Abstract

This paper analyzes and compares the deformation, failure characteristics, and energy characteristics of coal and rock under uniaxial compression. It is considered that the change laws of the total stress–strain relationship curves of raw coal and sandstone samples are similar, and they all exhibit the primary fracture compaction and closure stage, elastic deformation stage, fracture expansion stage and stress drop stage. The failure mode of coal and rock is a predominantly columnar splitting, and the fractured coal and rock bite each other. The ultimate bearing capacity, elastic modulus and peak strain of coal samples are small for sandstone. Under uniaxial compression, the ultimate bearing capacity, elastic modulus, and peak strain of coal samples were 46.17%, 63.32%, and 69.54% of sandstone, respectively. In the compaction stage, the proportion of releasable elastic energy of the coal sample was higher than that of dissipated energy, while that of the sandstone sample is the opposite. The proportion of releasable elastic energy of coal samples in other stages was higher than that of dissipated energy, and more than 80% of the total energy absorbed by coal and rock specimens in the loading process was stored in the form of releasable elastic energy. Other total energy was dissipated by the internal defects of the samples during compaction, sliding and new micro-cracks in the yield stage.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

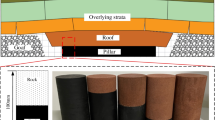

Room–pillar mining is a method of mining underground mineral deposits. Large-scale roofing and collapse accidents occur frequently due to the instability of the mine pillar in the goaf, which seriously affects the subsequent safe production of coal mines (Mu 3; Zhao et al. 2020). The ore pillar is composed of rock mass and roof rock mass, which is often subjected to a single load. Under the influence of continuous load, the initial micropores and cracks in the coal–rock mass initiate, expand and evolve, and the energy is continuously accumulated in the coal–rock mass. When a certain amount of energy is accumulated, it is released in the form of elastic energy, resulting in instability and failure (Yang et al. 2019; Zuo et al. 2022; Chen et al. 2021a).

Many scholars think that coal and rock can be regarded as a whole, and analyze the energy evolution law, fracture evolution characteristics and failure mechanism of coal rock composite structure during compression (Chen et al. 2021b, 2018; Yang et al. 2020, 2021). After the mining of coal resources, the roof rock mass is broken. Gao et al. (2) analyzed the loading rate effect of coal failure from the perspective of mechanical properties, acoustic emission characteristics and numerical simulation. Wang et al. (2021) analyzed the instability and fracture of axially parallel and vertically bedded gneiss samples, acoustic emission time series parameters and acoustic emission spatial positioning evolution characteristics. Meng et al. (2020) compared and analyzed the fracture mechanism of two kinds of brittle rocks, and the results showed that compared with marble, large-scale fracture events accounted for a large proportion in the failure process of granite under uniaxial compression. Zhang et al. (2020) analyzed the damage evolution characteristics of granite under uniaxial compression and established the analytical expression of rock damage variables based on acoustic emission and infrared radiation. Wang et al. (2020) studied the evolution characteristics of acoustic emission spectrum in marble failure process by combining fractal theory. Liu et al. (2020) compared and analyzed the deformation and failure characteristics of coal samples under two loading modes (tension and compression), the space–time evolution law of acoustic emission of coal samples and the micro-failure mechanism. Wang et al. (2018) studied the numerical investigation of the mechanical properties of coal masses with T-junctions cleat networks under uniaxial compression. Du et al. (2022) studied the shape ratio effects on the mechanical characteristics of rectangular prism rocks and isolated pillars under uniaxial compression. Xia et al. (2022) analyzed the acoustic emission characteristics and energy mechanism of CFRP-jacketed coal specimens under uniaxial compression. Li et al. (2022) studied the acoustic and thermal response characteristics of coal samples with various prefabricated crack angles during loaded failure under uniaxial compression. Tian et al. (2021) investigated the effective precursory information of coal sample instability and failure under uniaxial compression. The above researches mainly focus on coal rock combination, raw coal and raw rock. For the ore-pillar composed of coal and rock mass, the deformation, failure and energy characteristics of raw coal and raw rock should be compared and analyzed to clarify the difference characteristics between them, which is of great significance to the stability of pillar.

