sangnimnuan et al. 2016).

Much research focused on the flow law of single-phase or multiphase fluids in matrix-fracture systems in fractured shale gas reservoirs. Yao used EDFM combined with the finite element method to study the oil–water two-phase flow in the single simple fractures and the complex fracture networks (Yao et al. 2013; Huang et al. 2014). The fractures were downscaled using the cubic law, and the two-dimensional spatial fractures were simplified to the lines and the three-dimensional spatial fractures were simplified to the surfaces, as shown in Fig. 5.

Many scholars proposed the finite volume method and the finite difference method to solve the discrete fracture model and investigated the oil–water two-phase flow law in fractured reservoirs. Zhao used the finite difference method to solve EDFM, which accurately dealt with the permeability anisotropy and optimized the complex unstructured grid again (Yan et al. 2016; Zhao et al. 2020). Later, He developed a coupled flow model of the porous media and the EDFM for the shale gas reservoirs, which accurately characterized the fracture system designed at arbitrary angles. Wei used EDFM to simulate a three-dimensional natural fracture-artificial fracture coupled system based on the fractal theory, which reduced the grid computation while efficiently characterizing the fluid exchange process between matrix and fracture (Song et al. 2019; Wei et al. 2021).

In summary, the discrete fracture grid model can accurately characterize the complex structure of the matrix-fracture system. Still, the micro-transport mechanism of the shale gas and the discrete fracture grid model need to be further combined. Therefore, it is necessary to research the cross-scale transport numerical simulation methods of the shale gas reservoirs to realize the effective combination of the micro-transport mechanism and macro-dynamic simulation prediction, so as to provide support for the productivity evaluation of the shale gas wells and the adjustment of the development technology policy. Shale gas well productivity evaluation methods are summarized in Table 2.

Prospects of AI method in the gas well productivity evaluation

Since the common productivity evaluation methods are challenging to match the actual gas well production laws. The machine learning method based on the whole period production data is an effective method for evaluating gas well productivity that has emerged in recent years and is widely used in tight oil and gas (Song et al. 2019; Wang et al. 2021; Niu et al. 2022).

The principle of the machine learning method is to divide the gas well production data into two samples, including the training set and the test set. Pre-processing of the sample data is very critical, such as missing data interpolation, data normalization, and dimensionality reduction. The method applies random forest (RF), back-propagation neural network (BP), recurrent neural network (RNN), long-short-term memory neural network (LSTM), and support vector machine algorithm (SVM) to calculate the data (Han et al. 2020). The model constraint conditions are parameters such as reservoir thickness, porosity, and permeability, and then construct a productivity prediction model that can reflect the laws of the data model. Finally, the main geological and engineering factors affecting the productivity of a single well are analyzed, which can effectively evaluate the productivity of gas wells (Mishra and Lin 2017).

Discussions and future research directions

In this paper, investigation research of the shale gas well productivity evaluation methods is conducted. The following discussion and future research directions are presented below:

-

1.

The presented production decline methods, Arps, FMB, Blasingame, and A–G, have different application conditions, such as flow stage, fitting object, burial depth, effective thickness, porosity–permeability parameters, data volume, etc. In order to improve the accuracy of the results, the research directions mainly include: establishing a set of criteria for shale gas well productivity classification; establishing standard curves for identifying the declining stages based on the production characteristics of different gas wells; expecting to achieve a better fitting between the actual production curves and the type curves, particularly in the early unstable flow stage.

-

2.

The analytical methods have many idealized assumptions and ignore the importance of certain control factors in productivity evaluation. Therefore, it cannot better reflect the transport mechanism of shale gas in the actual shale reservoir. The research directions mainly include the characterization of complex fracture network parameters; the effect of stress sensitivity on porosity–permeability; the effect of formation temperature and pressure on desorption, etc.

-

3.

Different production parameters, engineering parameters, and geological parameters have different degrees of influence on the single well productivity. The research directions mainly include: establishing more refined geological models and complex fracture dynamic models; exploring numerical simulation methods for cross-scale flow; combining multi-factor analysis methods such as machine learning algorithms to carry out productivity influence factor analysis for two types of gas wells with high/low production, hoping to establish correlation type curves between main control factors and productivity index.

-

4.

