Abstract

There are many nanoscale pores in deep low permeability coal seams. The flow of coalbed methane (gas) in nanoscale pores belongs to the gas flow in porous media with medium and high Knudsen numbers. Its flow mechanism is one of the key unsolved scientific problems. In order to explore the gas transport law in nanopores of coal, a gas transport model based on microscopic boundary restriction was adopted to describe the gas flow law, and its rationality was verified by experimental data. The Field Emission Scanning Electron Microscope was used to scan the nanopores of customized anodized aluminum membrane. Then, the Maximally Stable Extremal Regions (MSER) algorithm of MATLAB and binarization algorithm were employed to quantify the pore structure parameters (equivalent pore size and porosity) of the membrane nanoscale pores. Finally, PMI micro-flow permeability tester was used to carry out different rarefied degree gas penetration experiments through anodized aluminum membranes, and the adopted gas transport model was verified. The results show that the binarization method is more accurate to characterize sample whose theoretical pore sizes are 20–35 nm, while MSER characterizes samples whose theoretical pore sizes are 110–150 nm and 200–300 nm more accurately. In other words, binarization method is more accurate for characterizing mesopores, while MSER algorithm is more accurate for macropores. The results have important reference value for more accurate extraction of nanopore parameters of porous media. Compared with traditional gas transport model, the adopted model considering the microscopic boundary restriction in this paper is closer to the experimental results. Moreover, it is suitable for describing the gas flow law in multiscale nanopores. The study provided important guiding significance for ascertaining the gas migration law in low permeability coal seam, improving the prediction accuracy of gas extraction and taking effective measures to increase production. The research results can further enrich the theoretical system of gas transport in coal, which is conducive to the efficient gas extraction, and is of great significance to promote the realization of carbon peak and carbon neutrality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There are multiple flow mechanisms of gas molecules in coal seams (Zhou 1990), because the pore structure inside the coal is intricate, including millimeter, micro and nanoscale pores. The flow of coalbed methane (gas) in nanoscale pores belongs to the gas flow in porous media with medium and high Knudsen numbers. According to the Knudsen number division mechanism of gas flow (Roy et al. 2003), when the Knudsen number (the ratio of the mean free path of gas molecules to the characteristic scale) is between 0.1 and 10, the gas flow in pores belongs to the transitional flow, that is, the gas flow in the nanoscale pores belongs to this interval. According to the applicable conditions of Klinkenberg slip effect (Klinkenberg 1941), the gas flow law in transitional flow region cannot be accurately described by the Navier–Stokes equation. The flow mechanism of gas in nanoscale pores is one of the key unsolved scientific problems. Due to the complex mechanism of gas transport in nanopores, it is difficult to solve the problem via traditional fluid mechanics theory and testing methods.

Some scholars have carried out relevant studies in theory and testing. In theoretical aspect, some scholars (Klinkenberg 1941; Javadpour 2009; Beskok and Karniadakis 1999; Karniadakis et al. 2005; Guo et al. 2015; Wang et al. 2016, 2019; Wu et al. 2016) proposed Darcy’s equations with modified terms to describe the gas flow in the transitional region. However, they did not take the influence of microscopic boundary restriction on gas molecular free path into consideration. Liu et al. (2022) constructed a gas transport model with micro-boundary constraints and deduced the equivalent apparent permeability model through modifying the gas dynamic viscosity, the mean-free path and the Knudsen number in nanoscale channels. Zeng et al. (2019) established a gas mass transfer model considering the dynamic variation of micro-fracture width, and the reliability of the model was verified by molecular dynamics (MD) simulation. Xu et al. (2004) performed the MD simulation of micro-Poiseuille flow for liquid argon in nanoscale. Ziarani and Mohamad (2006) reported the results from a nonequilibrium molecular dynamics (NEMD) simulation and analytical solution of Poiseuille flow through a nanochannel. Liu et al. (2018) adopted MD simulation to study the flow properties of gas mixture including nitrogen, oxygen mixture and carbon dioxide confined in parallel-plate. Other scholars (Ostad-Ali-Askari et al. 2017; Wang et al. 2021) used artificial neural networks to calculate permeability. The above models are more convenient to apply, but they are simplified or rely on empirical coefficients, making them not accurate enough.

