Abstract

Immiscible carbon dioxide (CO2) injection is one of the highly applied enhanced oil recovery (EOR) methods due to its high oil recovery potential and its ability to store CO2 in the reservoir. The main mechanism of immiscible CO2 injection is oil swelling. Generally, oil swelling is measured experimentally or measured using modeling methods. This research conducts oil swelling experiments using a simplified method in order to easily and accurately measure oil swelling and determines some of the most significant factors that may impact oil swelling during CO2 injection. The impact of varying CO2 injection pressure, temperature, oil viscosity and oil volume on oil swelling capacity was investigated. The simplified method managed to accurately determine the value of oil swelling for all the experiments. One of the factors that was found to impact the method significantly was the oil volume used. The oil volume in the experimental vessel was found to be extremely important since a large oil volume may result in a false oil swelling value. The oil swelling results were compared to other researches and showed that the method applied had an accuracy of over 90% for all the results obtained. This research introduces a simple method that can be used to measure oil swelling and applies this method to investigate some of the factors that may impact the oil swelling capacity during immiscible CO2 injection.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Carbon dioxide injection is currently one of the many applied EOR techniques due to its multiple advantages, including its ability to increase oil recovery and its potential for carbon storage in the hydrocarbon reservoirs (Fakher et al. 2017; 2018a, b; 2019a, b, c; Martin and Taber 1992; Verma 2015; Perera et al. 2016; Fakher, 2019a, b). CO2 can be either miscible or immiscible with the reservoir hydrocarbons based on the reservoir conditions and properties and the CO2 properties and injection procedure (Fakher and Imqam 2018; 2019a, b). Immiscible CO2 injection has currently gained much attention due to its ability to increase oil recovery from several types of oil reservoirs, including heavy oil reservoirs (Nourozieh et al. 2016; Fakher 2019a, b). The main mechanism by which immiscible CO2 injection can increase oil recovery is oil swelling (Fakher et al. 2018a, b; 2019a, b, c). During this interaction, the CO2 partially dissolves in the crude oil and thus results in an increase in the volume of the crude oil due to CO2 dissolution.

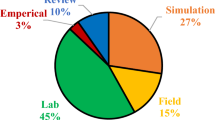

Multiple studies have conducted analytical, simulation and computer modeling to investigate CO2 injection’s impact on oil swelling. Zhang et al. (2019) underwent a numerical study to investigate the mechanism of CO2 in unconventional reservoirs. Rostami et al. (2017) utilized gene expression programming to develop a novel correlation used to determine CO2 swelling in oil as a function of oil MW, oil-specific gravity, reservoir temperature, bubble point pressure and saturation pressure. Richardson et al. (2019) and Ratnakar and Dindoruk (2020) studied the diffusivity of the gas in crude oil and its impact on oil recovery. Klins. and Ali (1982) performed a simulation study using a black oil model modified for CO2 injection to investigate the impact of immiscible CO2 injection on oil recovery. Barclay and Mishra (2016) developed novel empirical correlations for CO2 solubility in crude oil and for oil viscosity reduction due to CO2 saturation. Al-Jarba. and Al-Anazi. (2009) used a visual basic modeling technique to study the CO2–oil physical properties. Mullken, C.A. and Sandler, S.I. attempted to develop an analytical equation of state based on the Peng–Robinson equation of state to characterize the oil and CO2–oil binary interaction. Pacheco-Roman and Hejazi (2015) used a numerical method to predict the solubility and diffusivity of multiple gases in different heavy crude oils using a novel method based on delayed time and pressure decay data based on an analytical and graphical representation.

Several experiments have been conducted to study CO2 interaction with oil and its ability to increase oil recovery during immiscible CO2 injection (Tran et al. 2019; Hao et al. 2019; Alharthy et al. 2018; Mahzari. et al. 2019; Sanaei et al. 2018; Fakher and Imqam 2020, b, c, d; Hoffman and Rutledge 2019). Svrcek and Mehrotra (1982); Svrcek et al. (1989) performed experiments on extremely high molecular weight (MW) bitumen to investigate the impact of the CO2 altering the bitumen’s viscosity and density. Wang et al. (2019) introduced new wettability modifiers in an attempt to increase oil recovery from low permeability reservoirs. Holm and Josendal (1974) provided an overview of the main differences between miscible and immiscible CO2 injection. Yang and Gu (2006) developed a modified experimental setup based on the dynamic pendant drop volume analysis method to measure the solvent diffusion coefficient and oil swelling factor of a heavy oil using propane as the solvent. Pourafshary et al. (2019) investigated the impact of the water-to-CO2 ratio on the performance of CO2 EOR in sandstone cores using both core flooding experiments and reservoir simulation. Sugai et al. (2013) studied the impact of surface interfacial area, capillary pressure and grain size on oil swelling during CO2 injection. They used a modified pendant drop method setup, and an image analysis software to study the impact of these parameters. Ahmed et al. (2018) underwent an advanced screening and optimization experimental study on the use of CO2 foam for EOR application. Silva and Orr (1987) showed that as the MW of the oil increases, the CO2 solubility decreases. Bahralolom and Orr (1988) investigated the solubility of both CO2 and nitrogen in crude oil using flow visualization experiments to assess the importance of solubility and extraction on the overall oil recovery. All the methods mentioned previously have been shown to have a good accuracy; however, a simpler method that requires less timely and tedious equipment can prove to be very useful when precise equipment is lacking or when a fast and accurate value for oil swelling is needed.

