Abstract

Heavy metal pollution caused by oil well drilling operations is one of the environmental problems that the oil industry imposes on the environment. The source of such pollution should first be determined precisely to manage and control it. Studies show that the main source of environmental pollution in well drilling operations is the drilling fluid additives or the elements in the well column formations. In this research, in addition to measuring the concentration of heavy metals and comparing it with the existing standards, an attempt is made to determine the exact origin of these metals. To study the source of such pollution in the area of the Abteymour oil field in the southwest of Iran, 19 cuttings (from 8 formations), 10 waste samples (drilling mud and cutting), and 7 drilling muds and their additive samples from one of the wells were assessed to determine the concentration of heavy metals. In this study, a total of 56 elements were measured using the ICP-MS analysis method; however, 16 elements that had a higher concentration than the average of the upper crust (as a reference concentration) with Ni, Cr, and V elements were studied. These 16 elements included Fe, Ag, As, Ba, Bi, Cd, Cu, Mg, Mn, Mo, Pb, Sb, Sr, and W heavy metals, and Ca and S elements. The analysis of the examined elements' concentrations in muds and their additives revealed that samples of heavy water-based muds and barite contained the highest concentrations of the elements. The cuttings samples primarily had a higher concentration than the waste samples, which was due to the mixing of the cuttings of different depths in the waste and the dilution of the element concentration in the waste samples, according to an analysis of the variation of 19 elements compared to the depth. Among the studied formations, the Gachsaran Evaporite Formation has high concentrations of studied elements. This problem is due to the complexity of the lithology of Gachsaran Formation, which consists of all kinds of rocks such as anhydrite, gypsum, salt and marl. This result shows the importance of managing drilling operations in this formation to prevent the release of heavy metals in the environment. Based on the Igeo, Ca, Ag, As, Ba, Bi, Cd, Cu, S, Sb, and Sr elements had high levels of pollution in all samples of waste and drilling cuttings. Based on the EF, only Cr, Mn, and V elements had no enrichment, and other elements had different enrichment levels in waste and drilling cuttings samples. The main result of this study shows that the main source of heavy metal pollution in the first stage is the type of elements in the lithology of the well column formations and in the next stage is the type and additives of the drilling fluid used in the well. Specifically, in the Abteymour oil field, the main reason for the contamination of the Gachsaran formation is due to the complexity of the lithology and the use of heavy water base drilling mud. The results of this research show that before choosing the type of drilling fluid, it is necessary to do a detailed environmental study and identify heavy elements in subsurface formations and the designed drilling fluid.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

The drilling industry is one of the main sectors of the oil and gas industry and one of the most professional industrial activities worldwide. Due to the production of various types of soluble and insoluble solid and liquid waste, this operation, which is necessary for the development of gas and oil fields, has caused environmental concerns (Afkhami et al. 2013; Hossain et al. 2017; Shahbaz et al. 2023). Drilling contaminants, which are diverse in terms of toxicity and quantity, include oil brine, drilling fluids and cuttings, hydrocarbon compounds of the reservoir, necessary fluids for equipment maintenance, drilling sand, filters, etc. The primary contaminant sources are directly related to the cuttings, fluids, and compounds used in the drilling fluid (Zhang et al. 2016; Ismail et al. 2017; Mikos-Szymańska et al. 2018; Daae et al. 2019; Daneshfar and Ardjmand 2021). Due to the increasing energy demand, drilling operations increase every year; as a result, the drilling fluid wastes, which are also very hazardous, increase. The components of the drilling fluid and cuttings of drilled formations contain a vast range of contaminants. During drilling operations, these contaminants enter the environment as waste. When these wastes are disposed of in the environment, they may mix with the soil and cause soil contamination, or they may penetrate the surface or underground water and cause contamination and threaten the lives of organisms. Due to the variety of lithology, fluid compositions for drilling various formations, and the mutual and complicated effects of the fluid in the different lithological compositions of the formations, the amount of contamination and its distribution in the environment are different (Cunha et al. 2018).

Drilling cuttings contain heavy metals, barite, bentonite, special chemical materials, hydrocarbons, organic contaminants, and radioactive isotopes. The concentration of heavy metals in drilling cuttings depends on the type of drilling mud, its additives, and the amount of metal in the formations. Studies have shown that drilling mud is heavily contaminated with some heavy metals, such as Cd (Amin et al. 2018). Barite is the main source of heavy metals in water-based drilling mud (Li et al. 2005). Studies have shown trace metal concentrations as well as correlations between Hg and Cd concentrations and some other metals in barite (EPA 1993). The presence of some heavy metals in barite and their negative effects on the ecosystem have been confirmed (Neff 2008). Some trace metals (such as Cd, Cr, Ni, Pb, and V) cause toxicity to plants, animals, and humans in high concentrations. Hydrocarbon materials and heavy metals from drilling wastes usually contaminate the soil when soil microorganisms cannot degrade them. As a result, the soil turns into a paste-like, black mass without any biological activity (Ghazban 2011).

