Abstract

Surfactant flooding could be used to improve water flooding in fractured reservoirs due to the main mechanisms of wettability alteration and interfacial tension reduction. However, the surfactant flooding in fractured reservoir is not well studied. And there still exist some disputes like surfactant injection rate, surfactant application timing and surfactant injection size. The objective of this work is to study the effects of those parameters on surfactant oil recovery. A spontaneous imbibition model is established based on spontaneous imbibition experiments to verify the properties of rock, brine, oil and surfactant that would be used in the study of surfactant flooding. The spontaneous imbibition model is cut into two parts to create a vertical fracture in the middle. Then the fractured matrix is used as the model in the study of surfactant flooding. The simulation results show that considering the time cost and surfactant consumption, the surfactant injection rate of 0.027 cm3/h (i.e., 0.001 PV/h) is a proper injection rate for the base case, since the oil recovery rate is the same for the injection rate that is higher than 0.027 cm3/h, and the oil recovery is up to 90% ultimate oil recovery after injecting 2 PV surfactant solution. The analysis of surfactant diffusion and fracture porosity effects on surfactant oil recovery indicates that the surfactant diffusion is a key parameter to facilitate the movement of surfactant into the matrix. The injection rate has larger effect in the system with smaller fracture porosity. When the injection rate is higher than 0.53 cm3/h, the ultimate oil recovery is larger in the system with fracture porosity of 0.1% than the system with fracture porosity of 0.5%. In general, the earlier injection of surfactant results in a better result. For the base case, the surfactant flooding time and the required surfactant volume are smaller for the earlier application of surfactant. If the surfactant diffusion is negligible, the early injection of surfactant could increase the ultimate oil recovery. The maximum oil recovery is obtained after injecting 1.3 PV surfactant solution with the concentration of 0.01 g/cm3. But for the lower surfactant concentration, it needs more surfactant solution. Furthermore, the surfactant efficiency is reduced because less surfactant is imbibed into the matrix. So under the condition of injection safety, higher surfactant concentration should be applied. This work not only studied the injection rate effect on oil recovery, it also analysed the effect of surfactant diffusion and fracture properties on the choice of injection rate. In addition, this work explained why the surfactant should be applied before water flooding and whether surfactant application is feasible after completed water flooding. At the end, the surfactant slug size effect on oil recovery and how it is affected by the surfactant concentration are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water flooding in fractured reservoirs with unfavourable properties, for example low permeability and mixed-wet or oil-wet wettability, usually has poor performance because of unsatisfactory water imbibition into the matrix. Surfactant is studied for improving water flooding in fractured reservoirs since it could change matrix wettability and/or reduce water/oil interfacial tension (IFT) to enhance capillary imbibition and/or reduce residual oil saturation. The wettability alteration and IFT reduction are two main mechanisms of surfactant enhanced oil recovery (EOR) which depends on the oil/brine/rock system, the surfactant type and concentration, divalent ions, salinity, temperature and others (Standnes and Austad 2000; Standnes et al. 2002; Babadagli 2002, 2003; Seethepalli et al. 2004; Xu et al. 2005; Alvarez and Schechter 2016; Golabi et al. 2012; Alvarez et al. 2014; Gao and Sharma 2013; Karnanda et al. 2013).