Even though many researchers have conducted experiments to measure oil swelling, very little research has attempted to systematically investigate the factors that have a strong impact on oil swelling during CO2 injection and then quantify the impact of these factors. Also, most of the methods used in the literature are dependent on the observation of the volume change using specific experimental setups. This research introduces a simple method to measure oil swelling experimentally without the use of complex equipment, compared to the more complex and common place methods used in the literature. The accuracy of the method applied in this research was verified by comparing the results obtained to results obtained from several studies that were conducted on oil swelling. This research therefore introduces a simple method that can accurately measure oil swelling experimentally and investigates some of the main factors that may impact oil swelling during CO2, injection including CO2 injection pressure, temperature, crude oil viscosity and oil volume in the experimental vessel.

Background on the mechanism of oil swelling

Immiscible CO2 injection differs from miscible CO2 injection in terms of its interaction with crude oil. During immiscible CO2 injection, the CO2 will partially dissolve in the crude oil depending on the thermodynamic conditions, the oil properties and the CO2 properties. This dissolution will result in the oil volume increase or oil swelling. Even though a volume of the CO2 dissolves in the crude oil, there is still interfacial tension between the oil and the CO2 that is hindering part of the CO2 to dissolve. During miscible CO2 injection, the interfacial tension between the CO2 and the crude oil is eliminated (Norouzi et al. 2019). The CO2 will therefore completely dissolve in the crude oil regardless of either fluid’s volume. Both fluids will therefore become one single phase. The single phase will have an overall larger volume than either phase alone; however, it cannot be defined as oil swelling in the same manner as immiscible CO2 since the fluid is no longer oil phase, but a phase composed of both the oil and the CO2 together.

When CO2 is injected into the porous media bearing crude oil, the CO2 will begin to interact with the oil. Based on the thermodynamic conditions, including pressure and temperature, and the oil properties, the CO2 will begin to solubilize in the crude oil (Mullken and Sandler 1980). This solubility will result in an increase in the volume of the oil, which is referred to as oil swelling. Oil swelling can affect oil recovery significantly through many mechanisms, including mobilizing the residual oil (Hatzignatiou and Lu 1994), increasing the relative permeability of the oil by increasing the oil volume (Yang and Gu 2006) and increasing the mobility of the oil through small capillaries (Tran 2014; Du 2016). The main advantages that oil swelling will provide during oil recovery can be summarized as follows:

-

1.

Crude oil viscosity reduction When the CO2 dissolves in the oil, the volume of the oil will increase. This will result in a significant reduction in oil viscosity (Gao et al.2013). The viscosity reduction potential will increase with the increase in CO2 injection pressure and will decrease with the increase in temperature (Svrcek and Mehrotra 1982; Mohtahhari et al. 2013). A viscosity reduction of up to 90% has been reported in many cases during immiscible CO2 injection (Kang et al. 2013).

-

2.

Interfacial tension reduction immiscible CO2 injection has been shown to reduce interfacial tension (IFT) between the CO2 and water, and CO2 and oil significantly in the reservoir (Gao et al. 2013). The main IFT reduction mechanism is through CO2 solubility in the oil, especially at elevated pressures, which creates a reduction in the IFT; however, it is not reduced to zero since the CO2 is not miscible in the oil (Maneeintr et al. 2014).

-

3.

Blowdown recovery After CO2 injection is ceased and the CO2 dissolves in the oil, production is resumed. During production, the CO2 dissolved in the oil will begin to liberate, or come out of solution. This mechanism can result in an increase in oil recovery, reaching up to 18.6% in some cases (Klins and Ali 1982; Gao et al. 2013).

-

4.

Oil relative permeability improvement Since oil swelling increases the volume of the oil phase in the reservoir, the relative permeability of the oil will also increase. This can help in the mobilization of the oil and thus can improve oil recovery significantly.

-

5.

Improved oil mobility By reducing the oil viscosity in the reservoir, the mobility of the oil is improved, since the mobility can be defined as the permeability of the oil phase divided by the oil viscosity.

Experimental Description

The experimental material used to conduct the experiments, along with the experimental setup and procedure, will be explained in detail below.

Experimental material

The experimental material used to conduct all experiments is presented below.

Crude oil

Crude oil with viscosity ranging between 470 and 67 cp was used to conduct the experiments. The oil viscosity was varied by adding different weight percentages of kerosene in the crude oil. The composition of the crude oil was determined using gas chromatography–mass spectrometry and is shown in Table 1. The crude oil in the table represents the 470 cp oil with no additives.

