Abstract

Oil sands are characterized by shallow burial and extremely high viscosity, whose exploration technologies and production methods are quite different from that of conventional oil and gas. Oil sands with the largest reserve scale and best quality in China are developed in Fengcheng area of Junggar Basin. This paper presents the forming conditions and enrichment rules of oil sands in Fengcheng area. The dividing standards for effective thickness of oil sands are established with exploration technologies like high-density drilling, whole well section coring and the method of weight percentage of bitumen. The geologic reserves of oil sands are calculated with the method of weight percentage of bitumen. Open-pit mining practices and SAGD double horizontal well development tests are carried out, and good effects are obtained in SAGD production. At present, Fengcheng oil sands have been developed on a large scale with SAGD technology.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As the exploration of conventional oil and gas is more and more difficult, the role of the unconventional oil and gas resources—oil sands—is becoming more and more important in the world energy structure (Hein 2006; Xie et al. 2013; Humphries 2008; Masliyah 2011); the exploration and development of oil sands have become a hot topic and difficult in the unconventional oil and gas exploration field in China nowadays (Liu et al. 2009; Xue et al. 2011; Jia et al. 2007; Liu 1983; Kang et al. 2015; Shan 2015). Oil sands are abundant in resources in China, whose exploration and development are still at an initial stage. The exploration and development degree for oil sands in Fengcheng area of Junggar Basin is the highest in China (Kuang et al. 2016). The exploration and evaluation techniques, open-pit mining practices and SAGD double horizontal well tests for oil sands in Fengcheng area are analyzed in this paper, which can provide a reference for exploration and development of similar oil sands in China.

Geologic characteristics of Fengcheng oil sands

Fengcheng oil sands are located in Wuerhe District of Karamay, Xinjiang, about 120 km northeast of Karamay, whose tectonic zones lie in the northwest of proved and developed Fengcheng super-heavy oil reservoir (Fig. 1). Oil sand layers overlap the edge of the bedrock foothills with shallow burial; some are even directly exposed to the surface. The closer the oil sand layer is to the sand surface, the time for suffering from oxidation, water scrubbing and biodegradable alteration is longer, and the damage degree caused by it to crude oil is greater (Zhang et al. 2009). Oil sands have a symbiotic or transitional relationship with heavy oil and thin oil reservoirs (Fig. 2).

Oil sands in Fengcheng area are mainly developed in shallow strata of Jurassic Qigu Formation J3q and Cretaceous Qingshuihe Formation K1q (Tao et al. 2009; Zhou et al. 2008). Braided channels, diaras, channel sides and alluvial flat microfacies are developed in Jurassic Qigu formation J3q with braided fluvial facies deposition. The reservoir lithology is mainly sandstone; the average porosity, permeability and weight percentage of bitumen in oil sand layer are 29.53%, 954.5 mD and 9.38%, respectively. Distributary channels, interchannels and front sheet sand microfacies are mainly developed in Cretaceous Qingshuihe Formation K1q with braided river delta front subfacies deposition. The reservoir lithology is mainly small conglomerate and sandy conglomerate; the average porosity, permeability and weight percentage of bitumen in oil sand layer are 34.31%, 1089.65 mD and 11.85%, respectively. The reservoirs of Jurassic Qigu Formation (J3q) and Cretaceous Qingshuihe Formation (K1q) have extra high porosity, high oil content, high permeability and good pore connectivity.

The distribution of oil sands is mainly controlled by faults and unconformities; the type of oil sands is lithological–structural oil sands. Formation temperature and pressure of J3q formation are 21.67 °C and 1.74 MPa, respectively; formation temperature and pressure of Cretaceous K1q Formation are 18.65 °C and 1.22 MPa, respectively. The viscosity of stock tank oil ranges from 9689 to 47,300 MPa s at 50 °C of J3q formation, while that of Cretaceous K1q Formation is 266,000 MPa s. The viscosity and temperature are sensitive to each other: The viscosity decreases by 50–70% when the temperature increases by 10 °C.

