Abstract

This study applied vacuum-impregnated casting thin sections, fluorescence slices, scanning electron microscopy (SEM), pressure-controlled mercury porosimetry (PCP), rate-controlled mercury porosimetry (RCP), X-ray diffraction of clay minerals, overburden pressure, and conventional physical property strategies to determine the microscopic characteristics of the Chang 6 member, a typical tight sandstone reservoir in the Jingbian oilfield in the Ordos Basin, China. We also analyzed the controlling effects of pore structure on reservoir quality and oiliness. The results showed that the pore types of the Chang 6 sandstone reservoir can be divided into four categories: residual intergranular pores, dissolution pores, intercrystalline pores between clay minerals, and microfractures. The pore size of the Chang 6 sandstone reservoir ranged from 20 to 50 μm. We employed PCP and RCP strategies to characterize the pore structure of the Chang 6 reservoir. The pore radius was less than 2 μm, and on average, the throat radius was less than 0.3 μm. The reservoir physical properties were affected by diagenesis, particularly compaction, and the average porosity failure rate was 56.3%. Cementation made the reservoir more compact, dissolution improved the physical properties of the reservoir locally, and fracturing effectively improved the reservoir seepage ability; however, its influence on porosity was limited. The pore structure controlled the quality of the reservoir. The physical properties of the reservoir were closely related to the oil-bearing properties. The lower limits of porosity and permeability of industrial oil flow in the reservoir were 7.5% and 0.15 mD, respectively. These results provide an additional resource for the exploration and development of tight oil in the Ordos Basin.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Given the increasing difficulty of conventional oil and gas exploration and development, unconventional oil and gas resources are attracting global attention (Rogner 1997; Zou et al. 2012; Holditch 2013; Zhao et al. 2013; Islam 2014; Al-Fatlawi et al. 2019). Developing unconventional oil and gas is an inevitable trend in industry; in fact, from the perspective of exploration, the global oil and gas industry has quietly entered an era in which equal attention is given to conventional and unconventional resources (Zhao et al. 2012, 2013; Zou et al. 2012) and in which the proportion of produced unconventional oil and gas is growing increasingly larger. The term “unconventional oil and gas” refers to reservoirs that are different from conventional reservoirs in terms of their reservoir characteristics and the reservoir-forming mechanism, mainly including tight oil and gas, shale oil and gas, coalbed methane, and natural gas hydrates (Schmoker 1996, 2002; Law and Curtis 2002; Boswell and Collett 2011; Zhao et al. 2012; Wang et al. 2016; Sadeq et al. 2018). Economic production from these reservoirs usually cannot be achieved using traditional production technologies (Zhao et al. 2012). Looking at the history of exploration and the development of unconventional oil and gas globally, tight oil and gas—in particular, tight sandstone oil and gas—have been prioritized. The exploration and development of tight sandstone oil lag behind tight sandstone gas and have become a research hotspot for unconventional oil development (Zou et al. 2012, 2017).

Tight oil is defined as reservoir tightness with an absolute permeability of less than 1 mD; the economic output of source-rock oil can be obtained only through special measures, such as large-scale fracturing transformation (Zhao et al. 2012, 2013; Zou et al. 2012; Bai et al. 2013a, b, c). Tight oil mainly includes two types: tight sandstone oil and tight carbonate oil. Compared with conventional oil, tight oil has significant geological features. The distribution of tight oil has no obvious oil–water interface and has oil–water mixed storage, nonbuoyancy drive, and short-distance migration and accumulation (Bai et al. 2017). Tight oil is adjacent to an effective source rock and has a large area of a quasicontinuous distribution (Zhao et al. 2012, 2013, 2016; Bai et al. 2013a, b, c). Therefore, reservoir research is the key to efficiently exploring and developing tight oil. According to the definition and distribution characteristics of tight oil, tight oil is developed widely in continental oil-rich basins in China, and the Ordos Basin in Central China is perhaps the most common and important of these basins: more than 80% of the petroleum resources found in the basin are tight sandstone oil.

In recent years, important technological progress has been made in the study of tight sandstone oil, particularly of the microscopic pore structure of tight sandstone (Desbois et al. 2011; Loucks et al. 2012; Zhu et al. 2016; Lai et al. 2018). Through a variety of analytical and testing methods—notably high-precision experimental instruments, such as microcomputed and nanocomputed tomography (micro-CT and nano-CT), nuclear magnetic resonance (NMR) spectroscopy, rate-controlled mercury porosimetry (RCP), and field emission scanning electron microscopy (FE-SEM), combined with conventional strategies, such as casting thin section analysis, scanning electron microscopy (SEM), and pressure-controlled mercury porosimetry (PCP) (Clarkson et al. 2012; Bai et al. 2013a, b, c; Daigle and Johnson 2016; Liu et al. 2017; Zhang et al. 2017)—it has been recognized that the pore-throat diameter of tight sandstone is mainly distributed in the 300–900 nm range (Zou et al. 2011, 2016), that the pore structure is strongly heterogeneous (Bai 2014; Zhu et al. 2016; Zhang et al. 2016; Li et al. 2017), and that non-Darcy flow exists (Zeng et al. 2014; Bai et al. 2014). These characteristics are significantly different from those of conventional sandstone, and the importance of studying the microscopic pore structure of tight oil has been recognized gradually over time. Studying the Wuqi, Longdong, and Jiyuan areas of the Ordos Basin and applying RCP, Gao et al. (2011) and Li et al. (2012) concluded that the pore radius distribution and the throat radius of the Chang 6 to Chang 8 reservoirs were similar, ranging from 100 to 240 μm and from 0.3 to 4.4 μm, respectively. Bai et al. (2013a), however, used micro/nano-CT technology and found the pore-throat diameter to be from 5.4 to 26.0 μm at the micron scale and from 0.4 to 1.5 μm at the nanoscale. Xiao et al. (2016), using RCP, NMR, and micro-CT, determined the mean pore radius of the tight sandstones of the Shahezi and Denglouku Formations in the Cretaceous Songliao Basin to be from 7.2 to 33.6 μm (with a maximum of 184.5 μm) and found the average pore-throat ratio to be between 7.5 and 64, which was significantly lower than the pore radius (the main peak was between 120 and 160 μm) and pore-throat ratio (with an average of 94–332) determined using only RCP. There are certain advantages and disadvantages to each test method. Each method cannot fully and effectively characterize the pore-throat characteristics of tight reservoirs (Yao and Liu 2010; Zhao et al. 2015). Multiscale fusion is the inevitable trend and choice for accurate characterization, given that the use of a single testing method and technology has limitations when characterizing the microscopic pore throat of tight sandstone (Xi et al. 2016, 2018; Wu et al. 2018).