Experimentally, there are many unsolved problems in gas flow in nanopores. Coal samples were used for experiments, but pores in coal are complex and diverse, which is not specific to micro and nano pores. As the pore structure of nanoporous media is intricate, some scholars simplified it into nanotube or nanoplate model to study it. Cooper et al. (2003) measured gas permeability through a carbon nanotube-based “buckypaper” membrane and through commercially available porous anodized alumina membranes with 200 nm nominal pore dimensions. Guo et al. (2015) conducted experiments on nitrogen flow through nano membranes (with pore throat size: 20 nm, 55 nm, and 100 nm). Wang et al. (2017) carried out experiments on methane flow with alumina films under different rarefaction degree conditions to examine the intra-nanopore methane flow law. By using single-pore samples, the above studies are accurate but unrealistic.

To sum up, researching the gas flow (especially the transitional flow) mechanism with medium and high Knudsen numbers in nanopores is quite challengeable. The experimental study of gas flow in nanopores is a subject worthy of attention.

In summary, sample selection plays an important role in researching gas flow in nanopores. The extraction of the internal pore parameters of alumina membranes directly affects the calculation of the intrinsic permeability of the membranes. If the characterization results are inaccurate, it may lead to inaccurate experimental laws. Therefore, characterizing exactly is of crucial importance for the subsequent analysis of experimental results. At present, coal samples or single-hole films are used as samples, which cannot accurately describe the gas flow law of uniform micro-nano pores. The innovation of this study lies in: (i) a customized alumina film with uniform nanopores was used; (ii) two extraction methods of the pore characteristic, namely, MSER and the binarization, were used for comparison, which can characterize pore characteristics more accurately.

Therefore, in order to describe the gas flow in nanopores more accurately, a gas transport model based on the microscopic boundary restriction was adopted in this paper. According to the principle of the gas pressure difference penetration experiment, the permeability experiment of the nanoporous membrane with homogeneous nanopores was carried out with the PMI micro-flow permeability tester, and the model was verified. The study is instructive to ascertain the gas migration law in low permeability coal seam, improve the prediction accuracy of gas extraction and take effective measures to increase production.

Model derivation

Aiming at the dynamic viscosity change in the transitional flow, Beskok and Karniadakis (1999, 2005) introduced a sparse factor to characterize the rarefaction effect. By combing the general slip boundary conditions and the Navier–Stokes equation, they proposed a model suitable for the transitional flow region. The model can well describe and predict the flow velocity and flow rate without considering the effect of the microscopic boundary restriction on the free path of molecules. However, in the transitional flow region, the molecular free path and the pore characteristic scale are nearly in the same order of magnitude. Hence, the influence of the microscopic boundary restriction on the molecular mean free path cannot be ignored (Liu et al. 2022).

Molecular mean free path under the effect of microscopic boundary restriction

According to the expression of ideal gas molecule mean free path, the Knudsen number can be expressed as:

where Kn is the Knudsen number for the ideal gas, dimensionless; λ is the mean free path of the ideal gas molecule, m; L is the characteristic length (for a pipe with the width w and the height h, taking h; for a hole, taking r), m; μ is the viscosity of the ideal gas, Pa s; P is the gas pressure, Pa; R is the gas constant, J/(mol K); T is the gas temperature, K; M is the molecular mass of gas, kg/mol.

For the gas flowing in the nanopores, the pore characteristic length and the mean free path of the gas molecule are of the same magnitude order. Because of the constriction of the pore boundary, the mean free path of the gas molecule in nanopores will be smaller than that in the macroscopic boundary scale. Therefore, a valid value should be assigned to it, which is called the effective mean free path \({\lambda }_{\mathrm{e}}\) (Dongari and Agrawal 2012; Stops 1970; Zhang et al. 2010).

