Abstract

Wellbore instability is frequently encountered in the process of shale oil drilling. Due to the anisotropic strength characteristics of shale, most conventional models are not suitable for wellbore stability analysis in layered formation. In this paper, taking the continental shale in the north of Songliao Basin as the research object, the anisotropic elasticity and strength parameters of shale are measured experimentally. Based on pore elastic mechanics, an anisotropic wellbore stability model of layered shale is established, and the variation of collapse pressure under different formation conditions is analyzed. The results show that considering the elastic and strength anisotropy, the collapse pressure is the largest, and the influence of strength anisotropy is significantly greater than that of elastic anisotropy. The stability of horizontal wells drilled along the horizontal maximum principal stress is the optimal, followed by vertical wells and small angle directional wells. The actual drilling conditions of G101 well are basically consistent with the prediction results, which confirms the accuracy of the model. According to the traditional wellbore stability model, the equivalent density of collapse pressure in horizontal well section is 1.58 ~ 1.76 g/cm3. It is much lower than the collapse density of 1.86 g/cm3 calculated by the anisotropic model in this study. The findings of this study can help for better understanding of the mechanism of wellbore instability in horizontal wells in shale formations. The model can be used to guide the drilling engineering design of shale oil horizontal wells and reduce the losses caused by the instability of the wellbore.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, with the development of conventional oil and gas resources has gradually failed to meet the demand of current industrial development, the development of unconventional oil and gas resources such as shale oil has gradually become a focus of attention. However, the wellbore instability of shale formation seriously restricts the efficient development of shale oil. After drilling the formation to form a wellbore, the drilling fluid column pressure replaces the support provided by the formation, breaks the original stress balance of the formation, and causes the stress redistribution of the rocks around the wellbore (Asaka and Holt 2020; Ma and Chen 2015; Ma et al. 2016). If the redistributed stress exceeds the maximum load that the shale can support, it will lead to wellbore instability. In addition, drilling fluid intrudes into the formation, causing the increase of formation pore pressure and the decrease of shale strength, which will further aggravate the instability of wellbore (Ding et al. 2020; Ma et al.2020a, b, c, d; Ma et al. 2020a, b, c, d). In the development of shale oil, the unstable layered shale is usually the target layer to drill long horizontal well, and there is a particularity of itself, and the secondary stress distribution in horizontal wells is quite different from that in straight wells. In addition, due to the complex in situ stress, bedding and fracture development of shale reservoir, the risk of wellbore collapse is aggravated (Liu et al. 2016; Zeynali 2012; Ibrahim 2021; Zarei and Nasiri 2021).

Aiming at the wellbore instability of layered shale, researchers have carried out a lot of research and achieved rich results. Chenevert and Gatlin (1965), Aadnoy (1988); Dusseault and Gray (1992), Lee (2004), Shuai et al. (2015) analyzed the effect of bedding on wellbore stability by adopting single weak plane strength theory and anisotropic strength theory. Liang et al. (2014), Kang et al. (2011), Zhi et al. (2016), Nguyen et al. (2020) studied the relationship between wellbore stability and bedding shale based on single weak plane strength theory and linear elastic wellbore stability model. Chen et al. (2015a, b), Ma et al. (2019), Ma et al. (2020a, b, c, d) studied the effect of bedding plane occurrence and bedding plane strength reduction on the stability of vertical wells.

However, at present, for the instability of shale wellbore, the comprehensive consideration of elasticity and strength anisotropy is not insufficient. Hard and brittle shale strata have weak planes, and the research on formation collapse pressure mostly focuses on the influence of weak planes or formation mechanics anisotropy alone, and does not comprehensively study the dual influence of formation mechanics and strength anisotropy. Moreover, the current research on shale wellbore stability in China mainly focuses on the marine shale of Longmaxi formation in Sichuan, and the wellbore instability of continental shale in the north of Songliao basin has not been studied. Therefore, in this paper, the anisotropic wellbore collapse pressure model is established for the study of layered shale oil horizontal wells. The variation of wellbore collapse pressure of continental shale is analyzed, and an example is analyzed to verify the correctness of this method. The regularity of wellbore collapse pressure of continental shale is analyzed, and the correctness of the method is verified by the analysis of a horizontal well G101 of shale oil in the north of Songliao Basin. The research results of this paper reveal the mechanical mechanism of wellbore instability in anisotropic shale, which can be used to guide the drilling design of shale oil horizontal wells and the prevention of wellbore instability.

The research route of this paper is shown in Fig. 1. First, rock mechanics experiments are carried out for continental shale in Songliao basin. Then, the elastic and strength anisotropy parameters of shale in this block are determined, respectively. Next, the anisotropic wellbore stability model of shale is established. Afterwards, the difference of shale wellbore collapse pressure under three anisotropic conditions is analyzed and discussed. Finally, a well in the oil field is used to verify the accuracy of the model.

