Abstract

Water-based enhanced oil recovery methods have been developed to improve the oil production rate from ultra-tight reservoirs. By coupling the effect of surfactant as wettability alteration and water alternating gas injection method, we aimed to determine the most efficient enhanced oil recovery technique. We performed seven injectivity scenarios to measure the oil recovery factor by introducing the alkylbenzene sulfonic acid (LABSA) as a surfactant agent during the active carbonated water alternating gas (ACWAG) injection. To consider the effect of slug size during water alternating gas injection, we used two different slug sizes (0.3, and 0.6). After the water breakthrough, a little oil volume was produced, and the maximum oil recovery factor at 1.5 Pore Volume (PV) was 26%. This issue corresponded to the water channeling after the breakthrough point. For smaller slug sizes (0.3), the maximum oil recovery factor (78%) was reached in smaller pore volumes. One of the exciting results wass the considerable influence of slug ratio during the water alternating gas (WAG) injection, in which it provided more oil recovery factor (83%) when the gas volume is higher than the water volume. Finally, by introducing the coupling effect of active carbonated water (made by LABSA surfactant) and WAG injection, the maximum oil recovery factor was 85%, corresponding to the better efficiency of active carbonated water in interfacial tension reduction. The results of this comprehensive investigation can be extended in ultra-tight sandstone reservoirs and can be applied as a further guideline in numerical simulations.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to the new advancements in enhanced oil recovery (EOR) methods, there are still lack of efficient techniques to improve the oil recovery from tight and ultra-tight reservoirs regarding their different nature from other reservoirs (Afifi et al. 2021; Aycaguer et al. 2001; Ding et al. 2017; Li et al. 2021). Among numerous secondary and tertiary EOR methods, carbon dioxide enhanced oil recovery (CO2-EOR) methods play a substantial role in tight reservoirs as they can provide more convenient and feasible displacement sweep efficiency (Al-Bayati et al. 2018; Alquriaishi & Shokir 2011; AlRassas et al. 2022; Kuuskraa 2012; Wang et al. 2020).

CO2 huff-n-puff (or cyclic CO2 injection) is one of the recent efficient techniques which has used in many field applications (Han et al. 2018; Hu et al. 2020; Li et al. 2022a, b). The effective parameters that are important in cyclic CO2 injection are soaking time, pressure, and temperature. These parameters are primarily favorable in fractured carbonate reservoirs due to the feasibility of gas in order to transfer more conveniently through porous media. On the other hand, the injection of CO2 as a continuous phase would be a superior technique in tight reservoirs. It can reduce the interfacial tension and oil viscosity when injected in miscible conditions (Amin et al. 2012; Enayati et al. 2018; Zhou et al. 2017). Continuous Gas Injection (CGI) would be a proper method in water-wet reservoirs during the immiscible gas injection. It is evident that due to the limitations of CGI and its low oil recovery increase, it can not be a suitable method especially for tight and ultra-tight reservoirs (Al-Mudhafar & Rao 2017; Kulkarni & Rao 2005). A new method to increase the oil recovery is the process of intermittent (or alternating) injection of water and gas. In the water alternating gas injection (WAG), the first goal is to increase the volumetric sweep efficiency. Previous studies showed that WAG injection as a secondary EOR technique would be more efficient than primary EOR methods containing water or gas injection separately (Belazreg et al. 2019; Ebadati et al. 2019). Slug size is essential in increasing the oil recovery factor, which can be performed more efficiently in smaller slug sizes. The slug ratio is another important parameter that should be optimized as higher slug ratios can trap residual oil in the reservoir. Therefore, at higher slug ratios, recovering the remaining oil would be difficult and time-consuming (Afzali et al. 2018; Li et al. 2022a, b).

To improve oil recovery factor, gas-assisted gravity drainage (GAGD) method (Mahmoud and Rao 2007) would be a feasible method especially in the presence of active water aquifer by the production of oil above the oil–water contact level. Evaluated a set of experiments to consider the GAGD and free fall gravity drainage (FFGD) mechanisms in the presence and absence of active water aquifer. They observed that GAGD had higher oil recovery factor than FFGD; however, the presence of active water aquifer would improve the performance of FFGD. For increasing the oil recovery factor in those reservoirs with strong aquifers, Al-Mudhafar et al. (2018) experimentally evaluated the gas and downhole water sink-assisted gravity drainage (GDWS-AGD) method. In this method, the water cut had the minimum value and susbequently the oil recovery increased further by the increase of gas inejction rate (Al-Mudhafar et al. 2018).

