Abstract

The main objective of net pay determination, as an important step of any reservoir study, is to exclude non-reservoir intervals so that better results are obtained from reservoir characterization, hydrocarbon in-place calculations, and dynamic flow simulation of the reservoir. This study is a comprehensive presentation of the most applicable methods available for net pay determination, highlighting their strengths, limitations, and their input data, and presenting a new procedure to prepare the input data, determine the reservoir net pay, and validate the final results. These methods include conventional best-fit line and quadrant methods in a porosity–permeability cross-plot, Worthington method, rules of thumb, cumulative hydrocarbon column plot, and production constraints. This study, unlike previous ones, presents a stepwise methodology to reach the correct answer considering both rock and fluid properties. The necessity for the definition of net pay is discussed in the current study in the first step. Determination of net pay and the net-to-gross ratio is done by definition of some cut-off values for petrophysical properties such as porosity, water saturation, and shale volume. The new procedure presented in this study as a flowchart to determine pay zone uses different methods to determine cut-off values. The sequential and systematic use of all these methods gives a consistent and more reliable answer. The key steps to determine net pay is to find the porosity cut-off based on a porosity–permeability cross-plot and a pre-defined limiting value for permeability and then to use this value to find the shale volume and water saturation cut-offs using their cross-plots versus porosity. To take into account the fluid properties effect, a mobility cut-off is used as the starting point instead of permeability. Cumulative hydrocarbon column plots are used as a sensitivity tool to determine what percentage of the hydrocarbons will be discarded by any cut-off value. Finally, the determined net pay should be validated using the results of production logging and wireline formation tests. The proposed methodology was applied to a real field to determine its net pay. Porosity and water saturation cut-offs were calculated to be 2% and 55%, respectively, and due to the clean nature of the reservoir, a shale volume cut-off was not necessary. Simultaneous application of porosity and water saturation cut-offs discarded 6.3% of the hydrocarbon column for the field example.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Determination of net pay and the net-to-gross ratio is an important step performed in any reservoir study. The main objective of net pay determination is to exclude non-reservoir intervals so that better results are obtained from reservoir characterization, hydrocarbon in-place calculations, and dynamic flow simulation of the reservoir.

Some specialists question the necessity for the definition of net pay. They argue that with modern 3D reservoir modeling, it is unnecessary or even unrealistic to discard poor-quality sections; as discarding poor-quality sections will affect the reservoir model from both static and dynamic points of view. When poor-quality sections are cut out, not only are the hydrocarbon volumes downgraded, but also the reservoir connectivity and dynamics are made unrealistic. However, the benefits of the net pay definition, i.e., exclusion of non-pay sections, outweigh these drawbacks. The first benefit of net pay is that it reduces upscaling bias (Lalanne and Massonnat 2004; Cosentino 2001). As Lalanne and Massonnat stated: “Relationships between porosity, permeability, and water saturation are basically nonlinear, which induces a bias between raw and upscaled petrophysical distributions. A practical way to limit this upscaling bias is to apply some cut-off by discarding the low PHI—high Sw vertical portion of the hyperbolae. This renders the grid much more petrophysically homogeneous hence reducing the upscaling bias”. Another reason for excluding the non-reservoir section is that the non-reservoir section usually distorts the predictive algorithms which are used for porosity, permeability, and saturation because the accuracy of these same algorithms is reduced if they are to be used for both reservoir and non-reservoir sections (Worthington and Cosentino 2005). One other benefit is hardware efficiency during dynamic modeling, which results in fast and cost-effective modeling (Schoeling and Mark 2000). Once non-pay sections are discarded from dynamic simulation, the numerical performance of the model is improved and the running time is reduced, while—if properly done—the overall accuracy of the results will be unaffected (Cosentino 2001). Another reason for the definition of net pay is that net pay is essential for the definition of the recovery factor because the recovery factor needs to be defined based on the recoverable sections of the reservoir rock, i.e., net pay. As Worthington (2008) stated “In order to assess the efficiency of reservoir recovery mechanisms, the initial hydrocarbon volume must relate to the reservoir rock. Where it does not, the hydrocarbons have little chance of being produced, they may not contribute to reservoir dynamics, and they should not be included within that accumulation volume against which recovery efficiency is to be assessed.” Moreover, net pay determination can be used in other parts of reservoir studies. For example, it can be used to determine the high productive intervals for infill drilling (Yeager et al. 1996), potentially productive intervals for well completion and stimulation (Kessler et al. 2000; Grieser et al. 2001), and to estimate permeability from well test analysis (Spivey and Pursell 1998).

Despite many years of being incorporated within reservoir studies, the main issue regarding net pay determination is that it is inherently subjective, probably the most subjective stage in a reservoir study workflow (Cosentino 2001). One reason for this subjectivity is the lack of a standard definition among different disciplines involved in reservoir studies. Worthington and Cosentino (2005) discussed this problem and recommended some definitions. They classified the rock thickness based on porosity/permeability, water saturation, and shale volume cut-offs. According to their definition, “Gross rock” is the total thickness of the evaluation interval. “Net sand” is part of the rock that is clean, which is determined using shale volume cut-off. “Net reservoir” is part of the rock that is productive and has storage capacity. This can be determined based on the porosity/permeability cut-off. “Net pay” is part of the rock that contains sufficient hydrocarbons, which is defined based on the water saturation cut-off.

Another source of subjectivity is the lack of a standard methodology for net pay determination. Net pay intervals are generally determined by defining some cut-off values for petrophysical parameters related to hydrocarbon storage and flow capacity of the rock. Cut-off parameters can be porosity, water saturation, shale volume, pore size, permeability, mobility, formation resistivity, and movable hydrocarbon. Different combinations of these parameters with different cut-off values have been found in the literature. Therefore, the questions are: which parameters should be taken as the cut-off parameter? And by which method should one arrive at the cut-off value?

Some authors recommended that the reason for defining a net pay should be considered for cut-off determination, hence the need for fit-for-purpose cut-offs. Snyder (1971) classified the main usages of net pay determination as volumetric calculation of hydrocarbon in place, material balance calculations, drilling studies, and enhanced oil recovery studies. Vavra et al. (1992) and Cobb and Marek (1997) studies showed that cut-off determination should depend on reservoir production mechanisms: for natural depletion, absolute permeability is important while for water-flooding, relative permeability end-points are important. Reservoir rock and fluid type can also affect these cut-off values. For example, cut-off values are lower in a gas reservoir compared to an oil reservoir, due to lower viscosity and higher compressibility (Cobb and Marek 1997).