In view of the current mine pillar safety problems, the author collected coal body and roof samples on-site, conducted uniaxial compression experiments, and compared and analyzed the deformation and mechanical properties of raw coal and roof sandstone samples under unidirectional loading. The damage mechanism of raw coal and sandstone is analyzed from an angle, and the instability mechanism of the pillar composed of the “coal–rock” combination is revealed, which provides basic support for the safe and efficient mining of coal mines.

Experimental equipment and standard sample

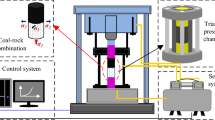

Test equipment

The experiment utilizes the AG-250kN IS Electronic precision material testing machine, as shown in Fig. 1. The maximum loading capacity was 250 kN, and the stress, strain, and time can be collected simultaneously during the whole loading process. The specimens were subjected to uniaxial compression experiments tests, with the axial direction controlled by displacement (0.05 mm/min loading rate).

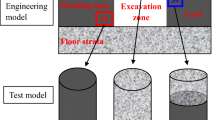

Standard sample

The coal–rock samples were collected from the No. K2 coal seam and its roof sandstone at the Chongqing Energy Investment Group Yuxin Energy Co., Ltd, Nantong Coal Mine. The coal–rock blocks larger than 200 mm were collected from the site, and processed in the laboratory into standard cylindrical samples with a of 50 mm diameter and 100 mm height. The sample accuracy of the samples passes the test requirements, and the samples are shown in Fig. 2.

Deformation and strength properties of coal and rock

Figure 3 presents the complete stress–strain relationship curve of raw coal under uniaxial compression.

Figure 4 presents the complete stress–strain relationship curve of sandstone under uniaxial compression.

It is evident from Figs. 3 and 4 that the complete stress–strain relationship curve of each coal and rock specimen follows the same four-stage change rules. These stage are, (1) primary fracture compaction and closure stage (OA), the stress–strain curve in this stage is concave, and the tangent modulus gradually increases with increasing axial strain. During the loading process, the micro-pores and fractures in the sample are slowly compacted and closed. (2) Linear elastic deformation stage (AB): the stress–strain curve is basically straight, and the strain can be recovered following unloading at this stage. (3) Crack propagation stage (BC), at this stage, the stress–strain curve deviates from the straight line and gradually assumes a concave shape. During unloading at this stage, the strain cannot be completely recovered. The low-strength material in the specimen failed first, and then the high-strength material yielded gradually. A significant number of internal micro-cracks were generated and expanded until they become macro-cracks. (4) Stress drop stage (CD): in this stage, the stress drops rapidly with the increase in strain, and the specimen is unstable and destroyed.

Table 1 shows the deformation parameters of each coal and rock sample under uniaxial compression. Where σc is the peak strength and E is the elastic modulus, εc is the axial strain value corresponding to the peak strength.

According to Table 1, the ultimate bearing capacity of three coal samples under uniaxial compression averages 32.88 MPa, the elastic modulus averages 3.28GPa, and the peak strain averages 12.81 × 10−3. The average value of the ultimate bearing capacity of the three sandstone samples is 71.21 MPa, the average value of the elastic modulus is 5.18GPa, and the average value of the peak strain is 18.27 × 10−3. It can be seen that the ultimate bearing capacity, elastic modulus and peak strain of coal samples are all small sandstone, and the ultimate bearing capacity, elastic modulus, and peak strain of coal samples are 46.17%, 63.32%, and 69.54% of sandstone, respectively. As coal and rock samples are heterogeneous natural media, the distribution of micropores and fractures within them varies, resulting in a degree of variation in the test results.