Previous studies have focused primarily on the overall characterization of the pore-throat distribution, but there is no extensive discussion on the influence of pore structure on reservoir quality, especially on the control of pore structure on the reservoir oiliness property. For example, what pore structure of tight sandstone has a suitable oil-bearing property, and what are the influencing factors? What are the lower limits of the physical properties of oil-bearing tight sandstone reservoirs? These important questions affect the exploration and development of tight sandstone oil. Based on the geological conditions of the study area, this study synthetically characterized the microscopic pore structure of tight sandstone from the macro- to microfracture levels and met the following research objectives: This study (1) defined the pore type, pore size, and distribution characteristics of the Chang 6 tight sandstone; (2) discussed the geological factors affecting different pore structure types of tight sandstone; (3) evaluated the differences between the reservoir and seepage capacity of sandstone with different pore structures; and (4) defined the influence of pore structure on oiliness and determined the lower reservoir-physical-property limit of oil-bearing sandstone.

Geological setting

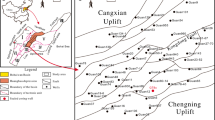

The Ordos Basin, located in the central part of China (Fig. 1a), is one of the most productive petroleum basins in China (Li 2004; Zhao et al. 2012; Jia et al. 2012); it is also a typical representation of a tight sandstone reservoir in China. The Ordos Basin is a multicycle superimposed basin developed on a Paleozoic stable craton basement (Li 2004; Liu et al. 2006). The Ordos Basin is the second-largest petroliferous basin in China, with an area of approximately 25 × 104 km2. The Ordos Basin consists of six first-order tectonic units, namely the Yimeng uplift, the Weibei uplift, the Western thrust belt, the Tianhuan depression, the Shanbei slope, and the Jinxi flexural fold belt (Fig. 1b). The largest area of the Shanbei slope is approximately 11 × 104 km2; its folds and faults are undeveloped, the stratigraphic dip is less than 1°, and more than 80% of the discovered oil and gas reserves are located in this tectonic unit.

Two sets of hydrocarbon-bearing strata of the Paleozoic and Mesozoic Eras developed in the Ordos Basin, and then, two petroleum systems were formed: the Paleozoic gas-bearing system and the Mesozoic oil-bearing system. The Upper Triassic Yanchang Formation in the Mesozoic oil-bearing system is the main oil-bearing strata in the Ordos Basin. According to the lithology and paleontology assemblage, the Yanchang Formation is divided into five lithologic sections containing 10 members, from bottom to top (Fig. 1c): T3y1 (Chang 10 member), T3y2 (Chang 9 and 8 members), T3y3 (Chang 7, 6, and 4 + 5 members), T3y4 (Chang 3 and 2 members), and T3y5 (Chang 1 member). Among these members, the Chang 6 member is the most important oil-producing member.

The Ordos Basin is a large river-delta-lacustrine sedimentary system created during the deposition of the Yanchang Formation (Li et al. 2009). The maximum area of the lake water reached 10 × 104 km2. Bordered by the 38° north latitude line, the thickness of the northern sediments is thin (100–600 m), while the thickness of the southern sediments is thick (1000–1400 m) (Yang and Li 1992). Given the regional tectonic setting, the provenance of the northeastern sediments is the Archean metamorphic rocks in the Yinshan and Daqingshan regions, while the provenance of the southwestern sediments is the Qinling orogenic belt and the Longxi ancient landform (Li et al. 2009). The Yanchang Formation records the complete evolutionary history of the formation, development, and extinction of a large freshwater lake basin (He 2003). In the early stage of Chang 7 member sedimentation, the lake area reached its maximum, forming a large distribution area of high-quality source rocks, with an average total organic carbon content of greater than 10% and a distribution area of 5 × 104 km2 (Bai 2014). The Chang 6 member represents the sedimentary period in which the delta was constructed; there are two primary provenance directions: the meandering river delta in the northeast and the braided river delta in the southwest. The distributary channel sand bodies overlap vertically and distribute horizontally in a continuous plane, which makes them effective reservoirs for petroleum accumulation. The Chang 4 + 5 members were formed via gradual evolution into a peat swamp sedimentary environment, in which mudstone was widely developed and an advantageous caprock was formed (Fig. 1c). Influenced by the sedimentary conditions and diagenesis, the Chang 6 to Chang 9 reservoirs have been fully compressed, forming a tight reservoir.

The Chang 6 member of the Triassic Yanchang Formation in the Jingbian oilfield was primarily deposited in a delta plain sedimentary environment and includes three types of microfacies: distributary channels, natural levees, and flood plains. Among them, the distributary channel sand body is the main reservoir; its lithology is silt to fine sandstone. Affected by the sedimentary environment and diagenetic conditions, the distributary channel is strongly heterogeneous, which has an important influence on and control of the development of reservoir pores.

Samples and experiments

We collected 265 drill core samples from 12 wells in the study area. After detailed core observations and descriptions, we selected 120 core samples from the Chang 6 member with burial depths of 1532.5–2002.3 m for oil and salt washing. After drying, the porosity and permeability of the samples were analyzed. According to the differences in their petrophysical characteristics, lithology and oiliness, 50 representative core samples with porosities ranging from 6.5 to 13.5% and permeabilities ranging from 0.03 to 1.50 mD were selected for casting thin sections, fluorescence thin sections, SEM, PCP, RCP, overburden porosity and permeability, and X-ray diffraction (XRD) of the clay minerals. Specifically, the procedure was to analyze 50 samples by casting thin section analysis and SEM. Twenty-five samples were selected for PCP, overburden porosity and permeability, and clay mineral X-ray diffraction analyses, and 10 samples were selected for RCP.

Casting thin section testing

We selected 50 samples and injected vacuum-impregnated red epoxy resin into the rock to prepare the casting thin sections. By observing the characteristics of the casting thin sections under a microscope, we were able to identify the mineral composition, mineral content, particle size, and particle distribution by counting at least 350 points on each thin section. We quantitatively observed the type, size, and distribution characteristics of the pores and counted the pores using Image J software, referring to the study of Sun and Guo (2016) for the specific extraction process for the quantitative analysis of pores.

Fluorescence thin section testing

Fluorescent thin sections were made from the core after both rough and fine grinding without oil washing. The rock structure, composition and pores were observed under a polarizing microscope, and then, fluorescence observations were conducted. According to the luminescence color and brightness, the composition and content of asphalt were observed under reflected light, and then, the oil-bearing characteristics of pores and fractures were observed.

