Abstract

Controlling lost circulation during drilling operations in a reservoir prone to fluid losses is typically remedied by cement squeezing or plug setting as the last resort. The aim being to minimize or stop drilling fluid losses and to regain full returns at surface, and to maintain wellbore integrity. Different placement methods of cement plugs have been discussed in detail in the literature, except for the ‘level-off’ method, which can be effective for curing complete loss circulation cases. Following modeling and calculations of this cement plug placement method, its design and execution procedures are discussed, together with two successful field cases in highly fractured carbonate reservoirs in the Middle East. Using drill pipe and a Retrievable-Test-Treat-Squeeze (RTTS) packer, set with some spacing from the loss zone, the method entails that the cement slurry is allowed to drop by gravity in order to cure lost circulation. As the column of fluid, mud and slurry in the well exceeds formation pore pressure, i.e., overbalanced conditions, a volume of acid-soluble cement slurry is allowed to slowly drop and freely penetrate the formation, i.e., through its fractures or caverns. During the penetration of this viscous slurry into the loss zone, the cement slurry can set and the fracture or fissure openings are plugged. Presented are detailed design calculations for the level-off placement technique, determination of required cement slurry and displacement volumes, and recommended displacement and RTTS packer setting depths. The expected depth of the top of cement plug is estimated. The design parameters are compared with field cases and explanations are given for possible discrepancies. Success of the operation is discussed in terms of final mud loss after cement plugging and Non-Productive Time mitigation. Detailed field procedures and execution are also presented. The level-off job is already practiced by the industry, but it is not published in the literature, in some cases they have different methods with causing some errors. To the best of authors’ knowledge, this is the first detailed description and stepwise calculation of the level-off cement placement technique in the literature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1. Introduction

During drilling and workover operations particularly high-pressure-high-temperature (HPHT), some instances of mud loss and lost circulation may generally be encountered (Alrasheed et al. 2018). Lost circulation is estimated to affect 75% of the wells drilled (Gockel et al 1987). There are two general approaches to lost circulation solutions: proactive and corrective. The proactive solution is based on wellbore strengthening and geomechanical analysis (Alberty and Mclean 2004; Wang et al. 2008), which is not discussed in this work. Following lost circulation occurrence, the situation must be efficiently cured (corrective solution); otherwise, well integrity could be severely challenged (Bogaerts et al. 2015). In overbalanced drilling, lowering the mud weight may cure loss situations, provided adequate overbalance pressure can be maintained. Failing that, pumping periodic Lost Circulation Materials (LCM) pills during drilling is another option that can put an end to mud loss. If the mud loss is not controlled but actually increases, two measures may be implemented, depending on the drilling program. An effective method is to continuously cure the mud loss by mixing LCM material in the circulating mud, which if done on a continuous bases may require bypassing the shakers, thus compromising mud properties and the ability to properly collect samples for geological analysis. Alternatively, drilling may be stopped and a high concentration LCM pill is spotted in static conditions. Spotting LCM pills is particularly recommended to prevent excessive mud loss in polymer and emulsion muds (Gockel et al. 1987; Davidson et al. 2000; Nelson and Guillot 2006).

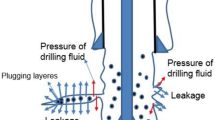

Particularly in highly fractured or cavernous and depleted reservoirs, mud losses may not be controllable by standard curing methods. In such cases, mud losses may increase further and lead to an almost formation-induced lost circulation or complete loss, e.g., mud losses > 100 bbl/hr. In such lost circulation situations, it is critically important to keep the hole full with mud or even with water (if mud is run out). Therefore, it is important to have available tanks full of mud and water. In lost circulation cases, it may be advised to drill a considerable thickness of the loss zone while ensuring continued LCM pumping and simultaneous filling up of the hole in an attempt to mitigate losses. This type of drilling without mud returns to surface is called blind drilling. Next, possible curing methods need to be considered as a matter of urgency, with the method selected dependent on availability of mud reserves and water. When standard techniques are ineffective, setting a cement plug can be an effective control method (Schlumberger 1995; Heathman 1996). Light weight slurries are typically selected, so as not to excessively exceed the formation pressure (Abbas et al 2003; Nelson and Guillot 2006; Bikmukhametov et al. 2014; Veisi et al. 2015). Different compositions of cement slurry may be used, including Diatomite suggested by Al-Sabagh et al. (2016). There are several methods of setting a cement plug: balanced plug, cement squeezing and the level-off method. In case of non-controllable, critical lost circulation by cement plugs, other curing methods may be used such as the use of gunk pills or a barite plug. A gunk pill, a combination of diesel and bentonite is usually used in water-based muds. Using a gunk pill is not an option in the reservoir section particularly due to its formation damage issues in addition to its environmental concerns (Goodman 1981).

