Abstract

A series of natural gas fields have been discovered in the deepwater area of the Qiongdongnan Basin (QDNB) of China. However, the natural gas generation process and mechanism still exist controversy. Hence, two semi-open systematic pyrolysis experiments were conducted on a modified apparatus to study the natural gas generation process and mechanism in the deepwater area of the QDNB in this study, including pressured experiments and non-pressure experiments. In the pressured experiments, a stress pressure ranges from 37.6 to 188.2 MPa and fluid pressure ranges from 14.4 to 96.0 MPa based on the thermal evolution model of the QDNB. In non-pressured experiments, only fluid pressure from 2.0 to 5.0 MPa for a hydrous condition was compared with pressured experiments. The experiment results indicate that the pressured experiments could decrease the generated yields, expulsion efficiencies and expulsion process of the liquid hydrocarbons. Moreover, the suppression effect appears to be stronger under high evolution than that of low-maturity stage. Additionally, liptinite preservation exists during the liquid hydrocarbons and natural gas generation at temperature over 420 °C, whereas the liquid hydrocarbon is cracking to gas at temperature over 500 °C as a function of lithostatic stress, fluid pressure, temperature and time. Hence, pressure plays an important role in influencing expulsion efficiencies and expulsion process of the liquid hydrocarbons and natural gas generation in the high maturity stage.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The Qiongdongnan Basin (QDNB) is located in the western part of northern passive continental margin of the South China Sea, which was well accepted as an inner belt of hydrocarbon accumulation zone (Wang et al. 2021; Zhang et al. 2014; Xie et al. 2008). It is well accepted that the QDNB is one of the Cenozoic basins (Fig. 1) with the stretch of northeast in the basin (Zhang et al. 2007; Zhu et al. 2008). In general, the QDNB is one of the four major hydrocarbon-bearing basins on the continental shelf in the northern South China Sea, and with an area of about 6,500 km2. The QDNB is now all covered by the ocean, and the seawater from northwest to southeast becomes deeper. The variation in depth of the shelf area ranges from 90m to 200 m at present. However, the depth from the slope to the ocean varies from 200 m to about 2000 m with a rapid depth alteration, leading to the fact that the QDNB is a sedimentary basin across the shallow-water and deepwater areas.

Recently, a series of natural gas fields have been discovered in the deepwater area of the QDNB, which is characterized by high pressure and high temperature of the strata (He et al. 2001; Shi et al. 2003; Wang et al. 2021). It has been acknowledged that the geothermal field in the deepwater area of the QDNB has been reported in previous studies (Zhang et al. 2010, 2014; Wu et al. 2013). The deepwater area of the QDNB is characterized by high heat flow (He et al. 2001), high maturity (Su et al. 2012a, b) and high geothermal gradient (Yuan et al. 2009; Hu et al. 2022), which has been widely developed in the southern area of the Chinese continent and was contributed from the subsidence movement since 5.3 Ma (Hu et al. 2013; Zhao et al. 2015; Su et al. 2018). Moreover, previous studies reveal that several influencing factors, including volcanic activity, the depth of Moho, faulting, rock properties and the active thermal event after cracking or superposition, can also affect the basin geothermal field (Huang et al. 1999, 2012). The adjustment of the stress field in South China Sea, as well as lithospheric thinning during Cenozoic can determine terrestrial heat flow (Zhan et al. 2006), thus may also lead to the fact that the geothermal field in the northern continental margin basin of the northern South China Sea is relatively high compared with other basins in China.

However, hydrocarbon generation and expulsion process in the deepwater area of the QDNB, which was characterized by high heat flow, high maturity and high geothermal gradient, were still unclear, and hydrocarbon generation mechanism in the high-pressure strata of the Qiongdongnan Basin was not fully investigated in previous studies. Previous studies mainly investigated the influence of high-pressure strata on hydrocarbon generation (Carr 2000; Hao et al. 2004; Wei et al. 2009). However, results of the previous studies exist controversy, the high pressure in the deepwater area of the QDNB can enhance or obstruct hydrocarbon generation was not clear at present.