Scanning electron microscopy

The core samples were cut and gold-coated. We observed the cement morphology, pore size and geometry using an FEI QUANTA 250 scanning electron microscope. We also observed the mineral forms of the diagenetic minerals and their effects on pore development.

Pressure-controlled mercury porosimetry (PCP)

PCP is an important testing technique used to evaluate the pore structure of tight reservoirs. PCP can obtain important parameters, such as the threshold pressure, the median pressure, the average pore-throat radius, the maximum pore-throat radius, and the maximum mercury saturation. The maximum mercury intrusion pressure was 32 MPa, and the corresponding pore-throat radius was approximately 25 nm. A PoreMaster PM-33-13 with a fully automatic aperture analyzer produced by Canta was used as the PCP test equipment. The formula for calculating the pore-throat radius of a certain point is:

where Ri is the capillary radius of point i, namely the pore-throat radius, and Pi is the mercury inlet pressure value of point i.

Rate-controlled mercury porosimetry (RCP)

RCP injects mercury into rock pores at a very low and constant speed to ensure the accuracy of the quasistatic mercury injection process. In this experiment, mercury was at a constant rate of 5 × 10–5 mL/min for two days, the maximum mercury intrusion pressure was 6.2 MPa, and the corresponding throat radius was approximately 0.12 μm. Since RCP maintains a quasistatic entry process, mercury will hold the pressure at each throat of the core, and the entire capillary pressure will increase. When mercury enters the pores, the pressure is released, and the pressure of the whole system is reduced. The pore and throat information can be obtained from the recorded curves of the mercury inlet pressure and mercury inlet volume.

Porosity and permeability

A core was drilled from a small sample with a diameter of 25 mm and a length of 35 mm, while the confining pressure was 1.4 MPa and the overlying pressure was 1.9 MPa. The porosity and permeability were measured by helium injection, with overlying pressures of 3 MPa, 6 MPa, 10 MPa, 15 MPa and 25 MPa. The confining pressure gas source was nitrogen, and the confining pressure value was half of the overlying pressure value.

Clay mineral X-ray diffraction

XRD of clay minerals is based on the principle of diffraction of Cu-Ka radiation. The mineral types are judged according to the peak value of the XRD, and the percentages of various clay minerals are given semiquantitatively. We separated clay particles with sizes of less than 2 μm and then heated them in a high-temperature furnace at 550 °C for 2 h.

Results

Petrology and pore types

According to the core observations and descriptions of the 12 wells in the study area and the results of the 50 casting thin sections (Fig. 2, Table 1), the Chang 6 member rock type was identified mainly as fine-grained arkose. The main clastic components include feldspar (from 42 to 64%, with an average of 53%) and quartz (from 19 to 28%, with an average of 24%), followed by rock debris (from 7 to 16%, with an average of 10%), of which the main components are volcanic and metamorphic debris. The Chang 6 sandstone displays good sorting, and the particle size ranges from 0.15 to 0.35 mm. There are many types of cements in the Chang 6 sandstone, and their contents vary greatly. The total amount of cement is 12.0% (ranging from 5.2 to 34.5%), and it is mainly calcite (from 1.1 to 28.4%, with an average of 3.9%), chlorite (from 0.2 to 6.3%, with an average of 3.2%), and laumontite (from 0.4 to 10.3%, with an average of 2.4%), followed by silica (from 0.1 to 5.5%, with an average of 1.2%), illite (from 0.1 to 6.2%, with an average of 0.6%), and small amounts of feldspar, barite, and kaolinite cements (Fig. 3).

According to the observations and statistics from casting thin section analysis and SEM, the pores of the Chang 6 sandstone in the study area can be divided into four types: residual intergranular pores, dissolution pores, intercrystalline pores of clay minerals, and microfractures; the sandstone has an average plane porosity of 5.26%. Residual intergranular pores are the most important pore type (with an average plane porosity of 3.16%). This pore type is mostly isolated, irregular in shape, and relatively few in number. Mineral dissolution pores are relatively well developed and are mainly feldspar dissolved pores (with an average plane porosity of 1.12%) and laumontite dissolved pores (with an average plane porosity of 0.35%) (Fig. 4a, b, f, g). The intercrystalline pores of clay minerals are composed mainly of kaolinite and chlorite (Fig. 4d, e). The microfractures include structural and dissolution fractures. After the formation of the structural fractures, later dissolution was favorable.

Typical pore types within the Chang 6 member in the Jingbian oilfield, Ordos Basin. a Intergranular pores, feldspar dissolution pores, and chlorite film, Well J217, 1695.63 m, red casting; b intergranular pores and feldspar dissolution pores, Well J332, 1631.11 m, red casting; c intergranular pores and chlorite film, Well J246, 1560.25 m, red casting; d chlorite clay film and developed intergranular pores, Well J831, 1750.20 m, SEM; e kaolinite filling pores in intercrystalline pore development, Well J805, 1924.31 m, SEM; f laumontite filling pores and dissolution, Well J831, 1816.93 m, SEM; g laumontite solution pores, Well J354, 1692.43 m, red casting; h fracture, Well J831, 1750.14 m, yellow-green fluorescence; i dissolution developed pores and dissolution fractures, which can reach 100 μm wide, Well J831, 1752.43 m, yellow-green fluorescence

Porosity and permeability

According to the results of the conventional physical analyses of 120 samples from 12 wells, the porosity of the Chang 6 reservoir was mainly in the range of 8%–12%, with an average of 10.1% (Fig. 5a); the permeability was mainly in the range of 0.1–2.0 mD, with an average of 0.95 mD and a median of 0.65 mD. Permeability of less than 1 mD accounted for 68.3% of the statistical samples, and permeability of less than 2 mD accounted for 89.2% of the total samples (Fig. 5b). According to the reservoir classification evaluation standard (Zhao 2012), the Chang 6 reservoir was a tight reservoir.

In Fig. 5c, a very poor correlation is visible between porosity and permeability. With an increase in porosity, permeability tended to increase, but the data points were scattered. This finding was related primarily to the strong microheterogeneity of the Chang 6 reservoir. Due to diagenetic modification, the pore distribution of the Chang 6 reservoir was uneven, the pore-throat system was complex, and the permeability was poor. The occasional microfractures increased the microheterogeneity of the Chang 6 reservoir. The factors affecting the physical properties in tight reservoirs are very complex and are primarily related to the cement types, cement content, and mutual transformation of diagenetic minerals during burial and diagenesis (Luo et al. 2016).

