Abstract

Investigation on the hybrid enhanced oil recovery solutions and methods is gaining attention during the last decade since they can activate multiple mechanisms such as viscosity reduction, interfacial tension (IFT) reduction, and wettability alteration. So, the current work is concentrated on the application of 1-octyl-3-methyl pyridinium chloride ([C8py][Cl]) and 1-dodecyl-3-methyl pyridinium chloride ([C12py][Cl]) as novel surfactants in the absence and presence of SiO2 nanoparticles (SiO2-NPs) for the first time for possible IFT reduction and rock wettability change (contact angle (CA) measurement). In this way, the concentration of ionic liquids (ILs) and SiO2-NPs ranged between 0–2000 ppm and 0–1000 ppm, respectively, to see the influence of these chemicals on the wettability change and IFT reduction. The point is that the higher concentrations of these chemicals were not examined since using higher concentrations makes it expensive and uneconomic for field-scale applications. The obtained results revealed that as the pH increases from 3 to 11 in the absence of different chemicals (formation brine/basic crude oil), the IFT experiences an increase from 20.3 to 31.2 mN/m, while the situation for CA is more complicated. In detail, the results revealed that increasing the pH in the range of 3–11 leads to an increase in the CA from 103.2° to 121.3° (increasing pH from 3 to 7) while a further increase in the pH leads to a reduction in CA value from 121.3° to 118.3°. Moreover, the results revealed that increasing the concentration of [C8py][Cl] from 0 to 2000 ppm led to a reduction in IFT value from 20.3 to 0.95 mN/m for pH of 3, from 27.3 to 2.2 mN/m for pH of 7 and from 31.2 to 5.4 mN/m for pH of 11. Besides, the measurements for [C12py][Cl] revealed that increasing the concentration from 0 to 2000 ppm leads to IFT reduction from 20.3 to 0.74 mN/m for pH of 3, from 27.3 to 0.9 for pH of 7, and from 31.2 to 1.4 mN/m for pH of 11. The results demonstrated a higher influence of [C12py][Cl] on the IFT reduction compared with the [C8py][Cl] due to the longer alkyl chain length of [C12py][Cl] which means more detergency power. Furthermore, the effects of these two ILs are examined on the wettability change which showed that both of the examined ILs are capable to manipulate the wettability of the rock surface toward water-wet conditions (53.3°) from oil-wet conditions (121.3°). Also, the influence of SiO2-NPs in the range of 0–1000 ppm is investigated on the IFT reduction and wettability change while the concentration of ILs is held constant at 2000 ppm since the concentration of 2000 ppm leading to the lowest CA and IFT values for both examined ILs. The obtained results reveal that not only the presence of SiO2-NPs with a maximum concentration of 1000 ppm leads to a reducing trend on the IFT in particular for the pH of 11 regardless of the used IL but also it changes the surface wettability to strongly water-wet condition with minimum CA value of 28.5°. In the last stage, the efficiency of the optimum chemical formulations was examined through core flooding experiments using conventional core flooding procedure and the core flooding experiments concomitant with the soaking time (30 days). The experiments revealed that the chemical formulation under a pH of 3 leads to the highest oil recovery factors while the lowest oil recovery factors are obtained under a pH of 11. Besides, the core flooding experiments followed by soaking reveal the ultimate oil recovery of 10.1 and 13.3% based on the original oil in place (OOIP) due to better activation of the wettability change mechanism which was 46% higher than the situation no soaking was performed. The findings of this study can help for a better understanding of the feasibility and applicability of using new hybrid surfactant-NPs-based EOR methods to activate wettability alteration and IFT reduction, especially with a main focus on one specific fraction of crude oil (resin fraction) instead of crude oil.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

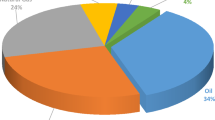

The application of enhanced oil recovery (EOR) processes gain increasing attention during the past three decades due to the lack of energy sources and the reduction in the oil production leads to global energy crises. In detail, using the natural pressure of the reservoir only 10–15% of the original oil in place (OOIP) can be produced, and further oil production of about 10–15% can be achieved if the secondary oil recovery processes apply into the depleted reservoirs. So, more than 65–70% of the OOIP still remained unrecovered and must be produced with new innovative methods called EOR techniques. The EOR methods are in different types of gas injection, chemical injection, in situ combustion, modified-water injection (such as smart water, low-salinity water, etc.), microbial injection, nanoparticles injection, etc. Unfortunately, although different EOR approaches were proposed and examined during the past decades, the main drawback of the used and examined EOR methods is the limited number of activated mechanisms through each EOR process moving the researchers toward proposing a new hybrid method that can activate multiple mechanisms with the main concentration on the interfacial tension (IFT) reduction, wettability change, viscosity reduction and swelling of crude oil (Cheraghian 2015; Abhishek et al. 2015).

In other words, considering the energy crises, and limitations of each EOR method, it is highly required to use hybrid methods which can produce more oil at a reliable rate especially using chemical-based EOR methods (Cheraghian and Hendraningrat 2016a). In other words, due to the advantages and disadvantages that exist for chemical EOR methods, it is highly required to combine the chemical methods with other EOR approaches such as low salinity and nanoparticles to eliminate the limitations and drawbacks (see Table 1).

As a way out, different hybrid methods were proposed based on the concomitant application of the low-salinity aqueous solution, surfactant solutions, nanoparticles (NPs), etc. (Bera and Belhaj 2016; Khalil et al. 2017; Li et al. 2021; Negin et al. 2016). Between the EOR processes, using NPs is an interesting and new approach since it reduces the IFT, changes the wettability of the rock surfaces toward more water-wet conditions, reduces the viscosity of the crude oil if it dissolves in the crude oil, etc. (Ju et al. 2006; Torsater et al. 2012; Zaid et al. 2013) (Al-Anssari et al. 2016; Saien and Gorji 2017; Ehtesabi et al. 2015; El-Diasty and Ragab 2013; Kazemzadeh et al. 2015; Mohammadi et al. 2017; Taborda et al. 2016, 2017; Wei et al. 2007). Besides the aforementioned possible mechanism can be activated using the NPs, it is possible to produce nano-emulsion using NPs (Bobbo et al. 2012), plugging the pores in a selective manner (Anganaei et al. 2014; Hashemi et al. 2013), thermal conductivity modification (Aveyard et al. 2003; McElfresh et al. 2012) manipulating the disjoining pressure (McElfresh et al. 2012; Zamani et al. 2012).

Moreover, NPs are good porous-scale transportation method since they are capable to penetrate and move through narrow pathways and throats makes them a good candidate to use as a carrier to deliver specific chemicals to a specific destination in the pore structure and network (Rodriguez Pin et al. 2009). Considering these advantages of NPs, recent studies are concentrated on the application of NPs in the EOR processes to recover more trapped oil by activating main mechanisms including reducing IFT and wettability change besides the other mechanisms aforementioned (de Castro Dantas et al. 2017; Moradi et al. 2015; Suleimanov et al. 2011). As an example, the effect of polysilicon NPs that are lipophobic and hydrophilic, and hydrophilic and lipophobic, respectively, are among the most examined ones studied during the rock surface wettability change investigations (Onyekonwu and Ogolo 2010).

Among the different possible NPs, it is well established that silica NPs application is a good approach to move the wettability of the rock surfaces toward strongly water-wet (highly required to produce more trapped oil under constant rate) (Cheraghian 2016; Hendraningrat et al. 2013a, b, c; Torsater et al. 2012).

The point is that although silica-based NPs are potential NPs for EOR purposes, there are other NPs examined by different researchers such as aluminum oxide (Al2O3), iron oxide (Fe2O3), etc. In detail, Mohammadi et al. 2017) performed several experiments to find if Al2O3-NPs are capable to produce higher oil from the sandstone rocks. Just a year after, Tarek (2015) investigate the idea of using a mixture of different NPs including Al2O3, Fe2O3, and SiO2 to prepare a hybrid solution for tertiary oil recovery purposes which can activate different effective mechanisms. They enlighten this fact that the NPs are applicable chemicals not only for thermal conductivity modification but also they are potential to activate several effective parameters including IFT reduction and wettability change (Cheraghian and Hendraningrat 2016b; Sheng 2010) (see Table 2).

