Abstract

Wax deposition in production tubing and pipelines is very critical in Nigeria petroleum industry. It can lead to a reduction in production, shut-in of wells, choking of flow lines, failure of downhole equipment, increased power requirement and loss in revenue. In the bid to address this issue, a Niger Delta crude oil sample was characterized in this study to know its wax deposition tendency and other chemical properties. The effect of temperature on the viscosity of the crude oil sample was studied, and the degree of viscosity reduction (DVR) of the crude oil sample in the presence of poly (ethylene-butene) (PEB) and nano-aluminium oxide (Al2O3) blend at different temperatures was evaluated. 100 ppm of nano-Al2O3 blend with 1000 ppm, 2000 ppm and 5000 ppm of PEB, respectively, was added to the crude oil sample at different temperatures, and the degree of viscosity reduction (DVR) in each blend at 10 °C, 15 °C, 20 °C, 30 °C and 35 °C was evaluated. The blend with 2000 ppm of PEB with 100 ppm nano-Al2O3 is the best for offshore application as it gave the highest DVR of 77.9% and 73.7% at 10 °C and 15 °C, respectively, while the other blends gave a DVR of about 70% at 10 °C and 15 °C. As the crude sample temperature approached the wax appearance temperature of 29 °C, the DVR of PEB/Al2O3 blend drastically reduced. PEB/Al2O3 blend inhibited wax precipitation, and at low temperatures, a significant reduction in the viscosity of the crude oil sample was observed, which makes it a good recommendation for offshore application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The world demand for energy has led exploration and production companies to expand their operations to cold environments like the deep offshore waters because oil reservoirs near the shoreline and on land have become depleted. These offshore operations have increased flow assurance problems encountered during petroleum production and transportation through pipelines. Flow assurance problems include hydrate formation, wax deposition, asphaltenes, naphthenates, scaling and equipment corrosion (Kutlik, 1998). Among the issues mentioned earlier, wax deposition is very common and poses a critical operational problem; it alters the rheological properties of crude oil hence impeding the flow of the oil.

In Nigeria, revenues from the oil and gas sector are the mainstay of the economy and foreign exchange providing about 35% of the nation’s GDP and 92% of total export revenue (Mosobalaje et al. 2019). Nigeria has a reserve of crude oils which contains moderate to high contents of paraffin wax with low sulphur content and high API gravity (Ajienka and Ikoku 1997). Most petroleum exploration and production operations in Nigeria goes on in the Niger Delta region, which is about 7.5% of Nigeria's landmass (Taiwo et al. 2009). The crude oil found in the Niger Delta region of Nigeria has wax deposits in the range of 30–45% (Adewusi 1997). The deposition of wax in the pipes during petroleum production may cause reduced production, frequent downtime, mechanical failure of tubular equipment and ultimately, an increase in production cost (Theyab and Yahya 2018). This has necessitated the use of many wax monitoring techniques and application of corrective measures.

Crude oil can be regarded as a Newtonian fluid with the pressure drop directly proportional to the flow rate. However, crude oil often contains a good percentage of paraffin wax, which can cause a non-Newtonian flow behaviour as well as increase the viscosity, pour point and yield stress of the crude oil (Huang et al. 2015). Depending on the crude oil composition, decreasing crude oil temperature causes wax crystallization and growth thereby causing resistance to crude oil flow (Abarasi 2014). Wax precipitation occurs when the crude oil temperature drops below the wax appearance temperature (WAT) (Zhang et al. 2014). The mechanisms of wax precipitation and deposition include molecular diffusion, shear dispersion, Brownian diffusion, gravity settling and sloughing of wax Montalvo (2012).