Pore-throat size and distribution characteristics

Pore size by casting thin sections

Statistical analysis of pore size by casting thin sections offers an intuitive advantage: It can be used to observe and count pores larger than 1 μm. According to the statistical results, the size of a single pore mainly ranges from 5 to 100 μm, and the overall distribution is close to a normal distribution; pores in the 20–50 μm size range account for 52.3% of the total samples (Fig. 6). It should be noted that, due to the limitation of the resolution of the casting thin section, only micropores and mesopores could be observed under the microscope.

Pore size by SEM

The pore sizes were measured by pore type. The diameters of the residual intergranular pores were mainly from 40 to 60 μm (Fig. 4a–d). The diameters of the dissolution pores were mostly from 5 to 20 μm, and the maximum was 100 μm (in almost completely dissolved particles) (Fig. 4b). There were many intercrystalline pores between clay minerals, and the pore diameters mainly ranged from 200 nm to 1 μm. The width of the structural fractures generally was not more than 20 μm (Fig. 4h), and the maximum width of the dissolution fractures reached 100 μm (Fig. 4i).

Pore size by pressure-controlled mercury porosimetry

According to the physical properties and oiliness characteristics, we selected 25 samples from 12 wells for PCP testing. The porosity distribution range of the test samples was 6.5%–13.3%, with an average of 9.6% (Table 2). The permeability ranged from 0.03 to 1.36 mD, with an average of 0.52 mD. According to the PCP results, the maximum pore-throat radius of the Chang 6 sandstone was 0.13–3.22 μm, with an average of 1.06 μm; the median pore-throat radius was 0.03–0.35 μm, with an average of 0.14 μm; the average pore-throat radius was 0.05–0.70 μm, with an average of 0.26 μm; the displacement pressure ranged from 0.23 to 5.74 MPa, with an average of 1.21 MPa; the saturation median pressure ranged from 2.12 to 28.23 MPa, with an average of 7.57 MPa; and the maximum mercury saturation ranged from 50.93 to 90.04%, with an average of 76.66% (Table 2).

Pore-throat structures by rate-controlled mercury porosimetry

PCP testing uses a high mercury pressure, which reveals a wide range of pore-throat distributions, but larger pore-throats may be missing (Pittman 1992; Romanenko and Balcom 2013). PCP reveals the total pore-throat system characteristics, but it cannot effectively separate pores and throats in the reservoir (He et al. 2011). RCP, however, injects mercury at a low pressure and a quasistatic rate. According to the fluctuation of the mercury injection pressure, pores and throats can be separated effectively, and then, the pores and throats in the reservoir can be characterized independently. According to the lithological, oiliness, and physical characteristics of the Chang 6 reservoir, we selected four typical samples on which to conduct RCP experiments (Table 3, Fig. 7). The results showed that the displacement pressure of the Chang 6 sandstone was from 0.33 to 1.90 MPa, with an average of 0.87 MPa; the pore radius was from 131.5 to 177.3 μm, with an average of 151.7 μm; the throat radius was from 0.29 to 1.28 μm, with an average of 0.74 μm; the pore-throat radius ratio was from 50 to 1200, with an average of 185–654; the maximum mercury saturation was from 37.17 to 66.04%, with an average of 53.32%; the average pore mercury saturation was 36.72%; the average throat mercury saturation was 16.60%; and the average pore-throat volume ratio was 2.74%.

The pore radius distribution curves of the four representative samples all followed a normal distribution, and the main pore radius values were consistent, generally between 100 and 200 μm, but the peak value of the pore radius was different (Fig. 8a). The throat radius distribution range of different samples varied greatly (Fig. 8b). The permeability of sample J217-8 was 0.69 mD, and the throat radius was 0.25–2.35 μm, with an average of 1.30 μm. The permeability of sample J805-10 was 0.09 mD, and the throat radius was 0.15–0.45 μm, averaging 0.30 μm. It was evident that the throat radius was the most important factor affecting reservoir permeability and controlling fluid flow and that a small throat radius indicated very low permeability. The distribution characteristics of the pore-throat radius ratios showed that the larger the permeability, the smaller the pore-throat radius ratio and the narrower the distribution range (Fig. 8c).

Full range of pore-throat sizes by pressure- and rate-controlled mercury porosimetry

PCP and RCP use the same physical process for injecting mercury into rock samples, so the mercury curve should be the same or similar (Zhao et al. 2015). The average maximum mercury saturation of PCP was 67.69%, whereas the average total mercury injection saturation of RCP was 53.32% (Table 3), and the difference between the two saturation values was 14.37%; this difference revealed the contribution of the pore-throat radius, with values ranging from 0.025 to 0.12 μm. The total mercury inflow curve of PCP was similar to that of RCP, but they were not exactly the same. For example, the permeabilities of the J217-8 and J805-10 samples were 0.69 and 0.09 mD, respectively, under the same mercury injection pressure, and the total mercury injection saturation of RCP was greater than that of PCP (Fig. 9). This phenomenon may have been caused by the following reasons: The heterogeneity of the reservoir may have impacted the results when the core was drilled in different parts of the same sample (Labani et al. 2013), the deformation of plastic particles under a high injection pressure may have made the mercury injection curve shift (Clarkson et al. 2013), or a high mercury rate may have changed the contact angle and interfacial tension and thereby produced the wetting hysteresis effect (Favvas et al. 2009; He et al. 2011).

PCP characterized the pore-throat radius in the range of 0.025–60 μm. The PCP results showed that a pore-throat radius greater than 1 μm was rare; most pore-throat radius measurements were less than 1 μm and mainly ranged from 0.1 to 1 μm. RCP revealed pores with a pore-throat radius greater than 0.12 μm; a pore-throat radius less than this value could not be characterized. The RCP results showed that the pore radius was from 100 to 200 μm, and the throat radius was from 0.15 to 2 μm. The pore diameters observed by casting thin section analysis and SEM, however, mainly ranged from 20 to 50 μm. Therefore, a single testing technology could not effectively determine the full pore size and throat distribution of tight sandstones; however, the combination of PCP and RCP did effectively characterize the full pore radius of tight sandstones (Zhao et al. 2015).

A pore-throat radius range between 0.025 and 500 μm can be found by combining PCP and RCP (Fig. 10). We measured a pore-throat radius of less than 0.12 μm by PCP, a pore-throat radius of 0.12–60 μm by both PCP and RCP, and a pore-throat radius of more than 60 μm by RCP. The whole pore-throat radius distribution curve showed a triple distribution. We measured the pore radius of the right-hand peak by RCP, resulting in pore radiuses between 131.5 and 177.3 μm (with an average of 151.7 μm), which mainly reflected the distribution of residual intergranular pores and dissolution macropores. The middle peak had the highest mercury saturation, and the pore radius was mainly between 0.12 and 2 μm (except for sample J805-10, which reflected the distribution of honeycombed dissolution pores, intergranular pores, and intercrystalline pores of clay minerals). The pore radius of the left-hand peak was less than 0.12 μm primarily because of the throat size and dead pores inside the granules, which had little significance on the reservoir space. The pore radius of the Chang 6 sandstone was less than 2 μm.