Specially designed high-pressure high-temperature vessel

A specially designed vessel was used to conduct experiments. This vessel could withstand high-pressure and high-temperature conditions, which were required to conduct the experiments.

Water bath

A large volume water bath was used to heat up the vessels and to maintain isothermal conditions. The vessels were completely submerged in the water bath for the duration of each experiment.

High-precision pressure transducers

In order to record the pressure, a high-precision transducer was used. The transducer was connected to the setup, and to a computer to log the pressure readings. Four pressure readings were logged every second.

Thermometer

A thermometer was suspended in the water bath to record the temperature of the vessels in the water bath to ensure that the temperature was constant. The experiment was repeated if a change of 0.3 °C or more was observed at any time during each experiment.

Distilled water

Distilled water was used both as the heating medium in the water bath and to pressurize the CO2 in the accumulator before injection. The distilled water was displaced via the pump.

High-pressure gauge

A pressure gauge was located at the outlet of the accumulator to record the injection pressure of the CO2 for all experiments.

Experimental setup

An illustration of the experimental setup used to conduct all experiments is shown in Fig. 1. The setup is composed of a syringe pump used to pressurize the CO2. The CO2 is housed in the accumulator, where water is injected via the pump to pressurize it. Two high-pressure vessels are used to conduct the experiments. One of the vessels is used to heat up the CO2 to the desired temperature before commencing the experiment. The other vessel houses the crude oil used for the oil swelling experiment. Both vessels are placed in the water bath in order to heat up before beginning the experiment. Once the CO2 and the oil are heated up, the CO2 is injected in the oil-bearing vessel and the experiment is then started. The pressure transducers are used to record the pressure in the vessels during CO2 injection and during the oil swelling process. The pressure transducers record the data and digitize them on the computer via electrical cables. This differs from the pressure gauge which represents the pressure reading via an analog indicator. The pressure transducers allow for the recording of the data for further analysis after the experiments were concluded while the pressure gauge was used mainly to ensure that there was no leakage and no sudden pressure change for the duration of the experiment.

Experimental procedures

The exact procedure followed to conduct all the experiments will be mentioned in this section. Each experiment was repeated at least three times in order to ensure repeatability and accuracy. The exact procedure is mentioned below.

-

1.

Place a predefined volume of crude oil in one of the pressure vessels. Place both cells in the water bath.

-

2.

Vacuum both cells for one hour. For the vessel bearing the crude oil, a mesh screen was placed to avoid the suction of the oil.

-

3.

Pressurize the CO2 in the accumulator to the design pressure. After pressurizing, inject the CO2 into the empty pressure vessel and leave it to heat for 6 h. The CO2 was heated separately before injection into the crude oil to ensure that the temperature change was not impacting the overall experiment. The CO2 has an extremely low temperature in the cylinder, and thus, it was imperative to equate its temperature to that of the experimental vessel before beginning the pressure recording.

-

4.

Inject the CO2 in the oil-bearing vessel and record the pressure change with time until no pressure change is observed.

-

5.

Once the pressure becomes stable, the initial and final pressures are recorded, and then, the experiment is terminated.

-

6.

Perform the oil swelling calculations using the concept of change in volume due to CO2 solubility in the crude oil. The oil swelling is calculated using the pressure values, and the properties of the oil and the CO2 at the pressures and temperatures used.

-

7.

Repeat each experiment at least three times and compare the results to ensure that the method used is repeatable and accurate.

Oil swelling calculation methodology

There are many methods by which oil swelling can be calculated. Some methods rely on empirical correlations, whereas others will rely on experimental results that are then analyzed and calculated using the principles of energy and matter conservation. Based on the experimental method implemented, the appropriate equation is applied. The majority of experiments that have been conducted to measure oil swelling relied on visual tests, where the oil can be seen through a transparent sight glass or vessel. However, the method used in this research relies on pressure change, which can then be translated to a volume change using the real gas equation of state. This method is highly advantageous since it requires no tedious calculations, and it also does not need sophisticated equipment in order to run the experiments.

Oil swelling can be simply defined as the ratio of the swelled oil volume to the original oil volume. Its most basic equation, based on the aforementioned definition, therefore becomes as follows:

where So is the oil swelling in ml/ml, Vso is the volume of the swelled oil in ml and Vuo is the volume of the unswelled oil or the original oil volume in ml.

The volume of the unswelled oil is extremely easy to determine, since it is usually predefined by the researcher before conducting the experiments. The more challenging volume to determine is that of the swelled oil. This experimental method relies on the change in pressure to determine the change in volume. In order to relate both the pressure and volume together, the real gas equation of state is used, as is shown:

where P is the pressure of the CO2, V is the CO2 volume that occupies the experimental vessel, which is known by knowing the volume of the oil in the vessel and the compressibility of the CO2, z is the compressibility factor of the CO2 determined using empirical correlations or charts, n is the number of moles, R is the universal gas constant and T is the temperature of the experiment.