Anisotropic mechanical properties of continental shale in Songliao Basin

Experimental core preparation

Through the observation of full-scale cores, it can be found that the shale bedding and fractures in this block are obviously developed, and the weak plane is clearly visible. Since the shale is prone to hydration expansion when encountering water, it cannot be cut and cored used in conventional processing methods, so the full-size core is processed by using the NC wire cutting method. According to the coring method in Fig. 2, the 0, 30°, 45°, 60°, 90° direction cores are processed, respectively, and both ends of the sample are cut flat and polished to make the length diameter ratio of the shale sample about 2.

X-RD diffraction experiment

The mineral composition of continental shale in Songliao basin is analyzed and tested by X-ray diffraction analysis technology. The main minerals of shale in this block are quartz and clay, the content of quartz is 23.4 ~ 29.4%, and the content of clay minerals is 33.3 ~ 45.6%. There is also a part of dolomite, calcite and plagioclase, which belongs to a typical hard brittle mineral. Quartz and feldspar are the main brittle minerals in shale. The brittle minerals of shale in this block generally exceed 50%, which is an important factor affecting the development degree of pores and microfractures in shale matrix. The higher the content of quartz and feldspar, the greater the brittleness of shale and the higher the possibility of fracture development (Liu et al. 2021). The clay minerals in the shale are mainly illite and chlorite, containing a small amount of illite–smectite mixed layer, without pure smectite minerals, and the content of smectite in illite–smectite mixed layer is not high, indicating that it has certain hydration characteristics, but its hydration expansion is not obvious. Illite content is 53 ~ 68.5%, chlorite content is 6.4 ~ 23.5%.

In the actual drilling operation, the filtrate of drilling fluid enters the formation, and the clay minerals are hydrated and dispersed, and the hydration expansion capacity is weak. However, different clay minerals have different hydration expansion characteristics along different directions. Different clay particles have different water absorption and expansion rates, resulting in different expansion pressures, resulting in unbalanced stress in the formation and reduced formation strength, which is easy to cause spalling and collapse of the formation along the bedding and fracture section. The polarity of water in the drilling filtrate is extremely strong, the hydroxyl group of water and the surface of the clay particles and the surface of the silt particles, replacing the original hydrogen bonds between clay particles, silt particles and clay particles and silt particles. It will reduce the binding force between rock particles, disperse rock particles, reduce the friction strength of bedding and fracture surface. As a result, the shale wellbore is unstable, resulting in serious borehole collapse.

Uniaxial and triaxial compression strength experiment

In order to clarify the mechanical anisotropy characteristics of shale in block G of Songliao Basin, the cores of the three wells are collected, and the uniaxial and triaxial experiments are carried out by TAW2000 microcomputer controlled triaxial stress testing machine. The core crushing morphology after loading in parallel bedding direction and vertical bedding direction is shown in Figs. 3 and 4.

The fracture morphology of shale is different after loading in parallel bedding and vertical bedding directions. When it is loaded in parallel to the bedding direction, it will generate multiple openings the bedding seam to form multiple groups of fragments along the bedding plane. However, the vertical direction of bedding loading will produce the shear crack first, and the shear crack and the micro-crack along the bedding are connected to each other to form a large volume fracture. It can be concluded that the rock loaded parallel to the bedding direction produces tensile failure along the structural plane, and the vertical bedding direction needs to overcome the shear strength of the shale body.

As can be seen from Table 1, since the shale in Block G is a bedding developmental formation, its uniaxial compressive strength is related to the coring angle of the core and is a function of the loading direction and the angle between the bedding planes. The strength of shale samples with sampling angle of 60° is the lowest, the strength of shale samples with sampling angle of 45° is slightly higher, while the strength of shale samples with sampling angle of 90° (perpendicular to bedding plane) is the highest, and the strength of shale samples with sampling angle of 0 (parallel to bedding plane) is lower than that of shale samples with sampling angle of 90°. With the increase of sampling angle, the strength is the highest when the loading direction is perpendicular to the shale bedding plane. According to Mohr Coulomb criterion, when the angle is 45° + φ/2 (φ is the internal friction angle), and then the strength increases gradually. These characteristics fully show that the shale in this block shows significant anisotropic mechanical characteristics.

As shown in Fig. 5, as the increase of confining pressure, the compressive strength of shale is enhanced. When the bedding direction and loading direction are at different angles, the failure form of shale also changes:

-

(1)

When the angle between the loading direction and the bedding is 0° ~ 30°, the splitting failure mainly occurs along the bedding plane.