Discussion

Factors influencing pore structure

Previous studies have shown that reservoir quality and differences in pore structure are influenced mainly by the original sedimentary conditions and the diagenesis intensity (Beard and Weyl 1973; Zhu et al. 2016; Lai et al. 2018). The Chang 6 sandstone in the Jingbian oilfield was deposited in a delta plain sedimentary environment, and the main reservoir was the sand body deposited via a distributary channel; the lithology was sandstone, with a grain size of fine sand, which had good sorting and a high degree of roundness. The original sedimentary conditions of the Chang 6 reservoir had similar characteristics. This study discussed the effect of diagenesis on the physical properties of the reservoir and the development degree of the pore structure; the diagenesis of the Chang 6 reservoir included the processes of compaction, cementation, dissolution, and microfracturing.

Compaction

Static rock pressure is the pressure caused by the weight of rock. The static rock pressure at a certain depth can be expressed as:

where Pr is the static rock pressure in MPa; ρr is the overburden rock density, which is 103 kg/m3; h is the burial depth; and g is the acceleration of gravity, which is 9.8 m/s2.

With increasing burial depth and overlying load of sediments, grains become increasingly compact, and the pore space decreases. Therefore, compaction is an important factor for the reduction of pore space. As the burial depth increased, the porosity of the Chang 6 sandstone decreased significantly. The burial depth increased from 1450 to 2050 m, and the average porosity decreased from 10.9 to 6.5%. As the depth increased to 100 m, the porosity decreased by approximately 0.73% (Fig. 11a). As the burial depth increased, the permeability decreased less obviously than porosity and the permeability abnormal zone (1650 m) appeared, both of which were mainly related to dissolution and microfracture development (Fig. 11b), indicating that the factors influencing permeability were complex. The relationship between the montmorillonite content and the feldspar content in the Chang 6 sandstone is not obviously related to burial depth (Fig. 11c). The source material for the Chang 6 sandstone in the study area is mainly from the northeast, and the maximum difference in burial depth is less than 700 m, which comprehensively reflects the similar evolution degree; in addition, burial depth has little influence on the transformation of clay minerals.

In the early diagenesis stage, compaction mainly destroyed the primary pores. During compaction, particles that deform plastically, such as biotite, will deform until they become mud, which further destroys the pore structure. When the middle and late diagenesis stages are reached, the effect of compaction on porosity becomes weaker because of rock consolidation (Fig. 12a). In different diagenesis stages, however, with an increase in the overlying effective stress, permeability decreases significantly. The average burial depth of the Chang 6 sandstone was approximately 1650 m, the average rock density of the overlying strata was 2.3 g/cm3 (calculated from the density log curve), and the calculated overburden static rock pressure was 38 MPa. The average measured pore fluid pressure in the Chang 6 member was 15 MPa, so the net effective overburden pressure was 23 MPa, and the surface air permeability was 10 times greater than the formation permeability (Fig. 12b).

The original porosity of sandstone is related to the particle diameter and sorting. Beard and Weyl's (1973) formula for calculating the original porosity of natural sandstone is as follows:

where S0 is the sorting coefficient of Trask, which is 1.23 for the Chang 6 sandstone (Cui et al. 2019), and the original porosity is approximately 40%. We calculated that the original porosity of the Chang 6 sandstone decreased by 22.5% on average because of compaction and that the porosity failure rate averaged 56.3% (Fig. 13). Comparatively speaking, when the amount of quartz and feldspar particles was relatively low and the amount of mica or mudstone debris was relatively high, the compaction was stronger and the loss of original intergranular pores was greater (Fig. 13a).

Intergranular pore and cement plot for the Chang 6 member in the Jingbian oilfield, Ordos Basin: a biotite is enriched in the layer, compacted and deformed, and the particles are in linear contact with each other, Well J621, 1562.85 m; b calcareous sandstone with calcite filling in the pores, and part of the particles are in floating state, Well J533, 1624.09 m; c cementation of chlorite clay on a grain surface and the second quartz overgrowth, Well J831, 1735.93 m; and d quartz-enlarged well developed margin, Well J963, 1871.28 m

Cementation

Cementation is the second factor that destroys the physical properties of reservoirs. Calcite, chlorite, and laumontite were the main types of cement in the Chang 6 sandstone in the study area. According to the formula for the cemented porosity loss (CEPL) proposed by Ehrenberg (1989),

where OP is the original porosity in %; COPL is the compactional porosity loss in %; CEM is the intergranular cement in %; and IGV is the intergranular volume in %.

Cementation reduced the original porosity by 12% on average and reduced the porosity failure rate by 30.0% on average; the maximum rate was 42% (Fig. 13). Differences in the cement type and precipitation time resulted in variations in the contribution rate of cementation to porosity destruction in different diagenetic stages. Clay minerals in the Chang 6 sandstone are characterized by a dominance of chlorite, which accounts for 86.8% of the total clay minerals, followed by illite. According to the morphology and distribution of clay minerals under the scanning electron microscope, chlorite occurs on the surface of particles in the form of clay film (Fig. 4d); this is likely due to in situ formation, which is consistent with previous research (Zhang et al. 2016; Cui et al. 2019). The early calcite cements effectively prevented compaction, but because the reservoir space was occupied by cement, the pores were almost completely destroyed (Fig. 13b). The chlorite film attached to the grain surface prevented the direct contact between pore water and rock, effectively prevented the formation of quartz overgrowths, and had a positive effect on pore preservation. In some parts of the reservoir, when chlorite film did not develop, quartz overgrowths were more easily generated, thus destroying the primary pores (Fig. 13c, d). The total amount of carbonate cement was negatively correlated with the physical properties of the reservoir (Fig. 14).

Dissolution

According to the regional thermal evolution history (Ren et al. 2017), the Chang 6 reservoir in the Ordos Basin reached stage A of the middle diagenetic phase (Ying et al. 2003), which is the primary oil generation stage. During thermal evolution, organic matter releases a large amount of water and carbon dioxide through decarboxylation (Zhu 1985) and acidic water is discharged into the sand body with initial migration, resulting in the dissolution of particles. Dissolution of the Chang 6 sandstone occurred within and outside of particles, and intergranular and intragranular pores were formed. The edge of the secondary dissolution pores mostly had irregular bay shapes, which were easily identifiable. The dissolution pores in the grains had mostly honeycomb shapes and good pore connectivity. The secondary pores generated by dissolution increased the porosity and improved the physical properties of the reservoir. According to the calculation for the dissolution increment (Beard and Weyl 1973; Bai 2014), the average increment of porosity in the Chang 6 reservoir was 2.9%.