Although many numerical and experimental investigations have been performed (contained various chemical and thermal enhanced oil recovery techniques in ultra-tight reservoirs), there is still a need to develop efficient methods to improve oil recovery factor. We implemented the water-based EOR methods and then comparing each scenario's results to find the efficient oil recovery methods. Therefore, we performed water alternating gas injection for different slug sizes and slug ratios. Due to the wettability alteration feature of surfactants, they can provide better results when WAG injection scenarios were coupled. The results of this study would be the straightforward advancement in the design of EOR techniques for ultra-tight reservoirs worldwide.

Methodology

Materials

We collected seven tight core samples with the outer diameter of 2.54 cm and approximate length of 2.55–2.71 cm from a sandstone reservoir in the Tarim Basin in China. The core samples were extracted from the depth of 1824–1916 m. According to the XRD analysis, sandstone core samples contained quartz with a weight percent (wt%) of 79.6%, dolomite, illite, and pyrite with 8.7 wt%, 8.4 wt%, and 3.3 wt%, respectively. The porosity and permeability ranged from 5.81–11.26% to 0.012–0.105 mD.

A conical filtering centrifuge was used to eliminate the solid particles and other formation chemical agents from the light crude oil. Then the viscosity and density were measured (at 70 °C (reservoir temperature) and room pressure (atmospheric pressure)). They were 1.26 cP and 0.861 g/cm3, respectively. The asphaltene content in purified light crude oil was measured (0.12 wt%), which had no significant effect on the experiments. As the crude oil contains 70.24 mol% of light and intermediate hydrocarbons (C1–C7), it was considered a light crude oil in this field. The remained crude oil component contained 29.76 mol% of C7+. Another reason for using light crude oil corresponded to its better miscibility when interacting with the gaseous phase.

The formation brine collected from the same reservoir that core samples were extracted to provide reliable results during the experiments; however, its physicochemical characteristics were analyzed in the laboratory. It is mainly contained 120,000 mg/L of sodium chloride (NaCl) with a viscosity of 1.14 cP. The concentration of other ions consisted of Ca2+, Mg2+ (450 mg/L and 215 mg/L) can be negligible as they cannot affect the results significantly.

Carbon dioxide (CO2) were prepared in the purification of 99.99% at reservoir temperature and atmospheric pressure. We used linear alkylbenzene sulfonic acid (LABSA) as a surfactant to produce the active carbonated water. LABSA, with the chemical formula of CH3(CH2)11C6H4SO3H, is a commercial surfactant and is widely used in EOR processes.

Experimental procedure

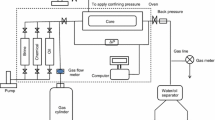

Coreflooding tests

The coreflooding apparatus, is schematically shown in Fig. 1. Firstly, to eliminate the clays, hydrocarbons, etc., from the sandstone tight core samples, they should be polished with methanol and toluene. Second, they will be dried, sealed (in order to prevent channeling from occurring between a core sample and inner surface of the core holder during injection), and put in a horizontal core holder. Forming brine was injected at different rates varied from 0.01 to 0.03 cm3/min. The porosity and permeability of each core sample are shown in Table 1. The porosity varied from 5.81 to 11.26%, while the permeability varied from 0.012 to 0.105 mD. It was indicated that this reservoir is one of the ultra-tight sandstone reservoirs. To measure the connate water saturation, crude oil was injected through core samples with the flow rate of 0.02 cm3/min. This point was called connate water saturation, where there was no water production after this point (Swc \(\approx\) 42.3–46.76%). The following procedure was done to measure the oil recovery factor.

-

1.

Formation brine with the flow rate of 0.02 cm3/min was injected to measure oil recovery factor.

-

2.

Carbon dioxide was injected with the flow rate of 0.02 cm3/min as a miscible phase to measure the oil recovery factor.

-

3.

CO2-water alternating gas injection (WAG) with various WAG slug sizes, gas alternating water (GAW) injection, and active carbonated water alternating gas injection (made by surfactant) were performed with the flow rate of 0.02 cm3/min. The gas injection for all scenarios was performed as continuous miscible CO2 injection.

-

4.

Finally, water flooding was applied to observe how much remained oil was produced.

Limitations

One of the issues in considering the active carbonated water alternating gas injection would be minimum miscible pressure (MMP) when the CO2 injection pressure is greater than MMP, it is important to investigate the core displacement efficiency and crude oil–gas mechanisms. It corresponded to the highest oil recovery factor and would be a limit specifically in unconventional reservoirs.