As per the gas dynamics theory and the expression of λ, the main parameter affecting λ is the dynamic viscosity μ. Considering the gas rarefaction degree, the dynamic viscosity is modified as follows (Beskok and Karniadakis 1999; Pollard and Present 1948; Michalis et al. 2010; Lv 2014) to get the effective dynamic viscosity.

where a is the rarefaction coefficient, dimensionless; \({\mathrm{Kn}}_{m}\) is the Knudsen number at average pressure.

The value of the rarefaction coefficient a should also be calculated. According to the dimensionless mass flow formula derived from Knudsen formula and the effective volume diffusion kinetics, the following equation can be obtained.

where \({\mathrm{Pr}}\) is the Prandtl number, taking 2/3.

Two sets of \(a\) can be obtained under each Knudsen number from Eq. (3). Among them, \({a}_{1}\) only reflects the average flow, but cannot accurately represent the flow under different Knudsen numbers. \({a}_{2}\) is the true solution of \(a\). When Knudsen number tends to be infinitely small, \({a}_{2}\) tends to 0, which is consistent with the change in continuous flow. When Knudsen number tends to be infinitely great, \({a}_{2}\) approaches a stable value, which conforms with the characteristics of free molecular flow. Therefore, \({a}_{2}\) is selected as \(a\) to calculate the effective dynamic viscosity and molecular free path.

As the effective mean free path can be obtained by modifying the dynamic viscosity, the corrected Knudsen number was obtained:

Gas transport model with microscopic boundary restriction

Beskok and Karniadakis derived the relationship between \(\alpha\) and \(\mathrm{Kn}\) as follows:

where \({\alpha }_{1}\) = 4.0, \(\beta\) = 0.4, \({\alpha }_{0}=\frac{64}{15\pi }\). Based on the mass flux of the B–K model, for porous media with a porosity of \(\varnothing\), the equal apparent permeability can be written as follows:

where KD is the intrinsic permeability:

The effective Knudsen number Kne was calculated to obtain the effective apparent permeability of the porous medium considering the microscopic boundary restriction (Liu et al. 2022) as follows:

Methodology and experiments

Anodic alumina membranes are of the uniform nanopore size and the simple structure, so they are suitable for the model validation of the transition flow zone. In this study, three kinds of anodic alumina membranes with different pore sizes were selected for gas penetration experiments. According to the laboratory safety management regulations, methane may cause safety problems for the laboratory if it is used in experiments. Helium is a kind of inert gas which has no interaction with alumina membrane, so it is suitable for measuring absolute permeability. For the sake of the laboratory safety, helium was chosen for the penetration experiments of alumina membranes with different pore sizes under different pressures. Firstly, process the scanning electron microscope (SEM) image by the Maximally Stable Extremal Regions (MSER) algorithm of MATLAB and binarization method to obtain the nanopore parameters. The intrinsic permeability was also calculated and substituted to the gas flow equation to obtain the theoretical flow rate. Secondly, measure the experimental flow rate. Thirdly, compare the theoretical value with the experimental one to validate the model.

Determination of pore parameters of nanoscale alumina membranes

The Field Emission Scanning Electron Microscope (FESEM) was used to scan the customized anodized aluminum membranes. The specimens used in the experiment were customized anodic alumina membranes with a thickness of 70 μm. They were divided into three sample groups based on different pore sizes (the theoretical pore sizes are 20–35 nm, 110–150 nm and 200–300 nm) and numbered M-1, M-2, M-3, respectively. The SEM results are shown in Fig. 1.

SEM images processing

The extraction of internal pore parameters of alumina membranes directly affects the calculation of the intrinsic permeability of the membranes. If the characterization results are not accurate, it is likely to result in inaccurate experimental laws. Therefore, accurate characterization has great impact for the subsequent analysis of experimental results. In this study, two extraction methods of the pore characteristic, namely MSER and the binarization were used. Their characterization results were compared to select the most accurate one for subsequent analysis.