The equation of state mentioned above must be included twice, both during the initial conditions and during the final conditions of the experiment. Pertaining to the initial conditions, all the variables in the equation of state are known since they are defined before conducting the experiment. Once the experiment is conducted, the final pressure can be recorded, and then by equating the initial and final conditions together, the final CO2 volume can be determined. The initial and final conditions can be equated since this is a closed system with no losses, and thus by the definition of the first law of thermodynamics, energy cannot be created or destroyed. Therefore, by conservation of both energy and matter, the initial and final conditions can be equated. The equation then becomes as follows.

where 1 and 2 represent the initial and final conditions for the CO2 of the experiment, respectively.

The experiments were all conducted under isothermal conditions, and the number of moles does not change due to the system being closed. This is especially true due to the extremely low oil volume used. If the oil volume is increased, then the mole change must be accounted for in the calculations. Also, the universal gas constant is a constant and thus will not change during the experiment. Based on this, the equation can be reduced to the following:

The unknown variables in the equation are now P2 and V2. The pressure is identified using the experiment, and thus, the only missing variable is now the V2, which is the volume of CO2 after swelling. It can be identified using the following equation:

where P1 is the initial pressure before gas expansion, V1 is the initial volume of the CO2, z2 is the compressibility factor after swelling, which can be obtained from correlations or charts, P2 is the equilibrium pressure after swelling ceases and z1 is the initial compressibility factor.

The above equations are all designed to measure the change in volume of the CO2. The volume obtained from Eq. (5) can then be used to calculate oil swelling using the initial oil swelling calculation shown in Eq. (1). This is done by using the above equations and performing mathematical alterations to account for the change in the oil phase volume.

In order to calculate the oil phase volume from the above equations, the final CO2 volume is used. By knowing the original oil volume, the original CO2 volume and the final CO2 volume, the following equation can then be used to calculate the final oil volume.

where Voil(f) is the final oil volume which is the main unknown needed to calculate oil swelling, Voil(i) is the initial oil volume which is predetermined before undergoing the experiment, and V1 and V2 are the initial and final CO2 volumes one of which is known, and the other is determined using Eqs. 2–5.

Results and analysis

This section will present and explain the results obtained from all the experiments conducted. The results will include the oil swelling values at different CO2 injection pressures, including 500, 1000 and 1500 psi, temperature using 25, 40 and 60 °C, oil viscosity using 470, 267 and 67 cp and oil volume using 0.5, 1 and 2 ml.

Carbon dioxide injection pressure effect

The effect of CO2 injection pressure on oil swelling was investigated using 500, 1000 and 1500 psi CO2 injection pressures. By using all three pressures, two different phases of CO2 were investigated, including gas and supercritical CO2, respectively. The results for the oil swelling at the different CO2 injection pressures can be seen in Fig. 2. Experiments were conducted at 40 °C using 1 ml of crude oil with 470 cp viscosity. Increasing the CO2 injection pressure resulted in an increase in the oil swelling. This is due to the CO2 being forced to dissolve in the oil with larger concentrations at higher pressures. The difference between the oil swelling values, however, is not too large. Also, it was found that the overall oil swelling values are relatively low, with the zero value being 1. This is mainly due to the partial dissolution of the CO2 in the oil due to the reduction in interfacial tension at the experimental conditions. If the pressure is increased, the oil swelling is expected to increase until a specific limit where the interfacial tension will reach zero. This is the point at which the injection is no longer immiscible and the mechanism is no longer oil swelling. Rather, the CO2 will become miscible since the minimum miscibility pressure has been reached. Based on this, the oil swelling values are usually considerably low to avoid reaching miscibility, thus focusing on immiscible CO2 injection. The difference between the 1000 and 1500 psi is also observed to be lower than that between the 500 and the 1000 psi. This could be due to the closeness of the 1000 psi to the supercritical state and the 1500 psi being supercritical CO2, which will have a larger overall dissolution compared to the 500 psi gaseous CO2.

Temperature effect

Another significant parameter that was investigated was the temperature effect. The impact of varying the experimental vessel temperature on oil swelling was investigated using 25, 40 and 60 °C. The results for oil swelling at all three temperatures are presented in Fig. 3. The experiments were conducted using 1500 psi CO2 injection pressure and 1 ml of crude oil with a viscosity of 470 cp at room temperature. At the 40 and 60 °C, the CO2 was in the supercritical state, whereas at 25 °C the CO2 was not supercritical, since supercritical CO2 will form at temperatures above 31.4 °C only. As the temperature increased, the oil swelling value decreased. This is mainly due to the increase in the activity of the CO2 molecules at higher temperatures, which reduces its tendency to dissolve in the crude oil. This reduces the oil swelling potential significantly. It is therefore much more difficult for the CO2 to become miscible in crude oil at higher temperature reservoirs. It is important to note that the temperature will have an impact on the oil viscosity as well, with the increase in temperature resulting in a decrease in oil viscosity. Since the crude oil used to conduct all the temperature experiments was the same, this viscosity reduction effect was negated. The effect of varying the oil viscosity was also studied in this research and will be explained in the following section to better illustrate the significance of both the temperature and viscosity effects.