The spontaneous imbibition of surfactant solution on oil-wet and water-wet chalk cores (Austad et al. 1998) showed that surfactants could recover some oil from oil-wet and mixed-wet cores under tertiary spontaneous imbibition conditions, but there was no extra oil recovered from water-wet cores under tertiary spontaneous imbibition conditions. It is believed that the extra oil obtained from oil-wet and mixed-wet cores results from the wettability alteration of the cores to more water-wet during the imbibition process. When the surfactant is used at the secondary spontaneous imbibition, the displacement processes gradually changes from the countercurrent flow governed by capillary forces to the cocurrent flow governed by gravity forces. Babadagli et al. (2005) conducted surfactant flooding and capillary imbibition experiments. They got the conclusion that if surfactant solution was used for the secondary recovery, surfactant flooding did not recovery more oil than water flooding for the untouched un-fractured portions of the reservoir. For the untouched fractured zones of the chalk reservoir, starting the project with surfactant injection is more effective than waterflooding. Sweep efficiency was more important than IFT reduction. As the tertiary recovery method, different recovery trends were observed. Earlier water breakthrough was observed in some cases. Some other cases exhibited high waterflooding recovery, whereas some cases exhibited low waterflooding but high surfactant recovery. The surfactant concentration and type and thus IFT are important factors. Oil recovery from a fractured formation is a function of both capillary imbibition rate and injection rate. The surfactant flooding experiments performed by Bennetzen et al. (2014) showed that the oil could be mobilized and recovered by tertiary injection of low interfacial tension surfactants. The oil recovery was high, but it occurred at a very low rate. Yousef et al. (2010) stated that as the flow rate increased, the contact time between matrix and fluid in the fracture decreased, which reduced the effect of capillary pressure, chemical transport, diffusion, etc. In the ideally water-wet case, the capillary diffusion coefficient is on the order of about 10−8 m2/s. In the intermediate-wet case, as established after ageing with initial water, the coefficient is on the order of about 10−11 m2/s. Chabert et al. (2010) also believed that Dynamic phenomena between the fracture and the matrix played a key role in the efficiency of surfactant EOR. Kamath et al. (2001) conducted water flooding in four carbonate cores. And the results suggested to increase the pressure gradients through infill drilling or decrease the interfacial tension through low tension flooding to increase oil recovery in those carbonate reservoirs. Lu (2012) compared the results of static imbibition and surfactant flooding experiments and claimed that the transverse pressure between the fracture and the matrix was important to induce surfactant transport into the matrix.

The experimental results are varying and some conclusions are incompatible. But no study explained the reasons that lead to the inconsonant and conflicting results. Therefore, further studies are needed to explore the mechanisms of surfactant flooding in fractured reservoirs. This paper explained some of the discrepant experimental results. The authors studied and analysed the surfactant injection rate effect on oil recovery at different conditions (different surfactant diffusion efficiency and fracture properties). The surfactant application time and the surfactant diffusion effect on the choice were discussed. At the end, the authors discussed the relationship between oil recovery and surfactant slug size, and the surfactant concentration effect on the choice.

Experimental data

The experimental data of Test 31 from Standnes and Austad (2000) are used to establish the model. The core was an outcrop rock from the Stevns Klint near Copenhagen, Denmark. The oil was an acidic crude oil from the North Sea diluted with n-heptane by 40 vol. %. Cationic surfactant n-C12-N(CH3)3Br (C12TAB) was used to do the spontaneous imbibition. Assume that the surfactant has no effect on brine density, i.e., the density of surfactant solution is 1.031 g/cm3. The imbibition experiment was conducted at 70° in an Amott cell filled with 350 cm3 surfactant solution with concentration of 1 wt%. The core and fluid properties are listed in Tables 1, 2, 3 and 4.

Model establishment

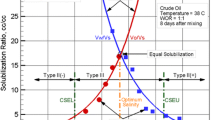

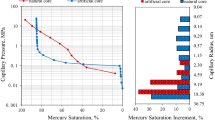

The experimental setup (Fig. 1a) is simplified to a homogeneous Cartesian model (Fig. 1b). Water/oil relative permeability can be calculated with Eq. 1 (Corey 1977), and shown in Fig. 2. The key parameters are listed in Table 5. The capillary pressure curves for the original wettability (i.e. oil-wet) and the water-wet wettability after wettability alteration by surfactant are shown in Fig. 3. The surfactant adsorption is happening after the surfactant concentration is higher than 0.001 g/cm3 in the solution. When the surfactant concentration in the solution is higher than 0.005 g/cm3, the surfactant adsorption is plateau, and the value is 0.2 mg/g (Fig. 4). Surfactant diffusion is 5 × 10−4 cm2/h which is about 1.4 × 10−11 m2/s. The water/oil IFT is decreasing with surfactant concentration, but after critical micellar concentration (CMC), the water/oil IFT keeps constant which is 0.8 mN/m (Fig. 5). The water/oil IFT at CMC is expressed with IFTCMC or σCMC. With the decrease in IFT, the capillary number is increasing and the residual oil saturation is decreasing. When the capillary number is 10−8, the residual oil saturation starts to decrease. When the capillary number is larger than 10−3, the residual oil saturation is decreased to minimum which is zero in this case. If the water/oil IFT is reduced to ultralow which results that the capillary number is larger than 10−3, the water phase and oil phase are miscible, and the relative permeability curves are like X shape (Fig. 6). The model is verified by the history matching of simulation results and experimental results (Fig. 7). The matrix is cut into two parts in the middle to create a fracture in the matrix and used as the model in the simulation study of surfactant flooding (Fig. 8). The capillary pressure of the fracture is zero. Brine/surfactant solution is injected from the horizontal injector at the bottom of the fracture, and fluids are produced from the horizontal producer at the top of the fracture. The original pressure is 270 atm which is about the same as the Ekofisk reservoir. The surfactant concentration is 0.01 g/cm3, which is the same as the concentration in the spontaneous imbibition. The main properties of the matrix and fracture in the model of fractured matrix are listed in Table 6.