Most of the shale gas well productivity evaluation methods are applicable to dry gas reservoirs, and there is less research on the mechanism of gas–water two-phase permeability in the early stage of shale gas wells. The size of the fracture fluid flowback rate and gas-phase permeability is directly related to the degree of development of the fracture network system. The factors affecting the degree of fracture development include geological factors such as the expansiveness of clay minerals, dual-action of matrix capillary, viscous forces on pore space, stress sensitivity, and the engineering factors such as the amount of sand addition, and horizontal well section length. Promoting integrated geological and engineering analysis of the shale gas reservoirs is the key to gas well productivity evaluation.

Conclusions

-

1.

The production decline analysis methods have promising applications in the gas field, mainly focusing on fitting production or pressure data. Data collection and pre-processing will affect the accuracy of the productivity prediction and geological parameters. Based on the production characteristics of shale gas reservoirs, dynamic following in the early stage of production is critical. The longer the production time, the better the result of the productivity evaluation.

-

2.

The analytical approach simplifies the complex geological conditions of shale gas reservoirs, but couples multiple cross-scale transport mechanisms, such as diffusion, adsorption–desorption, slip effect, and pressure sensitivity, which is beneficial for the analysis of the influences on the gas well productivity.

-

3.

The numerical simulation method improves the characterization of the geological conditions of shale gas reservoirs. However, it is difficult to build an accurate model, and a large calculating cost is required.

Abbreviations

- a :

-

Intercept

- b :

-

Declining constant (b = 0, it is exponential declining; b = 1, it is harmonic declining; b = 1, it is hyperbolic decreasing)

- C ti :

-

Initial Reservoir compressibility (MPa−1)

- C t :

-

Reservoir compressibility (MPa−1)

- D :

-

Declining rate

- D BDF i :

-

Initial decline rate of the quasi-stable flow stage

- D ∞ :

-

Rate of decline at the infinite time

- D i :

-

Rate of decline at the initial time

- G p :

-

Dynamic geological reserves at a certain pressure (m3)

- G :

-

Original geological reserves (m3)

- G p0 :

-

Dynamic geological reserves before the decline period (m3)

- m :

-

Slope

- n :

-

Extending index

- p i :

-

Initial formation pressure (MPa)

- p p :

-

Normalized pseudo-pressure (MPa)

- p t :

-

Pressure at a certain time (MPa)

- q :

-

Daily production (m3/d)

- q i :

-

Initial gas production (m3/d)

- Q :

-

Cumulative gas production (m3)

- t :

-

Time (d)

- t BDF i :

-

Quasi-stable flow start time (d)

- t ca :

-

Pseudo-time of mass equilibrium (d)

- Z :

-

Gas deviation factor

- Γ :

-

Gamma function

- μ gi :

-

Initial gas viscosity (mpa s)

- μ g :

-

Gas viscosity (mpa s)

- τ :

-

Characteristic relaxation time

- A–G:

-

Agarwal–Gardner method

- AI:

-

Artificial intelligence

- BP:

-

Back-propagation neural network

- BDF:

-

Boundary-defined flow

- DFM:

-

Discrete fracture grid model

- EUR:

-

Estimated ultimate recovery

- EDFM:

-

Embedded discrete fracture model

- FMB:

-

Flow material balance method

- K n :

-

Knudsen number

- LSTM:

-

Long short-term memory neural network

- MHD:

-

Modified hyperbolic decline model

- NPI:

-

Normalized pressure integral method

- NSRD:

-

Non-stimulated reservoir domain

- OGIP:

-

Original gas in place

- PLE:

-

Power-law exponent

- RF:

-

Random forest

- RNN:

-

Recurrent neural network

- SEPD:

-

The extended exponential production decline method

- SRD:

-

Stimulated reservoir domain

- SVM:

-

Support vector machine algorithm

References

Agarwal RG, Gardner DC, Kleinsteiber SW et al (1999) Analyzing well production data using combined-type curve and decline-curve analysis concepts. SPE Reservoir Eval Eng 2(5):478–486. https://doi.org/10.2118/57916-PA

Ali TA, Sheng JJ (2015) Evaluation of the effect of stress-dependent permeability on production Performance in shale gas reservoirs. SPE Eastern Regional Meet. https://doi.org/10.2118/177299-MS

Arps JJ (1945) analysis of decline curves. Trans 160(1):228–247. https://doi.org/10.2118/945228-G

Baca RG, Arnett RC, Langford DW (1984) Modeling fluid flow in fractured-porous rock masses by finite-element techniques. Int J Numer Meth Fluids 4(4):337–348. https://doi.org/10.1002/fld.1650040404

