Abstract

Due to the increasing demand and the price of hydrocarbon fuels, today, cost-effective enhanced recovery of oil and gas reservoirs has become one of the most interesting research topics. Since the Iranian reservoirs have a considerable potential to apply the chemical EOR processes, it seems that extensive research in this field is inevitable. One of the most important enhanced oil recovery techniques is injecting alkaline–surfactant into the reservoir. Although injecting alkaline–surfactant has been investigated in many researches, few studies reported on the effect of this process on the oil/water relative permeabilities which control the recovery performance. Today, the need for EOR processes is critical. One of the newest ideas for this respect is the concept of altering the rock wettability to more water wet. This phenomenon leads to making a path for oil in the larger routes, therefore increasing the recovery. In most cases, waterflooding has a low effect and by increasing the water production, the oil recovery becomes non-economical. In most studies, the effect of solution injection has been considered. In this study, we have investigated the effect of chemicals on interfacial tension and the wettability alteration based on relative permeability curves. In this work, using three surfactants, anionic (SDS), cationic (CTAB) and nonionic (Triton X-100), with sodium carbonate alkaline, relative permeabilities, wettability, IFT and the recovery efficiency in the porous media in the core scale have been investigated. The results show that cationic surfactant has the most effect on reduction in IFT and changing the wettability to water wetness, which has 70% recovery factor. Anionic surfactant has a greater effect on the reduction in interfacial tension in comparison with nonionic surfactant. Furthermore, nonionic surfactant has the most effect on changing the wettability to water wetness in comparison with anionic surfactant. Moreover, the recovery enhancement in the case of injection of alkaline–nonionic surfactant (67%) is more considerable than alkaline–anionic (65%).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to the high cost of surfactant, using alkaline with surfactant in chemical injection to improve the efficiency of the process is taken into consideration (Mozaffari et al. 2017a; Hosseini et al. 2019). Alkaline reacts with the acid composition of the oil and produces surfactant that increases oil recovery by reducing interfacial tension between the injected fluid and oil, altering wettability of porous medium and forming emulsion spontaneously which releases the oil from the pores (Zolfagharloo et al. 2018; Darjani et al. 2017). Relative permeability curves have an important role in the performance of the reservoirs and also one of the most important input data for the simulation of oil reservoirs (Mozaffari et al. 2015; Hosseini 2019; Liu et al. 2017). The effect of alkaline–surfactant solution on relative permeability and the increment of recovery have been less studied by the authors (Mozaffari et al. 2017b). Li et al. (2004) studied surfactant adsorption on reservoir rock and its effect on surfactant injection process for enhanced oil recovery in. They used chemicals that reduce the surfactant adsorption and cause desorption of adsorbed material on reservoir rock. Their laboratory results showed that existence of NaOH and chemicals that cause surfactant desorption, decrease the interfacial tension between oil and water significantly. They injected these materials in four different cores to understand desorption process and its effect on oil production better. The results showed that oil recovery can increase 13% more than before using surfactant–alkaline injection by adding chemicals which cause desorption of the materials (Li et al. 2004). Han et al. (2006) by experimental results showed that core wettability influences the efficiency of oil displacement in water injection. They simulated the experimental results and compared them with the modeling results and showed that the optimum wettability in water injection is neutral state. They studied this important effect on chemical injection and observed in water wet state increment in recovery of original oil in place is 28.6%, in neutral state it is 15.2%, and in oil wet state it is 16.7%. These results indicate that the reservoir rock wettability plays an important role in increment in complex chemical injection and water wet state has the highest percentage of recovery in three different wettability. They showed that wettability has no significant effect in the polymer injection and oil displacement (Han et al. 2006). Hunkey et al. (2010) implemented experiment on heavy oil by thirty different kinds of surfactants and alkaline. The results showed that by injecting alkaline–surfactant solution, the surface tension decreases and an emulsion between oil and water is processed and causes oil production without using thermal methods (Hunkey et al. 2010). Pei et al. (2012) studied injecting alkaline alone and injecting alkaline–surfactant simultaneously for heavy oil field. They found that tertiary oil recovery in injecting alkaline solution 4/0 wt% is equal to 21% of the original oil in place while adding surfactant to alkaline will increase oil recovery to 32%. They also found that adding surfactants to alkaline solution reduces surface tension that has an important role in the mechanism of enhanced oil recovery (Pei et al. 2012). Experimental investigation of EOR using low salinity water and nanoparticles in one of southern oil fields in Iran was conducted by Hosseini et al. (2018). They concluded that silica hydrophilic nanoparticle suspension has the ability to reduce contact angle between oil phase and water phase (altering the solid surface to water wet) when nanofluid concentration increases. Souraki et al. (2019) investigated the wettability alteration of carbonate reservoir rock using amphoteric and cationic surfactants. The results of their experiments showed that the CTAB surfactant is more effective than HABSA surfactant to improve oil recovery from carbonate reservoirs. In another study, experimental investigation of ionic content effect on wettability alteration in smart water for enhanced oil recovery was done by Baradari et al. (2019). Their results demonstrate that increasing sulfate concentrations in smart brine causes a dominant alteration on wettability of dolomite rock. In a similar study, Hosseini (2019) investigated the effect of asphaltene deposition on oil relative permeability, rock wettability alteration and recovery in WAG process. He concluded that asphaltene deposition caused a noticeable increase in differential pressure across the core, so the differential pressure in “water break through” was increased 1.45 times in water injection and 1.92 times in WAG process. Use of nonionic surfactant almost prevented the increase in differential pressure in both methods. In this study, the effect of alkaline–surfactant on the wettability and relative permeability and its effect on increasing oil recovery are studied. In this case, the process of injecting alkaline–surfactant as a secondary recovery and tertiary recovery after water injection is investigated. Also, effect of three types of surfactants, anionic, cationic and nonionic, on oil recovery is studied.

