Abstract

Process facilities for the separation of hydrocarbons from produced water in the oilfield are critical to flow assurance, product quality and environmental compliance. The formation of metal naphthenates, which are emulsion stabilizers and equipment foulers, is deleterious to performance and integrity of these processes and facilities. Manual removal of deposits of these organic salts formed at the oil–water interface during separation processes is difficult and expensive; hence, the best operational option is inhibition. The conventional method for the inhibition of metal naphthenates, which relies on suppressing the deprotonation of naphthenic acids by common ion effect, is no longer tenable because it exacerbates internal corrosion problems in topside facilities. Current industry focus is on the development of effective surface active agents for inhibition of naphthenates. There are a plethora of chemical compounds with naphthenate inhibition potential such as sulphonates, phosphate esters, aminated phosphonates and sulphosuccinates, but compatibility issues make the choice of inhibitor a complicated process. In this paper, the drivers and mechanism of oilfield metal naphthenate formation are reviewed. Surfactants for oilfield metal naphthenate inhibition and the mechanisms of inhibition are highlighted with a view to process optimization.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, there have been increasing reports of metal naphthenate deposition problems in offshore fields in several locations such as West Africa, South America, Asia and the North Sea (Juyal et al. 2015; Igwebueze et al. 2013; Gallup and Star 2004; Vindstad et al. 2003). This is a clear indication that gradually, more acidic reservoirs are being produced. Knowledge of the existence of organic acids in crude oil is not new to the petroleum industry. However, the investigation and understanding of their precipitation and deposition, as a distinct production challenge, and how to manage it, are relatively nascent. Acidic crudes are prone to metal naphthenate formation—a process where naphthenic acids occurring naturally in crude oil react with metal ions in the formation of water to produce organic salts as the reservoir fluid is depressurized during normal production (Rosseau et al. 2001). Metal naphthenate deposition usually occurs topside, especially in vessels in which phase separations take place or where the produced fluid is treated, causing serious flow assurance problems (Igwebueze et al. 2013). Many operators of fields producing acidic crudes have experienced clogging in separators, electrostatic coalescers, desalters, heat exchangers, filters and hydrocyclones, as well as fouling of the entire water treatment system due to metal naphthenate deposition (Igwebueze et al. 2013; Junior et al. 2013; Vindstad et al. 2003;). Apart from solid deposition in process facilities, metal naphthenates stabilize oil-in-water emulsions and in some cases form highly viscous sludge (Gallup et al. 2005). These outcomes reduce the efficiency of oilfield production activities such as dehydration, desalting and discharge of produced water with consequences on both oil quality and environmental sustainability of the project. The removal and disposal of metal naphthenate deposits is particularly tedious and expensive. Chemical inhibition complemented by process control remains the best option. With the problems associated with acid injection, the current drive is to develop environmentally friendly, robust, low-dose surfactant inhibitors for control of metal naphthenates in the oilfield.

Identification, quantification and characterization of naphthenic acids

‘Naphthenic acid’ describes several alkyl-substituted cycloaliphatic and acyclic organic acids in crude oil. Naphthenic acids in crude oil are complex mixtures of homologous acids represented with the general formula CnH2n + z O2. The carbon number (n) ranges from 10 to 50. ‘Z’ indicates hydrogen deficiency due to cyclopentane/cyclohexane ring structures and specifies the homologous series. ‘Z’ equals zero or a negative even whole number from − 2 to − 12. (Trace amounts of higher aromatic homologues exist.) A value of zero indicates that the acid lacks ring structures and is a fatty acid. − 2, − 4 and − 6 represent homologous series with 1, 2 and 3—saturated rings, respectively, and so on (Fan 1991). Small amount of nitrogen and sulphur components also occur in naphthenic acids Naphthenic acids occur mainly in biodegraded oils and are responsible for high oil total acid number (TAN) (Rosseau et al. 2001; Meredith et al. 2000). They are petroleum biomarkers, useful for oil–source rock correlation and elucidation of reservoir biodegradation mechanism (Meredith et al. 2000).

A class of C80–C82 tetraprotic naphthenic acids having molecular weight between 1227 and 1235 g/mol have been identified (Smith et al. 2007; Baugh et al. 2005). Also known as C80–tetraacids (C80–TA) or ARN acid (an allusion to their unique structural and molecular properties), they occur in low concentration (0.6–3.6 ppm) in oil but are the predominant acids in calcium naphthenate deposits (Juyal et al. 2015; Nichols et al. 2014). ARN acids have 4 to 8 rings in their structure. The 6-ring isomer is most abundant, and its molecular weight of 1231 g/mol is the ARN signature on the m/z spectrum, corresponding to the molecular formula C80H142O8 (Nordgård et al. 2010; Baugh et al. 2005) (Fig. 1). Lower molecular weight series of tetraprotic ARN acids with carbon number C60–C77 have been reported by Mapolelo et al. (2009), with Juyal et al. (2015) isolating C70H122O8, C71H124O8 and C72H126O8 homologues from calcium naphthenate (CaN) deposits of a Brazilian crude oil. Though there is an alternative hypothesis to the origin of ARN in oil, biosynthesis by archae in petroleum reservoirs is widely accepted (Brocart et al. 2007; Lutnaes et al. 2007). All crudes that have calcium naphthenate problems contain ARN, but ARN is not specific to particular kinds of crude neither is their presence a reliable diagnostic tool for CaN deposition problem (Subramanian et al. 2017; Brocart et al. 2007. The development of model UV-sensitive synthetic tetraacids (Pe10 and BP10) has facilitated better understanding of the complex nature of ARN acids (Sjöblom et al. 2014; Nordgård and Sjoblom 2008).