Different kinds of heavy metals have been discovered in the air, soil, and water habitats. They will consequently affect physical surroundings, plants, animals, and people differently in terms of toxicity. It is important to take the synergistic impact into account when determining an element's toxicity. The mobility of cationic metals increases in an alkaline environment as a result of the creation of complex metal complexes with organic solvents (McLean and Bledsoe 1992). This is due to the fact that drilling mud is often alkaline; if it builds up or spills in water settings or on the ground surface, pollutants will flow and spread throughout the local water or soil. Additionally, they affect the soil's microbial activity, the solubility of nutrients in the soil, the activity of soil organisms, the migration of some elements (such as Ca, Mg, Fe, Cu, Zn, P, and B) to underground water sources, and other factors.

Due to global warnings about environmental restrictions and risks and the need to provide environmental and safety assessment reports for industrial operations in various fields, continuous efforts have been made to use new technology and equipment to reduce the waste of drilling exploration and production wells. To effectively manage the environmental hazards of drilling operations, the type of contamination and its source should be identified. For this reason, the contamination of the environments around drilling platforms, wastes, and drilling fluids has been the subject of numerous studies.

In this study, drilling wastes from a well at the Abteymour oil field in the southwest of Iran were examined for the concentration of heavy metals and associated environmental indices. Samples of both fresh drilling fluid and return fluid, including cuttings, were taken in order to determine the content of heavy metals and major elements. Each formation might have some components that are different from those present in different drilling muds (water- and oil-based muds). In order to ascertain the elements, uncontaminated drilling cuttings from various formations were sampled. The depth of the sampling was used to assess their likely source.

Geological setting

Regarding geological location, the Abteymour oil field is located in the Zagros Zone and within the northern Dezful Embayment area. From a morphotectonic point of view, the Zagros Zone, which is one of the largest structural-sedimentary zones in Iran, includes a thrust zone, a simple folded zone, and the Dezful Embayment from northeast to southwest (Berberian 1995). Most of the oil fields in Iran are located in the Dezful Embayment area. As with other structures, the Abteymour oil field follows the general trend of the Zagros Structural Zone (NW–SE). Figure 1 shows the location of the Abteymour oil field in relation to the geological formations entirely composed of Quaternary alluvial deposits. The Quaternary alluvial deposits cover large parts of the Khuzestan Province, especially in the Dezful Embayment and the coastal plain. According to numerous drillings in the southwestern oil fields of Iran and according to subsurface geological studies, the dominant formations and lithology in these fields are listed in Table 1.

So far, nearly 60 wells have been drilled in this field to produce the oil from Asmari and Bangestan Reservoirs (development wells), as well as to identify the limits of the underground structure and determine the depth of different fluid levels (delineation wells). The crude oil production capacity of the Abteymour field is 60,000 barrels per day, produced through 50 wells from the Ilam (29 wells) and Sarvak (21 wells) reservoirs of this field. In this field, the production is done from 2 separate reservoirs (Asmari and Bangestan); therefore, the drilled formations from the surface to the Bangestan Reservoir include the Aghajari, Mishan, Gachsaran, Asmari, Pabdeh, and Gurpi Formations.

Methodology and material

In this study, the accumulation of some elements (including heavy elements) and environmental indices were investigated in 1 well of the Abteymour oil field. To achieve the purposes of this study, the samples were collected over a 6-month period. The samples were taken from the drilled formation, fresh drilling mud and its additive, and drilling waste. Drilling cutting samples (including 19 samples of different formations) were collected from the shaker. Then, the samples were cut, and pieces were prepared from them without contamination with drilling fluid. Fresh drilling mud samples (before fluid entered the well) were taken from light and heavy water-based mud (2 samples from each mud). Also, amples of mud additives (including Ferro Bar, Bentonite, and Barite) [2 samples from each additive] were collected. In addition, 10 samples were gathered from the drilling waste. The concentration of the elements (56 elements) was determined using the ICP-MS method. In addition, in a number of drilling cuttings of the Asmari to Sarvak Formations, the mineralogical composition was determined by the XRD method.

According to the purposes of environmental studies (such as investigating and determining possible sources and factors affecting the distribution and relationships of a number of contaminants), statistics are always a useful tool to achieve these purposes. Contamination is a quantitative and multivariate phenomenon; therefore, statistical methods can be used to describe or analyze it. Summarizing, classifying, and presenting data in the form of tables and graphs is the first step to identifying the distribution and changes of the studied parameters.

In this study, to compare the averages of concentrations in different environments (the averages in the upper crust and limestone, shale, and sandstone rocks) (Taylor and McLennan 1985; Clark and Washington 1924; Sageman and Lyons 2003; Kabata-pendias and Pendias 2011), the concentrations of the studied parameters are presented as graphs vs. depth.