Crude oil viscosity effect

Different crude oils will interact differently with the CO2 injected. It is therefore expected that crude oils with different viscosities will swell differently in the presence of CO2. This is mainly due to the difference in interfacial tension between the CO2 and crude oil containing a high percentage of lighter components compared to an oil with a prevalence of heavy components. The crude oil viscosity’s effect on oil swelling was investigated using three different viscosity values, including 470, 267 and 67 cp. The oil swelling results for all the oil viscosity values are presented in Fig. 4. All experiments were conducted using 1500 psi CO2 injection pressure and 40 °C, using 1 ml of crude oil. Increasing the oil viscosity resulted in a reduction in the oil swelling value. This is mainly due to the lighter oil having a lower IFT with the CO2 at the same condition, which in turn allowed for a larger swelling. The lighter oil will tend to reach miscibility with the CO2 much faster than the heavier oil, and thus, the IFT between the lighter oil and the CO2 is much lower at the experimental conditions. It is important to note that the difference between the oil swelling values of the three viscosities is not very large. This is mainly because the difference in the viscosity is not very significant. Even the 470 cp oil is not considered extremely heavy oil, since some oils may reach a viscosity of more than 10,000 cp at reservoir conditions.

Crude oil volume effect

The volume of the oil in the experimental vessel can have a significant impact on the oil swelling value obtained. This is mainly due to the restriction that the experimental vessel volume may pose if the volume is too small to accommodate the volume of the fully swollen oil and, thus, may result in a lower value than the actual potential for swelling. The impact of both decreasing and increasing the oil volume in the experimental vessel was therefore investigated using 0.5, 1 and 2 ml of crude oil. The oil swelling results using different volumes of oil can be seen in Fig. 5. Experiments were conducted at 1500 psi CO2 injection pressure, and also at 40 °C, using crude oil with a viscosity of 470 cp. Decreasing the oil volume from 1 ml to 0.5 ml resulted in an increase in the oil swelling. However, this was extremely slight, which indicates that the 1 ml volume did not confine the oil in the vessel significantly and thus had very little impact on the swelling capacity of the crude oil at the experimental conditions used. Increasing the oil volume from 1 to 2 ml resulted in a noticeable decrease in the oil swelling capacity. This shows that if the volume of the crude oil is too large compared to the experimental vessel, this may result in erroneous results for the oil swelling. The oil may have much larger potential to swell than that observed in the results due to the confinement of the oil in the vessel that is housing it caused by the small volume of the vessel or the excess volume of the oil used to conduct the experiment.

Simple oil swelling method validation

The results obtained from the experiments conducted were compared to several oil swelling results obtained from more than thirty different studies that used different methods to measure oil swelling in order to test the accuracy of the results obtained using the method applied in this research. This section presents the comparison between the experimental results and the results from the literature and also shows the degree of accuracy of the results obtained from the experiments compared to those obtained from the literature.

Carbon dioxide injection pressure effect

Oil swelling is a function of many parameters, and thus different oils will swell differently depending on their properties and the thermodynamic conditions under which they were subjected. The oil swelling values obtained using the three CO2 injection pressures used in this research, including 500, 1000 and 1500 psi, were plotted with oil swelling values obtained from other research conducted in order to compare the values obtained to others. The comparison is shown in Fig. 6. After the data were plotted, it was found that the values obtained from this research agreed with only a portion of the data points. A clear distinction can be made between the data points through the appearance of a separation. The majority of the data points that appear in the upper portion are oil swelling values associated with lighter crude oils, whereas the lower data points are associated with heavier crude oils, which have a lower swelling value at the same CO2 injection pressure. Since the crude oil used to conduct the experiments has characteristics that are more closely related to heavy oils, the oil swelling values obtained followed the data points related to the heavy oil. This can be seen much more clearly when isolating the data points that are more closely related to the heavy oil, as can be seen in the plot on the right in Fig. 6. A trend line was also incorporated in order to calculate the accuracy of the experimental results in comparison with the data points obtained from the literature. This was done in order to assess the accuracy of the results obtained using the experimental method to the results obtained using other methods presented in the literature. The accuracy percentages are shown in Table 2. The values obtained from the experiments had an extremely high accuracy compared to those obtained from the literature.