Crude oil acid content expressed as TAN (mgKOH/g) can be quantified by the traditional titrimetric method or by FTIR spectroscopy (Chakravarthy et al. 2016). A UV-based method for quantification of tetraacids derivatized by chemically engrafting chromophores such as naphthacyl and 2-bromo acetonaphthone is also available (Passade-Boupat et al. 2012; Simon et al. 2008). Several mass spectrometry-based methods have been adopted by various researchers for the detection of naphthenic acids in oil and deposits (Mohammed and Sorbie 2009a, b; Smith et al. 2007; Brocart et al. 2007; Haoa et al. 2005; Saab et al. 2005; Clemente and Fedorak 2004; Gabryelski and Froese 2003; Jones et al. 2001; Hsu et al. 2000; Fan 1991; Dzidic et al. 1988). There are several challenges to the detailed characterization of naphthenic acid such as poor peak resolution due to similar homologues, obscured fragmentation patterns due to several co-eluates, cumbersome derivatization, excessive fragmentation and poor volatility of high molecular weight acids (Dzidic et al. 1988; Lutnaes et al. 2006).

In addition to the flow assurance problems encountered with acidic oils, naphthenic acids are a major cause of high-temperature corrosion of steel in oil refineries (Turnbull et al. 1998). Naphthenic acids are toxic to the eco system when released into the environment via crude oil refinery waste or oil–sand extraction. Their toxicity to bacteria, plants and animals is linked to structure and polarity and is well documented in the literature (Holowenko et al. 2002; Kamaluddin and Zwiazek 2002; Dohkholyan and Magomedov 1984).

Chemical structure of C80 tetraacid (ARN) (Lutnaes et al. 2006)

Interfacial behaviour of naphthenic acids: metal naphthenate formation as an interfacial phenomenon

Naphthenic acids are amphiphiles; therefore, they tend to reside at the interface between oil and water in biphasic systems (Nordgård et al. 2010). Dynamic interfacial tension (IFT) measurements, Langmuir pressure–area isotherm and interfacial rheometry provide means to evaluate effects of bulk phase variables on interfacial process and to monitor the activity of interface-active substances. Increasing interfacial activity results in a decrease in oil–water interfacial tension. For an oil–water system containing naphthenic acid, the surface pressure of the Langmuir monolayer increases as metal naphthenate film forms at the interface and decreases if the film material dissolves in the bulk phase (Havre et al. 2002).

IFT studies using a model naphthenic acid showed that the process of metal naphthenate formation is initiated by diffusion of the amphiphilic acid to the oil–water interface where it dissociates to the more interface-active anion (Brandal et al. 2004). If the water phase contains cationic species, the extent to which IFT changes will depend on the nature and concentration of the cation in the water and naphthenic acid in oil. The ionization of acid groups to carboxylate anion in the aqueous phase induces diffusion of more naphthenic acids from the bulk to the interface. Thus, interacting equilibria are created: an adsorption–desorption equilibrium at the interface; partition equilibrium of undissociated acid between the aqueous and oil phase; and equilibrium between the dissociated and undissociated acid in the aqueous phase (Brandal et al. 2004) (Fig. 2). Naphthenic acids are sparingly soluble in water except the very low molecular weight members (Havre et al. 2002). The extent to which naphthenic acid dissociates depends on the pKa and partitioning coefficient of the individual acids (Nichols et al. 2014). The partition coefficient is a function of the pH, concentration and structure of the acid (Havre et al. 2002). Metal naphthenate formation is dominated by interfacial reaction mechanism. Brandal et al. (2004) observed that naphthenic acids extracted from deposits have dramatically higher interfacial activity compared to naphthenic acid extracted from crude oil, indicating that the greater abundance of tetraacids in naphthenate deposits is due to their greater interfacial activity.