Wax deposition causes an increase in the crude oil viscosity making crude oil transportation extremely challenging. Without a prior reduction in the heavy crude oil viscosity, transportation via pipeline is difficult requiring immense energy (i.e. high pumping power) to overcome the high-pressure drop in the pipeline due to high viscosity (Abarasi 2014). Viscosity is a profound function of wax deposition rate, and viscosity reduction is imminent to improve the smooth flow of the oil (Ekaputra et al. 2014). Viscosity reduction can be achieved through thermal treatment (Albuquerque 2019); blending viscous oil with a light oil (Mao et al. 2014), or through the use of wax inhibition chemicals such as pour point depressants (Deshmukh and Bharambe 2008) or wax crystal modifiers (Dobbs 1999; Towler et al. 2011).

Pour point depressants (PPD), usually, contain oil-soluble long-chain alkyl group and a polar moiety in the molecular structure. The long-chain alkyl group is inserted into the wax crystal, and the polar moiety exists on the wax surface and reduces wax crystal size (Deshmukh and Bharambe 2008). PPD does not entirely prevent the wax precipitation but instead shifts its manifestation towards a lower temperature (Manka and Ziegler 2001; Chen et al. 2010). Wax crystal modifiers, on the other hand, avoid the formation of large wax molecules by bonding to the wax crystal and impeding further growth (Sousa et al. 2019; Manka et al. 1999).

Wax prevention by temperature control

Several researchers have examined the relationship between rheology of crude oil and wax deposition. Ekaputra et al. (2014) studied the wax formation tendency of crude oil from Malaysian oil fields. Viscosity was measured at different shear rates in the range of 50, 100 and 500 s−1 and at different temperature from 5 to 50 °C. Their result showed that there is a linear trend between density and temperature, but there exists an inverse relationship between API gravity and density. It was also observed that temperature reduction causes an increase in viscosity but reduces shear stress.

Struchkov et al. (2019) studied the effect of temperature and hydrocarbon solvent (kerosene and diesel fuel) addition on thixotropy of waxy crude oil. It was discovered that the diesel-based solutions have higher WAT than the kerosene-based solutions. This implies that the increase in wax concentration in solution leads to an increase in WAT. Struchkov and Rogachev (2017) studied the effect of pressure, cooling rate, water cut and addition of mechanical impurities on change in wax appearance temperature (WAT) in oil. Results show that WAT grows with an increase in the concentration of wax in solution, increase in pressure, water cut, shear rate, the addition of mechanical impurities and decrease in gap size of the measuring system. Zhang et al. (2019) proposed a new method for wax deposition location based on heat–fluid coupling method. The regularities of temperature distribution and wax deposition location were simulated with different fluid producing intensities and moisture contents. With the migration of produced liquid, the temperature decreases from bottom to upward, while the decline rate becomes less.

In tackling wax deposition in the Niger Delta, Akankpo and Essien (2015) compared the effect of temperature on the viscosity of Niger Delta crude. The experimental investigation was carried out on five crude oil samples obtained from different reservoirs in the Niger Delta region. A capillary tube viscometer inserted in a thermostatically controlled water bath was used to measure the viscosity of the crude samples at different temperatures. The variation of the crude kinematic and dynamic viscosities with temperature was studied. The results show that the viscosity of Niger Delta crude oils reduces with an increase in temperature in all capillary or pipeline system.

Wax inhibition using nanoparticles

With the passing of the era of easy oil and the increasing difficulty of finding new resources, the oil and gas industry has begun extracting more resources from fields exposed to extremely harsh environments such as the offshore environment. The wax deposition is particularly challenging when the affected area is difficult to reach (Sousa et al. 2019), which is the case in the offshore environment. New technologies and solutions are being developed for reducing the difficulties faced in producing form extremely harsh environment. Nanotechnology has received great attention recently from the petroleum industry (Goshtasp et al. 2015; Wong and De Leon 2010).