Material

Crude oil phase

The oil used in this study is a dead oil sample which was obtained from one of Iranian south oil reservoirs. The oil has a viscosity of 3.31 cP and a density of 0.82 g/cc.

Aqueous phase

Distilled water and different solutions of water with 10,000, 30,000 and 50,000 ppm NaCl salt concentration were prepared. Then, in each series of aqueous solutions, the most concentrated solution was diluted to prepare different concentrations of the surfactant in solution. By these solutions, pH, density, IFT, wettability and core flood were measured.

Surfactants

The anionic surfactant used in this study is sodium dodecyl benzene sulfonate (SDS) (CH3C11H22C6H5OSO3Na) with molecular weight equal to 288.36 g/mol. The purity of this surfactant is more than 98%. Cationic surfactant that has been used in this study is dodecyl trimethyl ammonium bromide (C12TAB) (C12N(CH3)3Br), with molecular weight equal to 364.45 g/mol and purity more than 99%. A nonionic surfactant, Triton X-100 (C14H22O(C2H4O)10) with molecular weight equal to 646.85 g/mol and purity more than 99%, is also used. These surfactants were purchased from DAE JUNG Chemicals Company. Chemical structure of the surfactants is shown in Fig. 1.

Alkaline

The alkaline used in this study is sodium carbonate (Na2CO3). Sodium carbonate was purchased from Merck Company. Chemical structure of sodium carbonate is shown in Fig. 1.

Core sample

Core sample used for flooding tests was carbonate. Core sample is obtained from one of Iranian south oil reservoirs and cut to the little core samples in laboratory. Table 1 shows the dimensions of plugs used in this work.

Rock properties measurements

Before measuring porosity and permeability, plug samples must be cleaned of residual fluids and dried. Core samples were obtained from one of the Iranian carbonate reservoirs. A Soxhlet extraction method was used for cleaning of plug samples. A complete extraction took 8 days because of the low-permeability carbonate plug samples. After cleaning, the plug samples were put in an oven at a temperature of 140 °C for 24 h. In this work, for porosity measurement, the helium porosimeter was used to determine the porosity of the plug samples. This method employs Boyle’s law. Figure 2a depicts a schematic of helium porosimeter. Porosity properties of plug samples are provided in Table 2. Two jointed plugs were used as a core sample in permeability measurement experiment and waterflooding tests. After placing the core sample in the core holder, the overburden pressure was provided by water. Then, it was vacuumed by using a pump for 7 h. After that, the core sample was saturated with gas oil, and finally, permeability was measured by passing gas oil as a fluid with known viscosity (1.7 cP) through the core sample of measured dimensions. A schematic of permeability measurement apparatus is shown in Fig. 2b. Under different injection rates of gas oil, pressure drops across the core sample in the core holder were recorded. Then, a line through Δp versus q data was plotted, and finally, the absolute permeability of the core sample was calculated. Figure 3 shows the Δp versus q data and a line passes through these data. In this work, the unsteady-state technique was used to determine the relative permeability curves. Also, Jones and Roszelle graphical method was used to calculate relative permeability of oil and water based on production data (“Appendix” section). Permeability of the core sample was calculated which was 0.4 md.