Microfractures

Influenced by regional horizontal tectonic compressive stress, two groups of orthogonal fractures, oriented east–west and north–south, developed in the late Jurassic and late Cretaceous–Paleogene periods in the Ordos Basin (Zeng et al. 2007). According to coring observations and statistics of 56 exploration wells in the study area, 42 exploration wells have macrovertical fractures of differing scales in the Chang 6 member, and the longest continuous fracture was 2 m. Most of the fracture zone had oil-bearing properties (Fig. 15a), and approximately 30% of the fracture zone contained a dry layer that was filled and cemented primarily by calcite (Fig. 15b). We also found horizontal fractures in horizontally stratified cores, and in these cores, the oil-bearing properties of the fracture zones were obviously improved (Fig. 15c). According to our analysis, this phenomenon was mainly due to the release of pressure from the core to the surface, and the release of dissolved gas drove the oil to seep along the horizontal fracture.

Macro- and microfracture characteristics of the Chang 6 reservoir in the Jingbian oilfield, Ordos Basin. a Vertical fracture on a smooth fracture surface in oil-immersed fine sandstone, Well J805, 1976.23 m; b vertical fracture and fracture calcite cementation in a dry layer of fine sandstone, Well J831, 1739.00 m; c horizontal fracture development in oil-immersed fine sandstone, Well J831, 1751.63 m; d oil-rich branch fracture zone indicated by yellowish-green fluorescence with matrix pore oil-poor fluorescence, Well J831, 1738.23 m

Microscopically observed microfractures were closely related to the evolution of a regional tectonic stress field, and diagenesis could then promote the formation and development of these microfractures (Wang and Sun 2009). Microfractures were well developed in the Chang 6 reservoir; of 20 fluorescent samples, eight contained microfractures, and the blue-green fluorescence showed that the oil-bearing property of the fracture zone was better than that of the matrix pores (Fig. 15d). Microfractures were among most important channels for oil migration. The water present during formation percolated well along the fracture zone, and because of the dissolution of rock particles by acidic liquids, the width of dissolution fractures was obviously larger than that of sedimentary shrinkage fractures or structural microfractures; the maximum width of the microfractures was greater than 100 μm (Fig. 4i).

Influence of pore structure on reservoir quality

Usually, porosity is used to represent reservoir capacity and permeability is used to represent reservoir percolation capacity. Therefore, the physical properties of the reservoir can reflect reservoir quality. For tight reservoirs, however, the relationship between porosity and permeability is complex. Diagenesis has a significant influence on the development of pores in the reservoir. Therefore, the reservoir physical properties cannot fully explain the quality of the reservoir. Instead, the displacement pressure, the saturation median pressure, the median pore-throat radius, and other pore structure parameters are commonly used to characterize the quality of the reservoir. These parameters reflect the microscopic characteristics of the reservoir. We discovered that the mercury injection method was effective for evaluating the reservoir pore structure, displacement pressure, median saturation pressure, and median pore-throat radius, which were closely related to permeability, and that the correlation coefficient was more than 0.88 (Fig. 16a–c). The relationship between these parameters and porosity was complex; however, the correlation coefficient was very low (Fig. 16d–f). Therefore, permeability was the most important parameter used to evaluate the pore structure of tight reservoirs. The main factors affecting permeability in reservoirs were throat size and pore-throat connectivity, and thus, an effective pore structure system was the most important factor in controlling reservoir quality.

Effects of pore structure on oiliness

According to the 1143-m core logged data of 56 coring wells, the oil-bearing properties of the Chang 6 sandstone were generally poor, mainly at the oil spot (52%) level, followed by the oil immersion (30%) and the oil trace (15%) levels. Analysis of coring data of oil-based mud in well J259 showed that the original oil saturation of the Chang 6 reservoir was 50%. After modification by fracturing, the average daily oil production of exploration wells in the first month was approximately 2.5 t/d. After three months of rapid decline, the output stabilized at approximately 30% of the initial daily oil production.

The fluorescence thin sections of oil-bearing cores showed that different types of pores obviously fluoresced, but the fluorescence characteristics were most obvious in residual intergranular pores and dissolution pores (Fig. 17a–c). The reservoir physical properties were closely related to the oil-bearing properties—that is, the higher the oil-bearing grade, the better the reservoir physical properties (Fig. 18). According to the measured reservoir physical property data and oil-bearing observation results, the lower limits of porosity and permeability of an oil-immersed reservoir were 8.5% and 0.5 mD, respectively; the lower limits of porosity and permeability of an oil spot reservoir were 7.5% and 0.15 mD, respectively; and the lower limits of porosity and permeability of an oil trace reservoir were 6.0% and 0.07 mD, respectively. In practice, exploration proved that the lowest oil-bearing level of reservoirs with industrial oil flow was the oil spot type, the corresponding lower limit of porosity was 7.5%, and the lower limit of permeability was 0.15 mD.

Oil-bearing fluorescence characteristics of pores in the Chang 6 reservoir of Well J831 in the Jingbian Oilfield, Ordos Basin. a Residual intergranular pores shown by yellow-green fluorescence, Well J831, 1750.14 m; b residual intergranular pores shown by yellow-green fluorescence with poor pore connectivity, Well J831, 1816.95 m; c feldspar solution pores shown by yellow-green fluorescence with good pore-throat connectivity, Well J831, 1816.95 m

Conclusions

We used vacuum-impregnated casting thin sections, fluorescence slices, SEM, PCP, and RCP techniques to study the pore structure characteristics of the Chang 6 sandstone in the Jingbian oilfield, Ordos Basin. We also examined the effect of pore structure on the reservoir quality and oil-bearing properties. We achieved the following results:

-

(1)

The Chang 6 sandstone reservoir in the Jingbian oilfield included the following pore types: primary residual intergranular pores, dissolution pores, intercrystalline pores of clay minerals, and microfractures, containing mainly residual intergranular pores and dissolution pores; the pore diameter ranged from 20 to 50 μm at the micron scale.

-

(2)

Integrated PCP and RCP methods were used to comprehensively characterize the full pore size distribution of the Chang 6 sandstone, which ranged from 25 nm to 500 μm, but the average pore size was less than 2 μm.