The simulator ECLIPSE 2014.1 is used to do the simulation study of the effects of injection rate, injection timing and surfactant slug size on surfactant flooding in a fractured matrix. Both matrix and fracture are simulated explicitly and distinguished by the input properties. The simulation methods of wettability alteration and IFT reduction in ECLIPSE is introduced in previous paper (Cheng et al. 2018).

where \(k_{\text{rw}}\) and \(k_{\text{ro}}\) are water and oil relative permeability; \(k_{\text{rw}}^{0}\) and \(k_{\text{ro}}^{0}\) are the endpoints of water and oil relative permeability; \(S_{\text{w}}\) is water saturation; \(S_{\text{wir}}\) is the irreducible water saturation; \(S_{\text{or}}\) is the residual oil saturation; \(n_{\text{w}}\) and \(n_{\text{o}}\) are exponents of the water and oil relative permeability.

Results and analysis

Injection rate

Surfactant solution with concentration of 0.01 g/cm3 is injected into the fracture, and oil and surfactant solution are produced at the same rate as injection rate from the top of the fracture. The injection rates are listed in Table 7. The pressure drop between the injector and producer is increasing with the increase in injection rate. But because the matrix size is small, the pressure drop is only 0.727 atm even when the injection rate is 5.34 cm3/h.

Figure 9 shows all the injection rates leads to the same ultimate oil recovery which is around 80% and that the oil recovery is increasing with the increase in injection rate when the injection rate is smaller than 0.027 cm3/h (i.e., 0.001 PV/h). When the injection rate is higher than 0.027 cm3/h, the oil recovery is almost the same. After 80 days of surfactant injection, the oil recovery is about 70%. And the oil recovery rate is slower afterwards. The oil recovery reaches the plateau after 500 days of surfactant flooding. Figure 10 shows that the higher injection rate results in a lower oil recovery after injecting a certain amount of surfactant solution. Because of the small size of the matrix, most the injected fluid could be produced directly without any contribution to oil recovery when the injection rate is large. When the injection volume is 2 PV, the surfactant flooding time is about 83 days and the oil recovery is about 70% for the injection rate of 0.027 cm3/h. Figure 11 shows that the ultimate oil recovery increases slower when the injection rate is lower than 0.027 cm3/h, and the ultimate oil recovery has a power function relation with injection rate when the injection rate is higher than 0.027 cm3/h. Considering the surfactant flooding time, the injection volume, and the oil recovery, the proper injection rate for the model is 0.027 cm3/h.

Even though the pressure drop increases with the increase in injection rate, the ultimate oil recovery does not change, which implies that the pressure drop does not have significant effect on oil recovery. When the injection rate is lower than 0.027 cm3/h, the injection rate is smaller than the imbibition rate, so the oil recovery rate is decided by the injection rate. But when the injection rate is higher than 0.027 cm3/h, the injection rate is larger than the imbibition rate; thus, the oil recovery rate depends on the imbibition rate. The surfactant imbibition into matrix could be affected by the surfactant diffusion and the fracture properties. Therefore, some contrastive simulations have been done to study these parameters.