Enrichment of Fengcheng oil sands is mainly controlled by the types of sedimentary microfacies, location of faults and unconformities, characteristics of lithological and physical properties, and burial depths (Fang et al. 2008). Researches have shown that oil sands mainly enrich in the areas where channel bars and distributary channel microfacies are developed. It can be seen from the oil-bearing area map of each section and the section map of mineral deposits that the oil sands have a relatively higher enrichment degree near the fault and unconformity surface. Statistical analysis has shown that the porosity, permeability and oil-bearing of fine sandstone in this area are very good, which means that areas with relatively good lithological and physical properties are favorable for the enrichment of oil sands. Oil sands buried at or near the surface are prone to oxidation, surface water leaching and microbial decomposition, resulting in a significant reduction in oil content. Deeply buried oil sands are better preserved and have a relatively higher oil content.

Exploration technologies

Oil sand identification technology by small hole spacing drilling and whole well section coring

There are three oil sand deposits (No. 1, No. 2 and No. 3) in Fengcheng area (Fig. 1): No. 1 oil sand deposit is continuous and stable in oil sand layer and is explored with 200–300 m hole spacing; No. 2 and No. 3 oil sand deposits have great thickness variation and strong heterogeneity in oil sand layer and are explored with 50–200 m hole spacing.

All the boreholes are cored from the wellhead to the bottom (Fig. 3), and the core recovery is not less than 90%. The oil occurrences such as oil saturated, oil rich, oil soak, oil stain and oil traces in the oil sand layers are determined according to the lithology description and stratigraphic classification, and selection of various analytical samples of oil sands should be representative. In order to reflect oiliness and weight percentage of bitumen in oil sands, systematic sampling is required: Generally, select two or three samples every meter; when it comes to the area where quality change of oil sands is large, sampling should be appropriately increased to four or five per meter; sampling is required on the top, in the middle and at the bottom for thin oil sand layers.

In addition to the weight percentage of bitumen, oil sands are sampled as required in other test and analysis items, like rock minerals, reservoir physical properties, fluid properties and so on.

Calculation method of oil sand reserves

Two methods have been used to evaluate the reserves of Fengcheng oil sands: method of weight percentage of bitumen and the volumetric method. For shallow (buried depth of 0–200 m) oil sands or oil sands exposed to surface, exploration is carried out by means of exploratory pits, high-density drilling, whole well section coring and even analysis of weight percentage of bitumen (Fig. 3), and the reserves are calculated by the method of weight percentage of bitumen (Huang et al. 2014). For deeply buried oil sands (with a depth of 200–500 m), exploration and evaluation are carried out by conventional drilling, geophysical logging and analysis of porosity, permeability and saturation, and the reserves are calculated by the volumetric method (Qu et al. 2013; Gao et al. 2012). Fengcheng Cretaceous oil sands are taken as an example in this paper to discuss the reserves calculation method of weight percentage of bitumen.

The formula for geological reserves calculation by the method of weight percentage of bitumen is:

where N—geological reserves of oil sands, 104 t; Ao—oil-bearing area, km2; h—average effective thickness of oil sands, m; ρr—oil sand rock density, t/m3; ω—weight percentage of bitumen, f.

In the method, the effective thickness is determined by a comprehensive analysis of oil sand core and weight percentage of bitumen. The weight percentage of bitumen is an important index to determine the effective thickness of oil sands, and it can determine whether the oil sands have industrial exploitation value. By means of analyzing data of weight percentage of bitumen in cores, with methods of oil occurrence, inverse and analogy, the lower limit of weight percentage of bitumen is determined; thus, the lower limit of effective thickness of oil sands is determined.

Lower limit standard of effective thickness

Oil occurrence method

According to the data of weight percentage of bitumen in boreholes (Fig. 4, Table 1), the weight percentage of bitumen in oil-saturated cores of Fengcheng Cretaceous oil sands is 6.5–21.7%, with an average of 12.6%; the weight percentage of bitumen in oil-rich cores is 4.5–17.9%, 97.8% of which are more than 6%, with an average value of 10.3%; the weight percentage of bitumen in oil-soaked cores is 2.1–6.4% and only 16.6% cores of which are more than 6%, with an average value of 4.3%; the weight percentage of bitumen in oil-stained cores is 0.2–5.4%, all of which are less than 6%, with an average value of 2.9%. Based on the effective thickness of oil-saturated and oil-rich cores from Fengcheng heavy oil reservoir located in the south of the reservoir, the lower limit of the weight percentage of bitumen for Fengcheng Cretaceous oil sands is determined as 6%.