Results and discussion

Waterflooding and CO2 injection

To measure the oil recovery factor during waterflooding and CO2 injection (continuous miscible injection), core samples 1 and 2 were used. As shown in Fig. 2, a water breakthrough occurred at 0.3 PV, which indicated that no significant volume of oil would be produced after this point (the oil recovery factor was approximately 24%). After the water breakthrough, a little oil volume was produced, and the maximum oil recovery factor was 26% (it reached a plateau at 1.5 PV). This issue corresponded to the water channeling after the breakthrough point. We used core sample 2 to proceed with CO2 injection as a continuous miscible injection in the second step. It was observed that CO2 breakthrough occurred in 0.2 PV with an oil recovery factor of 21%. After the breakthrough, more oil volumes were produced, and the maximum oil recovery factor reached 45% (Fig. 3).

Water alternating gas (WAG) injection

In this section, we used core sample 3 to perform coreflooding tests with WAG injection scenarios. We performed the measurements until the oil recovery factor reached a plateau and there was no significant oil production. We continued the coreflooding tests for six cycles, starting with water and then finishing in the sixth cycle with gas injection. Again, more oil volume was produced after the breakthrough (at 0.3 PV of water injection in cycle 1), indicating that alternative water and gas injection would be an effective technique to enhance the oil recovery factor. The maximum oil recovery factor was 63.43% after 3.5 PV.

Effect of slug sizes in WAG injections

In this section, we focused on the effect of slug sizes during WAG injection, and we performed two coreflooding experiments with slug sizes of 0.3 (core sample 4) and 0.6 (core sample 3) in the slug ration of 1:1. As shown in Fig. 4, until the water breakthrough in 0.3 PV, there was no change in the oil recovery factor for both samples. For the core sample with a slug size of 0.3, the increase of oil recovery continued as for larger slug sizes (0.6), water breakthrough occurred earlier. Although the oil recovery factor was increased in core sample 4 experiment, the main parts of oil production corresponded to the O2 injection in the second cycle. Furthermore, it is concluded that the maximum oil recovery factor reached in smaller pore volumes for smaller slug sizes (Carpenter 2019; Sarlak et al. 2021). It is about 78% after 1 PV injection.

Effect of slug ratio during WAG injection

Slug ratio is expressed as the ratio of water or gas in alternating injection scenarios. In this part, we investigated the effect of the slug ratio during WAG injection. Therefore, we performed a coreflooding test with core sample 5 with the slug ratio of 1:2 with a slug size of 0.3. As shown in Fig. 5, slug ratio had a vital role in oil production as the oil recovery factor increased up to 83%. It was corresponded to the more volume of CO2 injection in comparison with the previous scenario. It can increase the displacement efficiency on a microscopic scale. When the slug ratio was 1:2 (due to the gravity segregation and higher water density during the water flow in the core samples), there was no significant increase in the oil recovery factor after 1.5 PV.

Gas water alternating (GAW) injection

This part investigated the gas water alternating injection to compare with WAG injection with core sample 6. The purpose of this experiment was to observe what would happen if the sequence of the injection phase changed. As shown in Fig. 6, it was observed that the maximum oil recovery factor in WAG injection (79%) which was higher than GAW injection (67%), because water can provide higher displacement efficiency than gas in the first stages of injection. It corresponded to the formation of water with more favorable mobility ratio in water-wet reservoirs. Moreover, in GAW injection, CO2 can cause viscous fingering issues in the initial stages of core flooding, and subsequent reduction on the overall volumetric sweep efficiency.

Coupling the effect of surfactant and WAG

As investigated in previous sections, WAG injection with a small slug ratio (0.3) and slug ratio of (1:2) has the optimum injectivity scenario to improve the oil recovery factor. Here, we investigated the coupling effect of surfactant (the wettability alteration agent caused to reduce the interfacial tension.) and WAG injection. Instead of formation water, we used active carbonated water, which was made by surfactant dissolved in water in alternating cycles. As shown in Fig. 7, the maximum oil recovery factor reached 85% in active carbonated water alternating gas injection (ACWAG). It corresponded to the better efficiency of active carbonated water in interfacial tension reduction.