Effect of surfactant diffusion

In the base case, the surfactant diffusion is 5 × 10−4 cm2/h. In order to study the effect of surfactant diffusion on surfactant EOR, the surfactant diffusion is set to zero in the contrastive simulation. The summary of the simulation results are listed in Table 8. Figure 12 shows that the injection rate has a dramatic effect on the oil recovery when the surfactant diffusion is zero, especially after 100 days’ injection. When the surfactant diffusion is ignored, surfactant is imbibed into the matrix by capillary pressure, gravity and the pressure difference between fracture and matrix. But the capillary force is decreased with the increase in the water saturation in the matrix and in this matrix the gravity force is very small (about 0.001 atm). In addition, the surfactant concentration will be diluted by the water in matrix and the adsorption, so surfactant efficiency is reducing with the imbibition distance into the matrix. When the capillary force is decrease to zero, the surfactant imbibition will depend on the pressure difference between fracture and matrix, which is increasing with the increase in the injection rate. Therefore, when the capillary imbibition stops (about 100 days in this case), the oil recovery is varying with injection rate. Comparing the oil recovery between the base case and the contrastive case (Fig. 13), it is obvious that surfactant diffusion could significantly increase the oil recovery. One reason could be that because the matrix size is very small, surfactant could diffuse into the whole matrix in a relatively short time. Another reason is that the matrix is homogeneous, so the sweep efficiency is not improved by the pressure difference, and fluid could be easily flow through the fracture system which makes it difficult to result in a large pressure drop between injector and producer. In reality, the reservoir is very complicated, so the injection rate may lead to a high pressure difference thus improve the sweep efficiency. The large size of the matrix in reservoir could decrease the relative efficiency of surfactant diffusion.

Effect of fracture porosity

The fracture width has effect on fracture porosity, fracture permeability and drop pressure between the injector and producer. Thus, in the contrastive case, the fracture width is reduced to 0.0034 cm. The fracture porosity and absolute permeability are calculated with Eqs. 2 and 3 separately. The properties of fracture are listed in Table 9.

where \(\phi_{\text{f}}\) is fracture porosity, fraction; \(V_{f}\) is fracture volume, cm3; \(V_{\text{t}}\) is total volume, cm3; \(b\) is fracture width, cm; \(L_{\text{t}}\) is block length, cm; \(K_{\text{f}}\) is fracture absolute permeability, mD; \(C\) is unit convert coefficient, 1011.

Comparing the ultimate oil recovery in two cases, Fig. 14 tells that the ultimate oil recovery is slightly smaller (about 0.3% OOIP) for the contrastive case with 0.1% fracture porosity when the injection rate is lower than 0.53 cm3/h, but the ultimate oil recovery is larger for the contrastive case when the injection rate is higher than 0.53 cm3/h. When the injection rate is 53.4 cm3/h, the ultimate oil recovery in the contrastive case is larger than the base case by 4% OOIP. The ultimate oil recovery is about 0.796 OOIP in the base case, but it starts to increase when the injection rate is higher than 2.67 cm3/h in the contrastive case, which indicates that the increase in the injection rate is more efficient to increase the pressure difference between fracture and matrix in the system with lower fracture porosity. The pressure drop between injector and producer does not have big difference between the two cases for all the injection rates, but Fig. 15 shows that when the fracture porosity is 0.1%, the ultimate oil recovery has obvious increase with the increase in the pressure drop when the pressure drop exceeds 0.4 atm, which implies that the pressure difference between fracture and matrix cannot be obtained from the pressure drop between injector and producer.

When the injection rate is higher than 0.027 cm3/h, the oil recovery curves are almost the same for the base case. However, for the contrastive case, the final oil recovery time to obtain the ultimate oil recovery is dramatically decreasing with the increase in injection rate (Fig. 16). The final oil recovery time is about 500 days when the injection rate is 0.01 PV/h. And it is reduced to 50 and 5 days when the injection rate is increased to 5.34 and 53.4 cm3/h separately. The results reveal that the oil recovery rate is enhanced by the increase in pressure difference between fracture and matrix which results from the fracture properties and injection rate. For the base case, the required injection volume to obtain the ultimate oil recovery is increasing with the increase in injection rate, which will lead to a higher cost. But for the contrastive case, the required injection volume is the same for the injection rate of 5.34 and 53.4 cm3/h (Fig. 17). Hence, for the contrastive case, the high injection rate (53.4 cm3/h) could be a good choice considering the oil recovery rate, the final oil recovery time, and the injection volume.

When the injection rate is smaller than 0.53 cm3/h, the pressure difference between the fracture and matrix is still too weak to impetus the oil recovery. So the main parameters of surfactant oil recovery are the same for both cases, which are capillary pressure and surfactant diffusion. On the contrary, when the high injection rate is applied, the brine or surfactant solution could be high-efficiently pushed into the matrix by the pressure difference, so the fluids flow faster in the matrix, which increases the capillary number. Therefore, the ultimate oil recovery is increased. At the same time, because of the increased influence of pressure difference, the relative contribution of surfactant diffusion to the oil recovery becomes smaller.