Inverse method

Since there is a symbiotic or transitional relationship between Fengcheng oil sands and heavy oil reservoirs, the lower limit of weight percentage of bitumen can be obtained through the lower limit of oil saturation of Fengcheng heavy oil reservoirs. By sealed coring and logging in a typical borehole, the original oil saturation and weight percentage of bitumen are analyzed with oil sand cores from the same depth (Fig. 5, Table 2), so that a relation curve (Fig. 6) of oil saturation vs. weight percentage of bitumen can be established. Oil saturation and weight percentage of bitumen have fine correlation: With their relation, the original oil saturation can be got under different weight percentages of bitumen; the weight percentage of bitumen can be calculated with different oil saturations from logging interpretation. The lower limit of oil saturation in Fengcheng heavy oil reservoir is 50%, and the weight percentage of bitumen is 6.02% according to the formula.

Analogy method

Athabasca river region in Canada is one of the world’s biggest oil sands. Lower Cretaceous McMurray Formation, the main reservoir, with average thickness of 40–60 m, is composed of uncemented fine–medium-grained quartz sand, and the thickness, porosity, weight percentage of bitumen and geological reserves are 7.2–30.5 m, 28–40%, 7–18% and 2592 × 108 m3, respectively.

The thickness of Cretaceous Qingshuihe Formation in Fengcheng area varies from 30 to 120 m, and the reservoir lithology is mainly fine–medium-grained lithic sandstone, and the effective thickness, porosity, weight percentage of bitumen and geological reserves are 5.0–51.5 m, 26–38%, 6–19% and 2603 × 104 t, respectively.

The geological conditions of oil sands in Fengcheng area of Xinjiang are similar to those of Athabasca oil sands in Canada. The lower limit of effective thickness of oil sands in Canada is the weight percentage of bitumen ≥ 7–8% and oil saturation ≥ 55%, while that of Fengcheng is the weight percentage of bitumen ≥ 6% and oil saturation ≥ 50%.

According to the above three methods, the lower limit of effective thickness of oil sands in Fengcheng area is determined: the weight percentage of bitumen in oil-saturated cores and oil-rich cores ≥ 6% (Tao et al. 2009).

Comparison of effective thickness calculated by logging interpretation and weight percentage of bitumen

In order to verify the reliability of reserves calculated by the method of weight percentage of bitumen, both coring in whole well section and logging have been carried out in the deeply buried No. 1 oil sands. Comprehensive logging is carried out in seven boreholes, and systematic sample selection and weight percentage of bitumen analysis are carried out for oil sand layers. Then, the effective thickness of these seven bore-holes is interpreted by logging interpretation and the method of weight percentage of bitumen. Results indicate that the effective thickness of the oil sand layers is the same, with a relative error range from − 0.27 to 3.21%, which meets the requirements of reserves calculation (Fig. 7, Table 3).

Reserve calculation with the method of weight percentage of bitumen

Taking a fault block of Cretaceous Qingshuihe Formation K1q2 in Fengcheng area as an example, this paper discusses how the parameters of reserve calculation are determined by the method of weight percentage of bitumen.

Oil-bearing area

It refers to the area of oil sand distribution that reaches the lower limit of the effective thickness. The oil-bearing area of each calculation unit is delineated on the top or bottom structure of the oil sand layer and determined by the effective thickness contour which is greater than or equal to 5 m. As for the fault or stratigraphic screened boundary, the oil-bearing area of K1q2 of a certain fault block, delineated by the outer oil-bearing boundary where the top surface of an oil layer intersects a fault or stratigraphic unconformity, is 2.73 km2 (Fig. 8a).

Effective thickness

It means the thickness of oil sand that reaches the lowest oil content of the oil sand and the thickness of the interlayer is deducted.The first step is to calculate the thickness of the oil-saturated and oil-rich core, and the weight percentage of bitumen of these cores are greater than or equal to 6%, and then remove the interlayer thickness from the calculated oil sand thickness. The lower limit of effective thickness in a single oil sand layer is 0.5 m, the lower limit of thickness where the thickness of the interlayer is deducted is 0.2 m, and the lower limit of minimum recoverable effective thickness is 5.0 m. The effective thickness of each calculation unit is calculated by weighing the contour area. The average effective thickness of the Fault Block K1q2 is 18.0 m (Fig. 8b).