Extraction of nanopore characteristics based on MSER method

MSER is an affine characteristic region extraction algorithm without smoothing the image. It possesses multiscale detection capabilities. Compared with traditional threshold methods, MSER has better stability, higher computational efficiency and better denoise capacity. The edges of irregular regions were fitted with ellipses. The SEM images of membranes were processed to obtain the dispersion degree, average pore size and nanopore porosity. As shown in Fig. 2, the processing steps are as follows.

Step 1: There are basically only bright and dark colors in the picture as shown in Fig. 2a. Only the dark region should be measured to obtain the nanopore parameters of the membrane using a MATLAB feature detection algorithm based on the local grayscale extremes of region Fig. 2b. Given a gray value interval, all the regions of this grayscale interval in the scanning picture were detected, see Fig. 2c.

Step 2: As shown in Fig. 2c, some elliptical pixels are also in the detected grayscale value interval. However, they are in nanopore gaps and they do not belong to the nanopores which are more uniform and closer to circle in shape. Therefore, the interval of the ratio of the ellipse major axis to the minor axis can be set to remove ellipses with larger ratios or not in the interval. The remained ellipses are shown in the regions in Fig. 2d.

Step 3: Many regions detected in Fig. 2c are duplicates. The spacing between the centers of the ellipses was subsequently set, and the regions with spacing less than the set value were considered as duplicated. These duplicated regions were removed to obtain the most appropriate ellipses (see Fig. 2e).

Step 4: There are still some detected regions which do not belong to nanopores in Fig. 2e. These extra detected regions are in pore gaps and most of them are in bright regions. As a result, the mean value of grayscale was set in the 5*5 neighborhood of the ellipse center. If the mean value is greater than the set one, the detected region is bright and the ellipse in this center should be removed. The final processing picture and related pore parameters can be obtained (Fig. 2f).

Extraction of nanopore characteristics based on binarization method

SEM images shown in Fig. 1 are of 8-bit grayscale with values ranging from 0 to 255. Their pores are composed of dark cool colors, while their pore walls are composed of bright and dark warm colors. The images are binarized to clearly collect pore parameters. The process pictures are shown in Fig. 3.

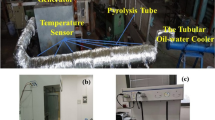

Gas flow experiments

PMI microflow permeability tester, as shown in Fig. 4, was used to test the permeability of different samples. The experimental system is composed of pressure control system, flow monitoring system, sample clamping system, gas permeation system and data acquisition system. In the experiment, the data of pressure and flow can be measured and acquired timely.

O-rings were used to ensure that the gas passes through the membrane samples completely. The pressure drop and flow rate produced by the gas passing through the samples was recorded by precision pressure gauges and flow gauges. The experimental procedures are as follows.

Step 1: Put the gasket, samples and sheets in the sample chamber in sequence. Next, add the sealing insert, making it higher than the edge of the sample chamber. Finally, tighten the chamber cap, press each O-ring to ensure that the gas passes through the sample and complete the sample loading.

Step 2: Open the high-pressure cylinder, adjust the pressure reducing valve, and control the gas pressure between 1 and 1.5 MPa. Open the experimental equipment, test whether the experimental equipment can operate normally. Open the experimental window, set the relevant parameters, and click on to start the experiment.

Step 3: Open the valve. The gas outflows from the cylinder into the equipment pipeline. It flows through the pressure sensor and flow sensor. The pipeline system controls its pressure stability by setting the maximum allowable pressure difference and the longest time to be kept. Record the flow and pressure values in the experiment. Continue the experiment.

Step 4: When the experimental flow rate or pressure reaches the threshold set by the flow sensor or pressure sensor, the experiment is ended. Then close the ventilation valve and open the exhaust valve to vent the remaining gas.

Step 5: Repeat the above experimental steps by testing membrane samples with different pore sizes to obtain the experimental gas pressure and corresponding flow rate.

Results and discussion

The theoretical flow rate obtained by two characterization methods—MSER and binarization algorithm was compared with the experimental flow rate. Hence, the accuracy of these two methods are comparable. Also, the experimental and theoretical flow rates of the modified model and several other traditional models were compared to verify the accuracy of the modified model.