Nanoparticles (NPs) possess unique qualities that enhance its wide application in the petroleum industry. These properties are its high surface area to volume ratio which enhances interaction sites (Sneh and George 1995; Mehdi et al. 2018); NPs can act as receptors for polymers, (Mao et al. 2014); and NPs are hydrophobic or hydrophilic in nature (Tuteja et al. 2008). Nanoparticles have higher stability, superior adsorption, catalytic behaviour and excellent dispersion ability (Haijiao et al. 2016). The uniqueness of nanoparticles is tied to its size. NPs have a dimension in the order of 100 nm (Afolabi and Yusuf 2019). Some applications of nanotechnology in the petroleum industry include corrosion inhibition (Atta et al. 2013), drilling fluid formation (Srawanti et al. 2020), enhanced oil recovery (Goshtasp et al. 2015; Abbas and Hadi 2015); asphaltenes stabilization (Mohammadi et al. 2011) and wax prevention (Davidson et al. 2012; Shah et al. 2010).

Some researchers have investigated the effect of the use of nanoparticle and polymer or surfactants for wax prevention. Yang et al. (2015) studied the effect of poly octadecyl acrylate (POA) and silica nanoparticle on the rheology and cloud point of a model waxy crude. The gelation point of the system was observed to decrease gradually with increasing POA concentration. However, it was observed that the polymer nanoparticle hybrid system had a significant effect on the rheology at lower concentrations than using only polymers as pour point depressant and offered optimal performance at 100 ppm.

Koroleva et al. (2017) studied the effect of various compounds such as non-ionic surfactants, Eumulgin O10 (polyethylene glycol and cetyl/oleyl alcohol ether), polymer molecule of polyvinyl alcohol (PVA) and SiO2 and Al2O3 nanoparticles on the complex stabilization of paraffin wax emulsions. The concentration of Eumulgin O10 was observed to effect an increase in the average diameter of the particles with increasing surfactant concentration. At the same time, the stability of wax dispersion will reduce if Eumulgin O10 concentration exceeded 2.0 wt%. When silica and alumina nanoparticles were introduced, the average diameter of paraffin particles increased 90–100 nm, but the diameter is not as high when the concentrations of other stabilizers are increased. Therefore, an increase in the size of wax particles is associated with an increase in velocity of the homogenizing mixture.

Subramanie et al. (2019) evaluated the effect of polymers, nanoparticles and the effect of their blend on the viscosity of Malaysian crude oil at different temperature and shear stress. Sodium cloisite Na+ nanoparticle and two wax inhibitors, namely: poly (ethylene-co-vinyl acetate) (EVA) and poly (maleic anhydride de-alt-1-octadecane) (MA) were used to improve the Malaysian crude rheology. A significant reduction in viscosity was observed when nanoparticle was added to the crude sample. At a temperature below the WAT, the nanoparticles were seen to reduce the viscosity of the crude oil. However, as the temperature approached WAT, there was no much effect on the crude oil viscosity. The effect of inhibitor at different concentrations of EVA and MA was investigated. EVA/sodium nano-clay blend was found to be the best combination which improved the value of viscosity followed by MA/sodium cloisite blend and then EVA and MA alone.

In Nigeria, the petroleum industry has incurred significant loss in revenue due to increased operational cost from tackling wax deposition. It is, therefore, imperative to seek efficient methods to prevent wax deposition and improve the flowability of crude oil in order to optimize production. This work investigates the effect of aluminium oxide (Al2O3) nanoparticle, and poly (ethylene-butene) (PEB) blend on wax deposition in Niger delta crude at temperatures between 10 and 35 °C.

Methodology

This study experimentally investigates the effect of a blend of polyethylene butene (PEB) and Al2O3 nanoparticle on the viscosity of a Niger Delta crude oil sample at varying temperatures. The materials used in this research include Nigerian Niger Delta crude oil sample, polymer—poly ethylene butene (PEB), nanoparticle—aluminium oxide (Al2O3) and xylene as a solvent.

The Al2O3 nanoparticle is spherical with silt size of 75 nm, the density of 3.9 g/cm3, the molar mass of 101.96 g/mol, a boiling point of 2977 °C and melting point of 2040 °C. It is hydrophilic. PEB used has a molecular weight of 84.16 g/mol and density of 0.865 g/cm3.