Energy properties of coal and rock

The deformation and failure process of the specimen are about accumulation, dissipation and release of the compression energy (Xie et al. 17; Ma et al. 2021). It is assumed that the energy of the loaded coal–rock system is conserved, and the total energy U is:

where Ud is the dissipated energy, Ue is the releasable elastic performance, and the dimension is MJ·m−3.

During loading, the specimen conserves both elastic energy that can be released and dissipative energy during loading. The relationship between dissipated energy and releasable elastic energy is shown in Fig. 5. The total energy input to the sample by the testing machine is:

In the practical calculation, Eq. (2) can be summed by sections using the stress–strain curve according to the concept of definite integral:

where m is the number of the calculated samples of axial stress–strain curve at any time during the test, j is the sampling point; σ1, and ε1 are the stress and strain at the sampling point.

The released elastic energy Ue of the sample can be computed using the shadow area covered by the triangle CFG in Fig. 5.

For the convenience of calculation, the unloading modulus E0 in the formula is approximated calculated by elastic modulus ET. According to Fig. 5, sandstone exhibits good linear behavior between stress and strain before reaching the peak value of uniaxial compression. In the energy calculation, the unloading modulus is substituted by elastic modulus ET, which has little impact on the test results. The dissipated energy can be calculated by the area enclosed by the stress–strain curve and unloading curve (OCG in Fig. 5).

Energy properties analysis of raw coal

Figure 6 depicts the complete stress–strain-energy relationship curves for the three raw coal samples under uniaxial compression.

According to the experimental results in Fig. 6, the energy parameters of raw coal samples in four stages during uniaxial compression are given, as shown in Table 2.

The absorbed energy of three coal specimens at the OA ranges was between 0.009 and 0.013 MJ·m−3, with an average value of 0.011 MJ·m−3, as shown in Table 2.The releasable elastic energy was between 0.006 and 0.009 MJ·m−3, with an average of 0.007 MJ·m−3. The dissipation energy was between 0.003 and 0.006 MJ·m−3, with an average of 0.004 MJ·m−3. The releasable elastic energy of three coal samples accounted for 65.67% of the absorbed energy, while the dissipated energy accounted for 34.33% of the absorbed energy. During the stage AB, the absorbed energy of three coal samples was between 0.082 and 0.100 MJ·m−3, with an average of 0.093 MJ·m−3. The releasable elastic energy was between 0.078 and 0.095 MJ·m−3, averaging 0.087 MJ·m−3. Also, the dissipation energy was between 0.004 and 0.009 MJ·m−3, with an average of 0.006 MJ·m−3. It was observed that the released elastic energy of three coal samples accounted for 93.49% of the absorbed energy, while the dissipated energy accounted for 6.51% of the absorbed energy. In stage BC, the energy absorbed by the three raw coal samples before the peak was between 0.156 and 0.219 MJ·m−3, with an average of 0.188 MJ·m−3. The releasable elastic energy was between 0.148 and 0.181 MJ·m−3, with an average of 0.165 MJ·m−3. Also, the dissipation energy ranges from 0.008 to 0.037 MJ·m−3, with an average of 0.023 MJ·m−3. The releasable elastic energy accounted for 88.51% of the absorbed energy, while the dissipated energy accounted for 11.48% of the absorbed energy. In stage CD, the absorbed energy of the three coal samples was between 0.186 and 0.224 MJ·m−3, with an average of 0.200 MJ·m−3. The releasable elastic energy was between 0.086 and 0.152 MJ·m−3, averaging 0.118 MJ·m−3. The dissipated energy was between 0.039 and 0.108 MJ·m−3, with an average value of 0.082 MJ·m−3. In this case, the elastic energy released by the three coal samples accounts for 59.22% of the absorbed energy, while the dissipated energy accounts for 40.78% of the absorbed energy.