A wide variety of methods is found in the literature regarding net pay determination. Masoudi et al. (2011, 2012, 2014a, b) and Egorov et al. (2019) used machine learning methods to find the net pay. In all these machine learning methods, well test results are used for training the algorithm which has lower resolution compared with petrophysical log data. Harfoushian and Suriyanto (2016) used formation tester results to find the net pay. They used measured in situ porosity and effective permeability during the test to find the cut-off values. Yang et al. (2019) determined the permeability and porosity cut-off values using core descriptions, thin section analyses, porosity and permeability test, mercury injection analyses, and well test data in a low permeability reservoir. To find the cut-off values, they considered the economic benefits and a balance between the cost and income for different oil prices. Skalinski et al. (2019) presented a new method of cutoff determination in carbonates using NMR logging based on the definition of T2 cut-off which is determined normally in the core laboratories. Al Jawad and Tariq (2019) provide insight into the application of the regression line method by applying two types of linear regressions: Least square and Reduce Major Axis Regression in estimating porosity, clay volume, and water saturation cutoff values in Mishrif reservoir/ Missan oil fields as a case study. Qassamipour et al. (2020) present a new methodology to find a logical permeability cut-off for gas reservoirs which can differ for different wells and/or fields. This technique is based on gas flow through porous media in tight rocks. Qassamipour et al. (2021) presented a new methodology for cut-off determination based on the estimated production profile in the reservoir interval using the predicted permeability distribution. They defined a hydrocarbon rate limit to find the net pay. Malik et al. (2021) presented a new method to directly determine the net pay from mudlogging data and mud gas systems, without defining cut-off values in low-permeability reservoirs where traditional log analysis is challenging. Shi et al. (2022) presented a method to determine the reservoir net pay by production logging and conventional logs in a granite fractured reservoir. The novelty of this study was the successful application of PLT logging in reserve estimation. Cahyaningati et al. (2021) presented the impact of gamma-ray normalization on net calculation by using petrophysical log data. The net pay calculation was carried out with and without normalization in the study. If the net pay value using normalization is compared to the net pay value before normalized, then the normalized value is optimized by more than 5%, which is a good amount of optimization. Thus, the results showed that to obtain an optimistic net pay value, normalization must be done. Another method for net pay determination is the analysis of pore throat size so that a correlation is found between this parameter and porosity/permeability. Once the correlation is found, a cut-off value for pore throat size can be used to arrive at a porosity/permeability cut-off. Since pore throat size distribution is normally determined by the MICP test (Mercury injection capillary pressure), this method does not take into account the effect of reservoir fluid type and rock-fluid interactions; thus the results may be misleading (Saboorian-Jooybari 2017). May (2009) used relative permeability curves and the fractional flow concept to determine water saturation cut-off: Production operation is normally constrained by a water cut limit; this water cut limit can correspond to a limiting water saturation—i.e., a water saturation cut-off—using fractional flow curves. May (2009) also proposed the crossing point of the relative permeability curve as an indication of water saturation cut-off; however, this method does not consider the fluid viscosities and thus can yield conservative water saturation cut-off especially when water viscosity is higher than oil viscosity. It must be noted that the methods proposed by May (2009) seem to be only applicable to reservoirs that have undergone water flooding. In green fields with reservoirs under natural depletion, such a water-cut constraint is not necessary.

Porosity, water saturation, and shale volumes are the parameters that are most commonly used in the industry for the net pay definition. The most common procedure to determine the net pay is to find the porosity cut-off using a porosity–permeability cross-plot and a pre-defined limiting value for permeability. This porosity cut-off value is then used to find the shale volume and water saturation cut-offs, using their cross-plots versus porosity. In this method, a porosity–permeability cross-plot is generated using experimental core analysis data, while shale volume-porosity and water saturation-porosity cross-plots are derived from petrophysical logs. To achieve better results, the porosity–permeability cross-plot could be categorized based on rock typing results, so that the starting permeability cut-off yields a different porosity cut-off value for each rock type. For example, the hydraulic flow unit concept (Amaefule et al. 1993) can be used to classify reservoir rock into several rock types. This will lead to a better correlation between porosity and permeability in each rock type, and thus more accurate cut-off values. The main challenge of using rock type-based cut-off values is that rock typing per se is a subjective task. Moreover, many rock type definitions, such as hydraulic flow unit, require permeability prediction in uncored areas of the reservoir, which in itself is a source of uncertainty.

The staring permeability cut-off can be determined by some rules of thumb which are based on the experiences in typical oil and gas reservoirs (Holtz and Hamilton 1998; Worthington et al. 2002). Alternatively, the permeability cut-off can be calculated from a mobility cut-off after applying the in situ fluid viscosity. The mobility cut-off is usually determined by rules of thumb. Moreover, Saboorian-Jooybari (2017) presented a method to determine the mobility cut-off based on Darcy’s Law and introduced an economic-rate constraint.

Although different articles have been published on this subject, each publication focuses on a specific method without considering the advantages, disadvantages, and uncertainties of input data, methodology, and results. No systematic and comprehensive methodology is presented that discusses the necessity for the definition of net pay and considers all available data and most engineers are not well-familiar with different methods. In the oil industry, it is used to utilize these techniques wrongly which results in wrong decisions. Verification methods like the hydrocarbon column technique are sometimes used as a method to determine cut-off values. This study presents a stepwise methodology to reach the correct answer considering both rock and fluid properties. Using mobility as the starting point and correct verification methods by considering the strengths and limitations of each method and input data are focused on in this study.

Net pay calculation methods

Several approaches have been offered for net pay determination. In all these methods some cut-off values are defined for reservoir parameters, based on which the formation can be divided into pay and non-pay sections.

Porosity–permeability cross-plot

In this method, core data are used to construct a porosity–permeability cross-plot, from which the porosity cut-off can be obtained. Once a porosity cut-off is found, other cross-plots (usually water saturation and shale volume versus porosity) can be used for determining saturation and shale volume cut-offs. Therefore, the key step in this method is to obtain the porosity cut-off from a porosity–permeability cross-plot. In the following sections, the methods proposed for determining the porosity cut-off from a porosity–permeability cross-plot are discussed.