Four different concentrations of poly (ethylene-butene) (PEB); 500 ppm, 1000 ppm, 2000 ppm and 5000 ppm solution were prepared by mixing 0.02 ml, 0.04 ml, 0.08 ml and 0.2 ml of PEB, respectively, in 40 ml (for each concentration) of xylene (solvent) at continuous stirring in a mixer at 1500 rpm for 30 min. 100 ppm nanofluid was prepared by mixing 0.01 g of nano-aluminium oxide (Al2O3) in 100 ml of xylene (base fluid) continuously using a Hamilton beach mixer at 1500 rpm for 30mins to achieve homogeneity. In preparing the polymer/nanofluid blend, 1wt% (3 ml) of the nanofluid was added to 3wt% (9 ml) of each concentration of polymer solution prepared and stirred at 28 °C for 30mins prior to being added to 300 ml of the crude oil sample.

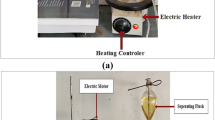

An electrical water bath and a chiller were used in conditioning the crude temperature to the required temperature prior to viscosity readings from the 12—speed rotary viscometer with measurement accuracy ± 4%. The dynamic viscosity of the blank crude sample (without inhibitor) and the viscosity of the crude oil mixed with the polymer and nanoparticle blend at different temperatures were obtained using the viscometer. The dial reading was taken after 1 min when the system reached equilibrium, and the pointer was stable. The specific gravity of the crude sample and the API density were obtained empirically using a hydrometer. The pour point of the crude was measured using a pour point tester, and the crude oil composition was obtained from a gas chromatograph carried out on the crude sample.

Degree of viscosity reduction (DVR)

It is essential to evaluate the degree to which the viscosity of the blank crude sample reduced at different temperature in the presence of the different polymer/nanoparticle blend concentration. The DVR can be used in assessing the efficiency of the inhibitors; a higher DVR indicates a more efficient inhibitor. The DVR is obtained from correlation by Subramanie et al. (2019) as shown in Eq. 1:

Results

The physiochemical properties of the blank crude oil sample (Table 1) show that the crude has wax content of 36.58% and density of 0.81 g/cm3, wax appearance temperature (WAT) of 29 °C, and the pourpoint is 10 °C. The API gravity is 43.19°, showing that the cde is light. The chromatography of crude sample (Fig. 1) shows that the crude contains about 37% of hydrocarbons of more than 16 carbon chains (wax formers).

Effect of temperature and inhibitor on the Newtonian behaviour of the fluid

The plot of shear stress against shear strain rate at different temperatures for the blank crude sample shows that at 35 °C, 30 °C, 25 °C and 20 °C, a linear shear stress/shear strain rate relationship. This implies that crude oil had Newtonian fluid properties. However, as the crude oil temperature was cooled down to 15 °C and 10 °C, the crude sample exhibited non-Newtonian fluid behaviour as the shear stress/shear strain rate relationship became nonlinear (Fig. 2).

A plot of shear stress against shear strain rate for the various inhibitors used in this study (Fig. 3) gives a better view of the Newtonian/non-Newtonian behaviour of the crude in the presence of inhibitors. For Newtonian fluids, as the shear strain rate increases, the shear stress increases proportionally. Figure 3a shows the plot of shear stress against shear strain rate at varying temperature when 100 ppm of the nanofluid was added to the crude. Notice that the crude still exhibited non-Newtonian behaviour at 10 °C and 15 °C (Fig. 3a). This implies that the nanofluid added did not prevent wax precipitation at 10 °C and 15 °C. When 1000 ppm PEB and 100 ppm Al2O3 blend was added to the crude sample, the crude exhibited Newtonian fluid (linear shear stress/shear strain rate curve) behaviour at all the shear stress studied (Fig. 3b). A similar linear trend was noticed in the plot of shear stress against shear strain rate in the experiment conducted with 2000 ppm PEB and 100 ppm Al2O3 (Fig. 3c). This implies that the inhibitor was able to prevent non-Newtonian fluid behaviour as was initially observed in the 10 °C and 15 °C in the blank crude. The plot of shear stress against shear strain rate of crude sample contaminated with 5000 ppm PEB and 100 ppm Al2O3 blend (Fig. 3d) showed a linear trend, confirming the effectiveness of the inhibitor in preventing non-Newtonian fluid behaviour.