Recently, there were some publications on application of swelling thixotropic polymers to put an end on lost circulation during managed pressure drilling MPD (Barry 2017; Ombe et al. 2020) when there was no safe mud window (Aljubran et al. 2018). Generally, it should be noted that magnesium-cement slurry is used for reservoir thief zones because it is soluble by an HCl-acid wash removing the reservoir rock formation damage. Whereas, a cement plug is usually used for plugging non-reservoir thief zones.

Assuming that sufficient drilling of the loss zone has been successfully achieved, and a static situation has been created while instigating loss control, a lower overbalance pressure typically ensues compared to dynamic circulating conditions during drilling. During static conditions, the aim is to reduce lost circulation to a level of less than 10 bbl/hr. At that stage, if the mud loss is low (< 10 bbl/hr), a balance plug may be applied for completely controlling the loss. However, in greater mud loss magnitudes at static conditions, a balance plug is not recommended, for the following reasons: (1) most of the pumped slurry will be lost to the loss zone and balancing the pressure may not be achievable, (2) there is the risk of a differential stuck drill pipe. In many severe lost circulation cases, squeezing of the cement slurry into the loss zone does not affect a cure as the pressure would exceed the fracture closure pressure (FCS), which would cause aggravation of the loss, and also there would not be enough time for the slurry to set in the near-wellbore region, due to ongoing losses (Dupriest 2009). To prevent squeezing and to allow greater time for the cement slurry to set in the loss zone, a hydrostatic packer may be a solution (Dupriest 2009); the hydrostatic packer is a column of light fluid pumped into the annulus or drill string to cause the total head at the loss zone to be less than or equal to FCS. However, the use of hydrostatic packers requires specialized engineering and field personnel to be trained to understand fracture behavior (Dupriest 2009). Therefore, alternatively, the practical ‘level-off’ method, explained here, is another solution which can be applied in the field in a straightforward manner without the requirement of specially-trained crew.

In the level-off method, using the drill pipes, the Retrievable-Test-Treat-Squeeze (RTTS) packer is installed inside casing with enough spacing from the loss zone. Next, some cement slurry is spotted above the loss zone in cased hole and with enough spacing from the packer (risk mitigation). Then, gravity is allowed to come into force to cure the loss zone. The volume of cement slurry will freely penetrate the formation, assisted by the presence of fractures or caverns, plugging the latter. Assuming success, the process is accompanied by a controlled drop in mud level (levelling off) in the drill pipe until hydrostatic pressure of the wellbore fluid column equals formation pore pressure.

Remedial cementing deploying the level-off method to overcome lost circulation is often performed on short notice, leaving little time for planning and design. The key to the success of a level-off job is, therefore, to quickly and accurately design the placement technique. To the best of the authors’ knowledge, there are no publications (except for Ashena et al. 2020) in the literature explaining on how to set a level-off cement plug, its required accurate design calculations and comparison with field cases. This method has already been applied by some drilling companies in the industry such as Bikmukhametov et al (2014) which provided examples of level-off cement plugging but no details and design calculations were presented.

Next, some industry methods of level-off design and calculations suffer from some errors. The errors are incurred due to making a simplification in their methodologies in which it is assumed that due to level-off the drop in the hydrostatic cement slurry pressure (denoted as \({P}_{x}\)) is equal to sum of the initial cement slurry hydrostatic pressure above the loss zone (\({P}_{c,i}\)) and mud column pressure (\({P}_{m,i}\)) minus the reservoir pore pressure (\({P}_{R}\)), that is, “ \(\Delta {P}_{x}={P}_{c,i}+{P}_{m,i}-{P}_{R}\)”. Subsequently, using \({P}_{x}\), the next parameters are evaluated such as the mud head loss and the final level of the cement slurry. The mentioned equation suffers from some errors because during the level-off process not only the cement slurry level drops, but also a mud level drop would occur due to the positioning of part of the mud from inside the drill pipe to the casing below the packer (with a larger bore than the drill pipe). Other investigators have described cement plugging techniques (but not the level-off method) in detail in numerous papers, e.g., Smith (1990) and Griffin (1990). The details of the level-off method are not only explained in this work, but also its more accurate version is developed and presented.

It is noted that this work is an updated version of the previous work by Ashena et al. (2020) which presented the first approach of the authors to the problem. In the work by Ashena et al. (2020), a formulation for level-off design was developed which suffered from the limitations of being applicable only to vertical wells, and only for single casing size where the slurry is being placed. Generally, Ashena et al.’s work (2020) and its workflow were not user-friendly and complex in practice (based on the feedback from some industry experts). Therefore, the authors strived to solve the problem by developing their second/updated methodology to solve the level-off problems, providing a more practical and straightforward workflow, which is also applicable to deviated or directional boreholes. This was done in this work by first evaluating the initial slurry volume first and then using that volume for finding the rest of required parameters such as the initial slurry height, etc. In this work, unlike the first approach, a stepwise flowchart for the workflow is provided in a graphical manner. Based on the preceding explanation, this manuscript is an original/practical contribution to the literature and practitioners.