Best-fit line method

This is the traditional method most commonly used in the industry. The first step in this approach is to assume a minimum permeability, below which the reservoir is not capable of flowing hydrocarbons. Therefore, rock sections below this permeability cut-off are considered to be non-pay; and the rock sections at or above this cut-off value are considered to be net pay. Table 1 shows the permeability cut-off values which are commonly used as rules of thumb.

It must be noted that, based on Darcy’s Law, in addition to rock permeability, fluid flow in porous media is also a function of fluid viscosity. Therefore, it would be more accurate to consider in situ viscosity in defining the permeability cut-off value. In other words, because of its smaller fluid viscosity, the permeability cut-off value for a gas reservoir must be smaller than a light-oil reservoir; and the value for a light-oil reservoir must be smaller than a heavy oil reservoir. Some authors thus suggested that a mobility (K/μ) cut-off of 1.0 mD/cP be used for both oil and gas reservoirs, instead of permeability (Saboorian-Jooybari 2017; Cobb and Marek 1998). This value can then be converted to permeability cut-off using the in situ viscosity value. Saboorian-Jooybari (2017) also presented a method to find the mobility cut-off based on Darcy’s Law and using an economic-rate constraint. Since this method is based on Darcy’s Law, the dominant flow regime needs to be in a pseudo-steady state and the reservoir must be homogenous; however, the pseudo-steady state flow regime does not prevail in exploration and production wells of green fields, and the assumption of homogenous reservoir conditions is not valid for many reservoirs including fractured or layered reservoirs where the reservoir pressure and drainage radius are different for each layer and well (Qassamipour et al. 2021).

Once the permeability cut-off value is assumed, the porosity cut-off is obtained from the permeability versus porosity function. This function can be obtained either by a simple regression method or a more advanced percentile method proposed by Delfiner (2007). To find a better correlation between porosity and permeability, core data could be first categorized based on lithology, reservoir zonation, or rock type, and then the correlation of each category is determined separately. When porosity cut-off has been found, this method can be similarly applied to define water saturation and shale volume cut-offs using their cross-plots versus porosity.

Quadrant method

Jensen and Menke (2006) proposed a probabilistic approach for porosity cut-off determination. Similar to the best-fit line method, in this method it is assumed that the permeability cut-off has already been established and we want to find the “best” value of the porosity cut-off. They used a probabilistic approach to analyze the accuracy and errors in the prediction of various porosity cut-off values from a porosity–permeability cross-plot. They defined four regions based on the cross-plot of log(K) versus φ (Fig. 1):

-

Region A: K < Kc and φ < φc: non-pay region correctly identified

-

Region B: K > Kc and φ < φc: pay region incorrectly identified as non-pay

-

Region C: K < Kc and φ > φc: non-pay region incorrectly identified as pay

-

Region D: K > Kc and φ > φc: pay region correctly identified.

Regions A and D represent correct identifications of non-pay and net-pay. Regions B and C correspond to erroneous non-pay and net-pay identifications (Jensen and Menke 2006)

The probability of incorrect identification depends on the quantity of data in Region B and Region C. Thus the best value of φc is the value for which:

-

The probability of having data points in regions B or C (i.e., Prob(B) + Prob(C)) is minimized

-

The probability of having data points in regions B and C are equal, i.e., Prob(B) = Prob(C)

In addition to its computational difficulties, a limitation of this approach is that it is sensitive to errors and the number of data points available: An erroneous value for the porosity cut-off is probable in data sets with less than 100 points (Bouffin 2007).

Worthington method

Worthington (2008) proposed using a bilinear cross-plot of equivalent circular pore diameter (K/φ)0.5 versus porosity, to find the onset of reservoir characters, i.e., the porosity above which (K/φ)0.5 is significant (Fig. 2). Note that this approach avoids the more familiar plot of porosity versus permeability.

An example of a Porosity–permeability data used for generating, b a plot of porosity versus equivalent circular pore diameter (Worthington 2010)

Rules of thumb and analog cut-off

If a porosity–permeability cross-plot is not available, cut-offs can be obtained from analogous or nearby reservoirs and fields with core data or from rules of thumb. Some rules of thumb for porosity, saturation, and shale volume cut-offs are shown in Tables 2, 3.

Cumulative hydrocarbon column percentage

In this method, the cumulative hydrocarbon column is plotted as a function of the petrophysical property for which the cut-off is to be determined, i.e., porosity, water saturation, and shale volume.

Hydrocarbon in place for a unit volume of each logged interval is calculated as:

These hydrocarbon-in-place data are then sorted based on the petrophysical property for which the cut-off is to be determined. The cumulative hydrocarbon column for each point is the summation of hydrocarbon in place of all intervals up to the point.

The cut-off value is considered to be the elbow point of the curve i.e. the threshold point beyond which the contribution to hydrocarbon storage is not significant (Geoloil 2016). When a single cut-off system should be used for the whole reservoir, this method is modified to compute the original oil in place (OOIP) of the whole reservoir, instead of the hydrocarbon column per well (Geoloil 2016). Alternatively, collective data from all wells can be used to produce a single curve. These plots are also useful as a sensitivity tool for analyzing the effect of any cut-off and determining what percentage of the hydrocarbons will be discarded by any cut-off value.

Cut-off determination methodology

The input data for net pay determination depend on the method of analysis. As described in “Introduction” Section, some proposed methods in the literature use specific data like advanced logs, mud logs, thin sections, and pore size distribution. However, the main and most common input data for net pay determination are log data, core data, and production test data. Porosity and water saturation from log data are used directly for cut-off determination. Moreover, other log data are used for permeability estimation, if necessary, in some methods. Lithology log data are also used for net pay determination if rock typing is used. Core data including RCAL and SCAL data are also used for net pay determination. Production data and production logging and wireline formation test data are also used for cut-off determination and validation of final analysis results. Besides these data, a complete reservoir description using static and dynamic data are useful to find the best method of net pay determination.

Regarding different methods to determine cut-off values for porosity, water saturation, and shale content, the following procedure is proposed to determine reservoir net pay:

-

1.

Determine the mobility cut-off for the reservoir

-

2.