Similar to the NPs which are recently proposed as new chemicals for EOR purposes, a new class of surfactants based on the ionic liquids (ILs) is examined during the past decades. ILs are a new and interesting class of chemicals, especially solvents which have considerable characteristics including high stability under high-salinity conditions and elevated temperature makes them a proper candidate for EOR purposes where the conventional surfactants lose their functionality under these harsh conditions (Chen et al. 2014; Dharaskar Swapnil 2012; Domańska 2005) (Lee and Kim 2013; Martins et al. 2014; Peng et al. 2011), etc. A detailed review performed by Dordzie and Dejam (2021) provided good insight regarding the application of NPs in the low-salinity solution for the fractured oil reservoirs considering the possible mechanisms. Besides, they reviewed the possible applications of surfactants along with the NPs in the low-salinity conditions which revealed the possibility of using this formulation for EOR purposes especially in the fractured reservoir types although the fine migration problem is concerning which pushes the researchers to perform more detailed investigation and studies regarding the application of such a formulation in fractured reservoirs.

Moreover, Olayiwola and Dejam (2019) performed a detailed survey on the application of surfactant-NPs dissolved in low-salinity aqueous solutions for both sandstone and carbonate reservoirs. According to their review, it is obvious that using NPs for EOR purposes is definitely better than using only water injection, but NPs injection is not more successful than surfactant injection. In this way, NPs are used as injectable chemical along with low-salinity water (LSW) or chemical agents including surfactants to improve the oil recovery. In detail, it is possible to use NPs for fines migration prevention appears during LSW injection by controlling the mobility of formation water, and reduce the surfactant adsorption on the pore walls of the reservoir.

On the other side, the considerable characteristics of ILs which come from their unique structure which is comprised of cationic and anionic sections convert these chemicals to a new class of surfactant. The point is that due to the unique structure of the ILs, it is possible to synthesize ILs for a specific task which means that synthesizing specific-task ILs is easily available for any desired application. In detail, it is possible to fabricate any desired IL for any purpose such as EOR processes by tailoring proper cationic and anionic sections to each other (José-Alberto and Jorge 2011; Khupse and Kumar 2010). In this way, different researchers have investigated the possible applications of different ILs, especially from the imidazolium family for EOR purposes through reservoirs with harsh and high-salinity solutions (Hezave et al. 2013c; Smit et al. 1991).

The results reported by those researchers revealed that the dissolution of cationic ILs in the aqueous solution can neutralize the opposite charges that existed in the solution due to the dissolved salts which provide the chance of easier packing of surfactant molecules in the interface which means lower IFT values. The results reported by Hezave et al. (2013a) demonstrated that this is not only the IFT variation that led to higher oil recovery during the EOR processes and this is the concomitant effect of IFT reduction and wettability change causes more oil production (Rodríguez-Palmeiro et al. 2015).

The other point is that besides the chemical combination, there is a complicated and undeniable interaction between the crude oil type and the chemical combination concomitant with the operating conditions such as pH which dictate the higher oil recovery can be achieved or not (Demirbas 2016; Demirbas and Taylan 2015; Muhammad et al. 2013). In this way, it is highly crucial to carefully examine the influence of crude oil (basic or acidic) on the efficiency of the used chemicals. Respecting this fact, in the current investigation, an alkaline crude oil was selected and examined concomitant with the pyridinium-based ILs and SiO2-NPs. The point is that among the different possible choices for the sample crude oil which are acidic type, basic type, or even a specific fraction of extracted resin or asphaltenic one, the current investigation was focused on the possible interactions that may exist between the different chemicals and a basic crude oil.

In general, crude oil is considered as four different fractions namely aromatics, saturates, resin, and asphaltene which the last two fractions have detergency nature which makes them like surfactant molecules (Demirbas et al. 2015; Lashkarbolooki et al. 2014). This is why several investigations were focused on the possible interactions that may exist between the chemicals and these specific fractions which can act as the natural surfactant and consequently affect the wettability land IFT of the system (Andersen 1994; Lashkarbolooki et al. 2016; Mozaffari 2015; Mozaffari et al. 2021, 2015; Wu et al. 1998).

As the last point, there are several investigations regarding the application of ILs from the imidazolium family using synthetic and crude oils with or without nanoparticles. For example, Hezave et al. (2013b) investigated the influence of different ILs from imidazolium and pyridinium families in the presence of salinity on the IFT and wettability of rock surface by performing a limited number of experiments. They reported that the presence of ILs reduced the IFT values, especially if salinity existed which reduced the repulsive forces that existed among the ILs molecules. Also, they claimed that the ILs adsorption of on the rock renders the wettability of the rock surface water-wet.

Besides, Abbood et al. (2022) studded the influence of SiO2-NPs on the IFT reduction and carbonate rock wettability change using only one IL with a constant alkyl chain length from the imidazolium family using the synthetic oil (asphaltenic fraction). They have claimed that the existence of 1-dodecyl-3-methyl imidazolium chloride ([C12mim][Cl]) in the presence of asphaltenic synthetic oil leads to considerable IFT reduction and even a considerable effect on changing the wettability to water-wet status. Moreover, they have reported that the addition of SiO2-NPs in different ranges of concentration considerably changed the wettability to strongly water-wet status while its influence on the IFT reduction was moderate compared with the addition of imidazolium family surfactant. The point is that although these investigations used the ILs from imidazolium and pyridinium families, no investigations were performed to investigate the effect of SiO2-NPs, pyridinium family as one of the most effective IL-based surfactants, pH as one of the most important operating conditions and basic crude oil.

Furthermore, Abbood et al. (2022) investigated the effect of another nanoparticle namely copper oxide (CuO) on the IFT reduction and wettability change in the existence of one imidazolium-based surfactant namely [C12mim][Cl]. They reported that the dissolution of [C12mim][Cl] reduced the IFT value to the minimum value of 0.65 mN/m especially if the aqueous solution comprised of formation brine while the CuO-NPs presence slightly reduced the IFT. Besides, their measurements revealed that although the presence of CuO-NPs slightly changed the IFT values, wettability change was significantly correlated to the presence of CuO-NPs, in particular if the solution was prepared using formation brine (0.65 mN m−1) (see Table 3).

In this way, the concomitant application of basic crude oil, pyridinium-based ILs namely 1-octyl-3-methyl pyridinium chloride ([C8py][Cl]) and 1-dodecyl-3-methyl pyridinium chloride ([C12py][Cl]) and SiO2-NPs under different concentrations of 0–2000 ppm and 0–1000 ppm, respectively, were examined for IFT reduction and wettability change purposes at pH of 3–11 for the first time according to the authors’ knowledge.

The reason behind the selection of 0–2000 ppm as the investigation range for the concentrations of ILs is that using low concentrations of surfactant may fall below the critical micelle concentrations (CMC) of the system leading to no practical application since surfactants can be significantly absorbed by the porous media, which affects their capability to reduce the IFT (Curbelo et al. 2007).

Also, using concentrations larger than 2000 ppm is not cost effective to be used in the field scale. In this way, 0–2000 ppm was selected to ensure about the finding of the CMC point and reduce the risk of losing functionality due to surfactant adsorption. Also, the NPs concentrations were considered between 0–1000 ppm since using higher concentrations may lead to two different limitations which first is the risk of precipitation and high operating cost while the second one is the turbidity of the prepared solution with higher concentration makes it impossible to measure the IFT of the binary solution using pendant drop or spinning drop IFT measurement techniques. Besides, the pH range was selected and tuned in a way that it covers at least three conditions acidic, neutral, and basic conditions which are so effective on the reactions that may exist between the oil constituents to produce in situ surfactant or another possible phenomenon which can directly affect the IFT and wettability of the system.

Besides, the influence of length of alkyl chain for the pyridinium-based surfactants is going to be examined concomitant with the pH as one of the most important operating conditions for the first time. Moreover, using NPs for EOR purposes has an intrinsic risk which is the risk of NPs precipitation due to agglomeration or other phenomena that may lead to pore plugging which in severe cases can cause catastrophic outcomes which is crude oil entrapment in the oil reservoir forever. In the light of this limitation, the effect of two pyridinium-based surfactants on the SiO2-NPs are going to be examined for the first time since any type of surfactant which can retard or eliminate the nanoparticles precipitation in the aqueous solution would be welcome to EOR industries. In other words, it is crucially necessary to investigate the stability of SiO2-NPs in the presence and absence of ILs to ensure the long-term stability of the prepared solutions to unveil the possible risk of SiO2-NPs precipitation while no investigation existed regarding the application of pyridinium-based surfactant for such a purpose.