-

(2)

When the angle between the loading direction and bedding is 30° ~ 75°, shear slip mainly occurs along the bedding plane.

-

(3)

When the loading direction and bedding are 75° ~ 90°, the shear failure of shale body mainly occurs, and the strength is the largest.

Determination of anisotropic elastic parameters of shale

Considering that the shale in block G of Songliao basin has significant hard brittle characteristics, the stress–strain curve shows significant elasticity and anisotropy. Therefore, shale can be assumed as transversely isotropic porous elastic medium, and the elastic constitutive equation of transversely isotropic porous elastic medium can be expressed as (Cao et al. 2017):

where \(\varepsilon\) is the strain vector under stratum coordinate; \(C\) is the flexibility matrix under stratum coordinate; \(\sigma\) is the stress vector under stratum coordinate, MPa; \(E_{{\text{h}}} ,E_{v}\) are the elastic modulus parallel to the bedding direction and perpendicular to the bedding direction, respectively, MPa;\(v_{{\text{h}}} ,v_{v}\) are the Poisson's ratio to the bedding direction and perpendicular to the bedding direction, respectively; \(G_{h} ,G_{v}\) are the shear modulus parallel to the bedding direction and perpendicular to the bedding direction, respectively, MPa.

Therefore, according to Eqs. (1) –(4), combined with the uniaxial shale mechanics test results of continental shale in Songliao Basin shown in Table 1, the elastic parameters of the block shale are shown in Table 2:

Determination of anisotropic strength parameters of shale

According to the uniaxial and triaxial compression test results of shale, the continental shale in Songliao basin shows significant anisotropic strength characteristics. If the traditional isotropic Mohr Coulomb criterion is used to characterize the strength of this shale, it will not accurately reflect the strength anisotropy of shale. In this paper, the single weak plane strength theory is used to describe the strength anisotropy of shale. The strength failure criterion of rock can be divided into discontinuous model and continuous model. Because the bedding shale has a large number of discontinuous weak planes, the discontinuous model can effectively predict the anisotropic strength of shale. Chenevert et al. (1965) confirmed through experiments that when the angle between the normal of the bedding plane and the maximum principal stress is 20° ~ 30°, its strength is about 40% lower than that of coring along the direction perpendicular to the bedding plane. In this paper, Jaeger's single weak plane strength failure criterion is used to describe the strength anisotropy of layered shale. A group of weak planes AB are developed in shale. It is assumed that the angle between AB plane (referring to its normal direction) and the direction of maximum principal stress is \(\beta\). Jaeger (1960) studied layered shale and established a single weak plane criterion. There are two forms of shear failure of layered stratum: shear failure along bedding plane and shear failure of rock matrix, which is expressed as:

Failure model of shale matrix:

Failure model of weak plane:

where \(\sigma_{1} ,\sigma_{3}\) are the maximum principal stress and the minimum principal stress, respectively, MPa; \(c_{0} ,c_{w}\) are the cohesion of shale matrix and weak plane, respectively, MPa; \(\varphi_{0} ,\varphi_{w}\) are the internal friction angle of shale matrix and weak plane, respectively, \(^\circ\); \(\beta_{0} ,\beta\) are the angle between the failure plane of shale body and the maximum principal stress, and between the normal of weak plane and the maximum principal stress, respectively, \(^\circ\);\(\beta_{0} = \frac{\pi }{4} + \varphi_{0}\).

According to the uniaxial and triaxial compression test results of shale, the mechanical parameters of shale are obtained by grid search method (Ma et al. 2020a, b, c, d). The theoretical strength under different confining pressures is calculated and compared with the measured results. The results are shown in Fig. 7.

As a typical structure of shale, the weak surface will affect the overall rock strength. However, rock strength is not only related to structure, but also related to its stress state. Therefore, by setting different confining pressure conditions, the relation between the strength of shale and the angle of weak plane is obtained, as shown in Fig. 6. As the increase of confining pressure, the rock strength is increased. As the change of dip angle of weak plane, weak plane failure occurs and the strength decreases obviously at some dip angles. However, under high confining pressure, the angle range is reduced along the weak plane, indicating that the rock is not easily destroyed along the weak plane under high confining pressure.

In Fig. 7, the method for obtaining the anisotropic strength parameters of shale is as follows: the grid search calculation (Ma et al. 2020a, b, c, d) is carried out on the test results of shale samples with sampling angles of 0 and 90°, and the optimal cohesion of shale matrix and the optimal internal friction angle of matrix are 10.00 MPa and 33°, respectively. The optimal cohesion and internal friction angle of the weak plane are 3 MPa and 27°, respectively, according to the grid search calculation of the test results of shale samples with sampling angle of 30°, 45° and 60°.