The distribution of contamination in different environments and materials is affected by natural (geological) and unnatural (anthropogenic) sources. Due to the variety of these sources, studying the concentration variation of each studied parameter separately did not clearly identify the main effective processes. Therefore, multivariate statistical analyses, which are based on data reduction and their classification into common groups, are very efficient in detecting and interpreting effective sources (Suk and Lee 1999). Cluster analysis is a set of methods and algorithms to group similar data and place them in appropriate groups. Hierarchical clustering is one of the most widely used cluster analysis methods in the earth sciences (Davis 1986; Tlili-Zrelli et al. 2013). Drawing a dendrogram is one of the characteristics of this method, and the selection of the cluster numbers is made automatically (Barzegar et al. 2017). In this method, measuring the similarity of data and classifying them in a set of clusters is done based on distance or correlation coefficient. Distance-based similarity shows that 2 data with low distance are very similar, while correlation-based similarity shows that two data with high correlation are more similar. Clustering algorithms include between-group linkage, within-group linkage, nearest neighbor, furthest neighbor, centroid clustering, median clustering, and Ward’s methods. Choosing a suitable method depends on the opinion of the expert and the compatibility of the analysis results with the existing conditions. In this research, according to the results of different methods, Ward’s method was used to link the clusters, and the squared Euclidean distance method was used to calculate the similarity index.

In environmental studies, especially when the distribution of elements is affected by both anthropogenic and natural factors, variation can be evaluated using pollution indices. Therefore, in this research, to evaluate contamination and environmental quality, the Igeo and EF were calculated for the studied parameters.

-

Igeo: It is one of the important geochemical indices to describe the concentration of elements in each area and is calculated based on the following relationship (Table 2) (Muller 1969):

Table 2 The degree of metal enrichment based on the Igeo classification $${\mathrm{I}}_{\mathrm{geo}}={\mathrm{log}}_{2}\left(\frac{\mathrm{Cn}}{1.5\mathrm{Bn}}\right)$$(1)Cn: measured concentration of metal; Bn: measured concentration of reference element.

-

EF: It is a suitable method to distinguish the natural or anthropogenic source of contamination, which can be calculated based on the following relationship (Table 3) (Sutherland 2000):

Table 3 The degree of metal enrichment based on the EF classification $$\mathrm{EF}=\frac{\frac{{C}_{n}}{{C}_{ref}}}{\frac{{B}_{n}}{{B}_{ref}}}$$(2)Cn: measured concentration of metal; Cref: measured concentration of metal in the reference environment (average in upper crust); Bn: measured concentration of reference element; Bref: concentration of the reference element in the reference environment (average in upper crust).

An element can be used as a reference that its distribution and abundance in the environment are not dependent on other elements, and human activities do not have a significant effect on its concentration. The concentration of these elements (such as Fe, Mn, Sn, and Al) is usually affected by natural resources (Janadeleh et al. 2018; Jahan and Strezov 2018; Shafie et al. 2013; Zahra et al. 2014). In this research, the Fe element was used as a reference element, and the average values of the upper crust were used as background concentrations. If EF is between 0.5 and 1.5, it indicates the effect of natural processes and crustal materials. EF values between 0.5 and 1.5 indicate the impact of natural factors, and EF values greater than 1.5 indicate the impact of anthropogenic factors (Zhang and Liu 2002).

Results and discussion

Only 16 elements with values above the average of the upper crust (McLennan 2001) in new drilling fluid, waste, and drilling cuttings were explored in this study, despite the concentration of 56 elements detected. Fe, As, Ag, Ba, Bi, Cd, Cu, Mg, Mn, Mo, Pb, Sb, Sr, and W heavy metals, as well as Ca and S elements, were among the 16 elements. Additionally, because of their significance in the pollution associated with the oil and gas industries, Ni, Cr, and V elements were also analyzed.

The XRD results for different formations showed that carbonate minerals were the main phases in all studied formations (Table 4). Quartz, Kaolinite and Halite minerals were the main minerals in the Asmari and Sarvak formations, respectively. To investigate the relationship between mineralogical composition and the accumulation of heavy metals in the samples of drilling cuttings, the concentration of Ag and Sr elements was investigated separately for each formation. These elements had the highest difference with the average of the upper crust in these 8 samples. The highest concentrations of the Ag element were observed in Sarvak limestone, Ilam limestone, Pabdeh limestone, Asmari sandstone, Asmari limestone, and Gurpi limestone, respectively. For the Sr element, the highest concentrations were observed in the samples of Pabdeh limestone, Gurpi limestone, and Asmari limestone, respectively. It seems that the accumulation of heavy metals in the studied formations depended on the type of element, the host rock, the diversity of the foundation of the rocks, and the ionic replacement of the elements (Marescotti et al. 2010; Buccione et al. 2021; Zinn et al. 2020). For instance, for Ag metal (which had the highest value in Sarvak limestone), calcite was the main phase and quartz and anhydrite were the secondary phases. In the Gurpi formation (which has the lowest value of Ag), calcite was the main mineral, and quartz, dolomite, and clay minerals were secondary minerals; in addition, albite and halite minerals were minor phases. Therefore, these variations in Ag mostly depended on the displacement of different rock foundations. Also, this observation can be proven in the case of Sr. In this regard, the highest concentration of Sr was observed in the Pabdeh formation sample, whose main mineral was calcite and whose secondary minerals were quartz, halite, dolomite, and hematite; in addition, its rare phase was clay minerals. The lowest value of Sr was observed in Asmari limestone, whose main minerals were calcite, quartz, and kaolinite, and whose secondary minerals were hematite, halite, and dolomite.