Analysis of characterization results

Helium was selected for the penetration experiments of alumina membranes with different pore sizes under different pressures. The parameters of experimental characterization result are shown in Table 1. As can be seen from the table, the equivalent radius of sample M-1 characterized by MSER/binarization methods are 33.2/26.4 nm. However, the theoretical radius ranges from 20 to 35 nm. While equivalent radius of sample M-2 characterized by MSER/binarization methods are 88.5/101.2 nm. However, the theoretical radius ranges from 110 to 150 nm. This is also applicable for sample M-3. And the values of equivalent mean pore size and porosity of three samples characterized by binarization algorithm are larger than those characterized by MSER.

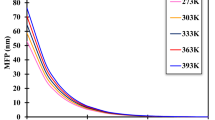

By substituting the equivalent pore size and porosity obtained from the two characterization methods and other experimental parameters into the modified model, the apparent permeability can be obtained. The theoretical flow rate of the modified model was calculated by the gas flow equation. The theoretical flow rates of the two characterization results were compared with the experimental flow rates. The results are shown in Fig. 5.

Figure 5 illustrates that as for sample M-1, the characterization results of binarization are closer to the experimental results than those of MSER (see Fig. 5a). However, as for samples M-2 and M-3 (see Fig. 5(b) and Fig. 5(c)), the opposite is true. Consequently, the binarization characterization results for sample M-1 and MSER characterization results for samples M-2 and M-3 were selected to verify the modified model in the subsequent computational process of model validation.

Validation of gas transport model in nanoscale pores considering microscopic boundary restriction

Accurately obtaining the nanopore parameters of membranes is the key premise of experimental research and model verification. By comparison, the more accurate characterization results in “Analysis of characterization results” section (the binarization characterization results for sample M-1 and MSER characterization results for samples M-2 and M-3) were selected and substituted into the modified model and other models to calculate corresponding gas flow rates of different models. Then, the obtained gas flow rates were compared with the experimental flow rates. The comparison results are shown in Fig. 6.

Figure 6a–c all depict that as for samples M-1, M-2 and M-3, the results of Klinkenberg model are smaller than experiment results on the whole. However, the results of Javadpour model are much larger than the experimental results. The results of modified model considering microscopic boundary restriction is closest to the experimental results in comparison, which proves that the proposed modified model considering the microscopic boundary restriction is more reasonable and accurate.

Discussion of results

In this study, both MSER and binarization algorithms were used to quantitatively characterize the SEM images and extract the pore parameters of the membrane samples in order to further calculate the intrinsic permeability. As shown in “Analysis of characterization results” section, by comparing the theoretical values obtained from the two methods with the experimental results, we found that the binarization method is more accurate to characterize sample M-1 (20–35 nm), while MSER is more accurate for samples M-2 (110–150 nm) and M-3 (200–300 nm). According to the widely used classification standard (Thommes et al. 2015) of the International Union of Pure and Applied Chemistry (IUPAC), pores can be divided into the following categories namely, micropores (< 2 nm), mesopores (2–50 nm) and macropores (> 50 nm). The binarization method can be used to characterize mesopores more accurately, while MSER algorithm is more appropriate to characterize macropores. The reasons are as follows. The binarization method uses a gray value to separate the target and the background, and the processing result is irregular shape, but MSER algorithm extracts the part with stable gray value to fit the ellipse for simulation. When the pore is relatively small, the irregular edges exert a great influence on the pore parameters. As a result, the extraction result of MSER presents a larger error, and it is smaller than the actual pore in general. If the threshold is given, the binarization method calculates the pore area by pixels, so the mesopores can be described better. When the pore is relatively large, the processing of fuzzy edges by the binarization method will cause great errors. MSER algorithm extracts the region with stable gray value and fits the ellipse for simulation, so its characterization results of macropores are more accurate.

Conclusions

According to the above theoretical analysis and experimental comparison, some meaningful conclusions are drawn as below.