pH effects on interfacial properties

As a rule of thumb, interfacial activity of naphthenic acids decreases with pH if pH < neutral and increases with pH if pH > 7 (Bai et al. 2010). Pressure–area Langmuir isotherms show that for a biphasic system containing naphthenic acid but no divalent cations, surface pressure increases with increasing pH because the molecular area increases owing to electrostatic repulsion between the greater number of dissociated carboxylic acid groups at the interface (Havre et al. 2002; Brandal et al. 2004). The effect peaked at pH of about 9 for an experimental system containing tetraacids because at this pH the tetraacid is optimally dissociated and the interfacial film is not overly soluble in the aqueous phase as would be the case at higher pH due to complete ionization of the tetraacid (Fig. 3). In essence, the interfacial film becomes more ionized and less stable as pH increases, resulting in a more rapid loss of interfacial area (Fig. 4). Under this condition, the film is more soluble in the aqueous phase and more prone to rupture. The rupture of the interfacial film promotes further reactions at the interface if metal cations are present, shifting the equilibrium position towards formation of more metal naphthenate (Brandal et al. 2004).

At low pH near the acid dissociation constant (pKa) of naphthenic acid in crude oil (which is 4.9), partition coefficient (Kow) is influenced by the equilibrium of dissociation and the undissociated form of the naphthenic acid is dominant in the aqueous phase, naphthenic acid at the interface will be unionized and they will be a positive interfacial tension (Brandal et al. 2004) (Fig. 2). Also the characteristic break in the Langmuir isotherm indicative of film collapse as area is reduced will be conspicuously absent, indicating an insignificant interfacial film. Interfacial tension decreases progressively as pH increases because naphthenic acids are more interfacially active in their dissociated state (Fig. 5). At pH > pKa, the dissociated form is dominant over the undissociated form in the aqueous phase (Havre et al. 2002). As pH increases further to high pH range, micellization and reverse micellization equilibrium begin to influence the partitioning of naphthenic acid, with the reverse micellization process having dominance probably due to naphthenic acid self-inhibition. It has been determined that only 5–10% of the naphthenic acid in crude oil in contact with an aqueous phase will exist in its dissociated form in the aqueous phase when the pH equals pKa (Passade-Boupat et al. 2012; Mohammed et al. 2009). This is probably due to structural effects and inhibitive effects of other naphthenic acids because the naphthenic acid content of crude oil is a spectrum of different molecular weights and solubilities and only the smallest naphthenic acids will be water soluble at a pH of 5.

Surface pressure–area isotherm of tetraacid at different pHs (Brandal et al. 2006)

Interfacial film stability (at constant surface pressure) of tetraacid at different pHs (Brandal et al. 2006). [A/A0] is the loss in interfacial area

Effect of pH on interfacial tension of biphasic system containing tetraacid (Brandal et al. 2006)

Metal ion effects on interfacial properties

The addition of metal cation stabilizes the interfacial naphthenate film, making it less soluble in the bulk phase which translates to an increase in surface pressure (Lutnaes et al. 2006) (Figs. 6, 7). The molecular area also decreases as Ca2+ and naphthenate anions are electrostatically attracted (Havre et al. 2002). Naphthenate interfacial film stability is dependent on the interfacial affinity of the cation and metal ion concentration (ionic strength). The interfacial affinity of the cation depends on the degree of hydration, whereas the ionic strength is a function of the metal ion concentration in the aqueous phase (Brandal et al. 2004). Interfacial activity of naphthenate salts is related to the valency of the cation (Mohammed et al. 2009). Generally divalent cations are more stabilizing to the interfacial film than monovalent cations because they can form diacid salts. Metal cations with higher hydration number have high interfacial affinity and produce less stable interfacial films because of the greater solubility of these films in the aqueous phase (Havre et al. 2003). In a comparative study of interfacial film pressure of model naphthenic acids and their salts, calcium salts had higher interfacial pressure and hence were more stable than magnesium salts (Brandal et al. 2004). The hydration number of Ca2+ and Mg2+ are 2 and 6, respectively.

Similarly, the interaction of an ARN monolayer with calcium ions results in a stronger, less soluble interfacial film, increasing the film stability and reducing its compressibility (Havre et al. 2002). Generally, ionic character of the interfacial film increases with ionic strength of aqueous phase. If Ca2+ is in excess in the bulk phase and the pH is close to acid pKa, the deprotonated naphthenic acid combines with divalent calcium in a ratio of 1:1 leading to electrostatic repulsion between the charged head groups, which results in an increase in the molecular area and compressibility of the Langmuir film. Conversely at low ionic strength, deprotonated naphthenic acid is in excess at the interface, densely packed 2:1 diacid salts are formed and the increase in area is minimal. Compressibility of the film and the area for pressure onset are both low (Havre et al. 2003).