Figures 2 and 3 show the dendrograms of cluster analysis for the studied parameters. The dendrograms of waste samples showed that 17 studied elements could be categorized into 3 clusters (Fig. 2). Due to low or no correlation, other studied elements were excluded from this analysis. For waste drilling, the first cluster included Pb, S, Mo, Sr, Cu, and Ag elements, the second cluster included Sb, Ba, Cd, and Cu elements and the third cluster included Cr, V, Ni, Mg, As, Mn, and Fe elements. In the drilling cutting samples, these elements were categorized into 4 clusters. The first cluster included Cr, Fe, V, and Ni elements, the second cluster included Ca, Mo, and Cd elements, the third cluster included Pb, Mn, Mg, and As elements and the fourth cluster included Sr, S, Cu, Sb and Ba elements (Fig. 3). The number of more clusters for the samples of drilling cuttings shows the effect of different lithologies on the accumulation of different elements in these cuttings. In the drilling waste, the rock fragments of different lithologies and depths were mixed together. The clustering of wastes in 3 groups was probably affected by 3 different sources for these elements, including lithology, drilling fluid and hydrocarbon materials of the reservoir. However, some elements are found in all these sources.

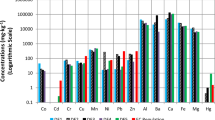

Figure 4 shows the values of the studied elements in samples of drilling fluid and its additives. Figures 5, 6, 7, 8 and 9 show the changes of these elements in samples of waste and drilling cuttings vs. depth in different formations. Due to the main lithology in the drilled formations, in addition to the average of the upper crust, the values of the studied elements have been compared to the maximum values in Chile’s sandstone and calcareous rocks (Kabata-Pendias and Pendias 2011; Peana et al. 2021). Investigating the trend of changes in the studied elements vs. depth in waste and drilling cutting samples showed that these 2 trends were incompatible in some cases. This means that the concentration of the studied elements, including heavy metals, in the waste is not only affected by the lithological composition. However, in waste, the lithological compounds from different depths are mixed, and in this case, the measured value will not exactly indicate the concentration at a specific depth. This process dilutes the concentration of the elements measured in the waste samples compared to the drilling cuttings. The type of drilling fluid and its additives, the way to recycle and reuse the fluid, and the penetration of hydrocarbons from the reservoir into the fluid flow are other effective factors in distinguishing these 2 trends from each other. Except for soluble rocks, the removal of each element in the mineralogical composition and its entry into the drilling fluid flow is a long and time-consuming process. Therefore, the speed of fluid flow in the well and its contact time with different formations will not have a significant effect on the increase in the concentration of elements in the waste.

-

Ag: At the beginning of the Aghajari formation, the concentration of Ag metal was higher in the waste sample than in the drilling cutting. The Aghajari formation contains a marl composition. The range of Ag variation in this lithological composition was between 0.07 and 0.1 ppm. On the other hand, this formation was drilled with light water-based mud with an Ag concentration equal to 0.7 ppm and a bentonite additive with an Ag concentration equal to 0.41 ppm. The combination of these 2 factors has increased the concentration of Ag in the waste samples from this formation. The highest value of Ag was in the depth range of the Gurpi formation, where oil-based mud was used for the drilling operation.

-

As: In the depth interval of the Gachsaran and Aghajari formations, the concentration of As was high in the waste. The highest concentration of this metal was in heavy mud samples, with a concentration equal to 89.6–98.9 ppm. The highest concentration of As in heavy water-based mud samples was 89.6–98.9 ppm; therefore, contamination and a high concentration of As can be expected in the depth ranges where this type of mud is used.

-

Ba: In the Mishan formation to the depth of the Gachsaran formation, Ba metal had a much higher concentration in the cutting samples than in other samples. The highest concentration of Ba was in drilling mud, additives to heavy water-based mud, and barite. The main use of barite is in heavy water-based mud, which is used for drilling marl, limestone, and shale formations. Therefore, Ba concentrations are high in the waste of these formations. On the other hand, the highest concentration of Ba is in clay and limestone rocks. Therefore, a high concentration of Ba in the drilling logs of the Gachsaran and Mishan formations can be due to the lithology.

-

Cd: The concentration of Cd in the cutting of the Pabdeh formation was very high, probably due to the composition of organic matter-rich shales. Stow showed that these shales had high concentrations of metals such as Cu, Mo, V, Cd, and Zn, which were higher than the normal value.