Finally, the authors are going to examine the influence of optimum chemical formulations on the tertiary oil recovery by performing different core flooding experiments using the quick flooding and the flooding procedure followed by soaking time for a period of 1 month. The soaking time was dedicated to the system since it would be possible to maximize the influence of wettability change on the oil recovery if the surfactant molecules have enough time for adsorption on the entire surface of the rock. In detail, since there is no report in the previously published works based on the best knowledge of the authors regarding influence of pH, SiO2-NPs, and pyridinium-based surfactants on tertiary oil recovery, the last phase of this investigation were focused on the tertiary oil recovery of chemical combinations with or without soaking on the oil recovery for the first time [see the following flowchart (Fig. 1)]. The noteworthy point is that the current investigation is aimed to fulfill the shortcoming that existed regarding the synergy between the nanoparticles and acidity of the aqueous solution in the presence of alkaline crude oil. The other point is that the synergy between ILs and different EOR chemical agents especially nanoparticles is highly limited, especially considering the pyridinium families since other IL families such as imidazolium are investigated in more literature although the overall conclusions and mechanisms are still in dark. Besides, most of the investigations are focused on the individual measurement of IFT and wettability alteration while the effect of these chemical formulations is limitedly examined through core flooding experiments which is one of the main targets of this investigation to enlighten the practical application of the obtained chemical formulation.

Materials and methods

Material and solutions

The sample crude oil (asphaltene content of 8.2% and resin contents of 5.5%) was provided from one of the Iranian oil fields namely Dorood oilfield with a density of 0.905 g.cm−3 under ambient temperature (20 °C) (Chehrazi et al. 2013). This oilfield is the largest Iranian offshore oil field (25 km and 5 km long and wide, respectively) located in the Persian Gulf which has 88 wells 47 of which are production wells (Chehrazi et al. 2013). The formation of this oilfield is a combination of Asmari, Surmeh, Yamama, and Manifa which the Asmari section has an API° degree of 23–25 while the API° of Surmeh, Yamama, and Manifa are 29.5, 35, and 31, respectively (Setudehnia 1978).

The worth mentioning point is that the current oilfield has 2 gas injection wells, and 12 water injection wells which means that this oilfield is good candidate for the water-based EOR processes. On the other side, the maximum production of 139.74 thousand bpd of crude oil and condensate was the old record of this reservoir which will lose its economic production rate in 2041.

Respecting the Dorood structure it can be observed that this oilfield is an elongated anticline, plunging toward the NNE from Cretaceous and late Miocene times. In detail, two independent structural events from late Cretaceous times led to an NNE–SSW-orientated folds while the second structural event occurred in late Oligocene– Pliocene times which uplift the structure (Bosold et al. 2005; Chehrazi et al. 2013; Fard et al. 2006). The point is that during the first period of structural modification, WNW–ESE which was perpendicular to the present-day fold axis was the main directional movement. On the other hand, the main stress direction during the second structural event was NE–SW, with a slight change to N020 (Berberian and King 1981; Beydoun 1991; Ghazban 2007), (James and Wynd 1965; Setudehnia 1978). The required core plugs and rock samples from the outcrop were analyzed using Energy-Dispersive Spectroscopy known as EDX analysis for the elemental analysis of the used rock thin sections. According to the performed analysis most of the used rock samples are made of oxygen, carbon, calcium, and magnesium which can be considered as an indication of dolomite core sample. Moreover, since the tin section surfaces are not smooth and homogenous, one can face with uncertainties during contact angle (CA) measurements moved the authors to measure the CA of each point at least three times. In other words, each reported CA data point is the average of at least three independent measurements with maximum uncertainty of ± 5° according to the statistical analysis.

The required salts with a purity of better than 99.5% were purchased from Sigma-Aldrich, USA, while the required SiO2 nanoparticles (20–30 nm) were supplied from Finenano, Iran (purity better than 99%). Besides, the required ILs were synthesized using a standard procedure and materials using 1-methyl pyridinium, 1-chlorododecane, and 1-chlorooctane (Merck/Fluka, purity > 99.5%).

IFT and CA measurement

Using the Pendant drop method for IFT measurement is one of the most interesting and applicable methods due to its unique advantages for accurate and fast IFT and CA measurement. (Yang et al. 2014). Respecting this fact, IFT and contact angle values were measured using pendant drop equipment (APEX Technologies Co., Arak. Iran) (see Fig. 2).

A brief description of the used equipment and related theory is given by Stauffer (Stauffer 1965).

where Δρ, g, and H are the difference between the bulk and drop phases, acceleration of gravity, and the shape-dependent parameter, respectively. Besides, the H value in Eq. (1) which is known as the shape factor value is correlated to the S value which is the d/D. To calculate the S value, it is required to find the D and d diameters which are the equatorial diameter and the diameter at the distance D from the top of the drop, respectively.

The equipment has three different sections, namely an automatic dispensing system, an image recording, and dispatching section, and online IFT and contacts angle calculation software. Using the first section, the required volume of the drop can be dispensed at the tip of the nozzle in an upward or downward direction depending on the difference between the bulk phase and drop phase using an automatic micro-metering injection system. In the second section, the camera and lens assembly capture the required images at different time intervals and dispatches them to the calculation software where the images are analyzed and the small diameter and large diameters are detected and calculated, and then converted to the IFT values. The point that must be defined is that the used software automatically detects the small and large diameters and then convert the calculated parameters to the IFT values. In this way, it is possible to consider the possible error as a constant parameter through all measurements which is highly crucial if anyone wants to compare the results to each other for different operating conditions.

Results and discussions

Effect of pH and ILs on the IFT

In the first stage of this investigation, the influence of two different parameters including pH as one of the operating conditions and IL concentration for two different ILs from one family namely [C8py][Cl] and [C12py][Cl] as one of the chemical parameters were investigated on the IFT variation. In this way, the pH was ranged between 3 and 11 to cover all three conditions of acidic, neutral, and basic conditions while the IL concentration was ranged between 0 and 2000 ppm to ensure the examining the concentrations which are well above the critical micelle concentration (CMC) value since most of the surfactants have a CMC value of below 1000 ppm. The performed measurements revealed that as the pH increases from 3 to 11, the IFT values increase from 20.3 to 31.2 mN/m. This trend is due to the formation of in situ surfactant from a reaction between the basic contents of the crude oil and acidic constituents of the formation brine leading to the formation of in situ surfactant which can act as the IFT reducing agent. As a consequence of this in situ formation, the IFT value reduces for the aqueous solutions with acidic pH while the IFT value starts to increase as the pH increases since the formation of in situ surfactants reduces as the pH increases due to the lack of acidic contents which can react with the basic contents of crude oil.

Besides the influence of pH on the IFT value, in the second phase of this section, the influence of IL concentration (0–2000 ppm) was examined on the IFT reduction. The measured IFT values showed that for the examined pH values in the range of 3–11, the presence of [C8py][Cl] (0–2000 ppm) can reduce the IFT value from 20.3 to 0.95 mN/m for pH of 3, from 27.3 to 2.2 mN/m for pH of 7, and from 31.2 to 5.4 mN/m for pH of 11 (see Fig. 2).

Besides the influence of pH on the IFT value, in the second phase of this section, the influence of IL concentration (0–2000 ppm) was examined on the IFT reduction. The measured IFT values revealed that for all of the examined pH values, the presence of [C8py][Cl] in the range of 0–2000 ppm can reduce the IFT value from 20.3 to 0.95 mN/m for pH of 3, from 27.3 to 2.2 mN/m for pH of 7, and from 31.2 to 5.4 mN/m for pH of 11 (see Fig. 2). A glance into Fig. 2 reveals a similar trend for [C12py][Cl] although the minimum values for different pH values using [C12py][Cl] as the chemical surfactant are lower than similar values measured for [C8py][Cl]. This behavior contributed to the longer alkyl chain length of [C12py][Cl] compared with [C8py][Cl] led to better packing of surfactant molecules at the interface. In detail, as the alkyl chain length increases the surface charges are well-distributed than the IL with a shorter chain length causing lower repulsive forces at the interface making it possible or the IL molecules to be packed and arranged in a more dense manner in the interface leading to lower IFT values. The other point is that as the alkyl chain length increases, the CMC value reduces. In detail, the measured IFT revealed that the aqueous solution which is modified by dissolved [C12py][Cl] leads to sharper IFT reduction compared with the aqueous solution modified by dissolved [C8py][Cl] in a similar concentration.

A closer look into Fig. 3 also revealed that as the pH increases, the slope of the IFT variation loses its sharpness which means a higher CMC value for both examined ILs as the pH increases. This observed trend can be directly correlated to the lower in situ formation and undesired interactions which can be appeared in the solutions with higher pHs, especially for the solutions, that have a basic pH of 11 since no in situ surfactant forms to boost the IFT reduction. The other point which can be extracted from the depicted results in Fig. 2 is that as the pH increases, the influence of [C12py][Cl] for IFT reduction is stronger than [C8py][Cl] which is related to the acidic nature of the used ILs, especially [C12py][Cl] compared with [C8py][Cl] leading to the better potential of the prepared solution by [C12py][Cl] for IFT reduction by forming in situ surfactants leading to sharper IFT reduction.