Anisotropic wellbore collapse pressure model of shale

Wellbore stress distribution model

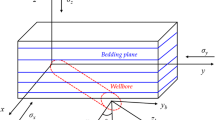

Considering that shale is a hard brittle rock, the stress–strain curve shows strong elasticity and significant anisotropy, so shale can be assumed to be a transversely isotropic medium. Once the borehole is drilled, the secondary distribution of stress around the well will occur. In order to accurately calculate the stress distribution around the well in transversely isotropic medium, necessary coordinate transformation is adopted. Four coordinate systems are involved here (Fig. 8): geodetic rectangular coordinate system, stratigraphic rectangular coordinate system, in situ stress rectangular coordinate system and borehole rectangular coordinate system.

The secondary distribution stress is closely related to the in situ stress and wellbore pressure, including three components: the in situ stress component before the wellbore is drilled, the stress component caused by wellbore formation, and the stress component caused by wellbore fluid pressure. Among them, the in situ stress component is solved by coordinate transformation, which is to convert the in situ stress to borehole rectangular coordinate system; the other two components are solved by the analytical formula derived by Aadnøy (1987). Finally, the three stress components can be linearly superimposed, and the borehole stress distribution model under the borehole rectangular coordinate system of the transversely isotropic medium can be obtained.

where \(\sigma_{xx} ,\sigma_{yy} ,\sigma_{zz} ,\tau_{xy} ,\tau_{yz} ,\tau_{xz}\) are wellbore circumferential stress in rectangular coordinate system, MPa; \(\sigma_{xx0} ,\sigma_{yy0} ,\sigma_{zz0} ,\tau_{xy0} ,\tau_{yz0} ,\tau_{xz0}\) are component of in situ stress in borehole rectangular coordinates, MPa; \(a_{ij}\) is the flexibility matrix coefficient of formation in borehole local coordinates, \(i = 1,2,3,j = 1,2, \cdot \cdot \cdot ,6;\) \(\phi_{1}^{^{\prime}} (z_{1} ),\phi_{2}^{\prime } \left( {z_{2} } \right),\phi_{3}^{\prime } \left( {z_{3} } \right)\) are the three analytic functions; \(\mu_{i}\) is the eigenvalue of characteristic equation corresponding to strain compatibility equation; \(z_{i}\) is the complex variable; \(\lambda_{i} ,\gamma_{i}\) are the intermediate variables related to characteristic roots.

In order to facilitate the calculation and solution of collapse pressure, the stress component in borehole cylindrical coordinate should be calculated first. According to the coordinate relationship shown in Fig. 8, through the transformation of the rotation axis formula, the wellbore stress component in cylindrical coordinates can be obtained as follows:

where \(\sigma_{r} ,\sigma_{\theta } ,\sigma_{z} ,\tau_{r\theta } ,\tau_{\theta z} ,\tau_{rz}\) are wellbore stress component in cylindrical coordinates, MPa;\(\theta\) is well circumference angle,\(^\circ\).

Calculation method of collapse pressure

In order to determine whether the wellbore stress exceeds the shale strength, the maximum and minimum principal stresses around the wellbore need to be obtained. According to the analysis of wellbore stress state, the maximum and minimum principal stresses can be obtained as follows:

The angle between the maximum principal stress and the borehole axis is as follows:

After the maximum and minimum principal stresses of the wellbore are obtained, the wellbore stability can be calculated in combination with the anisotropic strength criterion. Due to the existence of weak plane in shale, comprehensive calculation needs to be carried out according to borehole trajectory, bedding occurrence, angle between maximum principal stress and borehole axis, etc. It can be used to judge whether the weak plane failure or the main body failure occurs in the shale. The angle between the maximum principal stress and the normal direction of bedding plane is as follows:

where \({\varvec{n}}\) is the normal vector of bedding plane; \({\varvec{N}}\) is the direction vector of maximum principal stress in wellbore.

If the angle calculated by Eq. (11) satisfies \(\beta_{1} \le \beta \le \beta_{2}\), substitute the maximum principal stress and minimum principal stress of the wellbore calculated by Eq. (9) into Eq. (6) to judge the wellbore stability. The critical collapse pressure along bedding failure can be obtained by solving the nonlinear equation with \(p_{w}\). If the angle calculated by Eq. (11) does not satisfies \(\beta_{1} \le \beta \le \beta_{2}\), substitute the maximum principal stress and minimum principal stress of the wellbore calculated by Eq. (9) into Eq. (5) to judge the wellbore stability. The critical collapse pressure along body failure of shale can be obtained by solving the nonlinear equation with \(p_{w}\).