Temperature effect

A change in temperature of the reservoir can result in a change in the oil swelling capacity; however, a temperature change can also result in a change in other properties of the oil, most significantly the oil viscosity. It is therefore extremely important to compare the experimental results to those found in the literature. Figure 7 compares the results obtained from the experiments to those found in the literature. The initial observation from the plot will show that the data points do not follow a clear trend compared to the CO2 injection pressure, as shown in Fig. 6. This is due to changes that occur to the crude oil properties when the temperature changes. Since different crude oils will have different characteristics, they will behave differently under different temperature conditions. The general trend for oil swelling is observed to be decreasing with the increase in temperature, as was also observed in the experiments conducted. After removing the data points that are irrelevant to the crude oil used in this research, as is shown in the plot on the right in Fig. 7, a trend line was generated to evaluate the accuracy of the result obtained. Based on the accuracy results shown in Table 3, the experimental results had high accuracy, all above 90%, compared to the results from the literature.

Crude oil viscosity effect

Altering the crude oil viscosity will result in a change in the oil swelling capacity, as was shown in the experimental results. Figure 8 plots the oil swelling results from the experiments conducted and the results from the literature. The majority of the data obtained for viscosity are for oils with viscosity less than 500 cp, although some data points are higher in value. The general trend presented shows a decrease in oil swelling as the oil viscosity increases. The experimental results follow the general trend with high accuracy. This can be observed from the plot on the right in Fig. 8 and also from the accuracy results shown in Table 4.

Conclusion

This research investigates the extent to which the crude oil will swell under different conditions and the impact of different factors on oil swelling, including CO2 injection pressure, experimental vessel temperature, crude oil viscosity and crude oil volume in the experimental vessel using a simplified oil swelling measurement technique. The main conclusions obtained from this research are as follows:

-

1.

The oil swelling values that were obtained using the simplified method applied in this research were compared to several oil swelling values obtained from the literature and were found to follow the overall trend of the data points, which indicates that the method that was used had a high level of accuracy.

-

2.

Increasing the CO2 injection pressure resulted in an increase in the oil swelling, due to a larger volume of CO2 dissolving in the crude oil at the higher pressures.

-

3.

The oil swelling increased when the CO2 was in the near-critical phase and the supercritical phase compared to the oil swelling in the gaseous phase.

-

4.

Increasing the temperature of the experimental vessel resulted in a decrease in the oil swelling capacity regardless of the phase of the CO2. This is due to the increase in the activity of the CO2 molecules at elevated temperatures, which resulted in a lower tendency of the CO2 molecules to dissolve in the crude oil.

-

5.

Reducing the oil viscosity resulted in an increase in the oil swelling at the same experimental conditions.

-

6.

The oil volume in the experimental vessel should be as low as possible to avoid having the oil confined due to the volume of the vessel, which may result in a lower oil swelling capacity.

-

7.

The novel method used in this research has been validated by comparing the results obtained from this research to those published in the literature. Based on the comparison, a high accuracy match was obtained between the results.

Abbreviations

- S o :

-

Oil swelling

- V so :

-

Volume of swelled oil

- V uo :

-

Volume of unswelled oil

- P :

-

Pressure of CO2

- V :

-

Volume occupied by the experimental vessel

- z :

-

Compressibility factor of CO2

- n :

-

Number of moles

- R:

-

Universal gas constant

- T :

-

Temperature at which the experiment is conducted

- 1:

-

Initial conditions at the beginning of the experiment

- 2:

-

Final conditions after the experiment was concluded

- IFT:

-

Interfacial tension

References

Ahmed S et al (2018) Laboratory study of CO2 foam for enhanced oil recovery: advanced screening, optimization, and evaluation. Soc Pet Eng. https://doi.org/10.2118/192351-MS

Alharthy N et al (2018) Enhanced oil recovery in liquid-rich shale reservoirs: laboratory to field. Soc Pet Eng. https://doi.org/10.2118/175034-PA

Al-Jarba M, Al-Anazi BD (2009) A comparison study of the CO2-oil physical properties literature correlation accuracy using visual basic modelling technique. NAFTA J 60(5):287–291

Al-Murayri MT, Harding TG, Maini BB (2011) Solubility of methane, nitrogen, and carbon dioxide in bitumen and water for SAGD modelling. J Can Pet Technol Soc Pet Eng. https://doi.org/10.2118/148630-PA

Bahralolom IM, Orr F (1988) Solubility and extraction in multiple contact miscible displacements: comparison of N2 and CO2 flow visualization experiments. SPE Reservoir Engineering, Society of Petroleum Engineers. https://doi.org/10.2118/15079-PA

Barclay T, Mishra S (2016) New correlations for CO2-oil solubility and viscosity reduction for light oils. J Pet Prod Technol 6(4):815–823. https://doi.org/10.1007/s13202-016-0233-y

De RA, Ruiter, Nash LJ, Singletary MS (1994) Solubility and displacement behavior of a viscous crude with CO2 and hydrocarbon gases. SPE Reserv Eng Soc Pet Eng. https://doi.org/10.2118/20523-PA

Du F (2016) An experimental study of carbon dioxide dissolution into a light crude oil. Masters Thesis, Petroleum Systems Engineering, University of Regina