Hence, a comparative pyrolysis experiment of mudstone from deepwater area of the QDNB, including pressured experiments and non-pressured experiments, were conducted on a modified pyrolysis device with semi-open system. The modified experimental apparatus is characterized by continuous pressurized and/or depressurized, which can better simulate the natural condition in a hydrous and semi-open system. The pyrolysis facility can simulate the hydrocarbon generation and expulsion, which can better simulate the hydrocarbon generation under geological condition. Gas composition, yields of generated hydrocarbon gases, yields of expelled oil, yields of eluted oil and residual oil were measured both in pressured experiments and non-pressured experiments. The results were detailed analysis and explanation to study the influence of high pressure and temperature on hydrocarbon generation in deepwater area of the QDNB. Based on this, the natural gas generation process and mechanism in the deepwater area of the QDNB were investigated.

Experiments

Samples

In this study, two mudstone samples were collected from the Yacheng Formation in the QDNB. Two dark mudstone samples were from two boreholes of well, including YC13-1-3 and YC13-1-A2. The total organic carbon (TOC) contents and the pyrolysis data of the rocks were determined by a Rock–Eval VI instrument. The results of organic geochemical characteristics of the samples are listed in Table 1, and the hydrogen index and Tmax relationship diagram of mudstone samples from the Yacheng Formation in the deepwater area of the Qiongdongnan Basin are shown in Fig. 2. The data indicate that the type of organic matter from the source rocks of Yacheng Formation is type II2-III.

Pressure condition simulations

The mudstone samples from Yacheng Formation were characterized by typical type II2-III kerogen. The mudstone in Yacheng Formation can be utilized in simulating the hydrocarbon generation process in deepwater area of the QDNB. The burial history of selected drilling wells can be utilized to obtain the data of increasing for formation temperature. The temperature increasing program was following the burial history of selected drilling wells, which can better simulate the geological condition. The lithostatic stress (LS) and hydrostatic pressure (HP) of the source rocks at different burial depths can be calculated by the following equations:

where Pi is the LS of the source rocks, Pj is the HP of the source rocks. ρrock is the density of the rock (the value for 2.4 g/cm3 in this paper) and ρwater is 1.0 g/cm3, g is gravity about 10.0 m/s2, h is the burial depth for the rock (m). Fluid pressure (FP) of the source rocks at different depths can be calculated by the hydrostatic pressure (HP) with the pressure coefficient for the normal pressure system ranging from 0.9 to 1.2 in the QDNB (Shi et al. 2013).

In this study, two hydrous experimental systems, including pressured experimental system and non-pressured experimental system, were conducted in order to compare the process and mechanism generated hydrocarbon gases. In pressured experimental system, the LS and the HP (Su et al. 2020) at different experimental points can be calculated by Eqs. (1)(2). Additionally, the minimum and the maximum values of FP are 0.9 and 1.2 times for the hydrostatic pressure corresponding to the same buried depth, respectively, which can be obtained from the pressure coefficient ranging from 0.9 to 1.2. The value of the LS in no-pressured experimental system, the maximum and the minimum value of the FP, are 6.0 MPa, 5.0 MPa and 2.0 MPa, respectively. The applied FP was only aimed to simulate the hydrous conditions, which is called no-pressured experimental system. The calculated results for pressured experimental system and non-pressured experimental system are presented in Table 2.