The purpose of this technical paper is then to describe the level-off technique in detail: following a discussion on the theory, design calculations are given, followed by possible field verification. Finally, operational procedures are explained in a stepwise manner. The design focusses on the placement technique and determination of the required parameters, including the slurry and displacement volumes and packer setting depth. The composition of the cement slurry and flow calculations are outside the scope of the paper and are not discussed; and the reader can refer to other references such as Nelson and Guillot (2006). The method presented works for both vertical or deviated wells, for drilling and workover wells, and where losses occur in open-hole or cased-hole intervals. To provide a clear understanding of the calculations, two different case studies are discussed, pertaining to drilling and workover operations.

2. Design calculations

Successful application of the level-off cement plugging method to cure lost circulation depends primarily on an accurate design. For the scope of the design, several input parameters are required: formation pore pressure at the top of loss zone, well dimensions and volumes, mud and cement weights. The modeling approach considers the final levelled-off balanced condition to calculate the initial overbalanced situation wherein the hole is filled with original mud and with some initial cement slurry volume. In this approach, a list of significant design parameters is evaluated / derived.

The calculation procedure is presented stepwise. Figure 1 shows the calculation steps in form of a flowchart, Fig. 2 shows the steps in a typical well schematic. As shown in both figures, there are seven steps which are explained as follows:

Final mud height (\({h}_{m,f}\))

At the final levelled-off condition, the wellbore fluid pressure is balanced with the formation pore pressure. The wellbore pressure is equal to summation of the hydrostatic pressure by final cement slurry height remaining above loss zone or last casing shoe (\({h}_{c,f}\)) and the hydrostatic pressure by final mud height (\({h}_{m,f}\)) remaining in the wellbore. It is noted that \({h}_{c,f}\) is the height above loss zone; however, when the loss zone is near the casing shoe (short open-hole section), the height above casing shoe is considered as the basis for \({h}_{c,f}\). Therefore:

Using Eq. 1, \({h}_{m,f}\) [ft] is found as:

where\({P}_{R}\) is the pressure of reservoir formation or loss zone [psi]\({\rho }_{c}\) is cement slurry weight [ppg] and\({\rho }_{m}\) is drilling mud weight [ppg]

Dropped mud level in the drill pipe (\({\Delta {\varvec{h}}}_{{\varvec{m}},{\varvec{d}}}\))

Through levelling-off of wellbore pressure to formation pressure, the mud level in the drill pipe drops. The dropped mud level in the drill pipe is found as:

Initial volume of cement slurry above casing shoe (\({{\varvec{V}}}_{{\varvec{c}},{\varvec{i}}}\))

A successful level-off job is one which finally would provide a minimum cement plug thickness above the loss zone or the last casing shoe (in short open-hole sections). The initial volume of cement slurry designed to be placed above the casing shoe, \({V}_{c,i}\) for curing lost circulation, is equal to the final cement volume above casing shoe plus lost slurry volume to the loss zone / formation. The lost slurry volume is in turn equal to the volume of mud dropped in the drill pipe (volume of empty drill pipe) after leveling-off /balanced condition with the formation pressure is reached. Therefore:

where\({V}_{c,f}\) is the final volume of cement slurry above casing shoe [bbl]\({\Delta V}_{c,l}\) is the lost slurry volume to loss zone [bbl]\({\Delta h}_{m,d}\) is the dropped mud level in drill pipe (DP) after leveling-off /balanced condition with the formation pressure is reached [ft], and\({Cap}_{DP}\) is the capacity of drill pipe [bbl/ft]\({\Delta h}_{m,d}[MD]\) is equal to \({\Delta h}_{m,d}[TVD]\) because it is near the surface where the hole has no deviation.

It is noted that for curing lost circulation in cased-hole (i.e., through perforations or liner laps), the total volume of initial cement slurry is the same as the initial volume of cement slurry above the casing shoe. However, in short open-hole cases, the initial cement slurry volume above the last casing shoe (\({V}_{c,i}\)) differs from the total required volume of cement slurry (\(Total {V}_{c}\)). It is calculated as follows:

where\({V}_{OH}\) is the open-hole volume which is essentially filled with the cement slurry in short open-hole sections, the volume can be accurately determined using caliper logs if caliper log is part of the logging while drilling (LWD) or may be determined from experience based on washout observations. It is noted that in short open-hole cases, it is preferred to fill the whole open-hole section with cement slurry with the slurry extending up sufficiently above the last casing shoe.

To find the next design parameters, only the initial volume of slurry above the shoe (\({V}_{c,i}\)) is required.