The Non-Newtonian behaviour noticed at 10 °C and 15 °C in the blank crude and the crude inhibited with 100 ppm nanoparticle is as a result of precipitation of wax particles. Therefore, a plot of shear stress against shear rate for the inhibitors understudy at 10 °C (Fig. 4), and 15 °C (Fig. 5) clearly shows that with increasing shear strain rate, the shear stress increased linearly until the shear rate was 340 s−1. At this point, the wax particles deposited were sufficient to prevent a corresponding increase in shear stress for the increasing shear strain rate. Therefore, the shear stress/shear strain curve deviated to the right, signifying the onset of non-Newtonian fluid behaviour. However, in the samples inhibited by the nanoparticle PEB blend, the linear relationship between shear stress and shear strain at 10 °C and 15 °C was consistent at all shear strain rates. This implies that these blends were able to prevent wax precipitation or keep the size of wax particles small enough for the fluid to remain a Newtonian fluid.

Effect of shear strain rate and temperature on the viscosity of the fluid

The plot of the viscosity of blank crude against shear strain rate at varying temperatures (Fig. 6) shows that the increase in shear strain rate results in a decrease in viscosity. This is because the flow encounters less resistance at higher shear rates due to the long molecular chains (wax molecules) being broken, stretched and reoriented parallel to the driving force, thereby reducing the fluid viscosity. Also notice that for each shear rate considered, the viscosity of the crude sample at 10 °C was higher than the viscosity of the crude sample at higher temperatures. This is because an increase in temperature melts and keeps the wax particles in solution, hence decreasing the oil viscosity. In contrast, a reduction in temperature facilitates wax precipitation and increases viscosity.

Effect of temperature and inhibitor on the viscosity of the crude oil sample

The viscosities of the blank crude oil sample and crude sample in the presence of 100 ppm nanofluid, 5000 ppm polymer/100 ppm nanoparticle blend, 2000 ppm polymer/100 ppm nanoparticle blend and 1000 ppm polymer/100 ppm nanoparticle blend were evaluated at different temperatures (Fig. 7). As the temperature of the crude oil increases, the cohesive forces between the high molecular waxy components of the crude oil molecules decrease and their kinetic energy increases, reducing the agglomeration of waxy particles and thereby decreasing the viscosity of the oil and making it flow easily (Fig. 6). This implies that a rise in temperature increases the crude oil viscosity.

Notice that when 100 ppm of nanofluid alone was added, it increased the viscosity of the crude from 72.5 to 75 mPa s at 10 °C and from 59 to 62 mPa s at 15 °C which of course is undesirable. However, as temperature increased to 20 °C, the nanofluid reduced the viscosity to 15.2 mPa s from 26 mPa s at 20 °C (Fig. 7). There was no significant effect of the nanofluid on the viscosity of the crude at 25–35 °C. The blank crude viscosity curve and the viscosity curve of the crude with 100 ppm nanofluid matched closely at 25–35 °C.

Notice that the polymer/nanoparticle blend effected drastic viscosity reduction at 10–15 °C with the 2000 ppm polymer/100 ppm nanoparticle blend performing best when compared with the others by reducing the viscosity of the crude sample from 72.5 to 16 mPa s at 10 °C and from 69 to 15.5 mPa s at 15 °C (Fig. 7). However, the polymer/nanoparticle performance decreases as the crude sample approached the WAT of 29 °C. At temperatures of 30 °C and 35 °C, there was no significant change in viscosity with the addition of the Al2O3 nanofluid or PEB/Al2O3 blend. Increased temperature improves crude oil flowability and reduces its viscosity.