Conclusions

In this paper, we investigated water-based enhanced oil recovery methods in the ultra-tight sandstone reservoirs. We coupled the effect of surfactant as wettability alteration and water alternating gas injection to determine the most efficient enhanced oil recovery techniques. We performed seven injectivity scenarios to measure the oil recovery factor by introducing the alkylbenzene sulfonic acid (LABSA) as a surfactant during the active carbonated water alternating gas (ACWAG) injection. The main conclusions of this study are as follows;

-

The CO2 breakthrough occurred at 0.2 Pore volume (PV) with an oil recovery factor of 21%. After the breakthrough, more oil volumes oil were produced, and the maximum oil recovery factor reached 45%.

-

Alternative injection of water and gas would be an effective technique to enhance the oil recovery factor. The maximum oil recovery factor was 63.43% after 3.5 PV in WAG injection with the slug ratio of 0.6 and slug ratio of 1:1.

-

For the core sample with a slug size of 0.3, the oil recovery increases as for larger slug sizes (0.6), water breakthrough occurred earlier.

-

Slug ratio has an essential role in oil production as it increased the oil recovery factor up to 83% due to more volume of CO2 injection than in the previous scenario. It can increase the displacement efficiency on the microscopic scale.

-

The max oil recovery factor in WAG injection (79%) was higher than GAW injection (67%), as water can provide higher displacement efficiency than gas in the first injection stages. It corresponded to the formation of water's more favorable mobility ratio in water-wet reservoirs.

-

The maximum oil recovery factor reached 85% in active carbonated water alternating gas injection (ACWAG). It corresponded to the better efficiency of active carbonated water in interfacial tension reduction.

Abbreviations

- ACWAG:

-

Active carbonated water alternating gas injection

- CO2 :

-

Carbon dioxide

- EOR:

-

Enhanced oil recovery

- GAW:

-

Gas alternating water

- LABSA:

-

Linear alkylbenzene sulfonic acid

- MMP:

-

Minimum miscible pressure

- NaCl:

-

Sodium chloride

- PV:

-

Pore volume

- WAG:

-

Water alternating gas injection

- wt%:

-

Weight percent

References

Afifi HR, Mohammadi S, Mirzaei Derazi A, Mahmoudi Alemi F, Fouladi Hossein Abad K (2021) A comprehensive review on critical affecting parameters on foam stability and recent advancements for foam-based EOR scenario. J Mol Liq. https://doi.org/10.1016/j.molliq.2021.116808

Afzali S, Rezaei N, Zendehboudi S (2018) A comprehensive review on enhanced oil recovery by water alternating gas (WAG) injection. Fuel 227:218–246. https://doi.org/10.1016/j.fuel.2018.04.015

Al-Bayati D, Saeedi A, Xie Q, Myers MB, White C (2018) Influence of permeability heterogeneity on miscible CO2 flooding efficiency in sandstone reservoirs: an experimental investigation. Transp Porous Media 125:341–356. https://doi.org/10.1007/s11242-018-1121-3

Al-Mudhafar WJ, Rao D (2017) Lessons learned from the field-scale simulation of the gas-assisted gravity drainage GAGD process in heterogeneous sandstone oil reservoirs. SPE Western Reg Meet Proc. https://doi.org/10.2118/185732-ms

Al-Mudhafar WJ, Wojtanowicz AK, Rao DN (2018) Gas and downhole water sink-assisted gravity drainage GDWS-AGD EOR process: field-scale evaluation and recovery optimization. Proc SPE Symp Improv Oil Recover. https://doi.org/10.2118/190163-ms

Alquriaishi AA, Shokir EMEM (2011) Experimental investigation of miscible CO2 flooding. Pet Sci Technol 29(19):2005–2016. https://doi.org/10.1080/10916461003662976

AlRassas AM, Vo Thanh H, Ren S, Sun R, Le Nguyen Hai N, Lee KK (2022) Integrated static modeling and dynamic simulation framework for CO2 storage capacity in Upper Qishn Clastics, S1A reservoir, Yemen. Geomech Geophys Geo-Energy Geo-Resour 8:1–23. https://doi.org/10.1007/s40948-021-00305-x

Amin ME, Zekri AY, Almehaideb R, Al-Attar H (2012) Optimization of CO2 WAG processes in a selected carbonate reservoir - An experimental approach. In: Society of Petroleum Engineers - Abu Dhabi International Petroleum Exhibition and Conference 2012, ADIPEC 2012 - Sustainable Energy Growth: People, Responsibility, and Innovation. https://doi.org/10.2118/161782-ms

Aycaguer AC, Lev-On M, Winer AM (2001) Reducing carbon dioxide emissions with enhanced oil recovery projects: a life cycle assessment approach. Energy Fuels 15(2):303–308. https://doi.org/10.1021/ef000258a

Belazreg L, Mahmood SM, Aulia A (2019) Novel approach for predicting water alternating gas injection recovery factor. J Pet Explor Prod Technol 9:2893–2910. https://doi.org/10.1007/s13202-019-0673-2

Carpenter C (2019) Gas Injection Evaluated for EOR in Organic-Rich Shale. J Pet Technol. 268 27(01):440–453.