Calculate the permeability cut-off based on fluid viscosity.

-

3.

Calculated the porosity cut-off using the following methods:

-

Porosity–Permeability cross-plot

-

Best-fit line method

-

Quadrant method

-

-

Worthington method

-

Rules of thumb

-

Cumulative hydrocarbon method

-

-

4.

Determine the porosity cut-off considering the values obtained from each method, the percentage of the hydrocarbons discarded by each value, and other facts such as input data quality, reservoir conditions, and reservoir simulation model to be used.

-

5.

Calculate the water saturation and shale volume cut-offs using the following methods:

-

Cross-plots of SW versus PHI and Vsh versus PHI

-

Rules of thumb

-

Cumulative hydrocarbon method

-

-

6.

Determine the water saturation and shale volume cut-offs considering the values obtained from each method, the percentage of the hydrocarbons discarded by each value, and other facts such as input data quality, reservoir conditions, and reservoir simulation model to be used.

-

7.

Evaluate the combined effect of cut-off values on the discarded percentage of the hydrocarbons.

-

8.

Determine the final values of cut-offs and identify the net pay.

-

9.

Validate the final net pay with production logging test results if the evaluated interval is the open hole. It is expected that the defined net pay corresponds to the reservoir intervals with sufficient hydrocarbon storage and productivity. Mobility data from wireline formation tests could also be used for validation.

A flowchart of this cut-off determination methodology is illustrated in Fig. 3. To illustrate the validity of the proposed procedure, we applied the procedure to a field example.

Field example

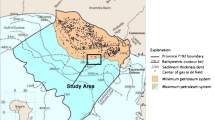

Field X contains two carbonate oil reservoirs located in the West of Iran. Eight wells have been drilled in this field, to have a commingled production from these reservoirs. This structure is a thrust belt which is mainly developed during Oligo-Miocene. The reservoir thickness is about 1150 ft. The difference between the fluid properties of these reservoirs is not significant.

Geological setting

Field X contains two carbonate oil reservoirs. The main reservoirs within the field belong to the Albian-Turonian-aged formation M. This formation contains two separate reservoirs M1 and M2, which are separated with a sealed shale layer. The average porosity and permeability of reservoir M1 are 6.5% and 2.3 mD, respectively. For reservoir M2, these values are 9.5% and 3.5 mD. A plot of the stratigraphic column of this field is shown in Fig. 4. As illustrated in the figure, the main lithology of the reservoir is limestone.

Available data and net pay determination

Core data from 4 wells are available in formation M of Field X. Table 4 shows a summary of all core data available in this field. In addition to the core data, petrophysical log interpretations are available for drilled wells and used for cut-off determination.

The first step was the determination of the porosity cut-off. Several methods were investigated in this study for the determination of porosity cut-off in this oil field. First, the methods which are based on porosity–permeability cross-plot-i.e. Best-fit line, and Quadrant methods—were examined. Worthington’s method was then investigated. After that, the cut-off was estimated based on rules of thumb in carbonate reservoirs (Table 2). Finally, the cut-off was investigated based on the elbow point on the cumulative hydrocarbon column percentage plot (Fig. 5). After the porosity cut-off was concluded, water saturation and shale volume cut-offs were obtained. Several methods were considered for these cut-offs, namely, cross-plots, rules of thumb, and elbow points on cumulative hydrocarbon column percentage.

The cumulative hydrocarbon percentage method was also used as a tool for making a sensitivity analysis of the effect of each proposed cut-off value. The cumulative hydrocarbon column percentage was plotted as a function of porosity, water saturation, and shale volume for all wells (Figs. 5, 6 and 7). As shown in these figures, the curves on each plot differ from one well to another. Because a single cut-off system is to be used for the whole reservoir, these plots were regenerated using the data from all wells collectively (Figs. 8, 9 and 10). These curves function as an average of cumulative hydrocarbon column percentage over the field, and thus they were used in this study for sensitivity analysis.

Results and discussion

Porosity cut-off

As discussed in the previous section, the first step in cut-off determination is the determination of the porosity cut-off. This was done by five methods: best-fit line, quadrant, Worthington, rules of thumb, and cumulative hydrocarbon column percentage methods. Each of these methods is discussed separately in the following sections.

Best-fit line method

The first method was the conventional best-fit line in a porosity–permeability plot. In this method, a porosity–permeability cross-plot was generated using all RCAL data available (Table 4). Once the cross-plot was produced, the correlation between porosity and permeability was generated using the method proposed by Delfiner. This correlation is shown in Cartesian and semi-log plots in Figs. 11, 12.

As discussed in “Porosity-permeability cross-plot” Section, mobility (K/μ) of 1.0 mD/cP was considered as the cut-off value. Since the reservoir is naturally fractured and has had no extensive production, the method proposed by Saboorian-Jooybari (2017) is not recommended for mobility cut-off determination, as discussed in “Best-fit line method” Section. Based on the PVT properties of this field, which are based on the surface samples in well No.1, in situ oil viscosities in M1 and M2 are about 0.41 cP and 0.59 cP, respectively. Considering the mobility (K/μ) cut-off of 1.0 mD/cP, these viscosity values yield permeability cut-offs between 0.4 and 0.6 mD. These values are in agreement with the lower limit of the rules of thumb shown in Table 1.

As shown in Fig. 12, these permeability cut-offs correlate with porosity cut-offs of around 6.5% to 7.3%. A comparison of these values with the rules of thumb in carbonate reservoirs (Table 2) indicates that these values are pessimistic. The cumulative hydrocarbon plot also reveals that if these porosity cut-offs are applied, around 27.3–33.9% of hydrocarbon will be discarded (Fig. 8).

Moreover, it must be noted that the permeability values used in the porosity–permeability plot are (absolute) air permeability, and have not been corrected for effective reservoir stress. Therefore, these values are generally larger than the effective oil permeability at reservoir conditions. This means that if corrected permeability data were used, even larger values for porosity cut-offs would be obtained.

Best-fit line method thus seems to overestimate the porosity cut-off, resulting in a too-conservative porosity cut-off value.