Therefore, it is imperative to evaluate the performance of the inhibitor at low temperatures for offshore application where the crude oil cools rapidly, and excellent inhibitor performance at low temperature is desirable.

Effect of PEB/Al2O3 blend on the viscosity of the crude oil sample at varying temperature

The degree of viscosity reduction of the 100 ppm Al2O3 nanofluid, 5000 ppm PEB/100 ppm Al2O3 nanofluid blend, 2000 ppm PEB/100 ppm Al2O3 nanofluid blend and 1000 ppm PEB/100 ppm Al2O3 nanofluid blend at varying temperature was plotted (Fig. 8). For offshore application, the inhibitor performance is best evaluated at low temperatures. Notice that the DVR of the 100 ppm nanofluid was negative at 10 °C and 15 °C. This is because adding 100 ppm Al2O3 nanofluid had an undesirable effect on the crude viscosity as it increased the viscosity of the crude sample at 10 °C and 15 °C. The nanoparticle alone was ineffective at low temperature due to its reduced surface area. A higher temperature increases the dispersion of the nanoparticle and effects a higher viscosity reduction.

However, the blend of PEB and Al2O3 nanofluid gave desirable results at low temperature. At 10 °C, the 2000 ppm PEB/ 100 ppm Al2O3 nanoparticle blend is the optimum as it reduces the viscosity of the crude by about 78% while the other blends effected a viscosity reduction by 68%. As the temperature rises to 20 °C, the DVR for 2000 ppm PEB/100 ppm Al2O3 nanoparticle blend and the 1000 ppm PEB/100 ppm Al2O3 nanoparticle blend reduced rapidly to 43% and 37%, respectively. However, the 5000 ppm PEB/100 ppm Al2O3 nanoparticle blend recorded a higher DVR form 68% at 10 °C to 79% at 20 °C. As the temperature of the crude sample approached the WAT, the three blends experienced a rapid DVR decrease from 25 to 30 °C and there was an eventual slight increase in DVR in the three blends at 35 °C.

Conclusion

The effect of PEB/Al2O3 nanoparticle blend on the viscosity of Niger Delta crude oil was investigated through experimental procedures and empirical correlations. It was observed that the rise in temperature and shear rate would result in a decrease in viscosity. Therefore, flow assurance problems will be more prominent at low temperatures where the crude oil viscosity is high. The addition of the different concentrations of PEB/Al2O3 nanoparticle blend to the crude oil sample greatly reduced the viscosity at low temperature with the best blend for offshore operation as the 2000 ppm polymer/100 ppm nanoparticle blend as it gave a DVR of 77.9% and 73.7% at a temperature of 10 °C and 15 °C. At higher temperatures, it is difficult to properly evaluate inhibitor performance as temperature already plays a key role in reducing the viscosity of the crude.

References

Abarasi H (2014) A review of technologies for transporting heavy crude oil and bitumen via pipelines. J Petrol Explor Prod Technol 4:327–336. https://doi.org/10.1007/s13202-013-0086-6

Abbas R, Hadi B (2015) Experimental investigation of SiO2 nanoparticles on enhanced oil recovery of carbonate reservoirs. J Petrol Explor Prod Technol 5:27–33

Adewusi VA (1997) Prediction of wax deposition potential of hydrocarbon systems for viscosity-pressure correlations. Fuel 76:1079–1083

Afolabi RO, Yusuf EO (2019) Nanotechnology and global energy demand: challenges and prospects for a paradigm shift in the oil and gas industry. J Petrol Explor Prod Technol 9:1423–1441

Ajienka JA, Ikoku CV (1997) Waxy crude oil handling in Nigeria: practices, problems and prospects. Energy Sources 12(4):463–478

Akankpo AO, Essien UE (2015) Comparative study of the effect of temperature on the viscosity of Niger Delta crude oils. Int J Sci Eng Res 6(11)