Initial height of cement slurry above casing shoe (\({{\varvec{h}}}_{{\varvec{c}},{\varvec{i}}}\))

The initial measured depth difference of cement slurry above the last casing shoe \({h}_{c,i}\{MD\}\) is found by:

where \({Cap}_{csg}\) is casing capacity [bbl/ft]

In vertical wells, \({h}_{c,i}\{MD\}\) is the same as the initial height (vertical) of cement slurry above the shoe \({h}_{c,i}\left\{TVD\right\}\) or simply \({h}_{c,i}\). Otherwise, in deviated wells, using \({h}_{c,i}\{MD\}\) and directional survey data, the \({h}_{c,i}\) can be found.

Equation 6 holds, provided that there is only one single casing size where the initial cement slurry is spotted / placed. In this case, for vertical wells, Ashena et al. (2020) used mathematical derivations to find \({h}_{c,i}\):

It is noted that in this work the conversion factor of “0.052” has replaced “g” (for gravitational acceleration) in Ashena et al. (2020) to match oil field units.

However, in vertical wells, if the initial slurry is located in two sizes of casings, \({h}_{c,i}\) is found as follows:

where the subscripts \(csg1\) and \(csg2\) indicate the first and second casing wherein the slurry is placed / located initially.

Depth of displacement (\({{\varvec{M}}{\varvec{D}}}_{{\varvec{d}}{\varvec{i}}{\varvec{s}}}\) and \({{\varvec{T}}{\varvec{V}}{\varvec{D}}}_{{\varvec{d}}{\varvec{i}}{\varvec{s}}}\))

The measured depth of the displacement (\({MD}_{dis}\)) is the measured depth to which the slurry is displaced by the mud. It is found by:

In vertical wells, \({MD}_{dis}\) and \({MD}_{csg}\) are the same as \({TVD}_{dis}\) and \({TVD}_{csg}\) and \({h}_{c,i}\{MD\}\) is the same as \({h}_{c,i}\) (TVD). However, in deviated wells, using directional survey data, \({TVD}_{dis}\) must be found as it will be needed for determination of installation depth of the RTTS packer:

Depth of RTTS packer (\({{\varvec{T}}{\varvec{V}}{\varvec{D}}}_{{\varvec{R}}{\varvec{T}}{\varvec{T}}{\varvec{S}}}\) and \({{\varvec{M}}{\varvec{D}}}_{{\varvec{R}}{\varvec{T}}{\varvec{T}}{\varvec{S}}}\))

The true vertical setting depth of the RTTS packer \({TVD}_{RTTS}\) is then found using the following equation:

\({\Delta h}_{dis}\) is the required vertical spacing between the displaced depth and the depth of RTTS packer. In vertical wells, \({MD}_{RTTS}\) (the measured depth of the RTTS) is the same as \({TVD}_{RTTS}\). In deviated wells, using well survey data, \({MD}_{RTTS}\) is found to later determine the displacement volume. Following the displacement, there should be enough spacing between the displacement depth and the RTTS packer depth (denoted by \({\Delta h}_{dis}\)). This is done to ensure that the cement slurry may not have any chance to be placed and set in the RTTS or the drill pipe. In case the spacing between the top of the slurry and the RTTS packer is ignored, the top of the cement slurry reaches the RTTS packer which may make it become stuck and not released. In such cases, the crew may proceed to milling the RTTS or even side-tracking the well in extreme cases. Therefore, typically a minimum vertical spacing (\({\Delta h}_{dis}\)) of 130–200 t (40–60 m) should be predicted between the bottom end depth of RTTS and the displacement depth. Otherwise, in case there are particular well limitations and risks, a lower or higher \({\Delta h}_{dis}\), may be allocated.

Volume of displacement (\({{\varvec{V}}}_{{\varvec{d}}{\varvec{i}}{\varvec{s}}}\))

The volume of displacement, \({V}_{dis}\), is the mud volume to be pumped so that the initial cement slurry can be spotted/placed at its appropriate depth. It is found by:

In vertical wells, \({MD}_{RTTS}\) and \({MD}_{dis}\) are the same as \({TVD}_{RTTS}\) and \({TVD}_{dis}\), and the term \(\left({MD}_{dis}-{MD}_{RTTS}\right)\) in Eq. 12 is equivalent to \({\Delta h}_{dis}\). However, in deviated boreholes, \({MD}_{dis}\) is found from Eq. 9, \({MD}_{RTTS}\) is found using its true vertical depth and well survey data.

Top of cement (TOC)

It is theoretically expected that, following the level-off establishment, the top of cement (TOC) be located at the following true vertical depth:

If the plan of the level-off method is executed exactly, the practically observed TOC is expected to coincide with the planned one. In deviated holes, using directional survey data, \({MD}_{TOC}\) is found.

3.1. Field checking of the design parameters

Once a level-off cement-plugging plan is ready by the well planning office, it is sent to the drilling supervisor at the rig-site for execution. Best practice would have the procedure and design calculations included in drilling plans. Prior to execution, the supervisor may need to double-check the plan by repeating the design calculations to reach the design parameters. If the double-check leads to the same results, the design is verified and implementation can follow.