Behmanesh H, Clarkson CR, Tabatabaie SH et al (2021) Effect of relative permeability on modeling of shale oil and gas production. In: SPE/AAPG/SEG Asia pacific unconventional resources technology conference, virtual, November 2021. https://doi.org/10.15530/AP-URTEC-2021-208361

Bello RO, Wattenbarger RA (2010) Multi-stage hydraulically fractured horizontal shale gas well rate transient analysis. In: Society of Petroleum Engineers, North Africa Technical Conference, and Exhibition, Cairo, Egypt, February 2010. https://doi.org/10.2118/126754-MS

Blasingame TA, Mccray TL, Lee WJ (1991) Decline curve analysis for variable pressure drop/variable flow rate systems. In: SPE gas technology symposium, Houston, Texas, January 1991. https://doi.org/10.2118/21513-MS

Bo F, Jing H, Jin X et al (2020) A semi-analytical model for horizontal-well productivity in shale gas reservoirs: Coupling of multi-scale seepage and matrix shrinkage. J Petrol Sci Eng. https://doi.org/10.1016/j.petrol.2020.107869

Brohi I, Pooladi-Darvish M, Aguilera R (2011) Modeling fractured horizontal wells as dual-porosity composite reservoirs—application to tight gas, shale gas, and tight oil cases. SPE Western North American Region Meeting, Anchorage, Alaska, USA, May 2011. https://doi.org/10.2118/144057-MS

Brown M, Ozkan E, Raghavan R et al (2009) Practical solutions for pressure-transient responses of fractured horizontal wells in unconventional shale reservoirs. SPE Reservoir Eval Eng 14(6):663–676. https://doi.org/10.2118/125043-PA

Carlson ES, Mercer JC (1991) Devonian shale gas production: mechanisms and simple models. J Petrol Technol 43(4):476–482. https://doi.org/10.2118/19311-PA

Chen Y, Fu L (2019) Establishment, comparison and application of power function decline model. Petrol Geol Recovery Efficiency 6:87–91

Chen J, Han H, Nian J et al (2018a) Application of the probability method to undeveloped EUR assessment of shale gas: a case study on one mature shale gas block in North America. Nat Gas Ind 7(2):52–58

Chen M, Yang H, Zhang X et al (2018b) Practical shale gas decline analysis in Changning shale gas play–a variable pressure drop study. Int J Oil Gas Coal Technol 18(3–4):353–383. https://doi.org/10.1504/IJOGCT.2018.093136

Cipolla CL, Lolon EP, Mayerhofer MJ et al (2009) Fracture design considerations in horizontal wells drilled in unconventional gas reservoirs. Society of Petroleum Engineers https://doi.org/10.2118/119366-MS

Civan F (2010) Effective correlation of apparent gas permeability in tight porous media. Transp Porous Media 82:375–384. https://doi.org/10.1007/s11242-009-9432-z

David Obembe A, Hasan M, Fraim M (2017) An anomalous productivity model for naturally fractured shale gas reservoirs. In: SPE Kingdom of Saudi Arabia annual technical symposium and exhibition, Dammam, Saudi Arabia, April 2017. https://doi.org/10.2118/188033-MS

Dershowitz B, Lapointe P, Eiben T et al (2000) Integration of discrete feature network methods with conventional simulator approaches. SPE Reserv Eval Eng 3(2):165–170. https://doi.org/10.2118/62498-PA

De SO (1976) Analytic solutions for determining naturally fractured reservoir properties by well testing. Soc Petrol Eng J 16(3):117–122. https://doi.org/10.2118/5346-PA

Duan X, Hu Z, Gao S et al (2018) Shale high-pressure isothermal adsorption curve and the production dynamic experiments of gas well. Pet Explor Dev 45(3):127–135. https://doi.org/10.1016/S1876-3804(18)30012-0

Duong AN (2011) Rate-decline analysis for fracture-dominated shale reservoirs. SPE Reserv Eval Eng 14(3):377–387. https://doi.org/10.2118/137748-PA

Fan D, Ettehadtavakkol A (2016) Transient shale gas flow model. J Nat Gas Sci Eng 33(6):1353–1363. https://doi.org/10.1016/j.jngse.2016.04.007

Fetkovich MJ (1980) Decline curve analysis using type curves. J Petrol Technol 32(6):1065–1077. https://doi.org/10.2118/4629-PA