Upon loading, the majority of the energy stored in the coal sample may be observed to be elastic energy that can be released. During the compaction stage, approximately 65.67% of the total absorbed energy was accumulated in the specimen as releasable elastic energy, and approximately 34.33% of the total energy was dissipated by the internal pores and cracks of the specimen. During the elastic stage, approximately 93.49% of the total absorbed energy was stored in the sample as releasable elastic energy, and about 6.51% of the total energy was dissipated through the formation of new micro-cracks in the sample. In the crack propagation stage, more than 88.51% of the total absorbed energy was stored in the specimen in the form of releasable elastic energy, and about 11.48% of the total energy is dissipated by the new micro-cracks in the specimen. At the post-peak stage, about 59.22% of the total absorbed energy is stored in the sample as releasable elastic energy, and about 39.51% of the total energy was dissipated by the new micro-cracks in the sample. The releasable elastic energy can promote the expansion, penetration, and sliding of the new cracks in the specimen after the peak value until the specimen completely loses its bearing capacity. In their natural state, raw coal samples release their elastic energy abruptly after the peak value, resulting in severe vibration and sound, and fragment ejection.

Energy properties analysis of sandstone

Figure 7 presents the stress–strain-energy relationship curves of the three sandstone samples under uniaxial compression.

According to the experimental results in Fig. 7, the energy parameters of sandstone samples in four stages during uniaxial compression are given, as shown in Table 3.

The absorbed energy of three rock samples at the stage OA ranges between 0.010 and 0.058 MJ·m−3, with an average value of 0.027 MJ·m−3, as shown in Table 3. The releasable elastic energy was between 0.004 and 0.031 MJ·m−3, with an average value of 0.013 MJ·m−3. The dissipated energy ranges from 0.006 to 0.027 MJ·m−3, with an average value of 0.013 MJ·m−3. The elastic energy released by the three coal samples accounts for 44.31% of the absorbed energy, while the dissipated energy accounts for 55.69% of the absorbed energy. During the stage AB, the absorbed energy of the three rock samples was between 0.215 and 0.430 MJ·m−3, with an average value of 0.325 MJ·m−3. The releasable elastic energy was between 0.200 and 0.396 MJ·m−3, with an average value of 0.298 MJ·m−3. The dissipated energy was between 0.014 and 0.035 MJ·m−3, with an average value of 0.027 MJ·m−3. The elastic energy released by the three coal samples accounts for 91.96% of the absorbed energy, while the dissipated energy accounts for 8.04% of the absorbed energy. In stage BC, the energy absorbed by the three rock samples before the peak was between 0.362 and 0.672 MJ·m−3, with an average value of 0.534 MJ·m−3. The releasable elastic energy was between 0.344 and 0.616 MJ·m−3, with an average value of 0.493 MJ·m−3. The dissipated energy ranges from 0.018 to 0.056 MJ·m−3, with an average value of 0.042 MJ·m−3. The releasable elastic energy accounts for 92.58% of the absorbed energy, while the dissipative energy accounts for 7.42% of the absorbed energy. In stage CD, the absorbed energy of the three rock samples was between 0.370 and 0.676 MJ·m−3, with an average value of 0.540 MJ·m−3. The releasable elastic energy was between 0.184 and 0.561 MJ·m−3, with an average value of 0.396 MJ·m−3. The dissipated energy ranges from 0.115 to 0.186 MJ·m−3, with an average value of 0.144 MJ·m−3. The elastic energy released by the three rock samples accounts for 69.95% of the absorbed energy, while the dissipated energy accounts for 30.05% of the absorbed energy.

Upon loading, the majority of the energy stored in the sandstone sample may be observed to be elastic energy that can be released. During the compaction stage, approximately 44.31% of the total absorbed energy was accumulated in the sample as releasable elastic energy, and approximately 55.69% of the total energy was dissipated by the internal pores and cracks of the sample. During the elastic stage, approximately 91.96% of the total absorbed energy was stored in the sample as releasable elastic energy, and about 8.04% of the total energy through the formation of new micro-cracks inside the sample. In the crack propagation stage, approximately 92.58% of the total energy was stored in the sample as releasable elastic energy, and about 7.42% of the total energy is dissipated by the new micro-cracks inside the sample. In the post-peak stage, about 69.95% of the total absorbed energy is accumulated in the sample as releasable elastic energy, and about 30.05% of the total energy was dissipated by the new micro-cracks inside the sample. The releasable elastic energy can promote the growth, penetration and slippage of new cracks inside the specimen after the peak value, until the specimen completely loses the load-bearing capacity. In their natural state, sandstone specimens release their elastic energy abruptly after the peak value, resulting in severe vibration and sound, and fragment ejection.