Fluids properties measurements

In this work, density of oil and brine for interfacial tension measurement was measured with DMA-45 of Anton Paar Company. For work in the range of 5–80 °C at ambient pressure, usually air and distilled water are used. Air and distilled water were used as standard substances for adjustment in these experiments. Results of the fluid density measurement are shown in Table 3. Then, for viscosity measurement, Cannon–Fenske viscometer is used. Table 4 summarizes results of the viscosity measurement of oil and water.

IFT measurement

In this study, in order to measure alkaline–surfactant solutions/oil interfacial tension values, spinning drop apparatus is used and for measuring surfactant solutions/oil and water/oil interfacial tension, pendant drop apparatus is used. All IFT tests were performed in ambient temperature and atmosphere pressure. In this project, oil/water interfacial tensions were determined at atmosphere pressure and ambient temperature. Two ISCO pumps were used in these experiments: one for injection of water into the chamber and another one for oil injection through capillary tube by constant flow rate. One pump was connected to the water cell and another to the oil cell. Water or surfactant solution was pumped into the IFT cell to full level. The spinning drop apparatus has been used in this study for measuring interfacial tension that is manufactured by Fars Enhanced Oil Recovery Technology Company. This apparatus is designed for measuring ultra-low interfacial tension with an acceptable accuracy. In this apparatus, a droplet of one fluid is injected into a capillary tube containing another fluid immiscible with it.

Relative permeability measurement and flooding experiment

Equipment

The equipment used in the work includes: ISCO pump, oil vessel, injected vessel, distillated vessel, back pressure regulator, core holder, valves, connections, collectors and gauge pressure. Flooding experiments were performed at room temperature of 30 °C and atmospheric pressure on cylindrical carbonate core sample, 38.94 mm in diameter and 86.52 mm in length.

Flooding tests

The schematic of experimental apparatus is depicted in Fig. 3. After preparing and cleaning the core sample, it was placed in the rubber sleeve and put in the core holder. This sleeve was used as a connection in exert of overburden pressure, on the rock. In these experiments, the overburden pressure was provided by water (4200 psi). After placing the core sample in the core holder, it was vacuumed by using a pump for 7 h and then to measure the pore volume, water is injected into core holder under constant pressure of 500 psi. In this step, valves 1 and 3 should be opened while others were closed. When pressure reached 500 psi, valve 5 was opened. After that, the pump injects water until the injection rate becomes zero. According to volume of injected water, pore volume of the core sample was calculated. To reach Swi, injection of oil was initiated. In this step, valves 1 and 3 were closed while others were opened. The injection of oil was continued until no water was detected at the outlet. By recording the overall volume of output water and knowing the volume of initial water in the core sample, Swi was determined. After these steps, the process of waterflooding initiated. According to Rapoport and Leas criterion of stabilization (Lutμw ≥ 1) and by substitution length of the core sample and viscosity of injected water in this criterion, it was considered that the injection rate should be 0.15 cc/min. For water injection under constant injection rate, valves 2 and 4 were closed and other valves kept open. In each set of experiment with constant injection rate, pressure and the amount of produced water and oil in collectors were recorded with respect to the volume of injected water. In each waterflooding tests, the experiments are finished when there is no oil production at the outlet. After closing valves 1 and 3, solution of injected solution vessel was changed to the selective AS solution and experiment should be continued until that there is no oil production at the outlet. Secondary AS flooding was done as well as water flooding. After completion of the experiment for selective alkaline–surfactant, the core sample was cleaned with toluene (using Soxhlet method) and should be dried at the temperature of 140 °C for 24 h in an oven. After that, the core sample was used for alkaline solutions with different surfactants again.