Gao S, Liu H, Ye L et al (2017) A coupling model for gas diffusion and seepage in SRV section of shale gas reservoirs. Nat Gas Ind 1(2):97–104. https://doi.org/10.1016/j.ngib.2019.06.004

Gu D, Ding D, Liu J et al (2016) Productivity prediction model of the staged fractured horizontal well in triple-media shale gas reservoirs. Petrol Geol Oilfield Dev Daqing. https://doi.org/10.2118/197069-PA

Guo B, Yang X (2019) Use of a new analytical model to match production data and identify opportunities to maximize well productivity in the Tuscaloosa marine shale reservoir. SPE Prod Oper 34(4):770–780. https://doi.org/10.2118/198892-PA

Han D, Jung J, Kwon S (2020) Comparative study on supervised learning models for productivity forecasting of shale reservoirs based on a data-driven approach. Appl Sci. https://doi.org/10.3390/app10041267

Hassan A, Mahmoud M, Al-Majed A et al (2020) Enhance the gas productivity for shale gas reservoirs using thermochemical treatment. In: The international petroleum technology conference. https://doi.org/10.2523/IPTC-19603-Abstract

Hu Y, Weijermars R, Zuo L et al (2018) Benchmarking EUR estimates for hydraulically fractured wells with and without fracture hits using various DCA methods. J Petrol Sci Eng 162(9):617–632. https://doi.org/10.1016/j.petrol.2017.10.079

Hu S, Hu X, He L et al (2019) A new material balance equation for dual-porosity media shale gas reservoir. Energy Procedia 158(8):5594–6002. https://doi.org/10.1016/j.egypro.2019.01.520

Huang Z, Gao B, Wang Y et al (2014) Two-phase flow simulation of discrete fracture model using a novel mimetic finite difference method. J China Univ Petrol 6(1):97–105

Huang T, Guo X, Chen F (2015) Modeling transient pressure behavior of a fractured well for shale gas reservoirs based on the properties of nanopores. J Nat Gas Sci Eng 23(6):387–398. https://doi.org/10.1016/j.jngse.2015.02.020

Ilk D, Rushing JA, Perego AD, Blasingame TA (2008) Exponential vs. hyperbolic decline in tight gas sands: understanding the origin and implications for reserve estimates using Arps' decline curves. In: Society of petroleum engineers. Annual technical conference and exhibition Denver, Colorado, USA, September 2008. https://doi.org/10.2118/116731-MS

Jia A, Wei Y, Jin Y (2016) Progress in key technologies for evaluating marine shale gas development in China. Pet Explor Dev 43(6):1035–1042. https://doi.org/10.1016/S1876-3804(16)30120-3

Jia A, Wei Y, Liu C et al (2019) A dynamic prediction model of pressure control production performance of shale gas fractured horizontal wells and its application. Nat Gas Ind B 7(1):71–81. https://doi.org/10.1016/j.ngib.2019.06.004

Jia B, Tsau J-S, Barati R (2020a) Investigation of shale-gas-production behavior: evaluation of the effects of multiple physics on the matrix. SPE Reserv Evaluat Eng 23(1):68–80. https://doi.org/10.2118/197069-PA

Jia P, Ma M, Cheng L et al (2020b) Capturing dynamic behavior of propped and unpropped fractures during flowback and early-time production of shale gas wells using a novel flow-geomechanics coupled model: a field example from the Chang Ning shale in China. In: SPE/AAPG/SEG unconventional resources technology conference. https://doi.org/10.15530/urtec-2020-3314

Jiang LJ, Sun HG, Yang S et al (2020) Investigation on multi-scale pore seepage model of shale gas reservoir considering diffusion and slippage effect. Microfluid Nanofluid. https://doi.org/10.1007/s10404-020-02388-6

Karimi-Fard M, Durlofsky LJ, Aziz K (2004) An efficient discrete-fracture model applicable for general-purpose reservoir simulators. SPE J 9(2):227–236. https://doi.org/10.2118/88812-PA

Lee SH, Jensen CL, Lough MF (2000) An efficient finite difference model for flow in a Reservoir with multiple length-scale fractures. SPEJ 5(3):268–275. https://doi.org/10.2118/65095-PA

Li G, Guo B, Li J et al (2019a) A mathematical model for predicting long-term productivity of modern multifractured shale-gas/oil wells. SPE Drill Complet 34(2):114–127. https://doi.org/10.2118/194495-PA