Albuquerque D, Oliveira T, Fortaleza E (2019) Modelling of wax deposition and removal by electrical heating in sub-sea oil pipelines. In: 25 ABCM international congress of mechanical engineering, Uberlândia

Atta AM, El-Mahdy GA, Al-Lohedan HA (2013) Corrosion inhibition efficiency of modified silver nanoparticles for carbon steel in 1 M HCl. Int J Electrochem Sci 8:4873–4885

Chen W, Zhao Z, Yin C (2010) The interaction of waxes with pour point depressants. Fuel 89(5):1127–1132

Davidson A, Huh C, Lawrence S (2012) Focused magnetic heating utilizing superparamagnetic nanoparticles for improved oil production. SPE international oilfield nanotechnology conference and exhibition. Society of Petroleum Engineers, Noordwijk, pp 1–16

Deshmukh S, Bharambe DP (2008) Synthesis of polymeric pour point depressants for Nada crude oil (Gujarat, India) and its impact on oil rheology. Fuel Process Technol 89:227–233

Dobbs JB (1999) A unique method of paraffin control in production operations. In: SPE-55647 presented at SPE rocky mountain regional meeting, Gillette, pp 15–18

Ekaputra AA, Khalik MS, Hosseinipour A, Saaid IB (2014) Impacts of viscosity, density and pour point to the wax deposition. J Appl Sci 14:3334–3338

Goshtasp C, Seyyed SKN, Mosayyeb K, Mahmood H, Mohsen M, Saeed B (2015) Effect of nanoclay on improved rheology properties of polyacrylamide solutions used in enhanced oil recovery. J Petrol Explor Prod Technol 5:189–196

Haijiao L, Jingkang W, Marco S, Ting W, Ying B, Hongxun H (2016) Review article. An overview of nanomaterials for water and wastewater treatment. Adv Mater Sci Eng 2016:10. https://doi.org/10.1155/2016/4964828(Article ID 4964828)

Huang Z, Zheng S, Fogler HS (2015) Wax deposition: experimental characterizations, theoretical modeling, and field practices. Taylor & Francis Group. LLC, Boca Raton (ISBN-13: 978-1-46656767-2)

Koroleva MY, Gorbachevski OS, Yurtov EV (2017) Paraffin wax emulsions stabilized with polymers, surfactants and nanoparticles. Theor Found Chem Eng 51(1):125–132

Kutlik R (1998) Flow assurance instrumentation. Offshore Technology Conference, Houston

Manka JS, Magyar JS, Smith RP (1999) Novel method to winterize traditional pour point depressants. In: SPE 56571-MS. Presented at SPE annual technical conference and exhibition, 3–6 October, Houston

Manka JS, Ziegler KL (2001) Factors affecting the performance of crude oil wax-control additives. In: SPE 67326–MS. Presented at SPE production and operations symposium, 24–27 March, Oklahoma City

Mehdi Z, Riyaz K, Abdolnabi H (2018) Improving the microscopic sweep efficiency of water flooding using silica nanoparticles. J Petrol Explor Prod Technol 8:259–269. https://doi.org/10.1007/s13202-017-0347-x

Mohammadi M, Akbari M, Fakhroueian Z, Bahramian A, Azin R, Arya S (2011) Inhibition of asphaltene precipitation by TiO2, SiO2, and ZrO2 nanofluids. Energy Fuels 25(7):3150–3156

Mao H, Qiu Z, Shen Z et al (2014) Novel hydrophobic associated polymer based nano-silica composite with core-shell structure for intelligent drilling fluid under ultra-high temperature and ultra-high pressure. Prog Nat Sci Mater Int 25:90–93. https://doi.org/10.1016/j.pnsc.2015.01.013

Zhu Mo, Zhong H, Li Y, Zeng C, Gao Y (2015) Research on viscosity-reduction technology by electric heating and blending light oil in ultra-deep heavy oil wells. J Petrol Explor Prod Technol 5:233–239. https://doi.org/10.1007/s13202-014-0126-x