Analysis of wellbore collapse pressure of continental shale in Songliao Basin

For continental shale in Songliao Basin, the collapse pressure is closely related to formation occurrence, borehole trajectory, shale rock mechanical parameters, in situ stress and pore pressure conditions, etc. In order to analyze the influence of anisotropic characteristics on the wellbore instability of continental shale, based on the measured data in the block, the equivalent density of collapse pressure is calculated under isotropic, elastic anisotropic, elastic and strength anisotropic conditions. The basic parameters are shown in Table 3.

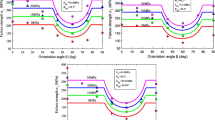

Calculation results of isotropic model

Figure 9 shows the hemispherical projection of the wellbore trajectory to the collapse pressure calculated by the isotropic model. The center of the contour line of equivalent density of collapse pressure is located in the projection center of the hemisphere, which is approximately symmetrically distributed along the direction of in situ stress, and the equivalent density of overall collapse pressure is relatively low. The collapse pressure is the lowest when the deviation angle is 0 and the azimuth is 90° or 270°. At the moment, the equivalent density of collapse pressure is 1.11 g/cm3; As the increase of the deviation angle, the collapse pressure gradually increases. When the deviation angle is 60° and the azimuth is 0 or 180°, the collapse pressure reaches the maximum value of 1.58 g/cm3. When the deviation angle is small, the borehole orientation has little effect on the collapse pressure. However, with the increase of deviation angle, the influence of borehole orientation on collapse pressure becomes more and more significant. The equivalent density of collapse pressure first decreases and then increases in the process of wellbore orientation from the minimum horizontal principal stress to the maximum horizontal principal stress.

Calculation results of elastic anisotropy model

Figure 10 shows the hemispherical projection of the wellbore trajectory to the collapse pressure calculated by the elastic anisotropy model. Under the condition of elastic anisotropy, the hemispherical projection of collapse pressure is no longer symmetrically distributed along the direction of in situ stress. The collapse pressure under elastic anisotropy is the lowest when the deviation angle is 0 ~ 30° and the azimuth is near 0 or 180° and the equivalent density of collapse pressure is 1.13 g/cm3. As the increase of the deviation angle, the collapse pressure gradually increases. When the deviation angle is 40° ~ 65°, the equivalent density of collapse pressure at azimuth angles of 50°, 130°, 230° and 310° reaches the maximum value of 1.71 g/cm3. Under certain specific orientations, the influence of well deviation angle on collapse pressure is not obvious which can be inclined here. When the borehole orientation is parallel to the direction of minimum horizontal in situ stress, the collapse pressure is the largest. In the process of borehole orientation from the minimum horizontal principal stress to the maximum horizontal principal stress, the equivalent density of collapse pressure will also decrease first and then increase.

Calculation results of elastic and strength anisotropy model

Figure 11 is a hemispherical projection of borehole trajectory to collapse pressure calculated by elastic and strength anisotropy model. When considering the elasticity and strength anisotropy at the same time, the calculated results of collapse pressure are exceedingly different from those of isotropic model and elastic anisotropic model. Therefore, when analyzing the collapse and instability behavior of continental shale in Songliao Basin, the elasticity and strength anisotropy of shale cannot be ignored. Taking into account the characteristics of elasticity and strength anisotropy, the highest collapse pressure appears in a horizontal well, and its borehole orientation is parallel to the direction of the minimum horizontal principal stress.

The equivalent density of the maximum collapse pressure is 1.86 g/cm3. When the borehole orientation is parallel to the direction of minimum horizontal in situ stress, the collapse pressure increases with the increase of well deviation angle. When the borehole orientation is parallel to the maximum horizontal in situ stress direction, the collapse pressure first decreases and then increases with the increase of well deviation angle, and the minimum collapse pressure equivalent density is 1.64 g/cm3. It can also be found from Fig. 10 that the equivalent density of collapse pressure of horizontal wells under different borehole orientations is quite different. Therefore, in the process of actual drilling, the borehole trajectory should be optimized and the variation range of borehole orientation should be reduced as far as possible to ensure that the drilling fluid density window in the whole horizontal section satisfies the requirements of wellbore stability.