Li H, Wang K, Bu C et al (2019b) Empirical method analysis of individual well production and EUR forecast in shale gas reservoir. Spec Oil Gas Reserv 26(3):74–78

Li L, Lee SH (2008) Efficient field-scale simulation of black oil in a naturally fractured reservoir through discrete fracture networks and homogenized media. SPE Res Eval Eng 11(04):750–758. https://doi.org/10.2118/103901-PA

Li W, Liu J, Zeng J et al (2020) A fully coupled multidomain and multiphysics model for evaluation of shale gas extraction. Fuel. https://doi.org/10.1016/j.fuel.2020.118214

Liu A, Liu S, Sang G (2020) Characterizing gas-water transport behavior in tight shale and its application on the well productivity. In: SPE annual technical conference and exhibition, Virtual, October 2020. https://doi.org/10.2118/201651-MS

Liu X, Zou C, Jiang Y et al (2013) Horizontal well dynamic evaluation method in shale gas reservoirs. Oil Drill Product Technol 3(4):55–58

Ma X, Li X, Liang F et al (2020) Dominating factors on good productivity and development strategies optimization in Weiyuan shale gas play, Sichuan Basin, SW China. Petrol Explor Dev 47(3):594–602. https://doi.org/10.1016/S1876-3804(20)60076-3

Mishra S, Lin L (2017) Application of data analytics for production optimization in unconventional reservoirs: a critical review. In: SPE/AAPG/SEG unconventional resources technology conference, Austin, Texas, USA. https://doi.org/10.15530/URTEC-2017-2670157

Mohamed F, Otulana D, Salazar I et al (2021) Innovative modeling to quantify the impact of natural fractures and optimize well spacing and increase productivity in the marcellus shale. In: SPE/AAPG/SEG unconventional resources technology conference, Houston, Texas, USA. https://doi.org/10.15530/urtec-2021-5271

Manda P, Nkazi DB (2020) The evaluation and sensitivity of decline curve modeling. Energies 13(11):2765. https://doi.org/10.3390/en13112765

Mattar L, Anderson D, Stotts G (2006) Dynamic Material Balance-oil or gas-in-place without shut-ins. J Can Petrol Technol 45:11. https://doi.org/10.2118/06-11-TN

Mattar L, Mcneil R (1998) The flowing gas material balance. J Can Pet Technol 37(2):719–729. https://doi.org/10.2118/98-02-06

Moinfar A, Narr W, Hui M-H et al (2011a) Comparison of discrete-fracture and dual-permeability models for multiphase flow in naturally fractured reservoirs. In: Society of petroleum engineers—SPE reservoir simulation symposium The Woodlands, Texas, USA. https://doi.org/10.2118/142295-MS

Moinfar A, Narr W, Hui MH, et al (2011b) Comparison of discrete-fracture and dual-permeability models for multiphase flow in naturally fractured reservoirs. In: Society of petroleum engineers—SPE reservoir simulation symposium. https://doi.org/10.2118/142295-MS

Moinfar A, Varavei A, Sepehrnoori K et al (2013) Development of a coupled dual continuum and discrete fracture model for the simulation of unconventional reservoirs. In: SPE reservoir simulation symposium, The Woodlands, Texas, USA. https://doi.org/10.2118/163647-MS

Monteagudo JEP, Firoozabadi A (2004) Numerical simulation of water injection in disconnected and connected fractured media using the jacobian-free fully implicit control volume method. In: SPE/DOE symposium on improved oil recovery, Tulsa, Oklahoma

Niu W, Lu J, Sun Y (2022) Development of shale gas production prediction models based on machine learning using early data. Energy Rep 8(7):1229–1237

Noorishad J, Mehran M (1982) An upstream finite element method for the solution of transient transport equation in fractured porous media. Water Resour Res 18(3):588–596. https://doi.org/10.1029/WR018i003p00588

Ozkan E, Raghavan R, Apaydin OG (2010) Modeling of fluid transfer from shale matrix to fracture network. In: Society of Petroleum Engineers. Annual Technical Conference and Exhibition, Florence, Italy. https://doi.org/10.2118/134830-MS

Ozkan E, Brown M, Raghavan R et al (2011) Comparison of fractured-horizontal-wellperformance in tight sand and shale reservoirs. SPE Reserv Eval Eng 14(2):248–259. https://doi.org/10.2118/121290-PA