-

Cr: The Cr concentration was 49 ppm in the light water-based mud and 74 ppm in the bentonite additive to this mud. Therefore, a high concentration of Cr in the waste of the Aghajari formation is related to this mud. The lithological composition was the source of the high concentration of this metal in the cuttings of the Gachsaran formation. Oily-based mud is used for drilling the Asmari, Pabdeh, Gurpi, Ilam, and Sarvak formations, containing less than 0.1 ppm Cr in its diesel. Therefore, the concentration of Cr metal in the samples of these formations, especially the Pabdeh formation, has a lithogenic source. On the other hand, Cr is one of the elements found in crude oil. Therefore, the presence of this element in the drilling cuttings of the reservoir or source formations can be justified.

-

Cu: Cu concentrations were high in cutting samples of the Gachsaran formation. Asmari, Gurpi, Ilam, and Sarvak formations are drilled with oil-based mud, which has a Cu value of less than 0.1 ppm; therefore, the Cu concentration in waste and cutting samples of these formations has a lithologic source. The concentration of Cu in the waste of the Aghajari and Mishan formations is due to the type of drilling mud and its additives.

-

Mo: Since Pabdeh, Gurpi, Ilam, and Sarvak formations are drilled with the same mud, it seems that the increase of Mo in the Sarvak and Pabdeh formations has a lithologic source.

-

Ni: The highest concentrations are in the waste and cutting samples of the Aghajari formation. For drilling the Aghajari formation, light water-based mud is used, with a Ni concentration of 28 ppm and 36 ppm in bentonite; therefore, a high concentration of Ni in the samples of the Aghajari formation is due to the mud and its additives. The concentration of this metal in the Pabdeh Formation cutting samples is also affected by the lithological composition. On the other hand, crude oil has concentrations of Ni metal, causing an increase in Ni metal in the waste and drilling cuttings of the reservoir and source formations.

-

Pb: Pb metal can accumulate in shale and limestone rocks; therefore, its accumulation in the cuttings and waste of the Mishan and Asmari formations can be justified.

-

Sb: Sb generally accumulates with Cd and Ni metals. Cd, Ni, and Sb elements in the Gachsaran formation cuttings have a similar trend; therefore, a lithological source can cause this increase. An increase in concentration was also seen in the waste of the Gurpi formation. The concentration of this metal in heavy mud was between 3.6–7.9 ppm and 21.9 ppm in barite; therefore, a high concentration in the waste samples of formations drilled with this mud can be influenced by the type of mud and its additives.

-

Sr: A high concentration of Sr in the drilling cuttings of the Gachsaran formation is directly due to the calcareous and marl lithology at the initial depths of this formation. The concentration of Sr in the Ilam, Sarvak, and Asmari formations is within the range of limestone and clay rocks. Therefore, it seems that the concentration of Sr metal in the samples of logs and residues from these formations has a geological source. In the Gurpi formation (which is composed of shale, marl, and limestone rocks), the Sr concentration is higher in the cutting samples than in the waste samples, indicating the lithogenic source of this metal.

-

V: The highest concentration is related to the Aghajari and Pabdeh formations. The Aghajari formation is drilled with light water-based mud and bentonite. The concentration of V was 106 ppm in this type of mud and 81 ppm in bentonite; therefore, an increase in concentration in the waste of these formations is due to drilling mud.

EF and Igeo were used to assess the circumstances and level of contamination of waste, cutting, and drilling mud samples. Igeo is one of the crucial environmental indicators that, by differentiating anthropogenic influences from natural variations in a substance's concentration in the environment, may detect even minute changes (Al-Khashman 2007; Feng et al. 2019; Liu et al. 2020). In Figs. 10 and 11, this index's fluctuation is displayed. Barite and heavy mud samples indicated a greater level of pollution, according to the analysis of Igeo in mud and its additive samples. There was significant pollution in the elements Ag, As, Ba, Bi, Cd, Cu, Pb, Sb, S, and Sr (Fig. 10). The Ferro Bar sample contained substantial levels of contamination in the Fe and Mo elements. There was no Ca, Cr, Mg, Mn, Ni, V, or W contamination in any of the mud samples or their additives. Ca, Ag, As, Ba, Bi, Cd, Cu, Sb, S, and Sr elements are highly contaminated in cuttings and waste samples, according to an analysis of Igeo vs. depth in various formations. Pollution levels for the elements Mg, Mo, and Sr are typical (Fig. 11).

The EF shows the level of contamination of elements in the sediment or soil. In environmental analysis, this index is one of the important indices to evaluate the concentration of elements under the influence of anthropogenic and natural factors. Figure 12 shows the variation of the EF in mud and its additive samples. The variations of the EF vs. the depth are presented in Fig. 13. The EF results in drilling mud samples showed that Ag, As, Ba, Bi, Cd, Cu, Pb, S, Sb, and Sr elements had high levels of enrichment, especially in barite and heavy mud samples (up to the extremely high enrichment level). In the cuttings and waste samples, Cr, Mn, and V elements had no enrichment. The highest levels of enrichment, especially in cutting samples, were related to Ca, Ag, As, Ba, Cd, S, Sb, and Sr elements.