The next significant parameter is the verification of the top of cement plug (TOC). Using Eq. 13, the theoretical design / expected TOC can be determined. As a follow-up, this value can be compared with the actual TOC observed when drilling out the cement plug after it gets hard. If the design and practically-observed TOCs are the same or near each other, the right design and execution plan has been confirmed in field practice. Otherwise, there is failure either in the design or implementation / practice phases. This will be discussed further in “Case Studies” section.

Execution

Following the design of a level-off method, the execution procedure of the method is explained as follows:

Pre-job meeting

-

1.

The service company representative should hold a pre-job meeting with his crew, the rig crew and all other involved personnel in cementing the well to review responsibilities and coordinate the operations to be performed. Safety should always be the top priority.

-

2.

Run in the hole with drill pipe and the RTTS packer. During the running in the hole, maintain filling up the annulus using pump-1 (from mud tank-1), to prevent any possible kick flows into the well.

-

3.

Set packer of the RTTS at its determined setting depth. Setting the packer makes the annulus disconnected to the well. Therefore, maintain filling up the well by pumping through the drill pipe using pump-2 from mud tank-2.

-

4.

Pump the prepared volume of cement (based on the program) into the well. Then, displace using the drilling mud until the top of the slurry reaches its initial determined level (with the required spacing below the RTTS).

-

5.

Shut the pump off, close a safety valve, install the fill-up line upstream of the safety valve, and install a pressure gauge in between. Periodically open the safety valve and monitor the drill pipe pressure at the surface. This will give the crew an idea on the well conditions, as the cement slurry is set.

-

6.

Allow the cement slurry level to drop and penetrate into the loss zone until the wellbore hydrostatic pressure levels-off or balances with the formation pore pressure. During this time, the slurry starts to thicken and set. We should allow enough waiting time of, e.g., 12 to 18 h (depending on the additives used in the slurry, specified in the program) and simultaneously monitor the surface pressure.

-

7.

After the specified waiting time, read the pressure gauge. If the pressure is negligible, prime the hole (fill up the drill pipe without applying surface pressure). The primed mud volume equals the penetrated volume of the cement slurry into the formation, which we can use to determine the real final top of cement plug (TOC). Therefore, at the end of the level-off process, we expect that mud loss stops. To check our model results, the actual top of the cement plug in practice is compared with the theoretical design top (as is done in the case studies). After the cement plug has set, during drilling out of the cement plug, it is also used to confirm the actual TOC. If they are nearly the same, it can indicate the success of the operations.

-

a.

Note: If some pressure readings are observed (e.g., 300 psi), try releasing the pressure stepwise to the choke manifold and burn pit. If the pressure could not be released, it signifies that the cement slurry could not properly plug the formation and we are connected to the reservoir. In such cases, we need to secure the well by bullheading (if possible).

-

a.

-

8.

Unset the RTTS packer and release the drill pipe.

It is noted that a level-off cement plugging may not be necessarily successful after one attempt; but rather, several attempts may be required in practice until the loss situation is under control.

3.2.1 Case studies and verification

Two field case studies (CSs) are presented to apply the calculations, along with their comparison with the field practice. They consist of real field examples in the Middle East.

CS I: Drilling, vertical hole, OH (with two size casing between packer and the loss zone)

In a workover job, during drilling 6 1/8 in hole vertically at the depth of 7700 ft (2347 m) with mud weight of 8.34 ppg (water) in a highly fractured carbonate reservoir, a mud loss of 30 bbl/hr was encountered, which was not controlled by spotting LCM pills, then the mud loss converted to a severe mud loss event with 60 bbl/hr loss. Therefore, to prevent an emergency situation, the level-off method was planned to be applied by running 5 in drill pipe and setting a 9 5/8 in RTTS packer, spotting of 13.36 ppg magnesium cement slurry (with enough height above the 7 in liner shoe) to cure the loss. All the required input parameters are listed in Table 1. Using reservoir pressure measurements in offset wells, formation pressure was estimated to be 2055 psi.

Task: Using the equations in this work and experience, we find the following design parameters:

-

Volume of magnesium cement slurry to cure the loss (above the shoe and total)

-

Depth of displacement

-

Depth of setting the RTTS packer

-

Volume of displacement

-

Final mud loss after cement plugging

-

Non-Productive Time (NPT)

-

Expected / theoretical top of cement plug (TOC).

During drilling-out the cement plug, the actual TOC in the field practice was observed at 6032 ft (1838.4 m). Possible reasons for the discrepancy between the field observation and theoretical expected values are discussed.