Experimental procedures

WYMN-3 is a high-temperature and high-pressure (HTHP) simulation apparatus with semi-open experimental system (Fig. 3). In this study, the hydrous pyrolysis experiments were finished by a HTHP simulator in order to conduct programmed pressure of LS and FP under the same temperature, heating rate and duration times. The apparatus includes a software control system and a hardware performance system. The former was controlled by a computer through corresponding to the transmission lines and recorded the data per minute for FP, LS, temperature and time. The control of the FP and LS is dominated to the subprime systems, which are consists of the fluid supplement system and the hydraulic control system. Temperature is monitored by thermocouples (XMT–131) installed at the different part, which are next with the outer wall of the reactor. Moreover, the simulator designs a vertical cylindrical reactor with internal hollow for the cylindrical sample cell, which outer diameter is almost the same internal diameter of the reactor. The effluent for generated oil and gas is withdrawn from the top of the reactor by a valve and fine pipe (diameter for 0.3 mm) as well as deep open faults served as vertical hydraulic conduits and channeled the deep high pressure into shallow permeable formations. Hence, the generated hydrocarbons could be occurred, discharged and controlled by the values in the HTHP simulator, which could be controlled by the electrical properties via software settings.

The cylindrical sample cell was encased by the cylindrical reactors and was filled with about rock samples at designed temperatures. The reactor was purged with helium of 2–15 MPa before sealing. The reactor was repeatedly filled with de-ionized water of 80.0 MPa by a high-pressure electric pump in order to simulate a hydrous environment. The programmed heating temperature can be described as follows: programmed at 1 °C/min to 200 °C and then to setting temperature of 300, 320, 340, 360, 380, 400, 420, 450, 500, 520 and 540 °C by controlling the oven temperature during the experiments, which combined with variable linear heating rates of 2.0 °C/h for 300–340 °C and 5.0 °C/h for 340–540 °C, respectively. In pressured experiments, the FP and LS altered with increasing temperature (Table 2). After the oven temperature was programmed increased from room temperature to 200 °C at 1 °C/min. The FP begins to increase at about 100 °C and reach 6 MPa at 200 °C. And the pressure was increased. While the FP is over the maximum value in the HTHP simulator, the valve opened automatically and expulses the vapor, gaseous and liquid hydrocarbons. The valve closes automatically and continues to heat by the designed temperature. The above processes, including samples loading, sealing and heating, were repeated for each designed temperatures until the end of the experiments, whereas the LS in non-pressured experiment and FP maintained are 6 MPa and 2–5 MPa, respectively.

Pyrolysis products collection

The valve and vent were opened after finishing the pyrolysis experiment and reducing the oven temperature to 150 °C. Hence, the pyrolysis products can be transferred to the gas–liquid separators. In this study, the generated hydrocarbon gases were collected by draining water. However, the generated liquid hydrocarbons, including expelled oil, eluted oil and residual oil, were characterized by varied occurrences and collected by different approaches. The expelled oil was collected by dichloromethane from the gas–liquid collector in the cold trap and instrument piping. The eluted oil was collected by dichloromethane from the sample surface. Moreover, the residual oil is to be extracted using a Soxhlet apparatus from the sample after the pyrolysis experiments.

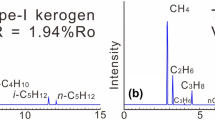

Pyrolysis products analysis

The chemical compositions of the gas products at different temperatures were determined. C1–C3 and the non-hydrocarbons were measured by a MAT 271 mass-spectrometer. C3 + was measured by an Agilent 6890 N gas chromatograph (GC) equipped with a capillary column (PLOT Al2O3 50 m × 0.53 mm i.d.). A flame ionization detector (FID) and a thermal conductivity detector (TCD) were connected to the column using Helium as the carrier gas. The GC oven temperature was initially set to 30 °C for 10 min, and then increased to 180 °C at 10 °C/min and held at this temperature for 20–30 min. Moreover, the liquid hydrocarbon was quantified by gravimetric method.

Results and discussion

The yields of pyrolysis products in different experimental systems

Liquid hydrocarbons can be divided into expelled oil, eluted oil and residual oil, and the gaseous hydrocarbons produced can be divided into four groups, including methane, ethane, propane and heavy gaseous hydrocarbons (C4–6). The yields of expelled oil, eluted oil and residual oil are presented in Table 3. The yields of methane, ethane, propane and heavy gaseous hydrocarbons (C4–6) are presented in Table 4.