Field application

Wellbore instability frequently occurs in a shale oil block in the north of Songliao Basin during drilling, resulting in serious downhole accidents such as wellbore collapse and sticking. The shale in the area is a typical hard brittle shale. The conventional isotropic model is used to analyze the wellbore collapse, and the results are quite different from the actual situation. Therefore, the wellbore collapse of a horizontal well G101 in the block is studied. The well depth is 4082 m, the horizontal section length is 1800 m, the actual drilling depth is 3087 m, and the final horizontal section length is 1300 m. In the process of well design, the conventional isotropic wellbore stability analysis model is used for the drilling fluid density. Therefore, due to the wellbore collapse and instability in the horizontal section, it takes 43.46 days to deal with downhole complex accidents, and the time to deal with downhole complex accidents reaches 58.34% of the whole well. The wellbore stability analysis model considering the influence of shale anisotropy and the conventional wellbore stability analysis model are used for comparative analysis.

It can be seen that the bedding plane has no obvious effect on the stability of vertical wellbore, and the formation collapse density is 1.02 g/cm3.The impact on horizontal wells is more serious. If the influence of bedding plane is not considered, the collapse density to maintain the stability of wellbore is 1.57 g/cm3. Considering the influence of bedding plane, the collapse density to maintain the stability of wellbore is 1.86 g/cm3. It is recommended to optimize the drilling orientation when designing horizontal wells in the block in the later stage. The influence of shale bedding on horizontal wells and deviated wells is very significant, especially when the well deviation angle is greater than 30° and the borehole orientation is within 90° of the minimum horizontal in situ stress direction. In the drilling of shale formation in the vertical section of well G101, the density of 1.12 ~ 1.30 g/cm3 is adopted according to the design. Wellbore collapse was not found during drilling, indicating that the analysis results of shale wellbore collapse pressure in vertical section are in good agreement with the actual situation. In the drilling of shale formation in horizontal well section, the density is 1.58 ~ 1.76 g/cm3 according to the design. The drilling fluid is much lower than the collapse density of 1.86 g/cm3 calculated by the anisotropic model in this paper. During this period, serious wellbore instability occurred, and the problem of wellbore collapse was not alleviated until the drilling fluid density was increased from 1.68 to 1.94 g/cm3 after 2876 m. The results of wellbore stability risk analysis are basically consistent with the actual situation.

Summary and Conclusions

-

(1)

The mineral composition test, uniaxial and triaxial compressive strength tests of shale in the northern block of Songliao Basin are carried out. The hard and brittle properties of shale in this block are defined, and the anisotropic elasticity and strength parameters of shale oil block in the north of Songliao basin are determined. The experimental results show that there are significant differences in shale strength at different sampling angles, and the shale strength is the lowest when the sampling angle is 60°. The failure modes of rock samples under triaxial compression include matrix shear failure and weak plane shear failure. The anisotropic elastic parameters of shale are as follows: the elastic modulus of parallel bedding plane is 11.258 GPa, the Poisson's ratio of parallel bedding plane is 0.1875, the elastic modulus of vertical bedding plane is 3.373 GPa, and the Poisson's ratio of vertical bedding plane is 0.2445. The anisotropic strength parameters of shale are as follows: the cohesion of shale matrix is 10.0 MPa, the internal friction angle of shale matrix is 33°, the cohesion of weak plane is 3 MPa, and the internal friction angle of weak plane is 27°.

-

(2)

According to the anisotropic characteristics of shale in the north of Songliao Basin, a calculation model of wellbore collapse pressure considering the anisotropy of shale elasticity and strength is established. Based on the measured rock mechanics and geomechanics parameters, the wellbore collapse pressures under isotropy, elastic anisotropy, elasticity and strength anisotropy are analyzed. The results show that the collapse pressure is the highest when elastic and strength anisotropy are taken into account, and the effect of strength anisotropy is obviously greater than that of elastic anisotropy. While the deviation angle is small, the borehole orientation has little effect on the collapse pressure. With the increase of well deviation angle, the influence of borehole orientation on collapse pressure becomes more and more significant. The stability of drilling horizontal wells along the direction of horizontal maximum principal stress is the best, followed by vertical wells and small angle directional wells, and the stability of drilling horizontal wells along the direction of horizontal maximum principal stress is the worst.

-

(3)

Taking a horizontal well G101 in the north of Songliao Basin as an example, the analysis shows that the analysis results are basically consistent with the actual situation by using the wellbore collapse instability analysis method considering the effects of shale elasticity and strength anisotropy. Therefore, it is recommended to design the drilling fluid density in the shale formation of vertical well section according to the conventional wellbore stability analysis method. In the shale formation of inclined well section and horizontal section, the method described in this paper is recommended, that is, the drilling fluid density is designed for the wellbore collapse instability analysis method considering the influence of shale elasticity and strength anisotropy. So as to reduce the risk of wellbore collapse and instability and ensure safe and rapid drilling.

-

(4)

The advantage of this paper is that the wellbore stability model of layered shale anisotropy is established, and the dual effects of shale elastic anisotropy and strength anisotropy are considered. The disadvantage is that this paper mainly analyzes from the perspective of mechanics, without considering chemistry and thermology.