Surface pressure–area isotherm of a synthetic naphthenic acid at different Ca2+ concentrations (pH 5.6) (Havre et al. 2002)

Interfacial film stability of synthetic naphthenic acid at different Ca2+ concentrations (pH 5.6) (Havre et al. 2002)

Molecular structure effects on interfacial properties

The molecular weight, structure and polarity of naphthenic acids influence their behaviour and partition coefficient (Goldszal et al. 2002). Solubility, oil–water partition coefficient and interfacial activity of naphthenic acids all decrease as molecular weight increases (Hanneseth et al. 2006). Therefore, larger molecular weight naphthenic acids and their salts will barely dissolve in the aqueous phase (Dyer et al. 2003). Having more saturated rings also increases naphthenic acid hydrophobicity (Havre et al. 2003). Hence, lower molecular weight naphthenic acids dissociate at the interface at lower pH compared to those of higher molecular weight (Hanneseth et al. 2006). The notably high interfacial activity of the large ARN molecule, which stands out as an exception from other naphthenic acids, is due to the its four protic carboxylic groups which outbalances the effect of molecular weight (Hanneseth et al. 2006) (Fig. 1).

Aromatic systems in naphthenic acid structures make for greater hydrophilicity and interface activity compared to saturated ring systems (Havre et al. 2003; Nordgård et al. 2012; Brandal and Sjöblom 2005). The π bonds of such aromatic naphthenic acids lends to denser packing at the interface which increases with ring condensation. Bulky, cyclic structures gives rise to interfacial films of low stability because of steric hinderance effect, low flexibility and compressibility compared to more aliphatic naphthenic acids (Nordgård et al. 2012; Brandal and Sjöblom 2005). As the aliphatic character of naphthenic acid increases, the interface film becomes more solid, rigid and compression resistant. Finally, structural effects may exert some influence on the micellization and reverse micellization equilibrium. Naphthenic acids with bulky ring systems behave more like hydrotropes with undefined critical micelle concentration and a gradual stepwise aggregation where the aggregation numbers are small in contrast to classical surfactant character of aliphatic naphthenic acids (Havre et al. 2002).

Formation and character of metal naphthenates: mechanistic and macroscopic aspects

Mechanistic aspects

Metal naphthenate formation is mainly via interfacial reaction mechanism. However, there is clear distinction between the reaction type, interfacial behaviour and nature of the two types of metal naphthenates–calcium naphthenate soap scale and sodium carboxylate soap emulsion. Whereas calcium naphthenate soap scales necessarily involves formation of insoluble precipitates, sodium carboxylate soap emulsions involve water-soluble species whose influence in the production system is limited mainly to emulsion stabilization. Sodium carboxylate soap emulsion formation is a saponification-style reaction between long-chain fatty acids and monovalent cations (Na+, K+) in brine. The formation of solid calcium naphthenate soaps involves complexation-style 2:1 bidentate binding of large molecular weight tetraprotic acids (ARN) to Ca2+ to give practically insoluble coordination compounds and can be interpreted within the framework of the crystallization theory (Taylor and Hiu 2018).

Also the kinetics of partitioning and dissociation of naphthenic acid is much slower in the presence of sodium ions than calcium ions because divalent calcium ions complex twice as much naphthenate ion as the monovalent sodium ion, so the rate of calcium naphthenate formation is higher than that of sodium naphthenate (Bertelli et al. 2014). The strong attractive forces between naphthenic acid and Ca2+ at the interface induce a chemical reaction which proceeds in two stages by sequential binding of the acid to the metal cation. The first stage involves formation of a positively charged acid–metal–water complex which is more interface active than the dissociated monomeric acid. The water is that of hydration and influences the interfacial activity of the complex. At the second stage, the less interfacially active complex is formed. The metal naphthenate may migrate into either of the bulk phases depending on the polarity of the complex or remain at the interface. By this reaction, density of dissociated acid at the interface reduces, inducing molecular diffusion of acids from the oil bulk into the oil–water interface (Brandal et al. 2004).

From a thermodynamics perspective, the formation of calcium naphthenate and its migration away from the interface shift the naphthenic acid/naphthenate anion equilibrium towards production of more naphthenate anion, and this in turn shifts the partition equilibrium towards partitioning of the acid into the aqueous phase (Moradi et al. 2013; Brandal et al. 2004) (Fig. 2). This calcium cation-induced partitioning is selective towards higher molecular weight naphthenic acids (Bertheussen et al. 2018).

Precipitation of metal naphthenates as with all crystallization phenomena proceeds via nucleation, particle growth and agglomeration (in the oil phase). The rate of nucleation is dependent on a number of physical parameters peculiar to the system: particle radius, solid–solution interfacial tension, molecular volume, temperature and supersaturation. Supersaturation is a function of the concentration of metal ion (ionic strength) and dissociated naphthenic acid (Havre 2004). It is particularly important at the nucleation stage as its increase will reduce induction time (the time required for nucleation and growth of measurable particles). If supersaturation is high, homogenous nucleation—a spontaneous process—is dominant. If supersaturation is low, heterogeneous nucleation, induced by exogenous particles such as mineral scales and corrosion products, will be dominant because the rate of homogeneous nucleation is low and the amount of exogenous particles is constant, independent of supersaturation. Shear and turbulence effects accelerate the nucleation of calcium naphthenates, since naphthenates are formed by molecular diffusion of acid from the bulk to the interface. However, with time this effect may be counterbalanced by attrition of particles. The growth rate is also influenced by supersaturation, temperature, particle size as well as shear/turbulence and cation/anion ratio. However, for a given metal naphthenate, temperature increase could have opposite effects on nucleation and growth (Havre 2004).