Fakher SM (2019) Asphaltene stability in crude oil during carbon dioxide injection and its impact on oil recovery: a review, data analysis, and experimental study. Masters Theses 7881

Fakher S (2019a) Investigating factors that may impact the success of carbon dioxide enhanced oil recovery in shale reservoirs. Soc Pet Eng. https://doi.org/10.2118/199781-STU

Fakher S et al (2020) Hydrolyzed polyacrylamide—fly ash reinforced polymer for chemical enhanced oil recovery: Part 1—injectivity experiments. Fuel 260:116310. https://doi.org/10.1016/j.fuel.2019.116310

Fakher S, Imqam A (2018) Investigating and mitigating asphaltene precipitation and deposition in low permeability oil reservoirs during carbon dioxide flooding to increase oil recovery. Soc Pet Eng. https://doi.org/10.2118/192558-MS

Fakher S, Imqam A (2019) Asphaltene precipitation and deposition during CO2 injection in nano shale pore structure and its impact on oil recovery. Fuel J 273:1029–1039. https://doi.org/10.1016/j.fuel.2018.10.039

Fakher S, Imqam A (2020a) A review of carbon dioxide adsorption to unconventional shale rocks methodology, measurement, and calculation. SN Appl Sci 2:5. https://doi.org/10.1007/s42452-019-1810-8

Fakher S, Imqam A (2020b) A data analysis of immiscible carbon dioxide injection applications for enhanced oil recovery based on an updated database. SN Appl Sci 2:448. https://doi.org/10.1007/s42452-020-2242-1

Fakher S, Imqam A (2020c) High pressure-high temperature carbon dioxide adsorption to shale rocks using a volumetric method. Int J Greenh Gas Control 95:102998. https://doi.org/10.1016/j.ijggc.2020.102998

Fakher S, Imqam A (2020d) Application of carbon dioxide injection in shale oil reservoirs for increasing oil recovery and carbon dioxide storage. Fuel. https://doi.org/10.1016/j.fuel.2019.116944

Fakher S et al (2017) Novel mathematical models to predict preformed particle gel placement and propagation through fractures. Soc Pet Eng. https://doi.org/10.2118/187152-MS

Fakher S et al (2018a) Investigating the viscosity reduction of ultra-heavy crude oil using hydrocarbon soluble low molecular weight compounds to improve oil production and transportation. Soc Pet Eng. https://doi.org/10.2118/193677-MS

Fakher SM et al (2018) Enhancing carbon dioxide flooding sweep efficiency in high permeability hydrocarbon reservoirs using micro-particle gels. Soc Pet Eng. https://doi.org/10.2118/192381-MS

Fakher S et al (2019b) A Comprehensive Review on Gas Hydrate Reservoirs: Formation and Dissociation Thermodynamics and Rock and Fluid Properties. Int Pet Technol Conf. https://doi.org/10.2523/19373-MS

Fakher S et al (2019c) A characterization of different alkali chemical agents for alkaline flooding enhanced oil recovery operations: an experimental investigation. SN Appl Sci 1:1622. https://doi.org/10.1007/s42452-019-1662-2

Fakher S et al (2019d) An experimental investigation of asphaltene stability in heavy crude oil during carbon dioxide injection. J Pet Explor Prod Technol. https://doi.org/10.1007/s13202-019-00782-7

Gao C et al (2013) Heavy oil production by carbon dioxide injection. Greenh Gasses: Sci Technol 3(3):185–195. https://doi.org/10.1002/ghg.1346

Hao H et al (2019) Feasibility study of gas-EOR using CO2 and N2 mixture in a heavy oil reservoir. Exp Pilot Test Carb Manag Technol Conf. https://doi.org/10.7122/CMTC-552521-MS

Hatzignatiou D, Lu Y (1994) Feasibility study of CO2 immiscible displacement process in heavy oil reservoirs. Pet Soc Can. https://doi.org/10.2118/94-90

Henni A, Mather AE (1999) Solubility of CO2, N2O, CH4, and C2H6 in Polar solvents.In: Journal of Canadian Petroleum Technology, Society of Petroleum Engineers

Hoffman BT, Rutledge JM (2019) Mechanisms for Huff-n-Puff cyclic gas injection into unconventional reservoirs. Soc Pet Eng. https://doi.org/10.2118/195223-MS

Holm LW, Josendal VA (1974) Mechanisms of oil displacement by carbon dioxide. J Pet Technol 26(12):1–427. https://doi.org/10.2118/4736-PA

Klins M, Ali SM (1982) Heavy oil production by carbon dioxide injection. In: Journal of Canadian Petroleum Technology, Society of Petroleum Engineers

Mahzari P et al (2019) an improved understanding about CO2 EOR and CO2 storage in liquid-rich shale reservoirs. Soc Pet Eng. https://doi.org/10.2118/195532-MS

Maneeintr K et al (2014) Analysis of heavy oil emulsion-carbon dioxide systems on oil-swelling factor and interfacial tension by using pendant drop method for enhanced oil recovery and carbon dioxide storage. Int J Env Sci Dev 5(2):118–123