Quadrant method

As discussed in “Quadrant method” Section, the Quadrant method is a probabilistic method to analyze the error and accuracy in the prediction of various porosity cut-offs from a porosity–permeability cross-plot using an assumed permeability cut-off. Four regions (Region A–D) are defined on a porosity–permeability cross-plot; the probability of incorrect identification depends on the quantity of data in Region B and Region C, i.e., regions with erroneous non-pay and net-pay identifications. The best value for porosity cut-off is the value for which the probability of having data points in regions B or C is minimized, and the probability of having data points in regions B and C is equal. Therefore, the best value for porosity cut-off is the value for which two functions are minimized: “Prob(B) + Prob(C)” and “Abs (Prob(B) − Prob(C))”. As discussed in “Best-fit line method” Section, considering mobility (K/μ) cut-off of 1.0 mD/cP, in situ viscosity values yield permeability cut-offs around 0.4–0.6 mD. Figures 13, 14 show the two functions versus porosity cut-offs for 0.4 mD and 0.6 mD permeability cut-offs. As shown in Fig. 13, for a permeability cut-off of 0.4 mD, “Prob(B) + Prob(C)” is minimized in a porosity interval between 6 and 12.5%, while “Abs (Prob(B) − Prob(C))” is minimized around 5.5% porosity. For a permeability cut-off of 0.6 mD (Fig. 14), “Prob(B) + Prob(C)” is minimized in a porosity interval between 6 and 12.5%, while “Abs (Prob(B) − Prob(C))” is minimized around 6% porosity.

Because “Abs (Prob(B) − Prob(C))” shows more distinct minimum values, which are also in agreement with the minimum interval of “Prob(B) + Prob(C)”, these minimum values were considered as porosity cut-off. Therefore, a porosity cut-off of around 5.5–6% is concluded from this method. The cumulative hydrocarbon plot reveals that if this porosity cut-off range is applied, 20.0–23.5% of hydrocarbon will be discarded (Fig. 8).

It must be noted that this method is only a variation of the Best-fit line method, and thus their results are in agreement. That is the reason why, similar to the best-fit line method, the Quadrant method overestimated the porosity cut-off, resulting in a too-conservative porosity cut-off value.

Worthington method

As discussed in “Worthington method” Section , Worthington proposed a bilinear cross-plot of equivalent circular pore diameter (K/φ)0.5 versus porosity to find the onset of reservoir characters. Figure 15 shows this plot for available core data. As shown in the figure, the onset of pore diameter is observed around 1–2% porosity (red band in Fig. 15); and for porosities below 1%, the pore diameter is insignificant. A comparison of these values with the rules of thumb in carbonate reservoirs (Table 2) indicates that this cut-off value is slightly optimistic, i.e., smaller than the commonly used rules of thumb. The cumulative hydrocarbon plot reveals that if this porosity cut-off range is applied, only 0.2–1.8% of hydrocarbon will be discarded (Fig. 8).

An upside of this method is that the extracted porosity cut-off is not very sensitive to the type of permeability used. In other words, almost the same result would be obtained if corrected effective oil permeability data were used for the generation of this plot.

Rules of thumb for porosity cut-off

As discussed in “Rules of thumb and analog cut-off” Section, as a rule of thumb, a porosity cut-off of around 2–4% is common for oil-bearing carbonate reservoirs. The cumulative hydrocarbon plot shows that if this porosity cut-off range is applied, 1.8–10.6% of hydrocarbon will be discarded (Fig. 8).

Cumulative hydrocarbon column percentage

Figure 5 shows the cumulative hydrocarbon column percentage versus porosity for individual wells. Figure 8 shows the same plot for the collective cumulative hydrocarbon percentage. As can be seen, in both individual and collective curves, the elbow points are around 2% porosity. As shown in Fig. 8, this porosity cut-off discards around 1.8% of hydrocarbon.

Discussion on porosity cut-off

Table 5 summarizes the results of porosity cut-off determination in Field X using various methods. Before making judgments about the value of porosity cut-off, it must be reminded that based on available data it is assumed that this field is a naturally fractured reservoir (NFR). The traditional approach to identifying cut-off values with matrix permeability does not work in fractured reservoirs (Aguilera 1995). Aguilera discussed this in detail in a technical note: “If there is natural fracturing around the wellbore that extends throughout a large portion of the reservoir, the matrix area exposed to the fractures can become quite significant. In this case, the product of the large area times the small permeability can allow very efficient hydrocarbon flow from matrix to fractures and then to the wellbore, constituting what is usually known as a dual porosity reservoir.” “A matrix permeability of 0.01 mD is not capable, in general, of contributing commercial production into a wellbore because of the small surface area of the matrix exposed to the wellbore. However, the same 0.01 mD matrix permeability can allow a very efficient flow of hydrocarbons from the matrix into a well-developed system of natural fractures.” Moreover, he argued that other things being equal, the amount of natural fracturing increases as the porosity and permeability of rock decrease. He concluded that it is better not to use porosity and permeability as cut-off criteria in NFRs. He suggested that other criteria such as water saturation and shale content be used as more reasonable criteria for pay determination. Aguilera’s argument is rational especially when a fractured reservoir is to be simulated by a single porosity reservoir simulation model. However, defining a porosity cut-off still has some advantages such as reducing upscaling bias, and hardware efficiency during dynamic modeling. It was, therefore, decided that a porosity cut-off be defined in this field, however, the value should be kept small so that pay zones are not mistakenly overlooked.

As shown in Table 5, the best-fit line method yielded too large porosity cut-offs. This is because the best-fitted line is almost flat for φ < 10%. This results in a large porosity cut-off value which discards a large proportion of the reservoir. The Quadrant method, which is similarly based on a porosity–permeability cross-plot, also yielded large porosity cut-offs. Based on the discussion above, these cut-off values were not used.

Rules of thumb are considered to be usually pessimistic, especially when horizontal wells or hydraulic fracturing are concerned (Baker et al. 2015). So these rules of thumb can show the upper limit for our cut-off value.

Worthington seemed to be the best method for cut-off determination due to several reasons: First, the methodology observes the fact that small porosities should not be overlooked in carbonate reservoirs because in this method we look for the onset of pore diameter at small porosities. Second, the results are in good agreement with the aforementioned idea that a small porosity cut-off should be defined in Field X. Third, the range proposed by this method is less than the rules of thumb which are known to be pessimistic and agrees with the value obtained from the elbow point on cumulative hydrocarbon column plot. Finally, the porosity cut-off obtained from this method is not very sensitive to the type permeability used, i.e., almost the same result would be obtained if either corrected effective oil permeability or air permeability is used. It was therefore decided that the upper limit, i.e., 2% be considered as the concluding porosity cut-off so that the results are not too optimistic. By applying this 2% porosity cut-off, 1.8% of the hydrocarbon column is discarded.