-

(3)

The pore distribution of the Chang 6 reservoir was affected mainly by diagenesis. Compaction was the most important factor in destroying reservoir porosity and permeability, and the average pore reduction rate was 56.3%. The average pore reduction rate due to cementation was 30%, and the dissolution increased by 2.9% on average. The fractures enhanced the seepage capacity of the reservoir, but the effect on the pores was weak.

-

(4)

The pore structure of the reservoir directly affected the physical development, especially the permeability. The better the pore structure, the more oil-bearing the reservoir. The lower limits of porosity and permeability were 7.5% and 0.15 mD, respectively, for the Chang 6 reservoir, which reached the industrial oil flow levels.

References

Al-Fatlawi O, Hossain M, Patel N, Kabir A (2019) Evaluation of the potentials for adapting the multistage hydraulic fracturing technology in tight carbonate reservoir. In: SPE middle east oil and gas show and conference. Society of Petroleum Engineers

Bai YB (2014) Formation mechanism and enrichment law of Chang 7 tight oil in Ordos Basin. Petroleum Industry Press, Beijing, pp 1–130

Bai B, Zhu RK, Wu ST, Yang WJ, Gelb J, Gu A, Zhang XX, Su L (2013) Multi-scale method of nano (micro)-CT study on microscopic pore structure of tight sandstone of Yanchang Formation, Ordos Basin. Petroleum Explor Dev 40(3):329–333

Bai YB, Zhao JZ, Fang CQ, Liu P (2013) Forming mechanism of quasi-continuous tight sandstone reservoir of Chang 6 oil-bearing Formation, Ordos Basin. Petroleum Geol Exp 35(1):65–71

Bai YB, Zhao JZ, Zhao ZL, Yin YY, Tong JN (2013) Accumulation conditions and characteristics of the Chang 7 tight oil reservoir of the Yanchang Formation in Zhidan area, Ordos Basin. Oil Gas Geol 34(5):631–639

Beard DC, Weyl PK (1973) Influence of texture on porosity and permeability of unconsolidated sand. AAPG Bull 57(2):349–369

Boswell R, Collett TS (2011) Current perspectives on gas hydrate resources. Energy Environ Sci 4:1206–1215

Clarkson CR, Freeman M, He L, Agamalian M, Melnichenko YB, Mastalerz M, Bustin RM, Radlinski AP, Blach TP (2012) Characterization of tight gas reservoir pore structure using USANS/SANS and gas adsorption analysis. Fuel 95:371–385

Cui WL, Zhang T, Zhang JF, Feng KM, Bai YB (2019) Diagenesis and influencing factors of Chang 6 tight sandstone in Lijiachengze area. Fault Block Oil Gas Field 26(3):304–308

Desbois G, Urai JL, Kukla PA, Konstanty J, Baerle C (2011) High-resolution 3D fabric and porosity model in a tight gas sandstone reservoir: a new approach to investigate microstructures from mm-to nm-scale combing argon beam cross sectioning and SEM imaging. J Petroleum Sci Eng 78:243–257

Daigle H, Johnson A (2016) Combining mercury intrusion and nuclear magnetic resonance measurements using percolation theory. Transp Porous Media 111:669–679

Ehrenberg SN (1989) Assessing the relative importance of compaction processes and cementation to reduction of porosity in sandstones: discussion; Compaction and porosity evolution of Pliocene sandstones, Ventura Basin, California: discussion. AAPG Bull 73(10):1274–1276

Favvas EP, Sapalidis AA, Stefanopoulos KL, Romanos GE, Kanellopoulos NK, Kargiotis EK, Mitropoulos ACh (2009) Characterization of carbonate rocks by combination of scattering, porosimetry and permeability techniques. Microporous Mesoporous Mater 120:109–114

Gao H, Xie W, Yang JP, Zhang C, Sun W (2011) Pore throat characteristics of extra-ultra low permeability sandstone reservoir based on constant-rate mercury penetration technique. Petroleum Geol Exp 33(2):206–211

He ZX (2003) Forming stages and evolution history of the Ordos Basin. Petroleum Industry Press, Beijing, pp 1–55

He SL, Jiao CY, Wang JG, Luo FP, Zou L (2011) Discussion on the differences between constant-speed mercury injection and conventional mercury injection techniques. Fault Block Oil Gas Field 18(2):235–237

Holditch SA (2013) Unconventional oil and gas resource development—-let’s do it right. J Unconv Oil Gas Resour 1:2–8

Islam MR (2014) Unconventional gas reservoirs: evaluation, appraisal, and development. Elsevier, Amsterdam

Jia CZ, Zou CN, Li JZ, Li DH, Zheng M (2012) Assessment criteria, main types, basic features and resource prospects of the tight oil in China. Acta Petrolei Sinica 33(3):343–350

Labani MM, Rezaee R, Saeedi A, Hinai AA (2013) Evaluation of pore size spectrum of gas shale reservoirs using low pressure nitrogen adsorption, gas expansion and mercury porosimetry: a case study from the Perth and Canning Basins, western Australia. J Petroleum Sci Eng 112:7–16

Lai J, Wang GW, Wang ZY, Chen J, Fan XQ (2018) A review on pore structure characterization in tight sandstones. Earth Sci Rev 177:436–457

Law BE, Curtis JB (2002) Introduction to unconventional petroleum systems. AAPG Bull 86:1851–1852

Li DS (2004) Return to petroleum geology of Ordos Basin. Petroleum Explor Dev 31(1):1–7

Li WH, Pang JG, Cao HX, Xiao L, Wang RG (2009) Depositional system and paleogeographic evolution of the late Triassic Yanchang Stage in Ordos Basin. J Northwest Univ 39(3):501–506

Li WC, Zhang YM, Wang F, Zhu J, Ye B (2012) Application of constant-rate mercury penetration technique to study of pore throat characteristics of tight reservoir: a case study from the Upper Triassic Yanchang Formation in Ordos Basin. Lithol Reserv 24(6):60–65

Li P, Zheng M, Bi H, Wu ST, Wang XR (2017) Pore throat structure and fractal characteristics of tight oil sandstone: a case study in the Ordos Basin, China. J Petroleum Sci Eng 31(1):665–674

Liu CY, Zhao HG, Gui XJ, Yue LP, Zhao JF (2006) Space time coordinate of the evolution and reformation and mineralization response in Ordos Basin. Acta Geol Sin 80(5):617–638

Liu XF, Wang JF, Ge L, Hu FL, Li CL, Li X, Yu J, Xu HJ, Lu SF, Xue QZ (2017) Pore-scale characterization of tight sandstone in Yanchang Formation Ordos Basin China using micro-CT and SEM imaging from nm- to cm-scale. Fuel 209:254–264

Loucks RG, Reed RM, Ruppel SC, Hammes U (2012) Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull 96:1071–1098