Martin FD, Taber JJ (1992) Carbon dioxide flooding. J Pet Technol 44(04):396–400

Mullken C, Sandler S (1980) The prediction of CO2 solubility and swelling factors for enhanced oil recovery development, American chemical society. Ind Eng Chem Process Des Dev 19(4):709–711

Norouzi H et al (2019) Analysis of secondary and tertiary high-pressure gas injection at different miscibility conditions: mechanistic study. Soc Pet Eng. https://doi.org/10.2118/191119-PA

Nourozieh H, Kariznovi M, Abedi J (2016) Measurement and correlation of solubility and physical properties for gas-saturated Athabasca bitumen. SPE Prod Op Soc Pet Eng. https://doi.org/10.2118/176016-PA

Pacheco-Roman FJ, Hejazi SH (2015) Estimation of solubility and diffusivity of gases in heavy oils by use of late-time pressure-decay data: an analytical/graphical approach. SPE J Soc Pet Eng. https://doi.org/10.2118/170957-PA

Perera M et al (2016) A review of CO2-enhanced oil recovery with a simulated sensitivity analysis. Energies J. https://doi.org/10.3390/en9070481

Pourafshary P et al (2019) Effect of water/CO ratio on performance of CO-based EOR in a sandstone reservoir—insights from core flood tests and simulations. Soc Pet Eng. https://doi.org/10.2118/198624-MS

Ratnakar RR, Dindoruk B (2020) Effect of GOR on gas diffusivity in reservoir-fluid systems. Soc Pet Eng. https://doi.org/10.2118/191531-PA

Richardson W et al (2019) Diffusivity of gas into Bitumen: Part II society of petroleum engineers data set and correlation. SPE J. https://doi.org/10.2118/195575-PA

Rostami A et al (2017) Modeling of CO2 solubility in crude oil during carbon dioxide enhanced oil recovery using gene expression programming. Fuel J 210:768–782

Sanaei A et al (2018) Comprehensive study of gas cycling in the Bakken shale. Unconv Resour Technol Conf. https://doi.org/10.15530/URTEC-2018-2902940

Sasaki K, et al. (2010) CO2 solubility characteristics of crude oils related to carbon capture and utilization (CCU), In: Novel Carbon Resource Sciences Newsletter

Silva MK, Orr F (1987) Effect of oil composition on minimum miscibility pressure-part 1: solubility of hydrocarbons in dense CO2. SPE Reserv Eng, Soc Pet Eng. https://doi.org/10.2118/14149-PA

Sugai Y, Babadagli T, Sasaki K (2013) Consideration of an effect of interfacial area between oil and CO2 on oil swelling. J Pet Prod Technol 4(2014):105–112. https://doi.org/10.1007/s13202-013-0085-7

Svrcek W et al. (1989) Properties of peace river bitumen saturated with field gas mixtures. J Can Pet Technol, Soc Pet Eng

Svrcek W and Mehrotra A (1982) Gas solubility, viscosity, and density measurements for Athabasca Bitumen. J Can Pet Technol, Soc Pet Eng

Tran T (2014) carbon dioxide-heavy oil systems: thermodynamics, transport and interfacial stability. Doctor of Philosophy Thesis Dissertation, Chem Eng, Missouri Univ Sci Technol

Tran S et al (2019) Studying phase behavior of oil-natural gas systems for designing gas injection operations: a Montney case study. Unconv Resour Technol Conf. https://doi.org/10.15530/AP-URTEC-2019-198201

Vali J et al (2011) A fast and simple method for modeling oil swelling in CO2 injection. Geopersia 1(2):39–46

Verma M (2015) Fundamentals of carbon dioxide enhanced oil recovery (CO2-EOR): a supporting document of the assessment methodology for hydrocarbon recovery using CO2-EOR associated with carbon sequestration United States geology survey United States department of interior

Wang M et al (2019) Novel wettability modifiers for improved oil recovery in tight oil reservoirs. Unconv Resour Technol Conf. https://doi.org/10.15530/urtec-2019-1069

Yang C, Gu Y (2006) Diffusion coefficients and oil swelling factors of carbon dioxide methane, ethane, propane, and their mixtures in heavy oil. J Fluid Ph Equilib 243(2006):64–73

Zhang F et al (2019) Numerical investigation to understand the mechanisms of CO2 EOR in unconventional liquid reservoirs. Soc Pet Eng. https://doi.org/10.2118/196019-MS

Acknowledgements

The corresponding author wishes to thank Missouri University of Science and Technology for its support through the Chancellors Distinguished Fellowship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fakher, S., Imqam, A. A simplified method for experimentally quantifying crude oil swelling during immiscible carbon dioxide injection. J Petrol Explor Prod Technol 10, 3031–3042 (2020). https://doi.org/10.1007/s13202-020-00867-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-00867-8