In the results of non-pressured experiments, the yields of oil alter with increasing of temperatures. The expelled oil in sample 1 increases from 0.007 to 0.036 mg/g.TOC and then decreases, and the eluted oil in sample 1 increases at first and then decreases. The liquid oil in sample 1 increases from 0.010 to 0.039 mg/g.TOC, whereas the residual oil in sample 1 increases at first and then decreases. However, in the results of pressured experiments, the yields of oil also alter with increasing of temperatures. The expelled oil in sample 1 increases at first and then decreases, and the eluted oil in sample 1 increases at first and then decreases. The liquid oil in sample 1 increases from 0.006 to 0.025 mg/g.TOC and then decreases, whereas the residual oil in sample 1 increases at first and then decreases. The alteration of pyrolysis products in pressured and non-pressured experimental systems is of same characteristics with sample 2.

The yields of C1 and C2+ gas fractions generation derived from organic-rich mudstone in two series of the pressured experiments (P–T–t) and the non-pressured experiments (T–t) reveal that the yields of methane increase with increasing temperatures, whereas the yields of ethane, propane and C4-6 increase at first and then decrease with increasing of temperatures may due to the secondary cracking of generated gas hydrocarbons at relatively high temperatures.

The process of liquid hydrocarbon generation in deepwater area of QDNB

Liquid hydrocarbon products generated during the simulation, including the expelled oil, the eluted oil and the residual oil. The yields of expelled oil, eluted oil and residual oil in pressured and non-pressured experiments of two samples are presented in Fig. 4. In general, the expelled oil and the liquid hydrocarbon show a trend of decrease after an initial increase with the yield peak at 500 °C. The expelled oil yields in non-pressured experiments are higher than the yield of pressured experimental system at the same duration time and temperatures. Moreover, the expelled oil yield of the mudstone sample of YC13-1–3 well is much lower than that of the mudstone sample from YC13-1-A2 well. Detailed data show that the amount of the expelled oil is greater than that of the eluted oil in the liquid hydrocarbon products of the generation, so the trend of the liquid hydrocarbon yield is more similar to the trend of the expelled oil yield. The residual oil yield shows a trend of increasing firstly and then decreased with the yield peak at 450 °C at the temperature from 340 to 540 °C. Generally, the residual oil yields in non-pressured experimental system are lower than that of pressured experimental system (Fig. 4).

Suppression expulsion during the low–medium-maturity stage leads to the expulsion efficiency up to 80% in high-over mature stage (Fig. 4 g, h). The characteristics of expulsion efficiency in pressured and non-pressured experimental systems are described as follows: (1) Mid-stationary stage (1.0% < Ro < 1.5%), the pressure inhibition enhances, as well as oil cracking gas and adsorption effects can also contribute to the burden of hydrocarbon expulsion. Hydrocarbon expulsion efficiency steadily increases with the increase in liquid hydrocarbon. (2) Late-efficient stage (Ro > 1.5%), the effect of stranded liquid hydrocarbon cracking gas enhances and expulsion efficiency increases up to 80% rapidly. (3) The expulsion efficiency under pressurized (fluid pressure plus lithostatic stress) mode is 10–15% lower than non-pressurized mode. The joint control of the fluid pressure and the lithostatic stress significantly inhibit the efficiency of liquid hydrocarbon expulsion and discharge process.

The process of gas hydrocarbon generation in deepwater area of QDNB

The generated hydrocarbon gases of the pressured and non-pressured pyrolysis experiment are presented in Fig. 5. The yield of the total gas and methane show an upward trend in the same duration time and temperature. The yield of the total gases and methane for pressured experimental systems is higher than that of non-pressured experimental system on the overall trend in the same duration time and temperature over 420 °C. However, the yields of the hydrocarbon gases, including ethane, propane and heavy gaseous hydrocarbons (C4–6), show a trend of increasing first and then decreasing with the yield peak at 420 °C.