Aqueous solution stability at the presence of SiO2-NPs

In the second stage, the stability of an aqueous solution containing SiO2-NPs was investigated since precipitation of NPs in the reservoir is an undeniable risk that must be reduced to its minimum level or in the best case eliminated to ensure no precipitation and pore plugging is existed during the injection of such a solution.

In detail, it is reported that if the surface of silica NPs was coated with Cetyltrimethyl ammonium bromide (CTAB) with a low concentration, the stability of the NPs was extremely affected toward positive situation which is more stability and later precipitation (Esumi 2001). Therefore, the initial surfactant concentration does not alter the IFT but ensures the stability of the NPs through the stearic repulsion.

In this way, a compatibility test must be performed to find the condition including concentration and pH leading to the most stable aqueous solution containing SiO2-NPs for a long period of time and at least one month. In this way, considering the optimum concentrations of ILs which led to the lowest IFT values (for both ILs were 1000 and 2000 ppm), the compatibility test was performed by changing the SiO2-NPs concentration between 0 and 1000 ppm and keeping the ILs concentrations constant at two values of 1000 and 2000 ppm.

All of the prepared solutions revealed long-term stability in the presence of ILs regardless of their alkyl chain length while the aqueous solutions prepared without ILs experienced precipitation after 6 h of solution preparation. As a consequence of these observations, it seems that the application of IL is a crucial parameter to stabilize the SiO2-NPs for a long period of time. The other important parameter that must be examined is the influence of pH as an effective operating condition on the NPs stabilities. The performed stability analysis on the aqueous solutions using 1000 and 2000 ppm IL, with pH values between 3 and 11 with SiO2-NPs concentration of 1000 ppm revealed that increasing the pH from 3 to 11 can increase the stability period of the aqueous solutions may be due to prevention of ionization of surfactants in the solution consequently leading to better dispersion of the SiO2-NPs in the solution.

The noteworthy point is that the observed correlation between the surfactant and NPs was correlated to the zeta potential by Esumi et al. (2001). In detail, they reported that enhancing the surfactant concentration directly increases its adsorption (attraction) to the oppositely charged NPs, shifts the zeta potential to 0 mV resulting in aggregation. Repulsion of the surfactant coated NPs increases with an increase in the surfactant concentration. As a result, the aggregation of the NPs becomes reverse, which refers to the peptization, when the concentration of CTAB increases (Esumi 2001). The surfactant adsorption increases with an increase in the concentration of surfactant due to the reordering pattern of the surfactant tail-head and head–tail at the interface, which results in the repulsion and attraction of NPs in order to accommodate more surfactant (Esumi 2001). Repulsion of the surfactant and NPs of similar charges enhances the stability of a solution of NPs at a low concentration of surfactant. The process of surfactant adsorption in the solutions of surfactant and NPs with the same charges is similar to that in the solutions of surfactant and NPs with the opposite charges. Therefore, the IFT decreases and the zeta potential changes based on the surfactant charges (Cheraghian and Hendraningrat 2016a, 2016b; Fereidooni Moghadam and Azizian 2014).

Effect of concomitant presence of ILs and SiO2-NPs on the IFT

In this section, the synergistic correlation of ILs and SiO2-NPs was investigated by measuring the IFT value of aqueous solution/crude oil by ranging the SiO2-NPs concentration between 0 and 1000 ppm while the ILs concentrations were kept constant at 2000 ppm since in the previous section, using ILs with a concentration of 2000 ppm leading to the lowest IFT value. The measured IFT values revealed that for both ILs, increasing the SiO2-NPs from 0 to 1000 ppm leads to a reduction in IFT value although this reducing effect is more evident as the pH increases. In other words, increasing the SiO2-NPs from 0 to 1000 ppm for [C8py]Cl] reduces the IFT value from 0.95 to 0.73 mN/m for pH of 3, from 2.2 to 1.33 mN/m for pH of 7, and from 5.4 to 1.3 mN/m for pH of 11 which means a considerable influence of pH on the effect of SiO2-NPs for reducing the IFT which is directly correlated to the better stability of SiO2-NPs in the solution with pH of 11 (see Fig. 4).

A glance into the depicted results for [C12py][Cl] also revealed a similar trend for the IFT reduction of SiO2-NPs in the presence of [C12py][Cl] with a concentration of 2000 ppm. Similar results were reported by Fereidooni and Azizian (2014) regarding the reducing effect of a low concentration of CTAB which was added to ZnO NPs which is slightly negatively charged (Arab and Pourafshary 2013).

In contrast to the results obtained in the current investigation and those reported by Fereidooni and Azizian (2014), and Ahualli et al. (2011) reported that the addition of a cationic surfactant to the solution comprises of anionic NPs led to a reduction in the effective surface charges of the solution from negative to positive while the interaction radius of the NPs and surfactant molecules remains constant with an increase in the surfactant concentration. As a consequence of this phenomenon, the particles aggregate due to the electrical attraction between the NPs and the surfactant causing a reduction in the number of ions in the solution.

Effect of ILs and SiO2-NPs on the wettability change

The individual influence of ILs on the wettability change and concomitant with SiO2-NPs was investigated using the CA measurements. The measured CA values for the aqueous solution containing ILs with concentrations of 0–2000 ppm revealed a direct correlation between the IL concentration and water-wet wettability change of the rock surface (see Fig. 5). The measurements demonstrated that as the pH increases from 3 to 7, the CA values increase to more oil-wet conditions while further increases of pH, leading to a reducing trend in the CA changed the rock surface to more water-wet status although the values never reached the contact angle values of pH = 3. In other words, it seems that an increase in pH leads to an overall increasing trend in the contact angle values toward more oil-wet conditions. This point can be correlated to isoelectric points (IEP) which are mostly in the range of pH = 8–10 (Alotaibi and Yousef 2016; Alotaibi et al. 2011).

In detail, it has been reported that as the pH value increases to basic conditions (pH > 9) and well far from the neutral conditions which are about pH of 7, the system is rendered toward oil-wet conditions or adhesion state (Mehraban et al. 2021). They correlated this obtained trend to the fact that the wettability moved toward oil-wet conditions under low and high pH ranges since the oil/water and rock/water interfaces become oppositely charged leading to electrostatic attraction, thus wettability alteration toward the oil-wet state. But the point is that, in the current investigation, the pH value was examined concomitant with the other operating parameters such as the IL concentration and type which can manipulate the pure effect of pH on the wettability. The point is that in contrast to the results reported by several researchers, Saw and Mandal (Saw and Mandal 2020) reported that calcite dissolution increases the Ca2 + ions in the aqueous solution which disturbs the pre-existing equilibrium.

At this time, the rock dissolution which is accompanied by the desorption of crude oil polar components leads to the higher water-wet conditions of the rock surface which directly increases the oil recovery. They also reported that another possible reason for better water-wet conditions after calcite dissolution comes from the SO4 2− ions adsorption concomitant with the Ca2+ on the rock surface. In other words, they claimed that as SO42− ions are adsorbed onto the carbonate surfaces, the positive surface charge density decreases which in turn minimizes the electrostatic repulsive force that existed between the carbonate surface (positively charged) and cations that existed in the brine. So, as a result of Ca2+ and other cations co-adsorption, Ca2+ ions react with the carboxylic acid groups that are bonded with the rock surface and thereby breaking the interactive interaction between oil and rock surface. As a consequence of this interaction, Ca2+–carboxylate complexes are formed and their subsequent release from the rock surface alters the rock surface to a more water-wet condition.

Besides, the analysis showed that both examined ILs led to wettability movement toward water-wet status as the IL concentration was increased. The reason for the observed trend is directly correlated to the higher number of surfactant molecules that can penetrate into the oil film existing on the rock surface. As a consequence of this penetration, the surfactant molecules stick to the surface of the rock rendering the surface more water-wet. In detail, surfactant molecules manipulate the electrostatic force, the hydrophobic force, and the attractive force between the polar components and surfactant molecules and rock morphology. In general, the wettability change of an oil-wet carbonate rock surface depends upon the type of surfactant, oil composition, the concentration of surfactant, and brine salinity. The other point which manipulates the efficiency of the surfactant for wettability change is the salts that existed in the solutions. In detail, salts accelerate the penetration and dispersions of the surface-active components to the interface consequently leading to higher adsorption of the surfactant molecules into the interface which moves the surface rock wettability to water-wet status from its initial intermediate condition.