-

(1)

The characterized equivalent radius differs greatly from the theoretical radius given by the manufacturer. The equivalent radius of the membrane can be accurately obtained via quantitative characterization of the membrane. Thus, the experimental data of gas flow are more reliable.

-

(2)

Binarization method is more accurate when characterizing sample M-1 (20–35 nm), while MSER is more suitable for samples M-2 (110–150 nm) and M-3 (200–300 nm). The study has proved that binarization method can be used to characterize mesopores more accurately, while MSER algorithm performs better when characterizing macropores.

-

(3)

Compared with the experimental result, the results of Klinkenberg model are smaller, while the results of Javadpour model are much larger. Compared with other models, the results of modified model considering microscopic boundary restriction is closer to the experimental results, which proves that the adopted modified model is more reasonable and accurate.

Abbreviations

- A :

-

The rarefaction coefficient, dimensionless

- \(k_{{{\text{app}}}}\) :

-

The equal apparent permeability

- K D :

-

The intrinsic permeability

- \(k_{{\text{e}}}\) :

-

The effective apparent permeability

- Kn:

-

The Knudsen number for the ideal gas, dimensionless

- Kne :

-

The effective Knudsen number

- \({\text{Kn}}_{m}\) :

-

The Knudsen number at average pressure

- L :

-

The characteristic length (m)

- P :

-

The gas pressure (Pa); R is the gas constant (J/(mol K))

- \({\text{P}}_{{\text{r}}}\) :

-

The Prandtl number, taking 2/3

- T :

-

The gas temperature (K); M is the molecular mass of gas (kg/mol)

- μ :

-

The viscosity of the ideal gas (Pa s)

- \(\mu_{{\text{e}}}\) :

-

The effective dynamic viscosity

- \(\emptyset\) :

-

Porosity

- λ :

-

The mean free path of the ideal gas molecule, m

- \(\lambda_{{\text{e}}}\) :

-

The effective mean free path

- FESEM:

-

The Field Emission Scanning Electron Microscope

- IUPAC:

-

The International Union of Pure and Applied Chemistry

- MSER:

-

The Maximally Stable Extremal Regions algorithm

- MD:

-

Molecular dynamics simulation

- NEMD:

-

Nonequilibrium molecular dynamics

- SEM:

-

The scanning electron microscope

References

Beskok A, Karniadakis GE (1999) Report: a model for flows in channels, pipes, and ducts at micro and nano scales. Microsc Therm 3(1):43–77. https://doi.org/10.1080/108939599199864

Cooper SM, Chuang HF, Cinke M et al (2003) Gas permeability of a buckypaper membrane. Nano Lett 3(2):189–192. https://doi.org/10.1021/nl0259131

Dongari N, Agrawal A (2012) Modeling of Navier-Stokes equations for high Knudsen number gas flows. Int J Heat Mass Transf 55(21–22):6291. https://doi.org/10.1016/j.ijheatmasstransfer.2012.06.017

Guo C, Xu J, Wu K et al (2015) Study on gas flow through nano pores of shale gas reservoirs. Fuel 143:107–117. https://doi.org/10.1016/j.fuel.2014.11.032

Javadpour F (2009) Nanopores and apparent permeability of gas flow in mudrocks (shales and siltstone). SPE J Can Pet Technol 48(8):16–21. https://doi.org/10.2118/09-08-16-DA

Karniadakis GE, Beskok A, Aluru N (2005) Microflows and nanoflows: fundamentals and simulation. Springer, New York

Klinkenberg LJ (1941) The permeability of porous media to liquids and gases. Drill Prod Pract 2(2):200–213

Liu H, Zhang Z, Hao M et al (2018) Molecular dynamics simulations on flow properties of gas mixture in nanochannels. Phys Gases 3(4):32–40. https://doi.org/10.19527/j.cnki.2096-1642.2018.04.004

Liu Y, Jia H, Zuo W et al (2022) A model for gas transport through nanopores based on effective molecular free path. J China Univ Min Technol 51(1):90–99. https://doi.org/10.13247/j.cnki.jcumt.001341