The influence of pressure on hydrocarbon generation and expulsion in deepwater area of QDNB

The hydrocarbon generation in previous studies was mainly conducted in a closed system or in an open system during the evolutionary process of hydrocarbon source rocks burial and compaction. However, the thermal fluid activity shows characteristics of semi-open system, indicating that the episodic-fluid fracturing and episodic-hydrocarbon expulsion will occur when fluid pressure over the critical value. The episodic-compaction and episodic-hydrocarbon expulsion has been confirmed in overpressure environment of Yinggehai Basin (Xie et al. 2004). As an adjacent area of Yinggehai Basin, the QDNB has characteristics of rapid sedimentation since neotectonic period (5.3 Ma), especially in the west area of the QDNB (Fig. 6). This led to a rapid evolution of the source rock of Yacheng Formation and the maturity of the source rocks can reach high-over maturity, where Ro is 2.1% at 5500 m of the burial depth for Well YA26-1-1 in the QDNB (Su et al. 2012a, b), which is higher than that of 1.2–1.6%Ro in the Vøring and Møre Basins (Aidos Kazankapov 2019). Therefore, the hydrocarbon expulsion has a close relationship with episodic-thermal fluid activity in this area.

Map showing the burial history curves for Yacheng Formation of the Qiongdongnan basin based on Ya13-1 gas field and parameter well YC13-1-4 (revised after Su et al. 2018)

The generation and expulsion process of the hydrocarbon in deepwater area of the QDNB indicates that the pressured experiments decrease the generated yields, expulsion efficiencies and expulsion process of the liquid hydrocarbons during kerogens cracking. The suppression effect appears to be stronger under high evolution than that of low–medium evolution. Additionally, pressured experiments favor liptinite preservation of the liquid hydrocarbons and natural gas generation at temperatures over 420 °C, whereas the liquid hydrocarbon is cracking to gas at temperatures over 500 °C, which was acted as a function of lithostatic stress and fluid pressure, temperature and time.

At the same temperature, the coupling effects of fluid pressure and lithostatic stress accelerate generation process of natural gas obviously. Similar to the deep depression with sustained, rapid and huge late settlement buried, the rapid heating pressurized condition at medium–high-maturity stage at medium–high-maturity stage results in a sharp increase in the yield rate of the generated hydrocarbon gases. On the one hand, the yield rate of expelled oil sharply declines during the medium–high-maturity evolution, which significantly promote the conversion of expelled oil and residual oil at medium–high-maturity stage. Rapid increase in expelled oil and residual oil yields accelerate the generation of natural gas. On the other hand, the yield of ethane, propane and heavier hydrocarbons decreases as they cracking into methane in the medium–high-maturity evolution, which also accelerate the generation of natural gas at the later stage.

Conclusions

In this study, two hydrous experimental systems, including pressured experimental system and non-pressured experimental system, were conducted in order to compare the process and mechanism generated hydrocarbon gases. Gas composition, yields of generated hydrocarbon gases, yields of expelled oil, yields of eluted oil and residual oil were measured both in pressured experiments and non-pressured experiments. The results were detailed analysis and explanation to study the influence of high pressure and temperature on hydrocarbon generation in deepwater area of the QDNB. Based on this, the natural gas generation process and mechanism in the deepwater area of the QDNB were deeply investigated. The main conclusion is as following:

-

(1)

Compared with the hydrocarbon generation process and characteristics for different experiment systems, the pressured experimental system significantly inhibited the generated yields, expulsion efficiencies and expulsion process of the liquid hydrocarbons, including expelled oil eluted oil and residual oil.