Results and discussion

Interfacial tension of alkaline surfactant systems

One of the main mechanisms in alkaline–surfactant injection process is reducing interfacial tension. In order to achieve the lowest IFT, optimal concentration of alkaline–surfactant solution should be determined. So interfacial tension experiments have been performed with a spinning drop apparatus and the results are shown in Fig. 4, where IFT is plotted as a function of alkaline concentration to determine optimal concentration. In IFT experiments, the surfactant concentration is kept constant because of its high price and the concentration of the alkaline is changed during the process. In the solution that contains CTAB, the lowest IFT is achieved at the concentration of 0.8 wt% of Na2CO3. When SDS is used as a surfactant, concentration of 0.6 wt% of Na2CO3 gives the lowest IFT, and when the Triton X-100 is used as a surfactant, concentration of 0.4 wt% of Na2CO3 gives the lowest IFT. Alkaline reacts with acidic components in crude oil and generates in situ surfactant that helps the main surfactant to reduce interfacial tension between water and oil (Green and Willhite 1998; Hosseini and Tahmasebi 2019). The bonds between water molecules and the hydrophilic head of surfactant and the bonds between oil and the lipophilic head of surfactant molecules are stronger than the bonds between oil and water molecules, and this fact causes significant reduction in IFT.

Relative permeability

To obtain relative permeability values, the method of Jones and Roszelle is used. First, a plot of λ−1ave versus PV is performed, and then, the equation between λ−1ave and PV is obtained by curve fitting and by derivative of this equation, the slope of the tangent at any point is obtained. As a result, at any point a line can be obtained that the intercept is equal to λ−12. Figure 5a shows graph of λ−1ave versus PV for water injection process, and Fig. 5b shows these graphs for AS injection. Relative permeability curves for water and alkaline–surfactant solutions are plotted in Figs. 6, 7 and 8. By comparing relative permeability curves of water and alkaline–surfactant solutions, a general upward movement in relative permeability curve is observed due to improvement in effective permeability of water and oil. Upward movement in oil relative permeability curves is due to changing rock wettability to a higher degree of water wetness. Oil relative permeability curve in alkaline solution and CTAB shows greater upward movement than other solutions. Surface of carbonate rock has positive charge, and alkaline reacts with the rock and changes the charge of the rock to the negative. Due to negative charge of surface of the rock and negative head of anionic surfactant, rock does not adsorb the anionic surfactant because of repulsion. But cationic surfactant like CTAB with positive head has adsorbed rock extremely, and it is the reason of wettability alteration of CTAB as cationic surfactant. Upward movement in water relative permeability curve is due to reduction in IFT between oil and water that allows water to move easier than oil. Increasing effective permeability of water will increase water injection rate and thus increase recovery rate. Figure 9 shows that water relative permeability values using SDS are higher than the others; it is obtained that when recovery rate is more important than total recovery, alkaline–surfactant SDS solution is best choice for injection.

Wettability determination

In this study, a qualitative method is used for determination of wettability. In other words, for qualitative evaluation of wettability, relative permeability curves are used for AS solutions with different surfactants. Forrest and Craig (1971) have presented a set of rules for classification of wettability based on relative permeability parameters obtained from the chart. These parameters are:

Interstitial water saturation

Saturation at which oil and water relative permeabilities are equal

Relative permeability of water at the maximum water saturation

Craig’s Rule of thumb that is used for determining strongly water-wet and strongly oil-wet reservoirs is summarized in Table 5. According to the rule of thumb specified by Craig, the results of the experiments conducted in this study for determining wettability of the samples are shown in Table 6. The results show that core samples were initially water wet and by alkaline–surfactant flooding, were more water wet. Solution that contains CTAB surfactant has greatest effect on wettability alteration through these solutions, and SDS effect is not dominant, so solution containing CTAB is the best choice for wettability alteration.

Performance of core flood experiments

In order to investigate effect of chemical injection on oil recovery, several injections experiments have been performed. Initially, the water was injected to core as secondary oil recovery, and then, alkaline–surfactant with optimal concentrations was injected as tertiary oil recovery. Also alkaline–surfactant was injected as secondary oil recovery.