In the second phase of this section, the synergistic effect between the ILs and SiO2-NPs was investigated to find if these formulations can change the rock wettability toward strongly water-wet conditions. In this way, by keeping constant the concentration of ILs at 2000 ppm and changing the concentration of SiO2-NPs (0–1000 ppm), the influence of these formulations on the wettability change was examined. Besides, the influence of pH values in the range of 3–11 was investigated using changing one factor at a time approach as the design of experiments method to find the interactions that may exist between these chemicals and pH values. The obtained results showed that although an increase in the SiO2-NPs for all the studied pH values of 3–11 led to better wettability change toward strongly water-wet, the best performance for [C8py][Cl] was obtained for pH of 7 which is a neutral condition, while for the [C12py][Cl] the acidic medium was more preferable for wettability change. The reason for this trend is correlated to the longer alkyl chain length of [C12py][Cl] leading to better neutralization of repulsive forces that may exist between the aqueous contents and the surface charges of the rock surface while [C8py][Cl] could not neutralize the severe pH condition consequently leading to worse functionality of SiO2-NPs t the acidic condition. In other words, [C8py][Cl] is less capable to dampen harsh acidic or basic conditions since the maximum wettability change was observed for a pH of 7 while for [C12py][Cl] both the acidic and basic conditions have better functionality can be achieved instead of a neutral condition (see Fig. 6).

The point is that the results reported by Hendraningrat and Torsæter (2014) are in a good agreement with those results obtained in the current investigation using silica-based nanoparticles.

Similar to the results obtained in the current study, it seems that using silica-based NPs is capable to alter the wettability of the core plug surface in the light of solid/fluid interface changes coming from the adsorption of hydrophilic NPs. Moreover, they claimed that regardless of the initial wettability condition of the core plug surfaces (water-wet or oil-wet), using silica-based NPs reduces the CA values which means moving the surfaces toward the water-wet status.

In detail, they claimed that if the hydrophilic NPs which here are the silica-based NPs utilize in an aqueous solution such as seawater, the CA of quartz plate reduces from 39° to 26° (more than 33% change in wettability (Morrow 1990).

Moreover, Ershadi et al. (2015) utilized hybrid carbon/silica nanotubes to change the wettability of rock toward a water-wet condition. It was reported by (Ershadi et al. 2015) that using a hybrid combination of nanoparticles is capable to render the rock surface more water-wet. The reduction of interfacial tension (IFT) is the most effective mechanism that might enhance oil production. A glance into the result revealed by (Sarafzadeh et al. 2014), regarding the dominant influence of nanoparticles on the wetness change as to compare it with the IFT reduction. According to the findings, it is possible to categorize the possible mechanisms regarding nanoparticle into three different classes, and one of the most important ones besides disjoining pressure and, density difference, is changing wetness. The application of nanoparticles can directly produce a gradient between reservoir fluids and injecting fluid by manipulating the density of fluids which can consequently affect the movement of oil film on the surface of rocks and replace it with water film which means changing the oil-wet condition (Al-Anssari et al. 2016; Maghzi et al. 2011; Wang et al. 2005).

Besides, Wasan and Nikolov performed an interesting visual-video microscopy-based investigation to examine solid surface modification with the assistance of immiscible liquid spreading on solid surface occur by Brownian motion. Their findings revealed that the nanoparticle arrangement leads to the formation of a wedge film between the oil and solid substrates (see Figs. 7 and 8. At this point, a pressure gradient appears between the thin layer and the bulk of fluid and is boosted as the nanoparticle concentration enhances. As a consequence of this pressure gradient, it would be possible to manipulate by affecting the film tension toward the vertex of the wedge which consequently can influence the surface wettability (Kondiparty et al. 2011; Wasan et al. 2011).

Nanoparticle packing leads to disjoining pressure gradient at the wedge vertex (Salehi et al. 2010)

Besides the other nanoparticles, Aghajanzadeh et al. (2019) have investigated the influence of silica-nanoparticles on the changing wetness of rock surface. They have reported that according to the obtained results the concentrations of nanoparticles and enhances changing wetness were shifted from oil-wet to water-wet. Moreover, the results of spontaneous imbibition examinations revealed an increase of about 15% higher oil recovery using nano-fluid compared with the case only formation brine was utilized. Finally, they examined the influence of nanoparticle presence in the injected solution during the core flooding experiments and found that not only the relative permeability curve was modified and moved toward the right side of the curve also the water relative permeability was reduced to 0.23 mD from its initial value of 0.43 mD at the residual oil saturation due to wetness change toward water-wet status from strongly oil-wet (Aghajanzadeh et al. 2019).

On the other hand, an innovative application of nanoparticles with anionic surfactants was performed by Ershadi et al. (2015) which it illustrated the possible effect of surfactant existence that might reduce the IFT values. As well as maybe, accelerate the penetration of nanoparticles to enhance their possible effect on the rock surface wettability, moreover, the reduced IFT and the wetness change strengthen one another, and that definitely will enhance the oil production, by producing more trapped oil from the reservoirs (Resasco et al. 2015).

Furthermore, Karimi et al. (2012) utilized Zirconium oxide (ZrO2) to alter the rock wetness surfaces. In addition, it was found that the adsorption of these nanoparticles might modify the surface toward neutral wet, as well as it was reported that measuring the air/water CA values demonstrated the change in wettability from oil-wet to neutral wetting states. In addition, as it was found the energy-dispersive X-ray, EDX, and the analysis of the samples aged in a solution containing nanoparticles of ZrO2 revealed that the surfaces are composed of Ca and Zr as constituent materials, which means zirconium, was adsorbed onto the surface (Alotaibi et al. 2011). One of the other innovative investigations is related to the production of a new family of nanoparticles, e.g., Fe3O4 NPs coated nanoparticle Ethylenediaminetetraacetic (EDTA) as a hydrophilic polymer or Sodium Lauryl Sulfate (SLS) as an anionic surfactant by the dip-coating method recently proposed by Shalbafan et al. (2019). In this method, a nanoparticle can effectively change the wettability of the rock surface from oil-wet to water-wet condition by activating the disjointing pressure mechanism.

The experiments conducted by Hendraningrat and Torsæter (2014) showed that using an optimal chemical formulation of nano-solutions for EOR purposes led to a reduction in the residual oil saturation by activating wettability change and another mechanism. They even claimed that an increase in the temperature has a direct effect on the displacement of trapped oil in the reservoir. Finally, they reported that using a nano-based chemical slug as an extended post-flush can increase the oil recovery up to 4.9% based on OOIP. In this way, considering the results reported by Hendraningrat and Torsæter (2014) and those obtained in this study, it is obvious that using SiO2-NPs + ILs is an effective chemical formulation for oil recovery.

Core flooding experiments using optimums solutions

The influence of 6 optimum aqueous solutions including 2000 ppm of [C8py][Cl] and [C12py][Cl] concomitant with 1000 ppm of SiO2-NPs in different pH conditions of 3, 7, and 11 were examined on the tertiary oil recovery by performing different core flooding tests. In this way, two kinds of core flooding experiments namely quick flooding and soaking flooding were introduced to find the ultimate impact of IFT reduction and wettability alteration on oil recovery. The core flooding tests (see Table 4) showed that the influence of [C12py][Cl] regardless of the examined pH led to a higher oil recovery factor compared with the [C8py][Cl] due to better IFT reduction capability and wettability change efficiency. In detail, [C12py][Cl] led to better IFT reduction and wettability change toward water-wet conditions due to longer alkyl chain length.

As is obvious in the results tabulated in Table 4, as the pH was changed to 11 from 3, the efficiency of the used chemical solution for oil recovery was reduced. The reason behind this fact is correlated to the production of in situ soap due to interactions occurring between the basic contents of the crude oil and acidic contents of the aqueous solution leading to saponification of the medium consequently strengthening the influence of the existing ILs on the IFT which directly affect the oil recovery factor. However, as the pH increases to the basic condition the formation of in situ soap and saponification faces retarded conditions leading to lower IFT reduction and lower oil recovery factor.

Finally, the influence of soaking was examined using the optimum operating condition (pH = 3) and chemical formulation to find if it is possible to find the influence of wettability change on the oil recovery compared with the influence of IFT which was previously examined through the quick and conventional core flooding experiments. In this way, after chemical slug injection into the core plug after the secondary oil recovery stage, the system was shut down (outlet and inlet valves were closed) for 30 days in the current investigation to give the chemical formulation a proper chance to be spread through the core plug and introduce its ultimate effect on the wettability change since the wettability change is a time-consuming phenomenon. According to these findings, it can be concluded that the difference between the oil recovery factors of No #1 and 4 and No #7 and 8 are attributed to the influence of wettability change since the IFT reduction mechanism is a rapid phenomenon while the wettability change is a time-dependent phenomenon. In this regard, it seems that introducing 30 days of soaking into the flooded core plugs increases the oil recovery factor up to 46.3% (for [C8py][Cl]) and 46.1% (for [C12py][Cl]) considering the oil recovery factor with and without soaking mostly due to ultimate effect of wettability change on the oil recovery.