Recommended design for CS I

The steps of the calculation procedure are followed to find the design parameters (with steps shown schematically in Fig. 3 and all design parameters in Table 2). In this well, the field experience indicated that after stabilization of monitored drill pipe pressures (24 h after displacement), the well (safety valve) was opened with no observed mud loss. The total NPT due to the lost circulation was 29 h. It consisted of 1 h for preparation and waiting for program, 6 h for tripping of DP with RTTS (in and out of the hole), 1.5 h for setting and unsetting packers, 1.5 h for making cement slurry (following packer set), 0.5 h for pumping slurry and displacement, 18 h wait on cement and monitoring pressures, 0.5 h for priming the well. This NPT is extremely lower than offset wells with average 120–150 h NPT to overcome such a severe mud loss event.

Next, after running the mill to tag top of the cement plug, the actual TOC was located at 6032 ft / 1838.4 m, which was about 14 ft (~ 4.5 m) lower than the expected theoretical depth. This indicates that probably due to severe lost circulation, a further few feet of the cement slurry (equivalent to 0.5 bbl) had penetrated into the loss zone. The reasons for this occurrence were attributed to possible uncertainty or inaccuracy in estimated loss zone pore pressure, inhomogeneous density within mud and cement slurry, excessively large fractures which are typical of the formation and lower than enough viscosity and consistency of the cement slurry. Overall, the job was successful to put an end to the lost circulation occurrence.

CS II: Drilling, deviated hole, OH (with single size casing between packer and loss zone)

During drilling, a deviated 8 ½ in hole at measured depth (MD) of 6562 ft (2000 m) with mud weight of 9.3 ppg (salt water) in a highly fractured carbonate reservoir, lost circulation occurred with mud loss rate of 90 bbl/hr. Therefore, level-off cement plugging method was planned to be applied by running the 5 in drill pipe and setting the 9 5/8 in RTTS packer. It is required that at the end of the job, a (vertical) height of 260 ft (79.25 m) cement plug is required to remain above last casing shoe / loss zone. The other required input parameters are listed in Table 3. Using reservoir pressure measurements in offset wells, the formation pressure was estimated to be 1900 psi.

Task: Using the equations in this work and experience, find the following design parameters:

-

Volume of magnesium cement slurry to cure the loss (above the shoe and total)

-

Depth of displacement

-

Depth of setting the RTTS packer

-

Volume of displacement

-

Final mud loss after cement plugging

-

Non-Productive Time (NPT)

-

Expected / theoretical top of cement plug (TOC).

During drilling-out the cement plug, the actual TOC in the field practice was observed at 6302 ft (1920.75 m). Possible reasons for the discrepancy between the field observation and theoretical expected values are discussed.

Recommended design for CS II

Following the same steps of the calculation procedure, the design parameters (with steps shown schematically in Fig. 4a and b). All the seven evaluated design parameters are listed in Table 4. In this well, the field experience indicated that after stabilization of monitored drill pipe pressures (18 h after displacement), the well (safety valve) was opened with no observed loss. The whole NPT due to the lost circulation was 31.5 h consisting of 0.5 h for preparation and waiting for program, 7 h for tripping of DP with RTTS (in and out of the hole), 1 h for setting and unsetting packers, 2 h for making cement slurry (following packer set), 0.5 h for pumping slurry and displacement, 20 h wait on cement and monitoring pressures, 0.5 h for priming the well. This NPT is extremely lower than offset wells with average 120–150 h NPT to overcome such a severe mud loss event. Therefore, this method was extremely effective in controlling lost circulation in an attempt and mitigate NPT.

a Schematic of the deviated well in the second case study, in which lost circulation occurred during drilling 8 ½ in hole. The first two steps of the calculation approach are indicated in the figure. “Final” denotes the final levelled-off / balanced condition. b Schematic of the initial condition of the well in the second case study, wherein the initial cement slurry was displaced to the designed displacement depth

After running the next drilling bit to tag and drill-out the cement plug, the actual TOC was found at 6302 ft (1920.75 m), which was about 22 ft (6.7 m) lower than the expected theoretical depth. This indicates that due to severe lost circulation, further few feet of the cement slurry (equivalent to 1.5 bbl) had penetrated into the loss zone. The reasons for this occurrence were attributed to possible uncertainty or inaccuracy in estimated loss zone pressure, inhomogeneous density within mud and cement slurry, excessively large fractures, and lower than enough viscosity and consistency of the cement slurry. The level-off cement plugging was successful to put an end to the lost circulation.

4. Summary and conclusions

In this work, a method called level-off cement plugging was introduced and devised to control lost circulation. In this method, after installing the RTTS packer inside casing with enough spacing from the loss zone, some cement slurry is spotted above the loss zone in cased hole and with enough spacing from the packer. Then, gravity is allowed to come into force such that the volume of cement slurry will freely penetrate the formation to cure and plug the loss zone. The key to the success of a level-off job is, therefore, to quickly and accurately design the placement technique, which is discussed in this work supported by some field case studies. The level-off job is already practiced by the industry, but it is not yet published in the literature. The industry uses different design methods, which may not be as accurate as this work.