-

(2)

The influence of pressure on expulsion efficiency can be divided into: (i) Mid-stationary stage (1.0% < Ro < 1.5%), Hydrocarbon expulsion efficiency steadily increases with the increase in liquid hydrocarbon. (ii) Late-efficient stage (Ro > 1.5%), the effect of stranded liquid hydrocarbon cracking gas enhances and expulsion efficiency increases up to 80% rapidly. (iii) The expulsion efficiency under pressurized (fluid pressure plus lithostatic stress) mode is 10 ~ 15% lower than non-pressurized mode.

-

(3)

The results reveal that an obvious promotion of natural gas yield mainly exists in the high-maturity stage. Meanwhile, the expelled oil and residual oil decreased, suggesting that the source rocks in the deepwater area of the QDNB can generate natural gas at high pressure at relative high-maturity level. Hence, the existed pressured condition of the deepwater area of the QDNB acts as the leading factor for influencing the natural gas generation process.

Data availability

The data used in this study are included within the article.

References

Carr AD (2000) Suppression and retardation of vitrinite reflectance, Part 2. Derivation and testing of a kinetic model for suppression. J Petroleum Geology 23(4):475–496

Hao F, Jiang JQ, Zou HY, Fang Y, Zeng ZP (2004) Differential retardation of organic matter maturation by overpressure. Sci China Series D-Earth Sci 47(9):783–793

He LJ, Wang KL, Xiong LP, Wang JY (2001) Heat flow and thermal history of the South China Sea. Phys Earth Planet Inter 126(3–4):211–220

Hu B, Wang LS, Yan WB, Liu SW, Cai DS, Zhang GC, Zhong K, Pei JX, Sun B (2013) The tectonic evolution of the Qiongdongnan Basin in the northern margin of the South China Sea. J Asian Earth Sci 77:163–182

Hu HY, Dai LD, Sun WQ, Zhuang YK, Liu KX, Yang LF, Pu C, Hong ML, Wang MQ, Hu ZM, Jing CX, Li C, Yin CY, Paramasivam S (2022) Some remarks on the electrical conductivity of hydrous silicate minerals in the Earth crust, upper mantle and subduction zone at high temperatures and high pressures. Minerals 12:161

Huang BJ (1999) Gas potential and its favorable exploration areas in Qiongdongnan basin. Nat Gas Ind 19(1):34–39

Huang BJ, Li XS, Wang ZF, Li L, Huang YW (2012) Source rock geochemistry and gas potential in the deep water area, Qiongdongnan basin. China Offshore Oil Gas 24:1–7

Kazankapov A (2019) Geochemistry of natural gases in the Vøring and Møre Basins. A thesis for the degree of Master of Science (Geology) of the Faculty of the Colorado School of Mines.

Shi XB, Qiu XL, Xia KY, Zhou D (2003) Characteristics of surface heat flow in the South China Sea. J Asian Earth Sci 22(3):265–277

Shi WZ, Xie YH, Wang ZF, Li XS, Tong CX (2013) Characteristics of overpressure distribution and its implication for hydrocarbon. J Asian Earth Sci 66(2013):150–165

Su L, Zheng JJ, Chen GJ, Zhang GC, Guo JM, Xu YC (2012a) a)The upper limit of maturity of natural gas generation and its implication for Yacheng formation in the Qiongdongnan Basin of the South China Sea. J Asian Earth Sci 54–55(4):203–213

Su L, Zheng JJ, Wang Q, Shen HL, Chen GJ (2012b) b) Formation mechanism and research progress on overpressure in the Qiongdongnan Basin. Natural Gas Geosci 23(4):662–672

Su L, Zhang DW, Yang HZ, Chen Y, Chen GJ, Zheng JJ, Xu YC (2018) Chemical kinetics evaluation and its application of natural gas generation derived from Yacheng formation in the deep-water area of the Qiongdongnan Basin. China Acta Oceanologica Sinica 37(1):50–59

Su L, Zhang DW, Zheng LJ, Liu XW, Yang X, Zheng JJ, Liu P (2020) Experimental study of the influences of pressure on generation and expulsion of hydrocarbons: a case study from mudstone source rocks and its geological application in the Tarim Basin. J Pet Sci Eng 189(2020):1–10. https://doi.org/10.1016/j.petrol.2020.107021