To sum up, it seem that using core flooding along with the soaking period leads to a significant oil recovery enhancement which makes such a chemical EOR processes more economical to be performed in the field scale.

The similar results were reported by Manshad et al. (2017) using four ionic liquids without NPs, namely: [C12mim]Cl, 1-octadecyl 3-methyl imidazolium chloride ([C18mim][Cl]), [C8Py]Cl and 1-octadecyl-3 methyl pyridinium chloride ([C18Py][Cl]). [C18mim][Cl]. They reported that application of these ionic liquids is capable to recover trapped oil with maximum recovery factor of about 13% based on original oil in place using only a solution with IL concentrations of 170 ppm.

Moreover, Zabihi and his coworkers (2020) examined the potential of two ILs from imidazolium and pyridinium chlorides with different alkyl chain. They reported the successfulness of ILs for higher oil recovery to the maximum value of 13% and 16.5%, respectively, for [C12mim][Cl] and [C18mim][Cl] by an effective reduction in IFT. Besides, they reported that using SDBS is more potential for oil recovery with tertiary oil recovery of about 26% based on OOIP although it is impossible to use SDBS solution with concentrations higher than 1600 ppm due to risk of precipitation.

In this way, it seems that using NPs with IL through the core flooding experiments as was used in the current investigation leading to better oil recovery due to activation of IFT reduction via the presence of IL molecules makes it possible to collect the oil drops trapped in the pores and throats to form a bigger oil bank and mobilize the oil bank. On the other hand, the presence of NPs can penetrate into the oil film formed at the rock surface and provide the chance of oil detachment from the surface and collect this type of inaccessible oil to form a secondary oil bank leading to more oil recovery compared with the individual application of IL or NPs through the core flooding experiments.

Summary and conclusions

The application of two ionic liquids (ILs) namely 1-octyl-3-methyl pyridinium chloride ([C8py][Cl]) and 1-dodecyl-3-methyl pyridinium chloride ([C12py][Cl]) as novel surfactants were examined in the presence and absence of silicon oxide nanoparticles (SiO2-NPs) under pH values of 3–11 for interfacial tension (IFT) reduction and wettability change were studied for the first time to find the possible synergism between these chemicals and pH in the present study. The obtained results revealed that:

-

Enhancing the pH (3–11) in the absence of different chemicals (formation brine/basic crude oil) led to an increase in the IFT value from 20.3 to 31.2 mN/m.

-

The contact angle (CA) measurements showed that increasing the pH from 3 to 11 increases the CA (103.2°–121.3°) if the pH increases from 3 to 7 while a further increase in the pH leads to a reduction in CA value from 121.3° to 118.3°.

-

Changing [C8py][Cl] concentration (0–2000 ppm) reduces the IFT from 20.3 to 0.95 mN/m for pH of 3, from 27.3 to 2.2 mN/m for pH of 7, and from 31.2 to 5.4 mN/m for pH of 11.

-

If [C12py][Cl] concentration enhances from 0 to 2000 ppm, IFT reduces from 20.3 to 0.74 mN/m for pH of 3, from 27.3 to 0.9 for pH of 7, and from 31.2 to 1.4 mN/m for pH of 11.

-

The results revealed a significant effect of SiO2-NPs on the IFT reduction as the pH increases from 3 to 11 while the IL concentration was held constant at 2000 ppm (regardless of the IL type).

-

The obtained results reveal that not only the presence of SiO2-NPs with a maximum concentration of 1000 ppm introduces a reducing effect on the IFT especially for the pH of 11 regardless of the used IL but also it can move the surface wettability toward strongly water-wet condition with minimum CA value of 28.5o.

-

The core flooding experiments revealed that it is possible to enhance the oil recovery to 6.9% and 9.1% based on the original oil in place (OOIP) using optimum chemical formulation under a pH of 3.

-

Moreover, the performed experiments revealed that introducing a soaking time of 30 days into the flooded core with the optimum chemical formulation under pH can activate the wettability change to its ultimate value which increases the oil recovery up to 46% considering the core flooding experiments with no soaking time.

Abbreviations

- Al2O3 :

-

Aluminum oxide

- API:

-

API gravity

- bpd:

-

Barrels produced in a single day

- CA:

-

Contact angle

- CMC:

-

Critical micelle concentration

- CTAB:

-

Cetyltrimethyl ammonium bromide

- CuO-NPs:

-

Copper oxide nanoparticles

- EDTA:

-

Ethylenediaminetetraacetic

- EDX:

-

Energy-dispersive X-ray

- EOR:

-

Enhanced oil recovery

- Fe2O3 :

-

Iron(III) oxide

- Fe3O4 :

-

Iron (II,III) oxide

- IFT:

-

Interfacial tension

- mD:

-

Millidarcy

- NE–SW:

-

Northeast-southwest

- NPs:

-

Nanoparticles

- NNE:

-

North Northeast

- OOIP:

-

Original oil in place

- pH:

-

Potential of hydrogen/power of hydrogen

- SiO2 :

-

Silicon dioxide

- SiO2-NPs:

-

Silicon dioxide nanoparticles

- SLS:

-

Sodium lauryl sulfate

- WNW–ESE:

-

West-northwest/east southeast

- X-ray:

-

X-radiation

- ZrO2 :

-

Zirconium dioxide

- [C8py][Cl]:

-

1-Octyl-3-methyl pyridinium chloride

- [C12py][Cl]:

-

1-Dodecyl-3-methyl pyridinium chloride

- [C12mim][Cl]:

-

1-Dodecyl-3-methyl imidazolium chloride

- [C18Py][Cl]:

-

1-Octadecyl-3 methyl pyridinium chloride

- [C18mim][Cl]:

-

1-Octadecyl 3-methyl imidazolium chloride

References

Abbood NK, Mayahi N, Hosseini S (2022) Effect of SiO2 nanoparticles+ 1-dodecyl-3-methyl imidazolium chloride on the IFT and wettability alteration at the presence of asphaltenic-synthetic oil. J Pet Explor Prod Technol 12(11):3137–3148

Abhishek R, Kumar GS, Sapru R (2015) Wettability alteration in carbonate reservoirs using nanofluids. Pet Sci Technol 33(7):794–801

Aghajanzadeh MR, Ahmadi P, Sharifi M, Riazi M (2019) Wettability modification of oil-wet carbonate reservoirs using silica-based nanofluid: an experimental approach. J Pet Sci Eng 178:700–710

Ahualli S et al (2011) Adsorption of anionic and cationic surfactants on anionic colloids: supercharging and destabilization. Langmuir 27(15):9182–9192

Al-Anssari S, Barifcani A, Wang S, Maxim L, Iglauer S (2016) Wettability alteration of oil-wet carbonate by silica nanofluid. J Colloid Interface Sci 461:435–442

Alotaibi MB, Yousef A (2016) The role of individual and combined ions in waterflooding carbonate reservoirs: electrokinetic study. SPE Reserv Eval Eng 20(01):077–086. https://doi.org/10.2118/177983-PA

Alotaibi MB, Nasr-El-Din HA, Fletcher JJ (2011) Electrokinetics of limestone and dolomite rock particles. SPE Reserv Eval Eng 14(5):594–603

Andersen SI (1994) Effect of precipitation temperature on the composition of n-heptane asphaltenes. Fuel Sci Technol Int 12(1):51–74

Anganaei H, Pourabdollah K, Rostami A (2014) Experimental improvement of nano-enhanced oil recovery using nano-emulsions. Arab J Sci Eng 39(8):6453–6461

Arab D, Pourafshary P (2013) Nanoparticles-assisted surface charge modification of the porous medium to treat colloidal particles migration induced by low salinity water flooding. Colloids Surf A 436:803–814

Aveyard R, Binks BP, Clint JH (2003) Emulsions stabilised solely by colloidal particles. Adv Coll Interface Sci 100:503–546

Bera A, Belhaj H (2016) Application of nanotechnology by means of nanoparticles and nanodispersions in oil recovery-A comprehensive review. J Nat Gas Sci Eng 34:1284–1309

Berberian M, King G (1981) Towards a paleogeography and tectonic evolution of Iran. Can J Earth Sci 18(2):210–265

Beydoun ZR (1991) Arabian plate hydrocarbon geology and potential—a plate tectonic approach