Agglomeration rate increases with number of particles. Therefore, homogeneous nucleation (which produces large number of small particles) favours agglomeration. Agglomeration is also influenced by calcium cation–naphthenate anion ratio at the interface. A system containing an excess of either the divalent cation or naphthenate anion results in particles that are electrostatically stabilized against agglomeration, whereas a 2:1 ratio of calcium ion to naphthenate ion is best for particle agglomeration, resulting in the increase in particle size. Turbulence also promotes agglomeration by increasing inter-particle collisions. In addition to agglomeration, Ostwald ripening may also play a role in particle growth. Particles can be still increased in size even after equilibrium is attained between calcium naphthenate precipitate and calcium and naphthenate ions (Havre 2004).

Macroscopic aspects

Generally high-TAN (acidic) crudes are co-produced with low-bicarbonate, high-calcium formation water (Gallup et al. 2002). The type of soap formed during field production is a function of the chemical composition of the oil and the metal content of brine (Sorbie et al. 2005). Table 1 summarizes the relationship between crude oil composition and type of metal naphthenate problem. The ratio of ARN to other lower molecular weight naphthenic acids in oil is a major determinant of the type of metal naphthenate soap that will be formed. Therefore, using TAN alone as an indicator of the risk or type of naphthenate soap problem is unreliable (Shepherd et al. 2006). A number of problems accompany metal naphthenate formation in the oilfield including deposition of solid calcium naphthenates, stabilized oil-in-water emulsions, formation of tight water-in-oil emulsions, calcium loading in export crude and formation of highly viscous sludge (Hurtevent and Ubbels 2006; Gallup et al. 2002).

Sodium carboxylate soap emulsion

Sodium naphthenate soap emulsions are monovalent salts formed by the reaction of low to medium molecular weight naphthenic acids (C15–C35) with monovalent cations (mainly Na+) (Debord and Srivastava 2009). The abundance of aliphatic long-chain carboxylic acids in sodium carboxylate soap emulsions is related to their distinctively surfactant structure—a long mostly unbranched hydrocarbon chain with a polar head group—which promotes binding to monovalent sodium ion at the interface. Conversely, the hydrophobic segments of higher molecular weight naphthenic acids comprise bulky alicyclic and aromatic groups which reduce their ability to bind monovalent ions while predisposing them to bind to divalent calcium ion (Mapolelo et al. 2009). Hence, carboxylate soaps are strong emulsifiers and partition more into the water phase. Some potassium carboxylate emulsion soaps have occurred in a West African field, but calcium carboxylates are rare (Runham and Smith 2009). From field observations, sodium carboxylate soap problems are associated with higher concentrations of bicarbonate ion because they form tight emulsions which are stabilized by interfacial sodium carboxylate–bicarbonate complexes (Gallup and Curiale 2007; Shepherd et al. 2006). This highly stable emulsion increases fluid viscosity which can reduce production rate (Turner and Smith, 2005). Asphaltenes, incompatible production chemicals like corrosion inhibitors, phosphoric acid scale inhibitors and shear can increase carboxylate soap emulsion stability (Gallup et al. 2002).

Apart from emulsion stabilization, the most notable flow assurance problem associated with sodium carboxylate soaps is the formation of sludge. Sludge formation begins when the amount of the fairly hydrophilic carboxylate soap exceeds its solubility limit (Nichols et al. 2014; Junior et al. 2013). Sludge is a highly viscous, paste-like carboxylate/bicarbonate-stabilized emulsion containing entrained solids such as sand, mineral scale and corrosion products. The inorganic minerals provide additional emulsion stabilization and make the sludge emulsion recalcitrant. In addition, paraffin precipitation enhances the stability of carboxylate soap emulsions. Densely packed carboxylate soap emulsion and sludge can contain large amounts of high-carbon-number paraffin (Shepherd et al. 2012). Serang field sludge was reported to be composed of 70% paraffins and iso-paraffins (C14–C28), 20% (C28–C30) carboxylate salts and < 5% inorganic material (Gallup et al. 2002). Large carboxylic acids with molecular weight up to 700 g/mol have been reported (Pauchard et al. 2009). Serious challenges arise in the field from sludge formation because of reduced storage capacity, restricted flow of petroleum due to constrictions arising from solid loading in subsea lines, risers and in separation vessels especially after treatment, and poor oil/water separation (Turner and Smith 2005).