Lv Q (2014) Equations of fluid motion in a wide range of Knudsen numbers. Tsinghua University, Beijing, pp 44–45

Michalis VK, Kalarakis AN, Skouras ED, Burganos VN (2010) Rarefaction effects on gas viscosity in the Knudsen transition regime. Microfluid Nanofluid 9(4–5):847–853. https://doi.org/10.1007/s10404-010-0606-3

Ostad-Ali-Askari K et al (2017) Artificial neural network for modeling nitrate pollution of groundwater in marginal area of Zayandeh-Rood River, Isfahan, Iran. KSCE J Civ Eng Korean Soc Civ Eng 21(1):134–140. https://doi.org/10.1007/s12205-016-0572-8

Pollard WG, Present RD (1948) On gaseous self-diffusion in long capillary tubes. Phys Rev 73:762–774. https://doi.org/10.1103/PhysRev.73.762

Roy S, Raju R, Chuang H, Cruden BA, Meyyappan M (2003) Modeling gas flow through microchannels and nanopores. J Appl Phys 93(8):4870–4879. https://doi.org/10.1063/1.1559936

Stops DW (1970) The mean free path of gas molecules in the transition regime. J Phys D Appl Phys 3(5):685–696. https://doi.org/10.1088/0022-3727/3/5/307

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KSW (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl Chem 87(9–10):1051–1069. https://doi.org/10.1515/pac-2014-1117

Wang H, Wang D, Yao B (2016) Study on flow equation of coal seam gas under different mechanisms. J Saf Sci Technol 12(4):20–24. https://doi.org/10.11731/j.issn.1673-193x.2016.04.004

Wang D, Liu S, Wei J et al (2017) A research study of the intra-nanopore methane flow law. Int J Hydrogen Energy 42(29):18607–18613. https://doi.org/10.1016/j.ijhydene.2017.04.195

Wang D, Li W, Wei J, Yu C, Zhang K (2019) Study of gas transport equation based on fractal characterization of rough micro-nano pores. J China Coal Soc 44(11):3432–3440. https://doi.org/10.13225/j.cnki.jccs.2019.0048

Wang M, Dong Y, Cai J et al (2021) Method for reservoir permeability prediction and quality evaluation based on BP neural network. Prog Geophys. https://doi.org/10.19527/j.cnki.2096-1642.2018.04.004

Wu K, Chen Z, Li X, Guo C, Wei M (2016) A model for multiple transport mechanisms through nanopores of shale gas reservoirs with real gas effect–adsorption-mechanic coupling. Int J Heat Mass Transf 93:408–426. https://doi.org/10.1016/j.ijheatmasstransfer.2015.10.003

Xu J, Zhou Z, Xu X (2004) Molecular dynamics simulation of micro-Poiseuille flow for liquid argon in nanoscale. Int J Numer Methods Heat Fluid Flow 14(5):664–688. https://doi.org/10.1108/09615530410539973

Zeng F, Peng F, Guo J et al (2019) The gas mass transport model considering the dynamic change of micro-fracture width in shale. Nat Gas Geosci 30(2):237–246

Zhang J, Fan J, Fei F (2010) Effects of convection and solid wall on the diffusion in microscale convection flows. Phys Fluids 22(12):186. https://doi.org/10.1063/1.3528310

Zhou S (1990) Mechanism of gas flow in coal seam. J China Coal Soc 01:15–24

Ziarani AS, Mohamad AA (2006) A molecular dynamics study of perturbed Poiseuille flow in a nanochannel. Microfluid Nanofluid 2(1):12–20. https://doi.org/10.1007/s10404-005-0036-9

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

JM contributed to the conception of the study, performed the data analyses and wrote the manuscript; HJ contributed significantly to analysis and manuscript preparation; PL and GF performed the experiment.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Miao, J., Jia, H., Li, P. et al. Experimental study on the law of transitional gas flow in porous media. J Petrol Explor Prod Technol 13, 723–733 (2023). https://doi.org/10.1007/s13202-022-01590-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01590-2