According to separate analyses of element concentrations in cutting, waste, and mud samples, the Abteymour oil field drilling operations are primarily concerned with cuttings from various formations, some of which can have high concentrations of pollutants, particularly heavy metals. These drilling cuttings are stacked up on the ground after drilling and are then subjected to different weathering processes. These substances are released into the environment as a result of weathering processes. Water and wind movement can disperse contaminants across a wider area, contaminating not only the soil and water ecosystems but also plants and animals. There are varied degrees of heavy metal pollution in the environment due to different types of drilling mud. Although it is possible to recycle drilling mud, in most cases, this fluid containing contaminants is released into the environment after the completion of drilling operations. Due to its fluidity, the diffusion of pollution occurs at a faster rate in the environment. Although among the 56 measured elements, 19 elements had a concentration higher than the average of the upper crust, none of these elements posed a threat to the ecosystem in terms of environmental indicators. Therefore, the management of the consequences caused by these elements is more important.

Conclusions

The conclusions of this study are as follows:

-

The main importance of this research lies in separating and diagnosing the source of heavy metal pollution during drilling operations for their proper management.

-

Comparing the concentration of the measured elements with the average of the upper crust showed that 16 elements have a concentration higher than this average, which include Fe, Ag, As, Ba, Bi, Cd, Cu, Mg, Mn, Pb, Sb, Sr, and W heavy metals, and Ca and S elements. In addition, in this study, Cr, V, and Ni elements were studied because of their importance in the environmental studies of oil fields.

-

The relationship between mineralogy composition and the accumulation of heavy metals showed that the concentration of heavy metals in the studied formations depended on the type of metal, the main composition of the host rock, the variety of rock foundations, and the ionic replacement of heavy metals. The highest concentrations of Ag and Sr metals were observed in calcareous compositional formations.

-

Based on the cluster analysis results, in drilling waste, the studied elements were categorized into 3 clusters. The first cluster included Pb, S, Mo, Sr, Cu, and Ag; the second cluster included Sb, Ba, Cd, and Ca; and the third cluster included Cr, V, Ni, Mg, As, Mn, and Fe. In drilling cuttings, the elements were categorized into 4 clusters. The first cluster included Cr, Fe, V, and Ni; the second cluster included Ca, Mo, and Cd; the third cluster included Pb, Mn, Mg, and As; and the fourth cluster included Sr, S, Cu, Sb, and Ba. In the drilling waste, the factors affecting the concentration of the elements included the rocky composition of the rocks and the type of mud and its additives. In cutting samples, lithology diversity (including limestone, sandstone, shale, and marl) is an effective factor.

-

The investigation of the variation of the studied elements vs. depth showed that the concentration of these elements in the cuttings was mostly higher than their concentration in the waste. In the waste, rock fragments from different depths were mixed with each other, and the measured concentration did not exactly represent the concentration of that element at a specific depth.

-

The highest concentration of heavy metals was observed in the samples belonging to the depth range of the Gachsaran formation, followed by the Aghajari, Mishan, and Pabdeh formations.

-

Regarding environmental indicators, in mud samples and their additives, Ca, Cr, Mg, Mn, Mo, Ni, and V elements were unpolluted and without enrichment. For other elements, the highest level of pollution and enrichment was observed in barite and heavy mud samples. Fe, Mo, and W elements had a high level of pollution only in the Ferro bar samples.

-

According to the Igeo values, Ca, Ag, As, Ba, Bi, Cd, Cu, S, Sr, and Sb elements had different levels of pollution in waste and drilling cutting samples. The highest pollution levels were related to Ag, As, Ba, S, and Sb elements.

-

According to the EF values, Cr, Mn, and V elements were not enriched in waste and drilling cutting samples. The highest enrichment was observed for Ca, Ag, As, Ba, Cd, S, Sr, and Sb elements.

-

Regarding environmental indicators, in waste and especially drilling cuttings, the release of these materials on the ground surface can lead to extensive environmental pollution.

Abbreviations

- Ag:

-

Silver

- Al:

-

Aluminium

- As:

-

Arsenic

- B:

-

Boron

- Ba:

-

Barium

- Bi:

-

Bismuth

- Ca:

-

Calcium

- Cd:

-

Cadmium

- Cr:

-

Chromium

- Cu:

-

Copper

- Fe:

-

Iron

- Hg:

-

Mercury

- Mg:

-

Magnesium

- Mn:

-

Manganese

- Mo:

-

Molybdenum

- Ni:

-

Nickel

- P:

-

Phosphorus

- Pb:

-

Lead

- S:

-

Sulfur

- Sb:

-

Antimony

- Sr:

-

Strontium

- V:

-

Vanadium

- W:

-

Tungsten

- Zn:

-

Zinc

- Bn :

-

Measured concentration of reference element (mg/kg)

- Bref :

-

Concentration of the reference element in the reference environment (mg/kg)

- Cn:

-

Measured concentration of metal (mg/kg)

- Cref :

-

Measured concentration of metal in the reference environment (mg/kg)

- EF:

-

Enrichment factor

- Igeo :

-

Geoaccumulation index

- ICP-MS:

-

Inductively coupled plasma mass spectrometry

- NW–SE:

-

North West-South East

- XRD:

-

X-ray diffraction

References

Abdideh M, Dastyaft F (2022) Stress field analysis and its effect on selection of optimal well trajectory in directional drilling (case study: southwest of Iran). J Pet Explor Prod Technol 12:835–849. https://doi.org/10.1007/s13202-021-01337-5

Afkhami F, Nasrabadi T, Karbassi AR, Vosoogh A (2013) Impact of oil excavation activities on soil metallic pollution, case study of an Iran southern oil field. Environ Earth Sci 70:1219–1224. https://doi.org/10.1007/s12665-012-2208-8

Al-Khashman OA (2007) The investigation of metal concentrations in street dust samples in Aqaba city, Jordan. Environ Geochem Health 29(3):197–207. https://doi.org/10.1007/s10653-006-9065-x

Amin SA, Hamid A, Al-Obiady MA, Al-Ani RR, Al-Mashhady A (2018) Assessment of some heavy metal concentrations in drilling md samples in Az Zubair oil field, Basra, Iraq. Eng Technol J 36(1):68–75. https://doi.org/10.30684/etj.36.1B.12

Barzegar R, Asghari Moghadam A, Evangelos T, Fakhri MS, Soltani S (2017) Identification of hydrogeochemical processes and pollution sources of groundwater resources in the Marand plain, northwest of Iran. Environ Earth Sci 76:297. https://doi.org/10.1007/s12665-017-6612-y

Berberian M (1995) Master blind thrust faults hidden under the Zagoros folds: active basement tectonics and surface morphotectonics. Tectonophys J 241(193):224. https://doi.org/10.1016/0040-1951(94)00185-C

Buccione R, Fortunato E, Paternoster M, Rizzo G, Sinis R, Summa V, Mongelli G (2021) Mineralogy and heavy metal assessment of the Pietra del Pertusillo reservoir sediments (Southern Italy). Environ Sci Pollut Res 28(4):4857–4878. https://doi.org/10.1007/s11356-020-10829-6

Clark FW, Washington HS (1924) The composition of the earth’s crust. United States Geological Survey, Washington, DC

Cunha CSM, da Silva YJAB, Escobar MEO, do Nascimento CWA, (2018) Spatial variability and geochemistry of rare earth elements in soils from the largest uranium-phosphate deposit of Brazil. Environ Geochem Health 40(4):1629–1643. https://doi.org/10.1007/s10653-018-0077-0

Daae HL, Heldal KK, Madsen AM, Olsen R, Skaugset NP, Graff P (2019) Occupational exposure during treatment of offshore drilling waste and characterization of microbiological diversity. Sci Total Environ 681:533–540. https://doi.org/10.1016/j.scitotenv.2019.05.131

Daneshfar MA, Ardjmand M (2021) A new approach in the optimal site selection of landfills for drilling cuttings from petroleum and gas fields. Chemosphere 270:129402. https://doi.org/10.1016/j.chemosphere.2020.129402

Davis FD (1986) A technology acceptance model for empirically testing new end-user information systems: theory and results. Sloan School of Management. Massachusetts Institute of Technology.

EPA (1993) Development document for effluent limitations guidelines and new source performance standards for the off shore subcategory of the oil and gas extraction point source category. https://doi.org/10.2118/25993-MS

Feng Y, Chenglin L, Bowen W (2019) Evaluation of heavy metal pollution in the sediment of Poyang Lake based on stochastic geo-accumulation model (SGM). Sci Total Environ 659:1–6

Ghazban F (2011) Environmental geology Fereydoun. Tehran University, Tehran (in Persian)

Hossain ME, Al-Majed A, Adebayo AR, Apaleke AS, Rahman SM (2017) A critical review of drilling waste management towards sustainable solutions. Environ Eng Manag J 16(7):1435–1450. https://doi.org/10.30638/eemj.2017.156

Ismail RA, Alias HA, Wan Sulaiman RW, Jaafar ZM, Ismail I (2017) Drilling fluid waste management in drilling for oil and gas wells. Chem Eng Trans 56:1351–1356. https://doi.org/10.3303/CET1756226

Jahan S, Strezov V (2018) Comparison of pollution indices for the assessment of heavy metals in the sediments of seaports of NSW, Australia. Mar Pollut Bull 128:295–306. https://doi.org/10.1016/j.marpolbul.2018.01.036

Janadeleh H, Jahangiri S, Kameli MA (2018) Assessment of heavy metal pollution and ecological risk in marine sediments (a case study: Persian Gulf). Hum Ecol Risk Assess Int J 24(8):2265–2274. https://doi.org/10.1080/10807039.2018.1443792

Kabata-Pendias A, Pendias H (2011) Trace element in soil and plant. CRC Press, Booca Raton

Li L, Ustin SL, Lay M (2005) Application of AVIRIS data in detection of oil-induced vegetation stress and cover change at Jornada, New Mexico. Remote Sens Environ 94:1–16. https://doi.org/10.1016/j.rse.2004.08.010