Calcium naphthenate soap scale

Calcium naphthenate soap scale also referred to as calcium naphthenate soap or organic scales are products of complexation of Ca2+ with high molecular weight naphthenic acids, particularly tetraprotic ARN acids. They have high calcium content of up to 6.2% and naphthenic acid content dominated by ARN acids (Juyal et al. 2015). Even so, significant quantities of lower molecular weight naphthenic acids including acyclic, mono- and bicyclic and alkylbenzoic structures have been identified in field deposits of calcium naphthenate (Mohammed and Sorbie 2009b). In addition, iron and magnesium naphthenates may occur in calcium naphthenate deposits (Runham and Smith 2009). Calcium naphthenates are largely oleophilic and either pass into the oil phase or remain at the oil–water interface; therefore, their interfacial activity is relatively limited (Oliveira et al. 2013; Rosseau et al. 2001). Divalent salts of low molecular weight naphthenic acids may be fairly oil soluble and certainly oil dispersible and cause calcium loading in oil and reduction in oil quality (Lutnaes et al. 2006; Goldszal et al. 2002).

Sundman et al. (2010) have determined that the large quantities of calcium in calcium naphthenate deposits in comparison with other divalent cations naturally occurring in produced water are not simply due to its higher natural abundance alone as earlier thought (Dyer et al. 2003). Rather, the affinity of ARN acids for Ca2+ is largely due to selectivity. This selectivity is probably due to an optimal balance between the ion size and hydration state of calcium cation. For example, low magnesium content relative to calcium is explained by considering the electrostatic shielding of the cations based on their hydration number. Mg2+ with higher hydration number of 6 compared to 2 for Ca2+ experiences greater electrostatic shielding. Therefore, Mg2+ has a lower tendency to complex with ARN and will barely participate in the formation of an interfacial film (Bertelli et al. 2014). In contrast to the weakly soluble coordination compounds formed by Ca2+, Mg2+ tends to form uncoordinated, water-soluble ionic species (Taylor and Hiu 2018). The solubility product of calcium naphthenate is much lower than that of magnesium naphthenate; thus, calcium naphthenate has a greater tendency to exists as a solid precipitate (Simon et al. 2012). Studying BP10, the affinity of tetraacids for metal cations was found to decrease in the order: Ca2+ > Ba2+ ≈ Sr2+ > Mg2+ ≫ Na+ (Sundman et al. 2010). Solid calcium naphthenate (CaN) deposits formed by ARN acids are a result of three-dimensional polymer-like networks in which calcium cations act as cross-linking agents. The highly extended structure of ARN is relevant to its cross-linking behaviour with calcium cations (Lutnaes et al. 2006).

The calcium naphthenate precipitate is sticky and binds particulates in the well stream such as sand, formation fines, mineral scales and iron sulphide (Junior et al. 2013). It is formed at the interface, but with the continuous accumulation of particulates, its density increases and fragmented lumps begin to drop into the water leg (Vindstad et al. 2003). These calcium naphthenate fragments foul the produced water system. The unique property of CaN to harden as it cools makes removal difficult and introduces the additional problem of solid disposal. It had been speculated that this behaviour is as a result of oxidation of the surface of the deposit on exposure to air, but the process is more likely related to the glass transition temperature of the material (Bertelli et al. 2014; Junior et al. 2013). Metal naphthenate removal and disposal comes at a considerable cost in addition to lost production during shutdown period.

Effect of asphaltenes on calcium naphthenate formation

A study by Pauchard et al. (2009) identified asphaltene–naphthenic acid interactions modulated by pH and acid structure as the main factor responsible for changes in interfacial behaviour of naphthenic acids and emulsion stability of a low-TAN crude oil. Asphaltenes are inhibitive to CaN formation. Subramanian et al. (2017) observed that the interfacial film formed by reaction of ARN with calcium was weakened by asphaltenes, resulting in reduction in the dilational elastic modulus of the film. The interfacial competition of asphaltenes with naphthenic acid affects the adsorption–desorption equilibrium and by extension naphthenic acid partitioning. The asphaltene effect is a function of the ionic strength of the aqueous solution. As ionic strength of brine decreases, competitive adsorption between asphaltenes and naphthenic acids at the interface increases due to higher asphaltene adsorption. Thus, asphaltenes take up more interfacial surface area for naphthenic acid adsorption, causing a reduction in naphthenic acid partitioning. Furthermore, the greater saturation of the interface induces interfacial displacement and rearrangements, leading to greater desorption of naphthenic acid from the interface (Moradi et al. 2013). Asphaltenes might also complex ARN in bulk oil, reducing the number of tetraacids available at the interface for complexation with calcium (Subramanian et al. 2017).