Water saturation cut-off

Water saturation-porosity cross-plot

Figure 16 shows a plot of water saturation versus porosity based on petrophysical log data in all wells. Because the data were too scattered, an average cross-plot (Fig. 17) was generated the same way as a porosity–permeability cross-plot is generated by Delfiner’s method. As shown in the figure, the 2% porosity cut-off corresponds to a water saturation cut-off of 62%. If this 62% water saturation cut-off is applied individually, 2.4% of hydrocarbon is discarded (Fig. 9).

It must be noted that water saturation values obtained from the petrophysical evaluation are uncertain in low porosity intervals. In other words, the cross-plot shown in Fig. 16 could be different in low porosity values if a different water saturation model was used. Given the low porosity cut-off value considered in this study (i.e., φc = 2%), it was concluded that the water saturation cut-off obtained from this method carries a large degree of uncertainty.

Rules of thumb for water saturation cut-off

As discussed in “Rules of thumb and analog cut-off” Section, as a rule of thumb, a water saturation cut-off of around 50% is common for oil-bearing reservoirs. The cumulative hydrocarbon plot versus water saturation shows that if this saturation cut-off is applied, 9.4% of hydrocarbon will be discarded (Fig. 9).

Cumulative hydrocarbon column percentage

Figure 6 shows the cumulative hydrocarbon column percentage versus water saturation for individual wells. Figure 9 shows the same plot for the collective cumulative hydrocarbon percentage. As can be seen, in both individual and collective curves, the elbow points are around 50–60%. As shown in Fig. 9, this water saturation cut-off range discards around 2.9–9.4% of hydrocarbon.

Discussion on water saturation cut-off

Table 6 summarizes the results of water saturation cut-off determination in Field X using various methods. The water saturation-porosity cross-plot method, which uses a previously obtained porosity cut-off, seems to be the most systematic. However, as discussed in 6.2.1, this method carries a large degree of uncertainty due to the uncertainty in water saturation of low porosity intervals. It was, therefore, decided that the 62% cut-off value obtained from this method should be of secondary importance in our final decision on the water saturation cut-off. Based on the rules of thumb, a smaller value, i.e., 50% is proposed for the water saturation cut-off. The elbow point of the cumulative hydrocarbon column plot also confirms that the water saturation cut-off is around 50–60%. A cut-off value of 55% was thus considered as the water saturation cut-off in this study. This value is also in agreement with the value suggested by Aguilera: in his technical notes on NFRs, Aguilera suggested saturation cut-offs in the order of 55%.

If this 55% water saturation cut-off is applied individually, 5.1% of hydrocarbon is discarded (Fig. 9). However, a fraction of this has already been discarded by applying the porosity cut-off. Figure 18 shows the collective cumulative hydrocarbon percentage versus water saturation for all wells, after applying the 2% porosity cut-off. As shown in the figure, when a 55% water saturation cut-off is applied after applying the 2% porosity cut-off, 4.6% of the remaining hydrocarbon is discarded. Simultaneous application of porosity and water saturation cut-offs discards 6.3% of the hydrocarbon column. Figure 19 shows the effect of the combination of these two cut-offs (φc = 2% and Swc = 55%) compared to other combinations. As shown in the figure, as the porosity cut-off increases and the water saturation cut-off decreases, more hydrocarbon is discarded. In the most pessimistic case (φc = 4% and Swc = 50%), 17.1% of hydrocarbon is discarded and in the most optimistic case (φc = 2% and Swc = 60%), only 4.2% of hydrocarbon is discarded. It must be noted that water saturation cut-off should not be applied in the transition zone in a reservoir simulation grid model (Geoloil 2016), because higher water saturations in this zone can be due to capillary effects.

Shale volume cut-off

Shale volume-porosity cross-plot

Figure 20 shows a plot of shale volume versus porosity based on petrophysical log data in all wells. Because the data were too scattered, an average cross-plot (Fig. 21) was generated the same way as a porosity–permeability cross-plot is generated by Delfiner’s method. As shown in the figure, the 2% porosity cut-off corresponds to 3.5% shale volume. However, this shale volume cut-off is too low to be applied. The reason behind this low shale volume cut-off is that formation M is a clean reservoir rock. The cumulative hydrocarbon plot versus shale volume shows that if this shale volume cut-off is applied, 32.3% of hydrocarbon will be discarded (Fig. 10).

Rules of thumb for shale volume cut-off

As discussed in “Rules of thumb and analog cut-off” Section, as a rule of thumb, a shale volume cut-off of around 50% is common for oil-bearing reservoirs. Due to the clean nature of formation M, this cut-off value has no significant effect on pay definition. The cumulative hydrocarbon plot versus shale volume shows that if this cut-off is applied, no significant fraction of hydrocarbon will be discarded (Fig. 10).

Cumulative hydrocarbon column percentage

Figure 7 shows the cumulative hydrocarbon column percentage versus shale volume for individual wells. Figure 10 shows the same plot for the collective cumulative hydrocarbon percentage. As it can be seen, in both individual and collective curves, the elbow points are around 1–9%, beyond which no significant hydrocarbon exists. As shown in Fig. 10, this shale volume cut-off range discards around 2.5–71.1% of hydrocarbon.

Discussion on shale volume cut-off

Table 7 summarizes the results of shale volume cut-off determination in Field X using various methods. The shale volume-porosity cross-plot and cumulative hydrocarbon column methods both yielded unrealistically low shale volume cut-off values. This is due to the clean nature of formation M. Figure 22 shows the histogram of shale volume based on petrophysical log interpretations in all wells. The figure clearly shows that the number of points with shale volume greater than 20% is insignificant. Therefore, it was decided that no shale volume cut-off is necessary for the field. Alternatively, one can apply the 50% cut-off value which is common as a rule of thumb (Table 3). However, applying this cut-off does not have any effect on the percentage of hydrocarbon discarded.