Liu M, Xu Y, Nawab J, Rahman Z, Khan S, Idress M, Ud Din Z, Ali A, Ahmad R, Akbar Khan S, Khan A, Qayash Khan M, Tang YT, Li G (2020) Contamination features, geo-accumulation, enrichments and human health risks of toxic heavy metal (loids) from fish consumption collected along Swat river, Pakistan. Environ Technol Innov 17:100554. https://doi.org/10.1016/j.eti.2019.100554

Marescotti P, Azzali E, Servida D, Carbone C, Grieco G, De Capitani L, Lucchetti G (2010) Mineralogical and geochemical spatial analyses of a waste-rock dump at the Libiola Fe–Cu sulphide mine (Eastern Liguria, Italy). Environ Earth Sci 61(1):187–199. https://doi.org/10.1007/s12665-009-0335-7

McLean JE, Bledsoe BE (1992) Behavior of metals in soils. EPA Environmental Assessment Sourcebook

McLennan SM (2001) Relationships between the trace element composition of sedimentary rocks and upper continental crust. Geochem Geophys Geosyst. https://doi.org/10.1029/2000GC000109

Mikos-Szymańska M, Rusek P, Borowik K, Rolewicz M, Bogusz P, Gluzińska J (2018) Characterization of drilling waste from shale gas exploration in Central and Eastern Poland. Environ Sci Pollut Res 25:35990–36001. https://doi.org/10.1007/s11356-018-2365-8

Muller G (1969) Index of geoaccumulation in sediments of the Rhine River. Geo J 2:108–118

Neff JM (2008) Estimation of bioavailability of metals from drilling mud barite. Integr Environ Assess Manag 4(2):184–193. https://doi.org/10.1897/ieam_2007-037.1

Peana M, Medici S, Dadar M, Zoroddu MA, Pelucelli A, Chasapis CT, Bjørklund G (2021) Environmental barium: potential exposure and health-hazards. Arch Toxicol 95(8):2605–2612. https://doi.org/10.1007/s00204-021-03049-5

Sageman BB, Lyons TW (2003) Geochemistry of fine-grained sediments and sedimentary rocks, vol 7. Elsevier, Amsterdam, p 407

Shafie NA, Aris AZ, Zakaria MP, Haris H, Wan YL, Isa NM (2013) Application of geoaccumulation index and enrichment factors on the assessment of heavy metal pollution in the sediments. J Environ Sci Health Part A Toxic/hazard Subst Environ Eng 48(2):182–190

Shahbaz M, Rashid N, Saleem J, Mackey H, McKay G, Al-Ansari T (2023) A review of waste management approaches to maximise sustainable value of waste from the oil and gas industry and potential for the State of Qatar. Fuel 332(2):126220. https://doi.org/10.1016/j.fuel.2022.126220

Suk H, Lee K-K (1999) Characterization of a ground water hydrochemical system through multivariate analysis: clustering into ground water zones. Groundwater 37(3):358–366. https://doi.org/10.1111/j.1745-6584.1999.tb01112.x

Sutherland R (2000) Bed sediment-associated trace metals in an urban stream, Oahu, Hawaii. Environ Geol 39:611–627. https://doi.org/10.1007/s002540050473

Taylor SR, McLennan SM (1985) The continental crust: its composition and evolution. Blackwell, Oxford

Tlili-Zrelli B, Hamzaoui-Azaza F, Gueddari M, Bouhlila R (2013) Geochemistry and quality assessment of groundwater using graphical and multivariate statistical methods. A case study: Grombalia phreatic aquifer (Northeastern Tunisia). Arab J Geosci 6:3545–3561. https://doi.org/10.1007/s12517-012-0617-3

Zahra A, Hashmi MZ, Malik RN, Ahmed Z (2014) Enrichment and geo-accumulation of heavy metals and risk assessment of sediments of the Kurang Nallah-Feeding tributary of the Rawal Lake Reservoir, Pakistan. Sci Total Environ 470–471:925–933. https://doi.org/10.1016/j.scitotenv.2013.10.017

Zhang J, Liu CL (2002) Riverine composition and estuarine geochemistry of particulate metals in China—Weathering features, anthropogenic impact and chemical fluxes. Estuar Coast Shelf Sci 54(6):1051–1070. https://doi.org/10.1006/ecss.2001.0879

Zhang A, Li M, Lv P, Zhu X, Zhao L, Zhang X (2016) Disposal and reuse of drilling solid waste from a massive gas field. Procedia Environ Sci 31:577–581. https://doi.org/10.1016/j.proenv.2016.02.089

Zinn YL, de Faria JA, de Araujo MA, Skorupa ALA (2020) Soil parent material is the main control on heavy metal concentrations in tropical highlands of Brazil. CATENA 185:104319. https://doi.org/10.1016/j.catena.2019.104319

Funding

Authors thank Khorramshahr University of Marine Science and Technology for their help and financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bakhtiari, H., Amanipoor, H. & Battaleb-Looie, S. Analysis of heavy metal accumulation and environmental indicators in fluids and drilling cuttings. J Petrol Explor Prod Technol 14, 41–58 (2024). https://doi.org/10.1007/s13202-023-01690-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01690-7