References

Aadnoy B (1988) Modeling of the stability of highly inclined boreholes in anisotropic rock formations (includes associated papers 19213 and 19886). SPE Drill Eng 3(3):259–268

Aadnoy BS (1987) Modelling of the stability of highly inclined boreholes in anisotropic rock formations, Offshore Europe.

Asaka M, Holt RM (2020) Anisotropic wellbore stability analysis: impact on failure prediction. Rock Mech Rock Eng 54:583–605

Cao W, Deng J, Liu W, Yu B, Tan Q, Yang L (2017) Pore pressure and stress distribution analysis around an inclined wellbore in a transversely isotropic formation based on the fully coupled chemo-thermo-poroelastic theory. J Nat Gas Sci Eng 40:24–37

Chen P, Yang CH, Zhao J (2015a) Wellbore stability analysis and well path optimization based on the breakout width model and mogi-coulomb criterion. J Pet Sci Eng 135:678–701

Chen P, Ma TS, Xia H (2015b) A collapse pressure prediction model of horizontal shale gas wells with multiple weak planes. Nat Gas Ind 2(1):101–107

Chenevert ME, Gatlin C (1965) Mechanical anisotropies of laminated sedimentary rocks. Soc Pet Eng J 5(01):67–77

Ding Y, Liu XJ, Luo PY (2020) The analytical model for horizontal wellbore stability in anisotropic shale reservoir. Geotech Geol Eng 38:5109–5126

Dusseault MB, Gray KE (1992) Mechanisms of stress-induced wellbore damage. In: SPE Formation Damage Control Symposium.

Ibrahim A (2021) A review of mathematical modelling approaches to tackling wellbore instability in shale formations. J Nat Gas Sci Eng 89(1–2):103870

Jaeger JC (1960) Shear failure of anistropic rocks. Geol Mag 97(1):65–72

Kang Q, Chen M, Yan J, Zhang F (2011) Stability model of borehole wall during the well test after acidizing treatment of sandstone reservoirs. Pet Explor Dev 38(5):589–593

Lee BH (2004) Borehole breakouts and compaction bands in two high-porosity sandstones. Int J Rock Mech Min 41:287–301

Liang C, Chen M, Jin Y, Lu Y (2014) Wellbore stability model for shale gas reservoir considering the coupling of multi-weakness planes and porous flow. J Nat Gas Sci Eng 21:364–378

Liu XJ, Zeng W, Liang LX, Lei M (2016) Wellbore stability analysis for horizontal wells in shale formations. J Nat Gas Sci Eng 31:1–8

Liu J, Yang Z, Sun JS, Dai Z, You Q (2021) Experimental investigation on hydration mechanism of sichuan shale (China). J Pet Sci Eng 201(3):108421

Ma TS, Chen P (2015) A wellbore stability analysis model with chemical-mechanical coupling for shale gas reservoirs. J Nat Gas Sci Eng 26:72–98

Ma TS, Chen P, Zhang QB, Zhao J (2016) A novel collapse pressure model with mechanical-chemical coupling in shale gas formations with multi-weakness planes. J Nat Gas Sci Eng 36:1151–1177

Ma TS, Liu Y, Chen P, Wu B, Fu J, Guo Z (2019) Fracture-initiation pressure prediction for transversely isotropic formations. J Pet Sci Eng 176:821–835

Ma YY, Li SB, Zhang LG, Liu SZ, Liu ZY, Li H, Shi EX (2020a) Study on the effect of well layout schemes and fracture parameters on the heat extraction performance of enhanced geothermal system in fractured reservoir. Energy 202:117811

Ma YY, Li SB, Zhang LG, Liu SZ, Liu ZY, Li H, Shi EX, Zhang HJ (2020b) Numerical simulation study on the heat extraction performance of multi-well injection enhanced geothermal system. Renew Energ 151:782–792

Ma TS, Zou J, Chen P, Liu H (2020c) Investigation on the influence coupling drilling fluid and formation boundary on acoustic wave propagation in drill string. Geomech Geophys Geoenergy Georesour 6:35

Ma T, Huang J, Jia L, Liu Y, Qiu Y, Zhang Y (2020d) Wellbore stability analysis for arbitrary inclined well in anisotropic formations. IOP Conf Ser Earth Environ Sci 570(6):062032

Nguyen T, Gosine R, Warrian P (2020) A systematic review of big data analytics for oil and gas industry 4.0. IEEE Access 8:61183–61201

Shuai H, Yang CH, Zhang BP, Guo YT, Wang L, Wei YL (2015) Experimental research on anisotropic properties of shale. Rock Soil Mech 36(3):609–616

Zarei V, Nasiri A (2021) Stabilizing asmari formation interlayer shales using water-based mud containing biogenic silica oxide nanoparticles synthesized. J Nat Gas Sci Eng 91:103928

Zeynali ME (2012) Mechanical and physico-chemical aspects of wellbore stability during drilling operations. J Pet Sci Eng 82–83:120–124

Zhi G, Chen M, Yan J, Shuai Y, Du X (2016) Experimental study of brittleness anisotropy of shale in triaxial compression. J Nat Gas Sci Eng 36:510–518

Acknowledgements

This work was supported by the National natural science foundation of China (Grant No. 51874098).