Bobbo S et al (2012) Viscosity of water based SWCNH and TiO2 nanofluids. Exp Thermal Fluid Sci 36:65–71

Bosold A, Schwarzhans W, Julapour A, Ashrafzadeh A, Ehsani S (2005) The structural geology of the High Central Zagros revisited (Iran). Pet Geosci 11(3):225–238

Chehrazi A, Rahimpour-Bonab H, Rezaee M (2013) Seismic data conditioning and neural network-based attribute selection for enhanced fault detection. Pet Geosci 19(2):169–183

Chen L et al (2014) Inexpensive ionic liquids:[HSO 4]−-based solvent production at bulk scale. Green Chem 16(6):3098–3106

Cheraghian G (2015) Effects of nanoparticles on wettability: A review on applications of nanotechnology in the enhanced Oil recovery

Cheraghian G (2016) Effects of titanium dioxide nanoparticles on the efficiency of surfactant flooding of heavy oil in a glass micromodel. Pet Sci Technol 34(3):260–267

Cheraghian G, Hendraningrat L (2016a) A review on applications of nanotechnology in the enhanced oil recovery part A: effects of nanoparticles on interfacial tension. Int Nano Lett 6:129–138

Cheraghian G, Hendraningrat L (2016b) A review on applications of nanotechnology in the enhanced oil recovery part B: effects of nanoparticles on flooding. Int Nano Lett 6(1):1–10

Curbelo FD et al (2007) Adsorption of nonionic surfactants in sandstones. Colloids Surf A 293(1–3):1–4

de Castro Dantas TN, de Souza TTC, Neto AAD, de Alencar Moura MCP, de Barros Neto EL (2017) Experimental study of nanofluids applied in EOR processes. J Surfactants Deterg 20(5):1095–1104

Demirbas A (2016) Deposition and flocculation of asphaltenes from crude oils. Pet Sci Technol 34(1):6–11

Demirbas A, Alidrisi H, Balubaid M (2015) API gravity, sulfur content, and desulfurization of crude oil. Pet Sci Technol 33(1):93–101

Demirbas A, Taylan O (2015) Recovery of gasoline-range hydrocarbons from petroleum basic plastic wastes. Pet Sci Technol 33(23–24):1883–1889

Dharaskar Swapnil A (2012) Ionic liquids (a review): the green solvents for petroleum and hydrocarbon industries. Res J Chem Sci 2231:606X

Domańska U (2005) Solubilities and thermophysical properties of ionic liquids. Pure Appl Chem 77(3):543–557

Dordzie G, Dejam M (2021) Enhanced oil recovery from fractured carbonate reservoirs using nanoparticles with low salinity water and surfactant: a review on experimental and simulation studies. Adv Coll Interface Sci 293:102449

Ehtesabi H, Ahadian MM, Taghikhani V (2015) Enhanced heavy oil recovery using TiO2 nanoparticles: investigation of deposition during transport in core plug. Energy Fuels 29(1):1–8

El-Diasty AI, Ragab AM (2013) Applications of nanotechnology in the oil and gas industry: latest trends worldwide and future challenges in Egypt. In: North Africa technical conference and exhibition. OnePetro

Ershadi M, Alaei M, Rashidi A, Ramazani A, Khosravani S (2015) Carbonate and sandstone reservoirs wettability improvement without using surfactants for chemical enhanced oil recovery (C-EOR). Fuel 153:408–415

Esumi K (2001) Interactions between surfactants and particles: dispersion, surface modification, and adsolubilization. J Colloid Interface Sci 241(1):1–17

Fard IA, Braathen A, Mokhtari M, Alavi SA (2006) Interaction of the zagros fold-thrust belt and the arabian-type, deep-seated folds in the abadan plain and the dezful embayment. SW Iran Pet Geosci 12(4):347–362

Fereidooni Moghadam T, Azizian S (2014) Effect of ZnO nanoparticle and hexadecyltrimethylammonium bromide on the dynamic and equilibrium oil–water interfacial tension. J Phys Chem B 118(6):1527–1534

Ghazban F (2007) Petroleum geology of the Persian Gulf. Joint publication, Tehran University Press and National Iranian Oil Company, Tehran

Hashemi R, Nassar NN, Pereira Almao P (2013) Enhanced heavy oil recovery by in situ prepared ultradispersed multimetallic nanoparticles: A study of hot fluid flooding for Athabasca bitumen recovery. Energy Fuels 27(4):2194–2201

Hendraningrat L, Li S, Torsæter O (2013a) Effect of some parameters influencing enhanced oil recovery process using silica nanoparticles: an experimental investigation. In: SPE reservoir characterization and simulation conference and exhibition. OnePetro. https://doi.org/10.2118/165955-MS

Hendraningrat L, Li S, Torsaeter O (2013b) A coreflood investigation of nanofluid enhanced oil recovery in low-medium permeability Berea sandstone. In: SPE international symposium on oilfield chemistry. OnePetro. https://doi.org/10.2118/164106-MS

Hendraningrat L, Li S, Torsaeter O (2013c) Enhancing oil recovery of low-permeability Berea sandstone through optimized nanofluids concentration. In: SPE enhanced oil recovery conference. OnePetro. https://doi.org/10.2118/165283-MS

Hendraningrat L, Torsæter O (2014) Effects of the initial rock wettability on silica-based nanofluid-enhanced oil recovery processes at reservoir temperatures. Energy Fuels 28(10):6228–6241

Hezave AZ, Dorostkar S, Ayatollahi S, Nabipour M, Hemmateenejad B (2013a) Dynamic interfacial tension behavior between heavy crude oil and ionic liquid solution (1-dodecyl-3-methylimidazolium chloride ([C12mim][Cl]+ distilled or saline water/heavy crude oil)) as a new surfactant. J Mol Liq 187:83–89

Hezave AZ, Dorostkar S, Ayatollahi S, Nabipour M, Hemmateenejad B (2013b) Effect of different families (imidazolium and pyridinium) of ionic liquids-based surfactants on interfacial tension of water/crude oil system. Fluid Phase Equilib 360:139–145

Hezave AZ, Dorostkar S, Ayatollahi S, Nabipour M, Hemmateenejad B (2013c) Investigating the effect of ionic liquid (1-dodecyl-3-methylimidazolium chloride ([C12mim][Cl])) on the water/oil interfacial tension as a novel surfactant. Colloids Surf A 421:63–71

James G, Wynd J (1965) Stratigraphic nomenclature of Iranian oil consortium agreement area. AAPG Bull 49(12):2182–2245

José-Alberto M-H, Jorge A (2011) Current knowledge and potential applications of ionic liquids in the petroleum industry. Ionic liquids: applications and perspectives

Ju B, Fan T, Ma M (2006) Enhanced oil recovery by flooding with hydrophilic nanoparticles. China Particuol 4(1):41–46

Karimi A et al (2012) Wettability alteration in carbonates using zirconium oxide nanofluids: EOR implications. Energy Fuels 26(2):1028–1036

Kazemzadeh Y, Eshraghi SE, Sourani S, Reyhani M (2015) An interface-analyzing technique to evaluate the heavy oil swelling in presence of nickel oxide nanoparticles. J Mol Liq 211:553–559

Khalil M, Jan BM, Tong CW, Berawi MA (2017) Advanced nanomaterials in oil and gas industry: design, application and challenges. Appl Energy 191:287–310

Khupse ND, Kumar A (2010) Ionic liquids: new materials with wide applications

Kondiparty K, Nikolov A, Wu S, Wasan D (2011) Wetting and spreading of nanofluids on solid surfaces driven by the structural disjoining pressure: statics analysis and experiments. Langmuir 27(7):3324–3335

Lashkarbolooki M, Ayatollahi S, Riazi M (2014) Effect of salinity, resin, and asphaltene on the surface properties of acidic crude oil/smart water/rock system. Energy Fuels 28(11):6820–6829

Lashkarbolooki M, Riazi M, Ayatollahi S, Hezave AZ (2016) Synergy effects of ions, resin, and asphaltene on interfacial tension of acidic crude oil and low–high salinity brines. Fuel 165:75–85

Lee Y-S, Kim D-W (2013) Cycling performance of lithium polymer cells assembled by in situ polymerization of a non-flammable ionic liquid monomer. Electrochim Acta 106:460–464

Li W et al (2021) Solvent manipulation of the pre-reduction metal–ligand complex and particle-ligand binding for controlled synthesis of Pd nanoparticles. Nanoscale 13(1):206–217

Maghzi A, Mohebbi A, Kharrat R, Ghazanfari MH (2011) Pore-scale monitoring of wettability alteration by silica nanoparticles during polymer flooding to heavy oil in a five-spot glass micromodel. Transp Porous Media 87(3):653–664