Weight percentage of bitumen

It refers to the ratio of crude bitumen to oil sand mass, and it is the percentage of asphalt A obtained in the laboratory by soaking unit mass oil sand in chloroform solvent. The weight percentage of the bitumen of a single hole is calculated by weighing the thickness of the oil sand layer where the sampling point is located. The average weight percentage of bitumen of each calculation unit is calculated by weighing the control volume of a single hole. The average weight percentage of bitumen of the Fault Block K1q2 is 11.1% (Fig. 8c).

Density of oil sand rock

It is calculated according to the arithmetic average of the sample analysis value: According to the rock density values of oil sand samples measured, the calculation units are calculated by the method of well point arithmetic average. The oil sand rock density of the Fault Block K1q2 is 2.095 g/cm3.

According to the above parameters, Formula (1) is used to calculate the geological reserves of crude bitumen for Fault Block K1q2 with a value of 2124.85 × 104 t (Table 4).

Mining test

Currently, there are two main methods for oil sands mining including open-pit mining (buried depth < 75 m) and in situ recovery (buried depth > 75 m). In Fengcheng area, open-pit mining tests are carried out in shallow oil sands (buried depth < 50 m), and dual horizontal SAGD wells tests are carried out in deeper oil sands (buried depth > 150 m) with good production results, which prove that SAGD is an effective oil sand mining method at present.

Open-pit mining test

Laboratory water washing separation experiment

Four reagents (A, B, C and D), prepared by mixing various surfactants with strong permeability according to different compositions and proportions, are used in oil sand separation comparison test with single lye. After evaluating the four reagents in the laboratory, B and D reagents with good oil extraction effect are selected for orthogonal test analysis. It is found that heating temperature, reagent mass fraction, heating separation time and agent–sand mass ratio have a greater impact on oil sand separation effect. The sequence of influence factors is: heating temperature > separating agent mass fraction > separation time > agent–sand mass ratio.

The agent D is selected as the optimal one through comprehensive analysis. The optimal separation operating conditions are as follows:

- (a)

Mass fraction of water washing agent is 1.0%.

- (b)

Heating temperature is 80 °C.

- (c)

Heating time is 15 min.

- (d)

Agent–sand mass ratio is 3.5:1.

The highest oil production rate of oil sands is over 91%.

Analysis of the experiment effect of open-pit mining

In No. 3 oil sands with shallow burial depth, the average buried depth in the top of it is 14 m. The thickness of oil sands is 6.6 m, and the weight percentage of bitumen is 9.2%. Pits I and II are explored in open-pit mining (Fig. 9). Oil sands in pit I are selected for field separation treatment and water washing process tests with agent D.

Field test results show that the washing technology in Fengcheng oil sands is feasible, and the washout efficiency of asphalt oil can be more than 90%. However, it is difficult for oil sands mining currently because of the high oil viscosity, immature technology and poor economic benefits. Oil sands with lower viscosity will be selected to continue the test next time.

SAGD pilot development

SAGD, steam-assisted gravity drainage. Its basic principle is based on steam as a heating medium, depending on heated fluid convection and heat conduction of steam, recovers heavy oil by gravitational effects. Steam helps to reduce viscosity, and gravity dominates oil drainage. SAGD usually adopts dual horizontal wells: Steam injection is in the upper horizontal well and oil production is in the lower horizontal well.

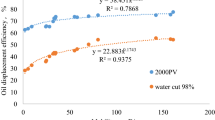

In J3q2 reservoir of No. 1 oil sands, the buried depth in the top of it ranges from 160 to 289 m. The thickness of oil sands is 22.9 m (Fig. 10). The weight percentage of bitumen is 9.0%. Three pairs of SAGD horizontal wells are implemented in Fengcheng oil sands, and two pairs of them have good production results. By the end of 2017, the daily oil production of well FW2101 is 20–30 t, the cumulative oil output is 27,737 t, the daily oil production of well FW2118 is 25–35 t and the cumulative oil output is 26,819 t (Fig. 11), which show that the production effect is good. SAGD is proved to be an effective way to develop oil sands in Fengcheng area. At present, Fengcheng oil sands have been developed in a large scale.