Injection timing

In this section, the injection timing of surfactant is studied to try to find out if surfactant should be applied at the secondary or tertiary recovery stage and whether surfactant could be used at the area swept by brine. Based on the previous study, the injection rate of 0.0005 PV/h is used. There are seven scenarios of surfactant injection following the pre-water flooding with volume of 0.4, 0.9, 1.3, 1.8, 2, 4, and 11 PV, and the results are compared with the results of surfactant flooding and water flooding (Fig. 18). The ultimate oil recovery is 80% OOIP for all the scenarios, which means the surfactant is imbibed into the whole matrix. Since the capillary pressure is zero after completed water flooding, and the gravity is very small in this model, the surfactant diffusion is the key parameter that let the surfactant go into the matrix and then change the matrix wettability and reduce the IFT, thus improve the oil recovery, which is proved by the contrastive case where the surfactant diffusion is neglected. When the surfactant diffusion is neglected, the ultimate oil recovery is about 0.5 OOIP for the surfactant flooding, and it decreases with the increase in the pre-water flooding volume (Fig. 19). The surfactant enhanced oil recovery is about 1.7% OOIP after injecting 15 PV surfactant solution for the scenario with 11 PV pre-water injection, which illustrates that the surfactant with poor diffusion efficiency should not be used after water flooding.

For the base case, the oil recovery rate is becoming slower after recovering about 90% of ultimate oil recovery, which is about 0.72 OOIP (Fig. 18). Plot the total injection volume of brine and surfactant solution and the injection volume of surfactant solution when the oil recovery is 0.72 OOIP in Fig. 20. It shows that the total volume has a linear relation with the pre-water flooding volume. And the required surfactant volume also increases with the increase in pre-water flooding volume. So even if the surfactant has high-efficient diffusion, the early surfactant application could reduce the time cost and surfactant consumption.

Surfactant slug size

The surfactant assumption is an important influence factor of the economy. The goal is to achieve the largest oil recovery in a reasonable cost of surfactant. In this section, the surfactant is injected before water flooding. And the surfactant injection volume is varying from 0.2 to 4 PV. The surfactant concentration in the base case is 0.01 g/cm3. Another injection concentration of 0.005 g/cm3 is used as the contrastive case. The relationship between injection volume of surfactant solution and the ultimate oil recovery is plotted in Fig. 21. After injecting 1.3 PV surfactant solution with concentration of 0.01 g/cm3, the ultimate oil recovery (about 0.8 OOIP) is obtained. But the ultimate oil recovery is about 0.5 OOIP for the contrastive case with surfactant concentration of 0.005 g/cm3. Besides, it requires much more surfactant solution to obtain the maximum oil recovery. The critical micelle concentration of the surfactant (C12TAB) is about 0.004 g/cm3 and required concentration to change the wettability to strongly water wet is no less than 0.005 g/cm3. When the surfactant is moving into the matrix, the concentration is diluted and becomes smaller and smaller with the distance into the matrix. For the small concentration, the dilution has a large negative effect on the surfactant efficiency. Therefore, the lower concentration results in a smaller oil recovery with the same surfactant slug size. The relationship between the injection mass of surfactant and the ultimate oil recovery (Fig. 22) shows that even injecting the same amount of surfactant, the ultimate oil recovery is smaller in the case with a lower surfactant concentration, which implies that the surfactant efficiency is decreasing with the decrease in surfactant concentration. The relationship between surfactant mass in matrix and the ultimate oil recovery are similar for both cases, and the ultimate oil recovery has a strong positive linear function relation with the surfactant mass in matrix (Fig. 23), which means the ultimate oil recovery depends on how much the surfactant goes into the matrix. This also implies that less surfactant can be imbibed into the matrix for the lower surfactant concentration; hence, the surfactant efficiency is reduced. Based on the previous analysis, it can be concluded that it needs less surfactant to obtain the maximum oil recovery with the application of higher surfactant concentration, so under the condition of injection safety, the relatively higher surfactant concentration is a better choice.

Summary and conclusions

A model is established by history matching with the experimental results given by Standnes and Austad (2000), so that the properties of matrix, brine, oil and surfactant are verified. Then the model is cut into two parts from the middle to create a vertical fracture. The fractured model is used to do the simulation study in this paper. The injection rate, injection timing and injection surfactant size are studied. The following are the main conclusions.