Effect of low molecular weight monoacids on calcium naphthenate formation

Brocart and Hurtevent (2008) demonstrated that low molecular weight monoacids are inhibitive to the formation of CaN by the ARN acids via inactivation of polymerization sites on the tetraacid. This occurs through monoacid–tetraacid associations at the interface where the divalent calcium ion complexes a monoacid on one arm and an ARN acid on the other. The association hinders cross-linking of ARN to solid polymer-like material leading to softening of the deposit (Brocart et al. 2007; Nordgård et al. 2012). Subramanian et al. (2017) reported that for a system containing a mixture of monoacids and tetraacid, the dilation elastic modulus decreases as monoacid concentration increases. Crude oil naphthenate risk assessment protocol developed by Passade-boupat et al. (2012) recognizes the inhibitive effect of low molecular weight naphthenic acid on ARN. It factors the ratio of ARN to total naphthenic acid content and the average partition coefficient of the naphthenic acid based on the equilibrium change in pH of the biphasic system. Furthermore, the release of protons by the deprotonated naphthenic acids has an inhibitive effect on the dissociation of more naphthenic acids. However, bicarbonate buffering of brine may offset this effect.

Drivers of metal naphthenate formation

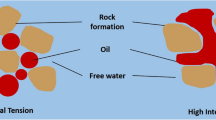

Metal naphthenate formation is directed by several factors which can be physical parameters related to process conditions such as pressure, temperature, shear, water cut and electrostatic field or chemical parameters, which are related to the chemistry of the reservoir fluids, such as naphthenic acid composition of oil, pH, bicarbonate content and ionic strength of brine.

Physical parameters

Pressure

The pressure of produced fluid decreases progressively from the formation to the separator. Depressurization leads to loss of dissolved CO2 and increase in pH (Rosseau et al. 2001). The rate of dissociation of naphthenic acid increases with the increase in pH, leading to the precipitation of metal naphthenates. The effect of pressure on metal naphthenate formation is not limited to pH control. It also indirectly influences more complex interfacial interactions of naphthenic acids and asphaltenes, as the loss of hydrocarbon light ends which accompanies depressurization affects asphaltene stability.

Temperature

Elevation in temperature increases the formation of calcium naphthenate (Dyer et al. 2006). This effect is directly related to the impact of temperature increase on partitioning of naphthenic acids. It was reported that the partition ratio of a model naphthenic acid approached unity with increase in temperature (Celesie et al. 2016). As partitioning increases, the amount of dissociated acid increases resulting in increase in the rate of reaction. However, the kinetics of calcium naphthenate soap scale formation and sodium carboxylate soap emulsion formation respond differently to change in temperature (Shepherd et al. 2012).

Water cut

Influence of water cut on metal naphthenate formation and brine pH is shown in Fig. 8. Metal naphthenate formation is usually at its peak between 25 and 50% water cut. It attains a plateau at about 50–60% water cut, after which it begins to decline (Mohammed and Sorbie 2010; Turner and Smith 2005). This decline tends to occur near the emulsion inversion point. For such fields in decline, reduction in water cut causes a re-emergence of metal naphthenate problem. Fields experiencing mainly carboxylate soap emulsion problems do not experience this decline in metal naphthenate formation near the inversion point but continue to experience the problem at up to 90% water cut and above (Runham and Smith 2009).

Influence of water cut on amount of calcium naphthenate precipitate and brine pH (Mohammed and Sorbie 2010)

Shear

The increase in shear creates smaller droplets and increases surface area for contact between cations in brine and naphthenic acids in the oil so that the rate of metal naphthenate formation increases (Runham and Smith 2009).

Electrostatic field

Electrostatic fields increase the rate of reaction and agglomeration of carboxylate soaps with attendant increase in the thickness of emulsion pads, solid concentration at the oil–water interface and water content of crude (Turner and Smith 2005).

Chemical parameters

pH

The pH of produced water is a crucial factor in CaN formation. Metal naphthenate formation increases with increasing pH. This is due to increase in dissociation rate of naphthenic acid. However, the increase in dissociation rate is not monotonic, but increases sharply at the point where pH of brine equals the pKa of the dominant naphthenic acid (Bertelli et al. 2014). Even at low calcium concentration in water, CaN formation can still occur substantially if pH is high (> 8) (Igwebueze et al. 2013). From field observation, the critical pH for metal naphthenate formation is between of 5.9 and 6.3 (Runham and Smith 2009).

Ionic strength

Ionic strength (metal concentration) of brine directly impacts the kinetics of naphthenic acid partitioning in an oil–water system. The increase in the ionic strength of brine causes greater partitioning of naphthenic acid into the aqueous phase and consequently increases the rate of metal naphthenate formation (Havre et al. 2002). However, the partitioning of naphthenic acids may not necessarily increase proportionately with ionic strength because it is a dynamic time-dependent process subject to the influence of other indigenous amphiphiles in crude oil especially asphaltenes. The effect of ionic strength on interfacial interaction of asphaltenes and naphthenes has been discussed.