Luo JL, Luo XR, Bai YB, Luo CY, Bai XJ, Li XJ, Li C (2016) Impact of differential diagenetic evolution on the chronological tightening and pore evolution of tight sandstone reservoirs—a case study from the Chang 7 tight turbidite sandstone reservoir in the Southwestern Ordos Basin. J Earth Sci Environ 38(1):79–92

Pittman ED (1992) Relationship of porosity and permeability to various parameters derived from mercury injection-capillary pressure curves for sandstone. AAPG Bull 76(2):191–198

Ren ZL, Yu Q, Cui JP, Qi K, Yang P (2017) Thermal history and its controls on oil and gas of the Ordos Basin. Earth Sci Front 24(3):137–148

Rogner HH (1997) An assessment of world hydrocarbon resources. Annu Rev Energy Enviorn 22(1):217–262

Romanenko K, Balcom BJ (2013) An assessment of non-wetting phase relative permeability in water-wet sandstones based on quantitative MRI of capillary end effects. J Petroleum Sci Eng 110:225–231

Sadeq D, Alef K, Iglauer S, Lebedev M, Barifcani A (2018) Compressional wave velocity of hydrate-bearing bentheimer sediments with varying pore fillings. Int J Hydrog Energy 43(52):23193–23200

Schmoker JW (1996) A resource evaluation of the Bakken Formation (Upper Devonian and Lower Mississippian) continuous oil accumulation, Williston Basin, North Dakota and Montana. Mt Geol 33(1):1–10

Schmoker JW (2002) Resource-assessment perspectives for unconventional gas systems. AAPG Bull 86:1993–1999

Sun YS, Guo SB (2016) Qualitative and quantitative characterization of shale microscopic pore characteristics based on Image analysis technology. Adv Earth Sci 31(7):751–763

Wang RF, Sun W (2009) A Study on micro cracks in super-low permeability sandstone reservoir of the Upper Triassic Yanchang Formation in the Ordos Basin. Geol Rev 55(3):444–448

Wang HJ, Ma F, Tong XG, Liu ZD, Zhang XS, Wu ZZ, Li DH, Wang B, Xie YF, Yang LY (2016) Assessment of global unconventional oil and gas resources. Petroleum Explor Dev 43(6):925–940

Wu ST, Zhu RK, Li X, Jin X, Yang Z, Mao ZG (2018) Evaluation and application of porous structure characterization technologies in unconventional tight reservoirs. Earth Sci Front 25(2):191–203

Xiao DS, Lu SF, Lu ZY, Huang WB, Gu MW (2016) Combining nuclear magnetic resonance and rate-controlled porosimetry to probe the pore-throat structure of tight sandstones. Petroleum Explor Dev 43(6):961–970

Xi KL, Cao YC, Beyene GH, Zhu RK, Jahren J, Bjørlykke K, Zhang XX, Hellevang H (2016) How does the pore-throat size control the reservoir quality and oiliness of tight sandstones? The case of the Lower Cretaceous Quantou Formation in the southern Songliao Basin, China. Mar Petroleum Geol 76:1–15

Xi KL, Cao YC, Liu KY, Zhu RK (2018) Factors influencing oil saturation and exploration fairways in the lower cretaceous Quantou Formation tight sandstones, Southern Songliao Basin, China. Energy Explor Exploit 36(5):1061–1085

Yang JJ, Li KQ (1992) Petroleum geology of China, vol 12. Petroleum Industry Press, Beijing, pp 1–72

Yao YB, Liu DM (2010) Petrophysical characterization of coals by low-field nuclear magnetic resonance (NMR). Fuel 89:1371–1380

Zeng LB, Li ZX, Shi CE, Wang ZG, Zhao JY (2007) Characteristics and origin of fractures in the extra low-permeability sandstone reservoirs of Upper Triassic Yanchang Formation in the Ordos Basin. Acta Geol Sin 81(2):174–180

Zeng JH, Yang ZF, Qiao JC, Feng X, Zhang ZY (2014) Study status and key scientific issue of tight reservoir oil and gas accumulation mechanism. Adv Earth Sci 29(6):651–661

Zhang ZQ, Shi YM, Li H, Jin W (2016) Experimental study on the pore structure characteristics of tight sandstone reservoirs in Upper Triassic Ordos Basin China. Energy Explor Exploit 34(3):418–439

Zhang LC, Lu SF, Xiao DS, Li B (2017) Pore structure characteristics of tight sandstones in the northern Songliao Basin, China. Mar Petroleum Geol 88:170–180

Zhao JZ (2012) Conception, classification and resource potential of unconventional hydrocarbons. Nat Gas Geosci 23(3):393–406

Zhao JZ, Bai YB, Cao Q, Er C (2012) Quasi-continuous hydrocarbon accumulation: a new pattern for large tight sand oilfields in the Ordos Basin. Oil Gas Geol 33(6):811–827

Zhao JZ, Li J, Cao Q, Bai YB, Er C, Wang XM, Xiao H, Wu WT (2013) Hydrocarbon accumulation patterns of large tight oil and gas fields. Oil Gas Geol 34(5):573–583

Zhao HW, Ning ZF, Wang Q, Zhang R, Zhao TY, Niu TF, Zeng Y (2015) Petrophysical characterization of tight oil reservoirs using pressure-controlled porosimetry combined with rate-controlled porosimetry. Fuel 154:233–242

Zou CN, Yang Z, Tao SZ, Li W, Wu ST, Hou LH, Zhu RK, Yuan XJ, Wang L, Gao XH, Jia JH, Guo QL (2012) Nano-hydrocarbon and the accumulation in coexisting source and reservoir. Petroleum Explor Dev 39(13):13–26

Zhu GH (1985) Formation of lomonitic sand bodies with secondary porosity and their relationship with hydrocarbons. Acta Petrolei Sinica 6(1):1–8

Zhu RK, Wu ST, Su L, Cui JW, Mao ZG, Zhang XX (2016) Problems and future works of porous texture characterization of tight reservoirs in China. Acta Petrolei Sinica 37(11):1323–1336

Funding

This research was supported by the Natural Science Basic Research Plan in Shaanxi Province of China (Program No. 2017JM4014) and the Shaanxi Provincial Education Department (Program No. 18JS090).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bai, Y., Zhao, J., Zhao, D. et al. Pore structure and its control on reservoir quality in tight sandstones: a case study of the Chang 6 member of the Upper Triassic Yanchang Formation in the Jingbian oilfield in the Ordos Basin, China. J Petrol Explor Prod Technol 11, 171–189 (2021). https://doi.org/10.1007/s13202-020-01042-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-01042-9