Manshad AK, Rezaei M, Moradi S, Nowrouzi I, Mohammadi AH (2017) Wettability alteration and interfacial tension (IFT) reduction in enhanced oil recovery (EOR) process by ionic liquid flooding. J Mol Liq 248:153–162

Martins MA et al (2014) Impact of the cation symmetry on the mutual solubilities between water and imidazolium-based ionic liquids. Fluid Phase Equilib 375:161–167

McElfresh P, Olguin C, Ector D (2012) The application of nanoparticle dispersions to remove paraffin and polymer filter cake damage. In: SPE international symposium and exhibition on formation damage control. OnePetro. https://doi.org/10.2118/151848-MS

Mehraban MF, Ayatollahi Sh, Sharifi S (2021) Experimental investigation on synergic effect of salinity and pH during low salinity water injection into carbonate oil reservoirs. J Petrol Sci Eng 202:108555

Mohammadi M, Dadvar M, Dabir B (2017) TiO2/SiO2 nanofluids as novel inhibitors for the stability of asphaltene particles in crude oil: mechanistic understanding, screening, modeling, and optimization. J Mol Liq 238:326–340

Moradi B, Pourafshary P, Jalali F, Mohammadi M, Emadi M (2015) Experimental study of water-based nanofluid alternating gas injection as a novel enhanced oil-recovery method in oil-wet carbonate reservoirs. J Nat Gas Sci Eng 27:64–73

Morrow NR (1990) Wettability and its effect on oil recovery. J Petrol Technol 42(12):1476–1484

Mozaffari S (2015) Rheology of Bitumen at the onset of asphaltene aggregation and its effects on the stability of water-in-oil emulsion

Mozaffari S, Ghasemi H, Tchoukov P, Czarnecki J, Nazemifard N (2021) Lab-on-a-chip systems in asphaltene characterization: a review of recent advances. Energy Fuels 35(11):9080–9101

Mozaffari S, Tchoukov P, Atias J, Czarnecki J, Nazemifard N (2015) Effect of asphaltene aggregation on rheological properties of diluted athabasca bitumen. Energy Fuels 29(9):5595–5599

Muhammad I et al (2013) SARA separation and determination of concentration levels of some heavy metals in organic fractions of Nigerian crude oil. Chem Mater Res 3(4):7–14

Negin C, Ali S, Xie Q (2016) Application of nanotechnology for enhancing oil recovery–a review. Petroleum 2(4):324–333

Olayiwola SO, Dejam M (2019) A comprehensive review on interaction of nanoparticles with low salinity water and surfactant for enhanced oil recovery in sandstone and carbonate reservoirs. Fuel 241:1045–1057

Onyekonwu MO, Ogolo NA (2010) Investigating the use of nanoparticles in enhancing oil recovery, Nigeria Annual international conference and exhibition. OnePetro

Peng X-M, Hu Y-F, Jin C-W (2011) Solubilities of imidazolium-based ionic liquids in aqueous salt solutions at 298.15 K. J Chem Thermodyn 43(8):1174–1177

Resasco DE et al (2015) Method and foam composition for recovering hydrocarbons from a subterranean reservoir. Google Patents

Rodríguez-Palmeiro I, Rodríguez-Escontrela I, Rodríguez O, Arce A, Soto A (2015) Characterization and interfacial properties of the surfactant ionic liquid 1-dodecyl-3-methyl imidazolium acetate for enhanced oil recovery. RSC Adv 5(47):37392–37398

Rodriguez Pin E, Roberts M, Yu H, Huh C, Bryant SL (2009) Enhanced migration of surface-treated nanoparticles in sedimentary rocks. In: SPE annual technical conference and exhibition. Society of Petroleum Engineers. https://doi.org/10.2118/124418-MS

Saien J, Gorji AM (2017) Simultaneous adsorption of CTAB surfactant and magnetite nanoparticles on the interfacial tension of n-hexane–water. J Mol Liq 242:1027–1034

Salehi M, Johnson SJ, Liang J-T (2010) Enhanced wettability alteration by surfactants with multiple hydrophilic moieties. J Surfactants Deterg 13(3):243–246

Sarafzadeh P et al (2014) Investigating the efficiency of MEOR processes using Enterobacter cloacae and Bacillus stearothermophilus SUCPM# 14 (biosurfactant-producing strains) in carbonated reservoirs. J Petrol Sci Eng 113:46–53

Saw RK, Mandal A (2020) A mechanistic investigation of low salinity water flooding coupled with ion tuning for enhanced oil recovery. RSC Adv 10:42570

Seid Mohammadi M, Moghadasi J, Naseri S (2014) An experimental investigation of wettability alteration in carbonate reservoir using γ-Al2O3 nanoparticles. Iran J Oil Gas Sci Technol 3(2):18–26

Setudehnia A (1978) The mesozoic sequence in south-west Iran and adjacent areas. J Pet Geol 1(1):3–42

Shalbafan M, Esmaeilzadeh F, Safaei A (2019) Experimental investigation of wettability alteration and oil recovery enhance in carbonate reservoirs using iron oxide nanoparticles coated with EDTA or SLS. J Petrol Sci Eng 180:559–568

Sheng JJ (2010) Modern chemical enhanced oil recovery: theory and practice. Gulf Professional Publishing, Houston

Smit B et al (1991) Structure of a water/oil interface in the presence of micelles: a computer simulation study. J Phys Chem 95(16):6361–6368

Stauffer CE (1965) The measurement of surface tension by the pendant drop technique. J Phys Chem 69(6):1933–1938

Suleimanov BA, Ismailov F, Veliyev E (2011) Nanofluid for enhanced oil recovery. J Petrol Sci Eng 78(2):431–437

Taborda EA, Franco CA, Lopera SH, Alvarado V, Cortés FB (2016) Effect of nanoparticles/nanofluids on the rheology of heavy crude oil and its mobility on porous media at reservoir conditions. Fuel 184:222–232

Taborda EA, Franco CA, Ruiz MA, Alvarado V, Cortes FB (2017) Experimental and theoretical study of viscosity reduction in heavy crude oils by addition of nanoparticles. Energy Fuels 31(2):1329–1338

Tarek M (2015) Investigating nano-fluid mixture effects to enhance oil recovery. In: SPE annual technical conference and exhibition. OnePetro. https://doi.org/10.2118/178739-STU

Torsater O, Engeset B, Hendraningrat L, Suwarno S (2012) Improved oil recovery by nanofluids flooding: an experimental study In: SPE Kuwait international petroleum conference and exhibition. Society of Petroleum Engineers. https://doi.org/10.2118/163335-MS

Wang D, Duan H, Möhwald H (2005) The water/oil interface: the emerging horizon for self-assembly of nanoparticles. Soft Matter 1(6):412–416

Wasan D, Nikolov A, Kondiparty K (2011) The wetting and spreading of nanofluids on solids: role of the structural disjoining pressure. Curr Opin Colloid Interface Sci 16(4):344–349

Wei L, Zhu J-H, Qi J-H (2007) Application of nano-nickel catalyst in the viscosity reduction of Liaohe extra-heavy oil by aqua-thermolysis. J Fuel Chem Technol 35(2):176–180

Wu J, Prausnitz JM, Firoozabadi A (1998) Molecular-thermodynamic framework for asphaltene-oil equilibria. AIChE J 44(5):1188–1199

Yang Z et al (2014) Interfacial tension of CO2 and organic liquid under high pressure and temperature. Chin J Chem Eng 22(11–12):1302–1306

Zabihi S, Faraji D, Rahnama Y, Zeinolabedini Hezave A, Ayatollahi S (2020) Relative permeability measurement in carbonate rocks, the effects of conventional surfactants versus Ionic liquid-based surfactants. J Dispers Sci Technol 41(12):1797–1811

Zaid HM, Yahya N, Latiff NRA (2013) The effect of nanoparticles crystallite size on the recovery efficiency in dielectric nanofluid flooding. J Nano Res 21:103–108

Zamani A, Maini B, Pereira-Almao P (2012) Flow of nanodispersed catalyst particles through porous media: effect of permeability and temperature. Can J Chem Eng 90(2):304–314

Acknowledgements

Authors thank Islamic Azad University, Dashtestan branch for their help and financial support in this research.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pazhoohan, M., Hezave, A.Z. Investigation on the synergistic effect of pH and pyridinium-based ionic liquid on the wettability alteration of dolomite rock and IFT of formation brine/alkaline crude oil at the presence and absence of SiO2 nanoparticles. J Petrol Explor Prod Technol 13, 2519–2537 (2023). https://doi.org/10.1007/s13202-023-01686-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01686-3