Conclusions

-

(1)

For oil sands with shallow burial depth (generally buried depth less than 200 m) or exposed to the surface, the cores are unconsolidated and highly fractured during extraction; thus, porosity and oil saturation error are big. The Weight percentage of bitumen can better represent the actual oil content of oil sands and is suitable for reserves calculation in hole drilling. For deep buried oil sand reserves, oil sands are explored by well drilling, and the volumetric method is suitable for reserves calculation. The results of the two reserves calculation methods are consistent, and the error is small.

-

(2)

Pilot development results indicate that SAGD is an effective way to develop oil sands currently.

-

(3)

Exploration and production experience of Fengcheng oil sands can provide important demonstration and reference for similar oil sands in China.

References

Fang CH, Liu RH, Wang HY et al (2008) Origin analysis and geological characteristics of oil sands in the Fengcheng area, Northwest Jungar Basin. Nat Gas Ind 28(11):127–130. https://doi.org/10.3787/j.issn.1000-0976.2008.11.039

Gao DC, Tong MB, Su GW et al (2012) Study on four-property relationship and effective thickness lower limit of Chang 6 reservoir in Laoshan area. Pet Geol Eng 26(3):43–45. https://doi.org/10.3969/j.issn.1673-8217.2012.03.012

Hein FJ (2006) Heavy oil and oil (tar) sands in North America: an overview and summary of contributions. Nat Resour Res 15(2):67–84. https://doi.org/10.1007/s11053-006-9016-3

Huang WH, Xie ZR, Niu W et al (2014) Determination of the effective thickness lower limit of oil sands in Fengcheng area, Junggar Basin. Xinjiang Pet Geol 35(4):309–402

Humphries M (2008) North American oil sands: history of development, prospects for the future. Congressional Research Service, Washington, DC

Jia CZ, Liu XJ, Lei Q et al (2007) Oil sands resources and evaluation methods of reserves. Petroleum Industry Press, Beijing

Kang YZ, Zhang DW, Zhao XL et al (2015) China’s unconventional oil and gas geology. Geological Publishing House, Beijing

Kuang LC, Xue XK, Huang WH et al (2016) Oil sand geology, enrichment and technology and application technology. Petroleum Industry Press, Beijing

Liu WZ (1983) A preliminary study on China heavy oil classification standard. Oil Drill Prod Technol 5(1):41–50

Liu RH, Wang HY, Wang GJ et al (2009) Potentials and prospects of tar sands resources in China. Nat Gas Ind 29(9):126–128. https://doi.org/10.3787/j.issn.1000-0976.2009.09.036

Masliyah JH, Czarnecki J, Xu Z (2011) Handbook on theory and practice of bitumen recovery from Athabasca oil sands (volume I: theoretical basis). Translated by Wang Yutao, etc. Petroleum Industry Press, Beijing

Qu CW, Zhang X, Lin CM et al (2013) Study on four-property relationship and effective thickness lower limit of Chang 9 reservoir in Zhenjing oilfield. Liaoning Chem Ind 42(2):131–134. https://doi.org/10.3969/j.issn.1004-0935.2013.02.009

Shan XL (2015) Oil sand exploration and production technology and application. Donghua University Publishing House, Shanghai

Tao Y, Yu L, Liu RH et al (2009) Geological features and resources evaluation of Cretaceous oil sand, Wuerhe Mine, Xinjiang. Pet Geol Eng 23(2):37–39. https://doi.org/10.3969/j.issn.1673-8217.2009.02.010

Xie XT, Shan XL, Fu YC et al (2013) A comprehensive method for exploring in situ oil sands. Pet Sci Technol 31(19):2022–2030. https://doi.org/10.1080/10916466.2011.652332

Xue C, Feng Q, Tian H (2011) Distribution and prospect of oil sand resources in China. Xinjiang Pet Geol 32(4):348–350

Zhang MY, He AD, Shan SH et al (2009) Approach to oil sand resource potentials and recovery process in northwestern margin of Junggar Basin. Xingjiang Pet Geol 30(4):543–545

Zhou W, Yu L, Zhang YD et al (2008) The factors for oil sand accumulation in Wuerhe area of Junggar Basin. Xinjiang Pet Geol 29(6):710–712

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, W., Wang, X., Sun, X. et al. Exploration and production practice of oil sands in Fengcheng oilfield of Junggar Basin, China. J Petrol Explor Prod Technol 10, 1277–1287 (2020). https://doi.org/10.1007/s13202-019-00828-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-00828-w