Net pay determination and validation

Using the calculated cut-off values for porosity (2%) and water saturation (55%), net pay is determined in each well using well-log data. For each well, NTG was calculated and its value will be used for other parts of the reservoir study like well test analysis. Figure 23 shows the determined net pay in a well of Field X as an example. As the reservoirs are fractured and all wells are cased-hole, it was not possible to validate the results by production logging and wireline formation tests.

The proposed methodology in this study which is used for the field example is a systematic and comprehensive methodology that considers all available data. Verification methods like hydrocarbon column are used to approve the final results. This study proposes a stepwise methodology as a flowchart to reach the correct answer considering both rock and fluid properties. The input data and the available methods for each step are defined in the flowchart. However, the limitation of each method described in “Net pay calculation methods” Section should be considered when using it for a real field. For example, the calculation of the Quadrant Method is difficult or it is sensitive to errors and the number of available data points, the method of Saboorian-Jooybari (2017) to find the mobility cut-off is limited to pseudo-steady state conditions and homogenous reservoirs, etc.

Quality and availability of key data like log data and core data are very important for cut-off determination and may limit the proposed procedure to reach the correct answer. Moreover, reservoir conditions like significant heterogeneity, complex dive mechanisms, and using IOR methods may affect the final results. Considering all facts such as all available data and the reservoir simulation model to be used are necessary to reach the correct answer for these reservoirs.

Conclusions

-

A new methodology for net pay determination is presented in this study.

-

This methodology considers different methods to determine porosity, water saturation, and shale volume cut-offs.

-

The most applicable methods for net pay determination are considered highlighting their strengths, limitations, and their input data and a new procedure to validate the final results.

-

This study, unlike previous ones, presents a stepwise methodology to reach the correct answer considering both rock and fluid properties.

-

The key step for the net pay determination is to find the porosity cut-off based on a pre-defined limiting value for permeability.

-

To consider the fluid properties, a mobility cut-off is used as the starting point, from which the permeability cut-off is calculated.

-

Shale volume and water saturation cut-offs are determined using the determined porosity cut-off.

-

Cumulative hydrocarbon column plots are used to determine what percentage of the hydrocarbons will be discarded by any cut-off value.

-

The determined net pay should be validated using the results of production logging and wireline formation tests.

-

Cut-offs are determined by considering the values obtained from different methods, the percentage of the hydrocarbons discarded for each cut-off value, and other facts available such as input data quality, reservoir conditions, and reservoir simulation model to be used.

-

This methodology was applied for a real field example:

-

Porosity, water saturation, and shale volume cut-offs were determined for the field example by using different methods (Tables 5, 6 and 7).

-

Porosity and water saturation cut-offs were calculated to be 2% and 55%, respectively. Due to the clean nature of formation M, shale volume cut-off was not necessary.

-

Simultaneous application of porosity and water saturation cut-offs discarded 6.3% of the hydrocarbon column for the field example.

-

As the reservoirs are fractured and all wells are cased-hole, it was not possible to validate the results by production logging and wireline formation tests.

-

Abbreviations

- K :

-

Permeability, mD

- K c :

-

Permeability cut-off, mD

- S W :

-

Water saturation, % or fraction

- Swc :

-

Water saturation cut-off, % or fraction

- V sh :

-

Shale volume, % or fraction

- PHI, φ :

-

Porosity, % or fraction

- φ c :

-

Porosity cut-off, % or fraction

- μ :

-

Viscosity, cp

- o :

-

oil

- w :

-

water

References

Aguilera R (1995) Naturally fracture reservoirs, 2nd edn. Pennwell Corp, Oklahoma

Al Jawad MS, Tariq BZ (2019) Estimation of cutoff values by using regression lines method in Mishrif reservoir/ missan oil fields. J Eng 25(2):82–95

Amaefule JO, Altunbay M, Tiab D, Kersey DG, Keelan DK (1993) Enhanced reservoir description: using core and log data to identify hydraulic (Flow) units and predict permeability in uncored intervals/wells. In: Presented at the SPE annual technical conference and exhibition, Houston, Texas, 03 October. https://doi.org/10.2118/26436-MS

Baker RO, Yarranton HW, Jensen J (2015) Practical reservoir engineering and characterization, 1st edn. Gulf Professional Publishing, Houston. https://doi.org/10.1016/C2011-0-05566-7

Bouffin N (2007) Net pay evaluation, a comparison of methods to estimate net pay and net-to-gross ratio using surrogate variables. M.Sc. Thesis, Texas A&M University, USA

Cahyaningati WP, Mariyanto M, Lestari W et al (2021) Effect of gamma-ray normalization on net pay calculation, a case study of “PE” field, central Sumatra basin. Ser J Phys Conf. https://doi.org/10.1088/1742-6596/1876/1/012024

Cobb WM, Marek FJ (1998) Net pay determination for primary and waterflood depletion mechanisms. In: Presented at the SPE annual technical conference and exhibition, New Orleans, 27–30 September. SPE-48952-MS. https://doi.org/10.2118/48952-MS

Cosentino L (2001) Integrated reservoir studies. Fundamentals of exploration and production series. Editions Technip, Paris

Delfiner P (2007) Three statistical pitfalls of Phi-K transforms. SPE Res Eval Eng 10(6):609–617. https://doi.org/10.2118/SPE-102093-PA

Egorov DV, Sabirov AR, Osmonalieva OT at al (2019) Applying machine learning methods to search for missing net pay zones in mature oilfields wells. In: Presented at the SPE Russian petroleum technology conference, Moscow, Russia, 22 October. https://doi.org/10.2118/196869-MS

Geoloil (2016) How to compute petrophysicals cutoffs with geoloil. http://www.geoloil.com/petroCutoffs.php. Accessed 18 Jun-2016

Grieser B, Hill B, Brinska J, Stout R (2001) Zone selection and production prediction using advanced logging technology. In: Presented at the SPE production and operations symposium, Oklahoma City, Oklahoma, 24 March. https://doi.org/10.2118/67198-MS

Harfoushian JH, Suriyanto O (2016) Net pay cutoff determination using in-situ permeability measurements with advanced formation testers. In: Presented at the SPE Asia Pacific oil & gas conference and exhibition, Perth, Australia, 25 October. https://doi.org/10.2118/182419-MS