- 1.

In the base case, the oil recovery rate is increasing with the increase in injection rate until the injection rate is 0.027 cm3/h (i.e., 0.001 PV/h). After injection of 1 PV surfactant solution, the oil recovery is 70% OOIP which is about 90% of ultimate oil recovery when the injection rate is 0.027 cm3/h. Considering the time and surfactant consumption, the injection rate of 0.027 cm3/h is the proper injection rate.

- 2.

Comparing with the base case where the surfactant diffusion is 5 × 10−4 cm2/h, the oil recovery is dramatically decreased in the contrastive case where the surfactant diffusion is set to zero. In addition, the injection rate has a larger effect on the oil recovery when the surfactant diffusion is very slow.

- 3.

The increase in the injection rate is more efficient to the system with smaller fracture porosity (0.1%) since the injection rate could increase the pressure difference between fracture and matrix, which results in an increase in oil recovery rate thus increase in the capillary number. So the ultimate oil recovery is improved when the injection rate is higher than 0.53 cm3/h.

- 4.

For the system with fracture porosity of 0.1%, when the injection rate is higher than 0.53 cm3/h, the required injection volume to obtain the ultimate oil recovery does not increase; at the same time, the final oil recovery time decreases. Therefore, the high injection rate (53.4 cm3/h) is a good choice.

- 5.

Surfactant should be used before water flooding because the required injection volume of surfactant to obtain the ultimate oil recovery is increasing with the increase in pre-water flooding volume. The surfactant-enhanced oil recovery is only 1.7% OOIP when the surfactant without diffusion function is applied after the completed water flooding.

- 6.

The maximum oil recovery is obtained after injecting 1.3 PV surfactant solution with the concentration of 0.01 g/cm3. But for the solution with a concentration of 0.005 g/cm3, the oil recovery rate is much less and it required much more surfactant solution to achieve the maximum oil recovery. The results also indicate that surfactant solution with lower concentration has a lower efficiency because less surfactant could be imbibed into the matrix.

Abbreviations

- b :

-

Fracture width, cm

- k :

-

Absolute permeability, mD

- K f :

-

Fracture absolute permeability, mD

- k ri :

-

Relative permeability of phase i, i = o, w

- L t :

-

Block length, cm

- Δm :

-

Surfactant mass in matrix, g

- N c :

-

Capillary number

- n :

-

Exponent

- q :

-

Injection rate, PV/h or cm3/h

- R of :

-

Ultimate oil recovery, fraction

- S w :

-

Water saturation

- S wi :

-

Initial water saturation, fraction or %

- S wir :

-

Irreducible water saturation, fraction or %

- S or :

-

Residual oil saturation, fraction or %

- V f :

-

Fracture volume, cm3

- V s :

-

Injection volume of surfactant solution, PV

- V t :

-

Total volume, PV or cm3

- V w :

-

Pre-water flooding volume, PV or cm3

- ϕ :

-

Matrix porosity, fraction or %

- ϕ f :

-

Fracture porosity, fraction or %

- 0:

-

Endpoints

References

Alvarez JO, Schechter DS (2016) Altering wettability in bakken shale by surfactant additives and potential of improving oil recovery during injection of completion fluids. In: Presented at the SPE improved oil recovery conference, Tulsa, Oklahoma, 11–13 April, 2016

Alvarez JO, Neog A, Jais A, Schechter DS (2014) Impact of surfactants for wettability alteration in stimulation fluids and the potential for surfactant EOR in unconventional liquid reservoirs. In: Presented at the SPE unconventional resources conference, Woodlands, Texas, 1–3 April, 2014

Austad T, Matre B, Milter J, Saevareid A, Øyno L (1998) Chemical flooding of oil reservoirs 8. Spontaneous oil expulsion from oil-and water-wet low permeable chalk material by imbibition of aqueous surfactant solutions. Colloids Surf, A 137(1):117–129

Babadagli T (2002) Dynamics of capillary imbibition when surfactant, polymer, and hot water are used as aqueous phase for oil recovery. J Colloid Interface Sci 246(1):203–213

Babadagli T (2003) Evaluation of EOR methods for heavy-oil recovery in naturally fractured reservoirs. J Petrol Sci Eng 37(1–2):25–37