The failure mode of raw coal and sandstone

Figure 8 depicts the failure morphological characteristics of raw coal and sandstone samples subjected to under uniaxial compression. The raw coal and sandstone show the failure mode of coexistence of shear and columnar splitting, and loose fractured coal and rock blocks fall, and its macro-fracture surface is approximately parallel to the axial compression direction. The fractured coal and rock blocks interlock each other to form a single compact mass and thus support the load. The primary and new fractures intersect and combine to form a macro-fracture surface, and the compressive strength decreases with the increase in strain, also known as strain softening.

Conclusions

In this paper, coal and rock samples were collected on site, and the deformation, mechanical and failure characteristics of coal and rock under uniaxial compression were carried out, and the damage mechanism of coal and rock was analyzed from the perspective of energy, and the following conclusions were drawn:

-

1.

The complete stress–strain relationship curves of the raw coal and sandstone samples are similar, and they all exhibit the primary fracture compaction and closure stage, elastic deformation stage, fracture expansion stage and stress drop stage, all showing brittle failure.

-

2.

The ultimate bearing capacity, elastic modulus, and peak strain of coal samples are all small. The peak strength of raw coal is about 46.17% of sandstone, the elastic modulus is about 63.32% of sandstone, and the peak strain is about 69.54% of sandstone.

-

3.

In the compaction stage, the proportion of releasable elastic energy of coal sample is higher than that of dissipated energy, while that of sandstone sample is opposite. The proportion of releasable elastic energy of coal samples in other stages is higher than that of dissipated energy, and more than 80% of the total energy absorbed by coal and rock samples in the loading process is stored in the form of releasable elastic energy, and other total energy is dissipated by the internal defects of the samples during compaction, sliding and new micro-cracks in the yield stage.

References

Chen Y, Zuo JP, Song HQ, Feng LL, Shao GY (2018) Deformation and crack evolution of coal–rock combined body under cyclic loading-unloading effects. J Min Saf Eng 35(04):826–833

Chen GB, Li T, Zhang GH, PF LÜ, XY Wu (2021a) Experimental study on the law of energy accumulation before failure of coal–rock combined body. J China Coal Soc 46(S1):174–186

Chen GB, Li T, Yang L, Zhang GH, Li JW, Dong HJ (2021b) Mechanical properties and failure mechanism of combined bodies with different coal–rock ratios and combinations. J Min Strata Control Eng 3(2):84–94

Du K, Li X, Su R, Tao M, Lv SZ, LuoZhou JJ (2022) Shape ratio effects on the mechanical characteristics of rectangular prism rocks and isolated pillars under uniaxial compression. Int J Min Sci Technol 32(2):16

Zuo JP, Song HQ (2022) Energy evolution law and differential energy instability model of coal–rock combined body. J China Coal Soc 47(8):3037–3051

Gao BB, Qian YN, Lv PB (2020) Study on failure mechanics and acoustic emission characteristics of coal sample under loading rate. Chin J Undergr Sp Eng 16(02):463–474

Li ZH, Tian H, Niu Y, Wang EY, Zhang X, He S, Wang FZ, Zheng AQ (2022) Study on the acoustic and thermal response characteristics of coal samples with various prefabricated crack angles during loaded failure under uniaxial compression. J Appl Geophys 200:104618

Liu B, Zhao YX, Zhang H, Yuan Y (2020) Acoustic emission characteristics of coal under uniaxial compression and Brazilian splitting. J Min Saf Eng 37(03):613–621