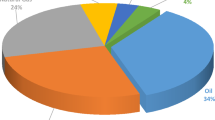

Water and alkaline–surfactant injecting to core

Figure 10 shows the oil recovery and pressure for water and alkaline–surfactant CTAB injection process. Oil recovery of water injection is about 59%, and for AS injection, it has improved to 70%. This improvement is due to IFT reduction between water and oil trapped after water injection. Wettability alteration to water wetness can also help increasing recovery because water occupies small pores and sweeps the oil to the larger pores. As it is demonstrated in Fig. 10, using AS causes 11% increase in recovery. Also by checking pressure profile, there is an increase in pressure with AS injection, which is due to formation of a massive bulk of oil. Figure 11 also shows the oil recovery and pressure for water and alkaline–surfactant TX-100 injection process. Oil recovery of water injection is about 59%, and for AS injection, it has improved to 67%. Increasing pressure with AS injection is due to formation of a massive bulk of oil. Figure 12 also shows the oil recovery and pressure, for water and alkaline–surfactant SDS injection process. According to the curve, oil recovery of water injection is about 59%, and then, for AS injection, oil recovery has improved to 65%. Figure 13 shows that in comparison with alkaline solutions with different surfactants used at tertiary EOR process, the maximum recovery was achieved by CTAB (70%), and then by TX-100 (67%) and SDS (65%), respectively.

Alkaline–surfactant injection as secondary recovery

Comparison between IFT of solutions containing SDS and TX-100 shows that IFT value is lower for the solution containing SDS than TX-100. However, comparison between the wettability alteration to water wet and the viscosity of solutions containing SDS and TX-100 shows that the amount of wettability alteration is slightly more for solution containing TX-100. The results shown in Fig. 14 display that recovery of alkaline–surfactant TX-100 is higher than recovery of alkaline–surfactant SDS. It can be concluded that the effect of the wettability altering to water wetness effect is greater than IFT effect on the recovery. Solution containing CTAB has a small value of IFT and has the greatest change in wettability to water wetness in comparison with other solutions, so it is expected that this solution has more recovery than others and this expectation is proved by experiments.

Fractional flow

The experimental relative permeability ratio of oil and water (kro/krw) versus Sw2 for alkaline solution and three different surfactants is demonstrated in Figs. 15, 16 and 17. It can be observed from these figures that relative permeability ratio curves exhibit an exponential relationship with water saturation. By using the curve fitting, relationship between relative permeability ratio and saturation was achieved. These functions are used in fractional flow equation instead of relative permeability ratio in Eq. (1):

Shifting fractional flow curve from left to the right shows that wettability is altered to water wet. kro/krw versus Sw2 at three different injection rates is plotted in Fig. 18. This figure shows that solution containing CTAB has more values of kro/krw than other solutions for the same Sw2 because the core was more water wet in the presence of alkaline–surfactant CTAB and this fact improves our last discussion about wettability alteration. Experimental values of fw and its values from Eq. (1) for alkaline and different surfactants are shown in Figs. 19, 20 and 21. Fitting empirical functions in Figs. 15, 16 and 17 can be used instead of kro/krw, in Eq. (1). In these figures, tangents have been drawn to fw curve from Swi intersecting the fw curve at (Swf, fwf). Intersect points for alkaline and three different surfactants are presented in Table 7. Difference between values of Swf for alkaline and three different surfactants is due to different values of Swi. The number of PVs needed to reach breakthrough (Qibt) is given by Eq. (2):

Qibt for alkaline and three different surfactants is shown in Table 7. Figure 19 shows that fractional flow curve of alkaline–surfactant CTAB is shifted to the right due to changing wettability to more water wet. Core with stronger water wetness has more Swi and less Sor that change the initial and final point of the curve, which causes fractional flow curve to shift to the right. Figure 20 shows a little shift to the right due to same above-mentioned reason. As it is demonstrated in Fig. 21, there is no significant shift in fractional flow curve, which could be the result of little change in wettability. Reduction in IFT makes fractional flow curves more smoother. Then, by plotting fractional flow versus saturation, average saturation behind the front can be obtained. More average saturation shows less residual oil remained in the core and more oil is replaced by the solution. The value of the average saturation behind the front for SDS alkaline surfactant is equal to 0.806, TX-100 alkaline surfactant is equal to 0.814 and for CTAB AS solution is equal to 0.845. These values indicate that using CTAB AS leads to highest recovery and using SDS AS leads to lowest recovery.

Conclusions

Based on the experimental results discussed in this study, the following results are concluded:

Increasing the alkaline concentration in the presence of surfactant causes a decrease in IFT toward a minimum.

Comparing the performance of surfactants used in this study, the maximum reduction in IFT was performed by CTAB, and then by SDS and TX-100, respectively.

CTAB has a wide range of ultra-low IFT. As we know some amount of alkaline is adsorbed to the rock so we must inject an over concentrated solution which CTAB is suitable for this purpose.