Montalvo P (2012) Modeling of wax deposition in a crude oil carrying pipeline. Master of Science Degree thesis. Department of Chemical Engineering, The University of Utah

Mosobalaje OO, Orodu OD, Ogbe D (2019) Descriptive statistics and probability distributions of volumetric parameters of a Nigerian heavy oil and bitumen deposit. J Petrol Explor Prod Technol 9:645–661

Shah SN, Shanker NH, Ogugbue CC (2010) Future challenges of drilling fluids and their rheological measurements. Am Assoc Drill Eng 10:1–16 (AADE-10-DF-HO-41)

Sneh O, George SM (1995) Thermal stability of hydroxyl groups on a well-defined silica surface. J Phys Chem 99:4639–4647. https://doi.org/10.1021/j100013a039

Sousa AL, Matos HA, Guerreiro LP (2019) Preventing and removing wax deposition inside vertical wells: a review. J Petrol Explor Prod Technol 9:2091–2107

Srawanti M, Satyajit C, Gupta DK, Mazumdar A (2020) An investigation on the effects of silica and copper oxide nanoparticles on rheological and fluid loss property of drilling fluids. J Petrol Explor Prod Technol 10:91–101

Struchkov IA, Rogachev MK (2017) Wax precipitation in multicomponent hydrocarbon system. J Petrol Explor Prod Technol 7:543–553

Struchkov IA, Roschin PV, Litvin VT, Ol’hovskaya VA, Kalinin ES (2020) Investigations of temperature and dilution effect on rheological properties of waxy crude oil. J Petrol Explor Prod Technol 10:755–767. https://doi.org/10.1007/s13202-019-00779-2

Subramanie PAP, Padhi A, Ridzuan N, Adam F (2019) Experimental study on the effect of wax inhibitor and nanoparticles on rheology of Malaysian crude oil. J King Saud Univ Eng Sci. https://doi.org/10.1016/j.jksues.2019.05.003

Taiwo EA, Fasesan SO, Akinyemi OP (2009) Rheology of doped nigerian niger delta waxy crude oil. Petrol Sci Technol 27(13):1381–1393

Theyab MA, Yahya SY (2018) Introduction to wax deposition. Int J Petrochem Res 2(1):126–131. https://doi.org/10.18689/ijpr-1000122

Towler BF, Jaripatke O, Mokhatab S (2011) Experimental invesigation of the mitigation of paraffin wax deposition in crude oil using chemical additives. Petrol Sci Technol 29(5):468–483

Tuteja A, Choi W, McKinley GH et al (2008) Design parameters for superhydrophobicity and superoleophobicity. MRS Bull 33:752758. https://doi.org/10.1557/mrs2008.161

Wong KV, De Leon O (2010) Applications of nanofluids: current and future. Adv Mech Eng. https://doi.org/10.1155/2010/519659

Yang F, Paso K, Norrman J, Li C, Oschmann H, Sjoblom J (2015) Hydrophilic nanoparticles facilitate wax inhibition. Energy fuels 29:1368–1374. https://doi.org/10.1021/ref502392g

Zhang F, Ouyang J, Feng X, Zhang H, Xu L (2014) Paraffin deposition mechanism and paraffin inhibition technology for high carbon paraffin crude oil from the Kazakhstan PK oilfield. Petrol Sci Technol 32:488–496

Zhang L, Qu S, Wang C, Guan B (2019) Prediction temperature field and wax deposition based on heat–fluid coupling method. J Petrol Explor Prod Technol 9:639–644. https://doi.org/10.1007/s13202-018-0494-8

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Odutola, T.O., Idemili, C.A. Effect of poly (ethylene-butene) and nano-aluminium oxide blend on the viscosity of Nigerian crude oil. J Petrol Explor Prod Technol 10, 2531–2539 (2020). https://doi.org/10.1007/s13202-020-00885-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-00885-6