Ding M, Yuan F, Wang Y, Xia X, Chen W, Liu D (2017) Oil recovery from a CO2 injection in heterogeneous reservoirs: the influence of permeability heterogeneity, CO2-oil miscibility and injection pattern. J Nat Gas Sci Eng 44:140–149. https://doi.org/10.1016/j.jngse.2017.04.015

Ebadati A, Akbari E, Davarpanah A (2019) An experimental study of alternative hot water alternating gas injection in a fractured model. Energy Explor Exploit 37(3):945–959. https://doi.org/10.1177/0144598718815247

Enayati M, Heidaryan E, Mokhtari B (2018) New investigations into carbon dioxide flooding by focusing on viscosity and swelling factor changes. Can Int Pet Conf. https://doi.org/10.2118/2008-064

Han J, Seo Y, Kim J, Han S, Lee Y (2018) Comparison of oil recovery and carbonate rock’s properties alterations by CO2 miscible flooding. In: Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering - OMAE. https://doi.org/10.1115/OMAE2018-78723

Hu X, Xie J, Cai W, Wang R, Davarpanah A (2020) Thermodynamic effects of cycling carbon dioxide injectivity in shale reservoirs. J Pet Sci Eng 195:107717. https://doi.org/10.1016/j.petrol.2020.107717

Kulkarni MM, Rao DN (2005) Experimental investigation of miscible and immiscible Water-Alternating-Gas (WAG) process performance. J Petrol Sci Eng 48(1–2):1–20. https://doi.org/10.1016/j.petrol.2005.05.001

Kuuskraa V (2012) QC updates carbon dioxide projects in OGJ’s enhanced oil recovery survey. Oil Gas J 110:72

Li D, Saraji S, Jiao Z, Zhang Y (2021) CO2 injection strategies for enhanced oil recovery and geological sequestration in a tight reservoir: an experimental study. Fuel 284:119013. https://doi.org/10.1016/j.fuel.2020.119013

Li X, Xue J, Wang Y, Yang W, Lu J (2022) Experimental study of oil recovery from pore of different sizes in tight sandstone reservoirs during CO2 flooding. J Pet Sci Eng 208:109740. https://doi.org/10.1016/j.petrol.2021.109740

Li X, Li A, Guo W, Liu S, Cui S (2022) Experimental study on mechanism of water-alternating-gas injection in thick sandstone reservoir. ES Web Conf. https://doi.org/10.1051/e3sconf/202233801001

Mahmoud TN, Rao DN (2007) Mechanisms and performance demonstration of the gas-assisted gravity-drainage process using visual models. SPE Ann Tech Conf Proc. https://doi.org/10.2523/110132-ms

Sarlak M, Farbod A, Tabatabaei Nezhad S A, Sahraei E (2021) Experimental investigation of CO2 in continuous and water alternating gas injection. Petrol Sci Technol 39(06):165–174. https://doi.org/10.1080/10916466.2010.549894

Wang Q, Yang S, Lorinczi P, Glover PWJ, Lei H (2020) Experimental investigation of oil recovery performance and permeability damage in multilayer reservoirs after CO2 and water-alternating-CO2 (CO2-WAG) flooding at miscible pressures. Energy Fuels 34(1):624–636. https://doi.org/10.1021/acs.energyfuels.9b02786

Zhou X, Al-Otaibi F, Kokal S (2017) Investigation of relative permeability characteristics for supercritical CO2 displacing water and remaining oil after seawater flooding in carbonate rocks at reservoir conditions. In: SPE Middle East Oil and Gas Show and Conference, MEOS, Proceedings. https://doi.org/10.2118/183782-ms

Funding

There is no funding for this paper.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, X., Luo, Z., Liu, J. et al. Experimental evaluation of the water-based enhanced oil recovery methods in ultra-tight reservoirs. J Petrol Explor Prod Technol 13, 1911–1918 (2023). https://doi.org/10.1007/s13202-023-01655-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01655-w