-

1.

In the level-off method, using the drill pipe, the RTTS packer is installed in cased hole with some spacing from the loss zone, and acid-soluble cement slurry is spotted above the loss zone, and allowed to drop by gravity so that it can freely penetrate into the formation through its fractures and plug them to cure lost circulation.

-

2.

Because a correct job design is critical for the success of this operation and different companies apply methods causing some errors, the paper presents a stepwise approach to determine its design parameters including the required slurry volume, required slurry height above the casing shoe (in short open holes) or loss zone (in very long open holes), recommended displacement depth and volume, RTTS packer setting depth and expected top of cement plug after pressure equalization.

-

3.

The workflow provided presents a detailed stepwise procedure for field execution of the methodology.

-

4.

The presented method works for both vertical and deviated wells, for drilling and workover wells, and where losses occur in open-hole or cased-hole intervals.

-

5.

Case studies have illustrated and verified that the application successfully put an end to the lost circulation. The operations also showed success in terms of NPT mitigation compared to offset wells. Comparing the theoretical and actual TOCs which is the best criterion for comparison of the developed theory and field practice, the small discrepancies from actual field practices are attributed to possible uncertainty or inaccuracy in estimated loss zone pore pressures, inhomogeneous density within the muds and cement slurries, excessively large fractures which are typical of the formation and lower than enough viscosity and consistency of the cement slurries.

Abbreviations

- Cap:

-

Capacity or volume per length

- CapDP :

-

Capacity of drill pipe

- Capcsg :

-

Capacity of casing

- hc,f :

-

(recommended) Final cement plug height above last casing shoe (in short open hole sections) or loss zone(in long open hole sections) after wellbore pressure levels off / balances with formation pressure [m or ft]

- hm,f :

-

Final mud height after wellbore pressure levels off / balances with formation pressure [m or ft]

- hc,i :

-

The same as h(c,i) {TVD}

- hc,i {TVD} :

-

Initial height (vertical) of cement slurry above the shoe [m or ft]

- hc,i {MD}:

-

Initial measured depth difference of cement slurry above the shoe [m or ft]

- MDcsg :

-

Measured depth of casing shoe [m or ft]

- MDdis :

-

Measured depth to which cement slurry is displaced by the mud [m or ft]

- MDRTTS :

-

Measured depth of RTTS packer [m or ft]

- MDTOC :

-

Measured depth of top of cement plug [m or ft]

- RTTS packer :

-

Retrievable-Test-Treat-Squeeze packer

- Total Vc :

-

Total required volume of cement slurry to be spotted / placed in a wellbore with open-hole for a level-off plug job [bbl]

- TOC:

-

Depth of top of cement plug [m or ft]

- TVDTOC :

-

True vertical depth of top of cement plug [m or ft]

- TVDcsg :

-

True vertical depth of casing shoe [m or ft]

- TVDdis :

-

True vertical depth to which cement slurry is displaced by the mud [m or ft]

- TVDRTTS :

-

True vertical depth of RTTS packer [m or ft]

- PR :

-

Pressure of the reservoir formation or loss zone [psi]

- Vc,f :

-

Final volume of cement slurry to remain above last casing shoe (in short open hole sections) or above loss zone (in long open hole sections) after leveling-off / balance of wellbore pressure with that of loss zone [bbl]

- Vc,i :

-

Initial volume of cement slurry designed to be spotted above last casing shoe or loss zone for curing lost circulation [bbl]

- Vdis :

-

The volume of displacement, which is the mud volume to be pumped so that the initial cement slurry can be spotted/placed at its appropriate depth [bbl]

- VOH :

-

Volume of the open-hole zone [bbl]

- ρc :

-

Cement slurry weight [ppg]

- ρm :

-

Drilling mud weight [ppg]

- ∆hdis :

-

Required (vertical) spacing between the displaced depth and the depth of RTTS packer [m or ft]

- ∆h(m,d) :

-

Dropped mud level in the drill pipe or depth of top of mud after wellbore pressure levels off / balances with formation pressure [m or ft]

- ∆Vc,l :

-

Lost slurry volume to the loss zone due to levelling-off / balancing of wellbore pressure with reservoir pressure [bbl]

- θ:

-

Hole inclination angle [degree]

References

Abbas R, Dole S, Junaidi HE, El-Hassan H, Francis L, McCraith S, Shuttleworth N, Van Der Plas K, Messier E, Munk T, Nodlans N, Svendsen RK, Therond E, Taoutaou S (2003) A safety net for controlling lost circulation. Oilfield Rev 15(4):20–27

Alberty MW, McLean MR (2004) A physical model for stress cages. SPE annual technical conference and exhibition, Houston, Texas, 26–29 September, SPE-90493-MS, DOI: https://doi.org/10.2118/90493-MS