Phan T, Kazempour M, Nguyen D et al (2018) Treating liquid banking problem to increase shale gas wells productivity. In: SPE international conference and exhibition on formation damage control; Lafayette, Louisiana, USA. https://doi.org/10.2118/189523-MS

Sangnimnuan A, Li J, Wu K et al (2016) Application of efficiently coupled fluid flow and geomechanics model for refracturing in highly fractured reservoirs. In: SPE hydraulic fracturing technology conference & exhibition. The Woodlands, Texas, USA. https://doi.org/10.2118/189870-MS

Seshadri J, Mattar L (2010) Comparison of power law and modified hyperbolic decline methods. In: Canadian unconventional resources and international petroleum conference

Stalgorova E, Mattar L (2012a) Analytical model for history matching and forecasting production in multifrac composite systems. In: Society of petroleum engineers. Canadian unconventional resources conference, Calgary, Alberta, Canada. https://doi.org/10.2118/162516-MS

Stalgorova E, Mattar L (2012b) A practical analytical model to simulate production of horizontal wells with branch fractures. In: Canadian unconventional resources conference, Calgary, Alberta, Canada. https://doi.org/10.2118/162515-MS

Su Y, Sheng G, Wang W et al (2016a) A multi-media coupling flow model for shale gas reservoirs. Nat Gas Ind 2:52–59. https://doi.org/10.2118/189523-MS

Su Y, Sheng G, Wang W et al (2016b) A multi-media coupling flow model for shale gas reservoirs. Nat Gas Ind 36(2):52–59. https://doi.org/10.1016/S1876-3804(21)60076-9

Sun Z, Shi J, Yang Z, et al (2019) Evaluation about adsorption gas and free gas content inside shale matrix under a wide range of atmosphere conditions. Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE. https://doi.org/10.2118/197176-MS

Song H, Su Y, Xiong X et al (2019) EUR evaluation workflow and influence factors for shale gas well. Nat Gas Geosci 10(2):1531–1537. https://doi.org/10.2118/426-PA

Swami V, Settari A (2012) A pore scale gas flow model for shale gas reservoir: a pore scale gas flow model for shale gas reservoir. In: SPE Americas Unconventional Resources Conference, Pittsburgh, Pennsylvania USA. https://doi.org/10.2118/155756-MS

Terminiello A, Crespo P, Nasca M (2020) Evaluating the performance of decline curve analysis equations during the early life of a well through the quantification of the uncertainty associated with the estimated ultimate recovery in a shale oil and gas formation. In: SPE/AAPG/SEG Latin America Unconventional Resources Technology Conference, 779. https://doi.org/10.15530/urtec-2020-1518

Tian L, Xiao C, Liu M et al (2014) Well testing model for multi-fractured horizontal well for shale gas reservoirs with consideration of dual diffusion in matrix. J Nat Gas Sci Eng 21(9):283–295. https://doi.org/10.1016/j.jngse.2014.08.001

Urban E, Yousefzadeh A, Virues CJ et al (2017) Evolution and evaluation of SRV in shale gas reservoirs: an application in the horn river shale of Canada. In: SPE Latin America and Caribbean Petroleum Engineering Conference, Buenos Aires, Argentina. https://doi.org/10.2118/185609-MS

Valko PP (2009) Assigning value to stimulation in the Barnett Shale: a simultaneous analysis of 7000 plus production hystories and well completion records. In: Society of petroleum engineers, hydraulic fracturing technology conference, The Woodlands, Texas

Valko PP, Lee WJ (2010) A better way to forecast production from unconventional gas wells. In: Society of petroleum engineers, annual technical conference and exhibition, Florence, Italy. https://doi.org/10.2118/134231-MS

Wachtmeister H, Lund L, Aleklett K et al (2017) Production decline curves of tight oil wells in Eagle Ford shale. Nat Resour Res 26(3):365–377. https://doi.org/10.1007/s11053-016-9323-229

Wang W, Fan D-Y, Sun H (2015) Productivity model and analysis of influence factors of staged multi-cluster fractured horizontal wells in shale gas reservoirs. Sci Technol Eng 31(3):36–41. https://doi.org/10.1016/j.petrol.2016.03.013

Wang Q, Hu Y, Zhao J et al (2019) Multiscale apparent permeability model of shale nanopores based on fractal theory. Energies. https://doi.org/10.3390/en12173381