Babadagli T, Al-Bemani A, Boukadi F, Al-Maamari R (2005) A laboratory feasibility study of dilute surfactant injection for the Yibal field, Oman. J Petrol Sci Eng 48(1):37–52

Bennetzen MV, Mogensen K, Frank S, Mohanty K (2014) Dilute surfactant flooding studies in a low-permeability oil-wet middle east carbonate. In: Presented at the international petroleum technology conference, Doha, Qatar, 19–22 January, 2014

Chabert M, Morvan M, Tabary R (2010) Fractured carbonates: a methodology to evaluate surfactant performances. In: Presented at the SPE improved oil recovery symposium, Tulsa, Oklahoma, 24–28 April, 2010

Cheng X, Kleppe J, Torsæter O (2018) Simulation study of surfactant imbibition mechanisms in naturally fractured reservoirs. In: Presented at SPE Norway one day seminar, Bergen. https://doi.org/10.2118/191309-MS

Corey AT (1977) Mechanics of heterogeneous fluids in porous media. Water Resources Publications, Fort Collins, Colorado, p 259

Gao B, Sharma MM (2013) A new family of anionic surfactants for enhanced-oil-recovery applications. SPE J 18(05):829–840

Golabi E, Seyedeyn F, Ayatollahi AS, Hosseini N, Akhlaghi N (2012) Experimental study of wettability alteration of limestone rock from oil wet to water wet by applying various surfactants. In: Presented at the SPE heavy oil conference Canada, Calgary, Alberta, 12–14 June, 2012

Hjuler ML, Fabricius IL (2009) Engineering properties of chalk related to diagenetic variations of Upper Cretaceous onshore and offshore chalk in the North Sea area. J Petrol Sci Eng 68(3):151–170

Kamath J, Meyer RF, Nakagawa FM (2001) Understanding waterflood residual oil saturation of four carbonate rock types. In: Presented at the SPE annual technical conference and exhibition, New Orleans, Louisiana, 30 September–3 October, 2001. https://doi.org/10.2118/71505-MS

Karnanda W, Benzagouta M, AlQuraishi A, Amro M (2013) Effect of temperature, pressure, salinity, and surfactant concentration on IFT for surfactant flooding optimization. Arab J Geosci 6(9):3535–3544

Lu J et al (2012) Surfactant enhanced oil recovery from naturally fractured reservoirs. In: Presented at the SPE annual technical conference and exhibition, San Antonio, Texas, 8–10 October, 2012

Reichenbach-Klinke R, Langlotz B, Wenzke B, Spindler C, Brodt G (2011) Hydrophobic associative copolymer with favorable properties for the application in polymer flooding. In: Presented at the SPE international symposium on oilfield chemistry, The Woodlands, Texas, USA, 11–13 April, 2011. https://doi.org/10.2118/141107-MS

Seethepalli A, Adibhatla B, Mohanty K (2004) Wettability alteration during surfactant flooding of carbonate reservoirs. In: Presented at the SPE/DOE fourteenth symposium on improved oil recovery, Tulsa, Oklahoma, 17–21 April, 2004

Standnes DC, Austad T (2000) Wettability alteration in chalk: 2. Mechanism for wettability alteration from oil-wet to water-wet using surfactants. J Petrol Sci Eng 28(3):123–143

Standnes DC, Nogaret LA, Chen H-L, Austad T (2002) An evaluation of spontaneous imbibition of water into oil-wet carbonate reservoir cores using a nonionic and a cationic surfactant. Energy Fuels 16(6):1557–1564

Xu W, Ayirala SC, Rao DN (2005) Measurement of surfactant-induced interfacial interactions at reservoir conditions. In: Presented at the SPE annual technical conference and exhibition, Dallas, Texas, 9–12 October, 2005

Yousef AA, Gary AP, Mojdeh D (2010) Mechanistic modeling of chemical transport in naturally fractured oil reservoirs. In: Presented at the SPE improved oil recovery symposium, Tulsa, Oklahoma, 24–28 April, 2010

Funding

Funding was provided by Norges Teknisk-Naturvitenskapelige Universitet (Grant No. 81770702).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Cheng, X., Kleppe, J. & Torsæter, O. Simulation study of surfactant injection in a fractured core. J Petrol Explor Prod Technol 9, 3079–3090 (2019). https://doi.org/10.1007/s13202-019-0705-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-0705-y