Ma QF, Liu ZH, Qin YP, Tian J, Wang SL (2021) Rock plastic-damage constitutive model based on energy dissipation. Rock Soil Mech 42(5):1210–1220

Meng LC, Xu RC, Wang AM, Huang ZQ, Yuan GX (2020) Characteristics of strength and acoustic emission of granite and marble under uniaxial compression. J Eng Geol 28(06):1178–1185

Mu Y (2020) Analysis of disaster causing factors and exploration techniques in concealed mined areas in Shenfu mining area. Prog Geophys 35(3):1017–1024

Tian H, Li ZH, Shen XF, Zang ZS, Song JJ, Zhang QC (2021) Identification method of infrared radiation precursor information of coal sample failure and instability under uniaxial compression. Infrared Phys Technol 119:103957

Wang CL, Zhang CS, Li Y, Zheng C (2018) Numerical investigation of the mechanical properties of coal masses with T-junctions cleat networks under uniaxial compression. Int J Coal Geol 202:128–146

Wang CY, Chang XK, Liu YL, Guo WB (2020) Spectrum evolution characteristics of acoustic emission during the rupture process of marble under uniaxial compression condition. Rock Soil Mech 41(S1):51–62

Wang XL, Zhan SB, Yan SX, Jiang PC, Zhou N (2021) Experimental research of the effect of different bedding direction on acoustic emission characteristics of gneiss under uniaxial compression. J Henan Polytech Univ (Nat Sci) 40(01):138–145

Xia Z, Yao QL, Li XH, Yu LL, Shan CS, Li Y, Hao YS (2022) Acoustic emission characteristics and energy mechanism of CFRP-jacketed coal specimens under uniaxial compression. Constr Build Mater 342:127936

Xie HP, Ju Y, Li LY (2005) Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin J Rock Mech Eng 24(17):3003–3010

Yang L, Gao FQ, Wang XQ, Li JZ (2019) Energy evolution law and failure mechanism of coal–rock combined specimen. J China Coal Soc 44(12):3894–3902

Yang K, Liu WJ, Dou LM, Chi XL, Wei Z, Fu Q (2020) Experimental investigation into interface effect and progressive instability of coal–rock combined specimen. J China Coal Soc 45(5):1691–1700

Yang WJ, Xie Q, Ban YX, He XB, Peng GY (2021) The acoustic emission characteristics and damage constitutive model of sandstone under variable loading rates. Chin J Undergr Space Eng 17(01):71–79

Zhang YB, Wu WR, Yao XL, Liang P, Tian BZ (2020) Acoustic emission, infrared characteristic and damage evolution of granite under uniaxial compression. Rock Soil Mech 41(S1):139–146

Zhao YL, Li SC, Xiao W (2020) Visualization analysis and prospect of the current research situation in the field of coal mining subsidence in China. Coal Sci Technol 48(1):202–210

Zhao PX, He YC, Li SG, Lin HF, Jia YY, Yang EH (2020) Coal thickness effect on mechanics and energy characteristics of coal–rock combination model. J Min Saf Eng 37(5):1067–1076

Funding

This work was supported by the Research Fund of State and Local Joint Engineering Laboratory for Gas Drainage & Ground Control of Deep Mines (Henan Polytechnic University) (No. SJF202004), Huai’an Natural Science Research Program (HAB202154), Natural Science Foundation of the Jiangsu Higher Education Institutions of China (21KJB440001), 2021 “Huaishang Talents Program” Excellent Doctor of the Huai’an Higher Education Institutions (Z302J22516).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest regarding the publication of the paper.

Ethical standard

Ethics approval is not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, Y., Li, X., He, W. et al. Comparative analysis of deformation failure and energy properties of raw coal and sandstone under uniaxial compression. J Petrol Explor Prod Technol 13, 543–552 (2023). https://doi.org/10.1007/s13202-022-01573-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01573-3