Wang T, Wang Q, Shi J et al (2021) Productivity prediction of fractured horizontal well in shale gas reservoirs with machine learning algorithms. Appl Sci. https://doi.org/10.3390/app112412064

Warren JE, Root PJ (1963) The behavior of naturally fractured reservoirs. Soc Petrol Eng J 3(3):245–255. https://doi.org/10.2118/426-PA

Watson AT, Iii JMG, Lee WJ et al (1990) An analytical model for history matching naturally fractured reservoir production data. SPE Reserv Eng 5(3):384–398. https://doi.org/10.2118/18856-PA

Wei Y, Wang J, Yu W et al (2021) A smart productivity evaluation method for shale gas wells based on 3D fractal fracture network model. Petrol Explor Dev 48(4):911–922. https://doi.org/10.1016/S1876-3804(21)60076-9

Wu Y, Moridis GJ, Bai B et al (2009) A multi-continuum model for gas production in tight fractured reservoirs. In: Society of petroleum engineers, hydraulic fracturing technology conference, The Woodlands, Texas. https://doi.org/10.2118/118944-MS

Yan X, Huang Z, Yao J et al (2016) An efficient embedded discrete fracture model based on mimetic finite difference method. J Petrol Sci Eng 145:11–21. https://doi.org/10.1016/j.petrol.2016.03.013

Yao J, Sun H, Fan D-Y et al (2013) Transport mechanisms and numerical simulation of shale gas reservoirs. J China Univ Petrol (edition of Nat Sci) 37(1):91–98. https://doi.org/10.2118/201651-MS

Yin H, Zhao E, Fu J et al (2015) Production analysis of composite model of five regions for fractured horizontal wells in shale gas reservoirs. J Southwest Petrol Univ Sci Technol Ed 37(3):9–16. https://doi.org/10.11885/j.issn.1674-5086.2015.03.04.07

Zeng J, Liu J, Li W et al (2019) Characterizing gas transfer from the inorganic matrix and kerogen to fracture networks: a comprehensive analytical modeling approach. SPE/AAPG/SEG Asia Pacific Unconventional Resources Technology Conference, Brisbane, Australia. https://doi.org/10.15530/AP-URTEC-2019-198303

Zeng J, Liu J, Li W et al (2021) Shale shrinkage transition induced by the matrix-fracture equilibrium time lag: a neglected phenomenon in shale gas production. In: SPE/AAPG/SEG Asia Pacific unconventional resources technology conference. https://doi.org/10.15530/AP-URTEC-2021-208403

Zhang J, Huang S, Cheng L et al (2015) Effect of flow mechanism with multi-nonlinearity on production of shale gas. J Nat Gas Sci Eng 24:291–301. https://doi.org/10.1016/j.jngse.2015.03.043

Zhang P, Hu L, Meegoda JN (2017) Pore-scale simulation and sensitivity analysis of apparent gas permeability in shale matrix. Materials 10(2):104. https://doi.org/10.3390/ma10020104

Zhao J, Liu C, Yang H et al (2015) Strategic questions about China’s shale gas development. Environ Earth Sci 73(11):6059–6068. https://doi.org/10.1007/s12665-015-4092-5

Zhao Y, Lu G, Zhang L et al (2020) Numerical simulation of shale gas reservoirs considering discrete fracture network using a coupled multiple transport mechanisms and geomechanics model. J Petrol Sci Eng 145:107588

Zhong C, Leung J (2019) Numerical investigation of water blockage in secondary fractures and apparent permeability modeling in shale gas production. In: SPE/AAPG/SEG unconventional resources technology conference, Denver, Colorado, USA. https://doi.org/10.15530/urtec-2019-592

Zhu W, Ma D (2018) Effective stress characteristics in shale and its effect on shale gas productivity. J Nat Gas Geosci 3(6):339–346. https://doi.org/10.1016/j.jnggs.2018.12.001

Zhu W, Ma D, Qi Q et al (2018) Multi-zone coupling productivity of horizontal well fracturing with complex fracture networks in shale gas reservoirs. Nat Gas Ind B 5(1):80–89. https://doi.org/10.1016/j.ngib.2017.12.006

Funding

This work was supported by the General Program of Chongqing Natural Science Foundation (No. cstc2020jcyj-msxmX0659).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, Y., Li, X., Liu, X. et al. Review of the productivity evaluation methods for shale gas wells. J Petrol Explor Prod Technol 14, 25–39 (2024). https://doi.org/10.1007/s13202-023-01698-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01698-z