Comparing the performance of surfactants used in this study, the maximum wettability alteration toward water wet was performed by CTAB, and then by TX-100 and SDS, respectively.

Wettability alteration has more effect on ultimate recovery in comparison with IFT reduction according to ultimate recovery curves.

Whenever the limiting parameter is production rate, SDS is a better choice because it has a more krw increment in comparison with other.

Finally, comparing the performance of alkaline–surfactant flooding achieved in this project, the maximum ultimate recovery was obtained by CTAB, and then by TX-100 and SDS, respectively.

Abbreviations

- f o :

-

Oil fractional flow

- f w :

-

Water fractional flow

- f w2 :

-

Terminal water fractional flow

- k o :

-

Effective permeability of oil (D)

- k w :

-

Effective permeability of water (D)

- k ro :

-

Relative permeability of oil

- k rw :

-

Relative permeability of water

- Q i :

-

Number of pore volume

- q i :

-

Injection rate (cc/min, cc/s)

- q o :

-

Oil flow rate

- q w :

-

Water flow rate

- S oi :

-

Initial oil saturation

- S or :

-

Residual oil saturation

- \(\overline{{S_{\rm w}}}\) :

-

Average water saturation

- S wD :

-

Normalized water saturation

- S wf :

-

Front water saturation

- S wi :

-

Initial water saturation

- S w2 :

-

Terminal water saturation

- Φ :

-

Porosity

- α :

-

Angle between the system and horizontal plane

- λ o :

-

Mobility of oil

- λ w :

-

Mobility of water

- \(\overline{{\lambda^{- 1}}}\) :

-

Average apparent viscosity

- \(\overline{{\lambda_{r}^{- 1}}}\) :

-

Apparent viscosity

- μ o :

-

Oil viscosity (cP)

- μ w :

-

Water viscosity (cP)

- ρ o :

-

Oil density (g/cc)

- ρ w :

-

Water density (g/cc)

- σ :

-

Interfacial tension (dyne/cm)

References

Baradari A, Hosseini E, Soltani B, Jadidi N (2019) Experimental investigation of ionic content effect on wettability alteration in smart water for enhanced oil recovery. Pet Sci Technol 1:11. https://doi.org/10.1080/10916466.2018.1550509

Darjani Sh, Koplik J, Pauchard V (2017) Extracting the equation of state of lattice gases from random sequential adsorption simulations by means of the Gibbs adsorption isotherm. Phys Rev E 96:052803. https://doi.org/10.1103/PhysRevE.96.052803

Forrest F, Craig FF Jr (1971) The reservoir engineering aspects of waterflooding, 1st edn. H. L. Doherty Memorial Fund of AIME, Society of Petroleum Engineers, New York

Green WD, Willhite G (1998) Enhanced oil recovery. Henry L. Doherty Memorial Fund of AIME, Society of Petroleum Engineers, Dallas, pp 286–291

Han D, Yuan H, Wang H, Dong F (2006) The effect of wettability on oil recovery by alkaline/surfactant/polymer flooding. In: SPE annual technical conference and exhibition, 24–27 September, San Antonio, Texas. https://doi.org/10.2118/102564-MS

Hosseini E (2019) Experimental investigation of effect of asphaltene deposition on oil relative permeability, rock wettability alteration, and recovery in WAG process. Pet Sci Technol 1:11. https://doi.org/10.1080/10916466.2018.1482335

Hosseini E, Tahmasebi R (2019) Experimental investigation of performance of biosurfactant to wettability alteration and interfacial tension (IFT) reduction in microbial enhanced oil recovery (MEOR). Pet Sci Technol. https://doi.org/10.1080/10916466.2019.1575863

Hosseini E, Hajivand F, Yaghodous A (2018) Experimental investigation of EOR using low-salinity water and nanoparticles in one of southern oil fields in Iran. Energy Sour A Recov Util Environ Effects 40(16):1974–1982. https://doi.org/10.1080/15567036.2018.1486923

Hosseini E, Hajivand F, Yaghodous A, Soltani R (2019) Experimental investigation of the effect of dispersed silica and alumina nanoparticles on oil-aqueous phase interfacial tension. Pet Sci Technol. https://doi.org/10.1080/10916466.2018.1476530

Hunkey R. M, Wu Y, Bai B, Dunn-Norman S (2010) An experimental study of alkaline surfactant flooding for ultra shallow heavy oil reservoirs. Society of Petroleum Engineers, SPE western regional meeting. https://doi.org/10.2118/132537-MS