Holtz MH, Hamilton DS (1998) Reservoir characterization methodology to identify reserve growth potential. In: Presented at the international petroleum conference and exhibition of Mexico, Villahermosa, Mexico, 3–5 March, SPE-39867-MS. https://doi.org/10.2118/39867-MS

Jensen JL, Menke JY (2006) Some statistical issues in selecting porosity cutoffs for estimating net pay. SPWLA-2006-v47n4a3, Petrophysics 47(4)

Kessler C, Frisch G, Ron H, Stegent N (2000) New petrophysical process improves reservoir optimization by linking stimulation design, reservoir modeling, and economic evaluation. In: Presented at the SPE/AAPG western regional meeting, Long Beach, California, 19 June. https://doi.org/10.2118/62544-MS

Lalanne BJ P, Massonnat GJ (2004) Impacts of petrophysical cut-offs in reservoir models. In: Paper SPE-91040-MS presented at the SPE annual technical conference and exhibition, Houston, Texas, 26–29 September, https://doi.org/10.2118/SPE-91040-MS

Malik M, Hanson SA, Clinch S (2021) Tutorial: maximizing value from mudlogs - integrated approach to determine net pay. Petrophysics 62(01):4–15. https://doi.org/10.30632/PJV62N1-2021t1

Masoudi P, Tokhmechi B, Zahedi A, Jafari MA (2011) Developing a method for identification of net zones using log data and diffusivity equation. J Min Environ 2(1):53–60

Masoudi P, Tokhmechi B, Ansari Jafari M (2012) Application of bayesian in determining productive zones by well log data in oil wells. J Petrol Sci Eng 95(1):47–54. https://doi.org/10.1016/j.petrol.2012.06.028

Masoudi P, Arbab B, Mohammadrezaei H (2014a) Net pay determination by artificial neural network: case study on Iranian offshore oil fields. J Petrol Sci Eng 123(November):72–77. https://doi.org/10.1016/j.petrol.2014.07.007i

Masoudi P, Arbab B, Rezaei H (2014b) Net pay determination by Dempster rule of combination: case study on Iranian offshore oil fields. J Petrol Sci Eng 123:78–83. https://doi.org/10.1016/j.petrol.2014.07.014

May A (2009) Net pay cutoffs from capillary pressure. Adapted from a presentation at AAPG geoscience technology workshop, “Geological aspects of estimating resources and reserves,” 9–11 September, Houston, Texas, Search and Discovery Article #120008.

Qassamipour M, Khodapanah E, Tabatabaei-Nezhad SA (2020) A new methodology to define net pay zone in gas reservoirs. Iran J Oil Gas Sci Technol 9(2):13–30

Qassamipour M, Khodapanah E, Tabatabaei-Nezhad SA (2021) A comprehensive method for determining net pay in exploration/development wells. J Petrol Sci Eng. https://doi.org/10.1016/j.petrol.2020.107849

Saboorian-Jooybari H (2017) A structured mobility-based methodology for quantification of net-pay cutoff in petroleum reservoirs. SPE Res Eval Eng 20(2):317–333. https://doi.org/10.2118/183643-PA

Schoeling LG, Mark S (2000) Improved reservoir management/characterization for independent operators in mature basins, a case study: south slattery field, power river Basin, Wyoming. In: Presented at the SPE/DOE improved oil recovery symposium, Tulsa, 3–5 April. SPE-59299-MS. https://doi.org/10.2118/59299-MS

Shi X, Cui Y, Xu S et al (2022) Determination of Fluid properties and reservoir net pay cutoffs by production logging and conventional logs in exploration wells: a case study of the granite fractured reservoir in JZ Oilfield in Bohai Sea. In: Presented at the offshore technology conference Asia, March 22–25. https://doi.org/10.4043/31347-MS

Skalinski M, Mallan R, Edwards M et al (2019) Defining net-pay cutoffs in carbonates using advanced petrophysical methods. Petrophysics 60(01):17–36. https://doi.org/10.30632/PJV60N1-2019a1

Snyder RH (1971) A review of the concepts and methodology of determining “Net Pay”. In: Presented at the fall meeting of the society of petroleum engineers of AIME, New Orleans, Louisiana, 03 October. https://doi.org/10.2118/3609-MS.

Spivey JP, Pursell DA (1998) Errors in input data and the effect on well-test interpretation results. In: Presented at the SPE permian basin Oil and gas recovery conference, Midland, Texas, 23 March. https://doi.org/10.2118/39773-MS.

Vavra CL, Kaldi JG, Sneider RM (1992) Geological Applications of Capillary Pressure: A Review. AAPG Bull 76(6):840–850

Worthington PF (2008) The application of cutoffs in integrated reservoir studies. SPE Res Eval Eng 11(6):968–975. https://doi.org/10.2118/SPE-95428-PA

Worthington PF, Cosentino L (2005) The Role of cut-offs in integrated reservoir studies. SPE Res Eval Eng 8(4):276–290. https://doi.org/10.2118/SPE-84387-PA

Worthington PF, Allen D, Comes I et al (2002) A validation criterion to optimize core sampling for the characterization of petrophysical facies. Petrophysics 43(6):477–493

Worthington PF (2010) Net pay--what is it? What does it do? How do we quantify it? How do we use it? In: Presented at Asia Pacific Oil and Gas Conference & Exhibition, Jakarta, Indonesia, 4–6 August. SPE-123561-PA. https://doi.org/10.2118/SPE-123561-PA

Yang T, Cao Y, Wang Y, Liu K, He C, Zhang S (2019) Determining permeability cut-off values for net pay study of a low-permeability clastic reservoir: a case study of the Dongying sag, eastern China. J Petrol Sci Eng 178:262–271. https://doi.org/10.1016/j.petrol.2019.03.030

Yeager DL, Frantz JH, Moody MA, Neese MA (1996) Evaluation of infill drilling potential of the Beekmantown formation, Bakersville field, Coshocton County, Ohio. In: Presented at the SPE Eastern regional meeting, Columbus. Ohio, 23 October. SPE-37335-MS. https://doi.org/10.2118/37335-MS

Funding

The authors have no financial or proprietary interests in any material discussed in this article.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zeyghami, M., Taghizadeh Sarvestani, M. A comprehensive methodology for reservoir cut-off determination. J Petrol Explor Prod Technol 13, 1551–1573 (2023). https://doi.org/10.1007/s13202-023-01636-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01636-z