Funding

The author, Kai Liang is extremely thankful for the financial help for the National natural science foundation of China (Grant No.51874098).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the co-authors, the corresponding author states that there is no conflict of interest.

Ethical statements

-

The manuscript is submitted to only this one journal for consideration.

-

The submitted work is original and have not been published elsewhere in any form or language (partially or in full).

-

This study will not be split up into several parts to increase the quantity of submissions and submitted to various journals or to one journal over time.

-

Results are presented clearly, honestly, and without fabrication, falsification or inappropriate data manipulation (including image based manipulation). Authors adhere to the discipline-specific rules for acquiring, selecting and processing data.

-

The author has not plagiarized other people's data, text or theory, and has given appropriate recognition to other reference works, and has made a clear citation mark in the text.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

\(\varepsilon\) | The strain vector under stratum coordinate |

\(C\) | The flexibility matrix under stratum coordinate |

\(\sigma\) | The stress vector under stratum coordinate, MPa |

\(E_{{\text{h}}} ,E_{v}\) | The elastic modulus parallel to the bedding direction and perpendicular to the bedding direction, respectively, MPa |

\(v_{{\text{h}}} ,v_{v}\) | The Poisson's ratio to the bedding direction and perpendicular to the bedding direction, respectively |

\(G_{h} ,G_{v}\) | The shear modulus parallel to the bedding direction and perpendicular to the bedding direction, respectively, MPa |

\(\sigma_{1} ,\sigma_{3}\) | The maximum principal stress and the minimum principal stress, respectively, MPa |

\(c_{0} ,c_{w}\) | The cohesion of shale matrix and weak plane, respectively, MPa |

\(\varphi_{0} ,\varphi_{w}\) | The internal friction angle of shale matrix and weak plane, respectively,\(^\circ\) |

\(\beta_{0}\) | The angle between the failure plane of shale body and the maximum principal stress,\(^\circ\) |

\(\beta\) | The angle between the normal of weak plane and the maximum principal stress,\(^\circ\) |

\(\sigma_{xx} ,\sigma_{yy} ,\sigma_{zz} ,\tau_{xy} ,\tau_{yz} ,\tau_{xz}\) | Wellbore circumferential stress in rectangular coordinate system, MPa |

\(\sigma_{xx0} ,\sigma_{yy0} ,\sigma_{zz0} ,\tau_{xy0} ,\tau_{yz0} ,\tau_{xz0}\) | Component of in situ stress in borehole rectangular coordinates, MPa |

\(a_{ij}\) | The flexibility matrix coefficient of formation in borehole local coordinates,\(i = 1,2,3,j = 1,2, \cdot \cdot \cdot ,6\) |

\(\phi_{1}^{^{\prime}} (z_{1} ),\phi_{2}^{\prime } \left( {z_{2} } \right),\phi_{3}^{\prime } \left( {z_{3} } \right)\) | The three analytic functions |

\(\mu_{i}\) | The eigenvalue of characteristic equation corresponding to strain compatibility equation |

\(z_{i}\) | The complex variable |

\(\lambda_{i} ,\gamma_{i} ,\xi_{i} ,\Delta\) | The intermediate variables related to characteristic roots |

\(p_{w}\) | The wellbore pressure, MPa |

\(R\) | The borehole radius, m |

\(\sigma_{r} ,\sigma_{\theta } ,\sigma_{z} ,\tau_{r\theta } ,\tau_{\theta z} ,\tau_{rz}\) | Wellbore stress component in cylindrical coordinates, MPa |

\(\theta\) | Well circumference angle,\(^\circ\) |

\({\varvec{n}}\) | The normal vector of bedding plane |

\({\varvec{N}}\) | The direction vector of maximum principal stress in wellbore |

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, S., Liang, K., Wang, C. et al. Study on the mechanism of anisotropic wellbore instability in continental shale in Songliao Basin. J Petrol Explor Prod Technol 12, 2551–2563 (2022). https://doi.org/10.1007/s13202-022-01504-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01504-2