Li J, Wang W, Gu Y (2004) Dynamic interfacial tension phenomenon and wettability alteration of crude oil–rock–alkaline–surfactant solution systems. In: SPE annual technical conference and exhibition, 26–29 September, Houston, Texas. https://doi.org/10.2118/90207-MS

Liu F, Darjani Sh, Akhmetkhanova N, Maldarelli Ch, Banerjee S, Pauchard V (2017) Mixture effect on the dilatation rheology of asphaltenes-laden interfaces. Langmuir 33(8):1927–1942. https://doi.org/10.1021/acs.langmuir.6b03958

Mozaffari S, Tchoukov P, Atias J, Czarnecki J, Nazemifard N (2015) Effect of asphaltene aggregation on rheological properties of diluted athabasca bitumen. Energy Fuels 29(9):5595–5599. https://doi.org/10.1021/acs.energyfuels.5b00918

Mozaffari S, Tchoukov P, Mozaffari A, Atias J, Czarnecki J, Nazemifard N (2017a) Capillary driven flow in nanochannels—application to heavy oil rheology studies. Colloids Surf A Physicochem Eng Asp 513:178–187. https://doi.org/10.1016/j.colsurfa.2016

Mozaffari S, Li W, Thompson C, Ivanov S, Seifert S, Lee B, Kovarik L, Karim MA (2017b) Colloidal nanoparticle size control: experimental and kinetic modeling investigation of the ligand–metal binding role in controlling the nucleation and growth kinetics. Nanoscale 9:13772–13785. https://doi.org/10.1039/C7NR04101B

Pei H, Zhang G, Ge J, Ding L, Tang M, Zheng Y (2012) A comparative study of alkaline flooding and alkaline/surfactant flooding for Zhuangxi heavy oil. In: SPE heavy oil conference Canada. Society of Petroleum Engineers. https://doi.org/10.2118/146852-MS

Souraki Y, Hosseini E, Yaghodous A (2019) Wettability alteration of carbonate reservoir rock using amphoteric and cationic surfactants: experimental investigation. Energy Sour A Recov Util Environ Effects 41(3):349–359. https://doi.org/10.1080/15567036.2018.1518353

Zolfagharloo A, Hosseini E, Ebrahimian E, Moradi S (2018) Experimental investigation of effect of palmitic acid as inhibitor on particle size of asphaltenes flocs using imaging techniques. Energy Sour A Recov Util Environ Effects 40(1):108–114. https://doi.org/10.1080/15567036.2017.1405118

Acknowledgements

We are grateful to the companies of Oil Industries Engineering and Construction (OIEC) and Sarvak Azar Engineering and Development (SAED) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Jones and Roszelle method

Jones and Roszelle graphical technique, which is an industry-accepted procedure (Li et al. 2004), is illustrated as follows.

When a displacement is conducted at constant injection rate, at any instant of time the total pressure drop is related to fluid and rock properties by Eq. (3) (Li et al. 2004):

where Kb is the base permeability for the relative permeability data

Define the effective or apparent viscosity and the average apparent viscosity with Eqs. (4) and (5):

By integrating Eq. (3) and using Eq. (5), at the outlet end of the core (point 2):

Computation of individual relative permeabilities requires values of the apparent viscosity at the Sw2. Thus, krw and kro can be calculated from Eqs. (7) and (8):

And,

where \(\lambda_{2}^{- 1}\) is the apparent viscosity at the outlet end of the core sample.

Only the average apparent viscosity is determined from experimental data. Jones and Roszelle developed a relationship between \(\bar{\lambda}^{- 1}\) and \(\lambda_{2}^{- 1}\) to compute values of \(\lambda_{2}^{- 1}\). They showed that drawn tangents to the graph of \(\bar{\lambda}^{- 1}\) versus Qi intersect the Qi = 0 at \(\lambda_{2}^{- 1}\). Thus, it is necessary to express \(\bar{\lambda}^{- 1}\) versus Qi.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hosseini, E., Hajivand, F. & Tahmasebi, R. The effect of alkaline–surfactant on the wettability, relative permeability and oil recovery of carbonate reservoir rock: experimental investigation. J Petrol Explor Prod Technol 9, 2877–2891 (2019). https://doi.org/10.1007/s13202-019-0671-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-0671-4