Aljubran MJ, Ombe EM, Alluhaydan AS, Thomas S (2018) ‘Innovative mechanical tapered scab liner design and deployment to restore well integrity’ SPE kingdom of saudi arabia annual technical symposium and exhibition, Dammam, Saudi Arabia, 23–26 April 2018, https://doi.org/10.2118/192407-MS

Alrasheed A, Oqaili AH, Aljubran MJ, Ezi PC (2018) Deployment of fully automated MPD and manganese tetroxide mud system to drill ultra-narrow mud window in HPHT gas wells. Paper presented at the SPE/IADC managed pressure drilling and underbalanced operations conference and exhibition, New Orleans, Louisiana, USA https://doi.org/10.2118/190000-MS

Al-Sabagh AM, El-Awamri AA, Abdou MI, Hussien HA, Abd El Fatah HM, Rasmy WE (2016) Egyptian diatomite as high fluid loss squeeze slurry in sealing fractures and high permeable formation. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2015.09.005

Ashena R, Ghalambor A, Hekmatinia A, (2020) Curing lost circulation in fractured reservoirs using a ‘level-off’ cement plugging method – case studies in drilling and workover applications. SPE-199277, Proceedings of the spe international conference and exhibition on formation damage control, held 19–21 February, Lafayette, Louisiana, USA doi:https://doi.org/10.2118/199277-MS

Barry JA (2017) SPE lost circulation workshop, Powerpoint slide, Dubai, UAE, viewed 26 September 2019

Bikmukhametov A, Iliasov S, Okromelidze G, Garshina O, Chugaeva O (2014) Experience of using the foamed cement technology for difficult lost circulation control. SPE 171803-MS, Presented at the Abu Dhabi international petroleum exhibition and conference, Abu Dhabi, UAE, 10–13 Nov. doi: https://doi.org/10.2118/171803-MS

Bogaerts M, Azwar C, Bellabarba M, Dooply M, Salehpour A (2015) Wellbore cementing: an integral part of well integrity. SPE OTC-25800, Presented at the offshore technology conference and exhibition, Houston, Texas, USA, May 4–7. DOI: https://doi.org/10.4043/25800-MS

Davidson E, Richardson L, Zoller S (2000) Control of lost circulation in fractured limestone reservoirs. IADC/SPE 62734, Presented at the iadc/spe asia pacific drilling technology, Kuala Lumpur, Malaysia, Sep. 11–13. https://doi.org/10.2118/62734-MS

Schlumberger Dowell 1995. Cementing engineering manual. Revisions 1, Jan

Dupriest FE (2009) Use of new hydrostatic packer concept to manage lost returns well control and cement placement in field operations society of petroleum engineers SPE 112657-PA. SPE Drill Complet J. https://doi.org/10.2118/112657-PA

Gockel JF, Gockel CE, Brinemann M (1987) Lost circulation: a solution based on the problem. SPE/IADC 16082. Presented for presentation at the SPE/IADC drilling conference, New Orleans, LA, March 15–18. DOI:https://doi.org/10.2118/16082-MS.

Goodman MA (1981) Lost circulation in geothermal wells: survey and evaluation of industry experience prepared by Enertech engineering and research co. for sandia national laboratories, Contract no 13 8769

Griffin TJ (1990) Cementing calculations. In: Nelson EB (ed) Developments in petroleum science. Elsevier, Amsterdam

Heathman JF (1996) Advances in cement-plug procedures. SPE 36351, JPT, September, p. 825–831. DOI:https://doi.org/10.2118/36351-JPT.

Nelson E, Guillot D (2006) Well cementing. 2nd edn. Published by Schlumberger. ISBN-10: 0978853008

Ombe EM, Elyas O, Cox D,JA Barry (2020) Novel approach for lost circulation treatment while drilling with an MPD system by using a combined high-strength, pressure-activated and thixotropic swelling polymers. Paper presented at the international petroleum technology conference, Dhahran, Kingdom of Saudi Arabia, January 2020. https://doi.org/10.2523/IPTC-19847-Abstract

Smith DK (1990) Cementing SPE monograph Volume 4, Henry L. Doherty Series, 2nd edn

Veisi MS, Taoutaou S, Steven A, Pasteris M, Wedhaswari VR, Awalt M, Permata E (2015) Engineered highly crush-resistant cement slurry to prevent lost circulation. Soci Pet Eng. https://doi.org/10.2118/176038-MS

Wang H, Sweatman RE, Engelman R, Deeg WFJ, Whitfill DL, Soliman MY, Towler BF (2008) Best practice in understanding and managing lost circulation challenges. SPE Drill Complet. https://doi.org/10.2118/95895-PA

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ashena, R., Ghalambor, A., Elmgerbi, A. et al. ‘Level-off’ cement plugging method to cure lost circulation verified with case studies. J Petrol Explor Prod Technol 11, 2777–2789 (2021). https://doi.org/10.1007/s13202-021-01177-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-021-01177-3