Wang B, Lü FL, Li S, Li J, Yang ZL, Li L, Wang XF, Lu YT, Yang TT, Wu JW, Sun GZ, Ma HX, Xu XY (2021) A buried submarine canyon in the Northwestern South China Sea: architecture, development processes and implications for hydrocarbon exploration. Acta Oceanol Sin 40(2):29–41. https://doi.org/10.1007/s13131-021-1751-0

Wei T, Zou YR, Cai Y, Liu JZ, Song ZG, Peng PA (2009) Can pressure promote hydrocarbon generation from organic matter?-New experimental proof. Geochemical J 43(4):287–292

Wu JF, Yang SC, Zhang GC, Shan JN, Tang XY (2013) Geothermal history and thermal evolution of the source rocks in the deep-water area of the northern South China Sea. Chinese J Geophys 56(1):70–180

Xie YH, Wang ZF, Tong CX (2008) Petroleum geology of Yacheng 13–1, the largest gas field in China’s offshore region. Mar Pet Geol 25(4–5):433–444

Xie XN, Liu XF, Zhao SB, Jiang T (2004) Fluid flow and hydrocarbon migration pathways in abnormally pressured environments. Earth Sci J China Univ Geosci 29(5):589–595

Yuan YS, Zhu WL, Mi LJ, Zhang GC, Hu SB, He IJ (2009) Uniform geothermal gradient and heat flow in the Qiongdongnan and Pearl River Mouth Basins of the South China Sea. Marand Petrol Goel 26(7):1152–1162

Zhan WH, Zhu ZY, Sun LT, Sun ZX, Yao YT, Qiu XL (2006) The epoch and diversities of neotectonic movement in the South China Sea. Acta Geol Sin 80(4):491–496

Zhang GC, Mi LJ, Wu SG, Tao WX, He SB, Lü JJ (2007) Deep-water area: the new prospecting targets of northern continental margin of South China Sea. Acta Petrolei Sinica 28(2):15–21

Zhang GC, Zhu WL, Mi LJ, Zhang HH, Liang JS, Qu HJ (2010) The theory of hydrocarbon generation controlled by source rock and heat from circle distribution of outside-oil fields and inside-gas fields in South China Sea. Acta Sedmentologica Sinica 28(5):987–1005

Zhang GC, Zhang YN, Shen HL, He YP (2014) An analysis of natural gas exploration potential in the Qiongdongnan Basin by use of the theory of joint control of source rock and geothermal heat. Nat Gas Ind 1(4):41–50

Zhao ZX, Sun Z, Wang ZF, Sun ZP, Liu JB, Zhang CM (2015) The high resolution sedimentary filling in Qiongdongnan Basin. Northern South China Sea Marine Geol 361:11–24

Zhu WL, Zhang GC, Gao L (2008) Geological characteristics and exploration objectives of hydrocarbons in the northern continental margin Basin of South China Sea. Acta Petrolei Sinica 29(1):1–9

Acknowledgements

The study is joint supported by the Western Light Talent Culture Project of the Chinese Academy of Sciences (Y404RC1), Science and Technology Program of Gansu Province (1501RJYA006) and the National Petroleum Major Projects (2016ZX05026-007-005).

Funding

The study is joint supported by the Western Light Talent Culture Project of the Chinese Academy of Sciences (Y404RC1), Science and Technology Program of Gansu Province (1501RJYA006) and the National Petroleum Major Projects (2016ZX05026-007-005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, S., Su, L., Zhang, D. et al. Hydrocarbon generation and expulsion process in the deepwater area of the Qiongdongnan Basin of China: insights from artificial thermal maturation experiments. J Petrol Explor Prod Technol 13, 427–438 (2023). https://doi.org/10.1007/s13202-022-01558-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01558-2