Bicarbonate content

High bicarbonate content of brine increases CaN formation. This effect is related to the emulsion stabilization ability of bicarbonate. In a field simulation test, it was observed that despite relatively low pH, CaN formation increased due to the increase in bicarbonate concentration (Nichols et al. 2014). This means that calcium naphthenate may precipitate at untypically low pH values if bicarbonate content (and calcium content) of the brine is high. The low-level dissociation of tetraacid at low pH is sufficient to produce calcium naphthenate deposition due to the emulsion stabilizing effect of bicarbonate. Bicarbonate content of oil may increase by commingling of fluid or can be contributed by residual CO2 in the separator (Nichols et al. 2014).

Naphthenic acid content

Generally, high acid content in oil is associated with CaN formation. Therefore, broadly speaking, calcium naphthenate formation increases with the increase in the concentration of naphthenic acid in the oil phase (Hanneseth et al. 2006). However, no correlation has been established between oil TAN and rate of metal naphthenate formation. Lower-TAN crude may present a higher risk of calcium naphthenate formation than one of higher TAN (Nichols et al. 2014). A more informative index for assessing the calcium naphthenate formation risk is the ratio of ARN acid content to total acid content. Higher ARN acid content relative to non-ARN acids in the oil will favour CaN formation.

Metal naphthenate mitigation

Process control

Process control and chemical control are the main approaches to mitigating metal naphthenates formation. Change in operational conditions such as pressure and temperature can be employed as metal naphthenate mitigation measures (Rosseau et al. 2001). Process design as a method of metal naphthenate mitigation adopts design philosophies such as high-pressure processing, wash tanks and split production which exploit the drivers of metal naphthenate formation. An understanding of the drivers of metal naphthenate formation provides the impetus for non-conventional facilities design or changes/modifications to the characteristic design of the components of process equipment including the material, shape, size and features of individual parts. This is discussed in detail elsewhere (Runham and Smith 2009).

Process control must be optimized to maximize naphthenate inhibition without compromising on quality and production parameters such as crude dehydration and well flow rate (Runham and Smith 2009). Identifying the potential for calcium naphthenate problem at the early stages of field development is key to effective process control, as it enables the inclusion of mitigation measures into the design concept, which is more effective and seamless than having to re-optimize operation parameters of an existing production process or to modify existing facilities design (Turner and Smith 2005). Process control strategies for metal naphthenate formation are tailored to the nature of the soap formed. However, process control rarely ever results in satisfactory mitigation due to operational limitations. Therefore, sustained control of naphthenate formation throughout the life of a field requires the development of chemical control solutions complemented by process control (Oliveira et al. 2013).

Chemical inhibition of metal naphthenate formation

Acid inhibitors

Metal naphthenate inhibitors can be broadly classified as acid and non-acid inhibitors. Traditionally, metal naphthenate inhibition is accomplished in the oilfield by the addition of organic acids like acetic acid and the use of sequestering agents which complex the metal ions in produced water or by neutralization of naphthenic acids in oil (Nordgård et al. 2010). Copious chemical injection is usually required to achieve success using any of these methods. Though acetic acid is by far the most common, other organic acids including formic acid, citric acid, glycolic acid, sulphonic acid, myristic acid and lauric acid have been applied in the field (Nichols et al. 2014; Gallup and Curiale 2007; Vindstad et al. 2003; Gallup et al. 2002). More aggressive options such as phosphoric acid or hydrochloric acid injection have been adopted in cases where organic acids gave unsatisfactory results (Nichols et al. 2014; Vindstad et al. 2003; Gallup et al. 2005). Blends of acetic acid and demuslifier are some of the most commonly used chemical formulations for metal naphthenate inhibition (Runham and Smith 2009). HCl–phosphoric acid blends have also been used in treatment of carboxylate soap emulsions (Gallup et al. 2002). However, phosphoric acid may be incompatible with produced water, while HCl has been reported to cause poor oil dehydration (Vindstad et al. 2003).

Generally acid inhibitors work by reducing the pH of the aqueous phase, thereby suppressing the dissociation of naphthenic acids at the interface. Large quantities of acetic acid are often required for successful inhibition because a significant portion of the acid is used to overcome bicarbonate buffering in the brine (Bretherton et al. 2005; Gallup and star 2004). For instance, a platform was reported to inject, on average, 3000 l of acetic acid per day for control of metal naphthenate formation (Debord and Srivastava 2009). Therefore, cost, logistics and storage are important considerations, especially offshore and even more so when sodium carboxylate soaps are involved (Melvin et al. 2008). More importantly, low-dose acetic acid injection can increase the corrosion rate of process equipment even for inhibited systems (Nordgård et al. 2010; Bretherton et al. 2005) and in some cases may be counterproductive, especially if the pH is lowered to below 6 (Brocart and Hurtevent 2008 Melvin et al. (2008). While acetic acid offers the advantage of being able to dissolve already formed calcium naphthenate deposits, it should be used circumspectly in the oilfield due to its potential to also corrode gas-side facilities, destabilize asphaltenes and encourage the proliferation of sulphate reducing bacteria (Junior et al. 2013; Oliveira et al. 2013; Turner and Smith 2005). The ultimate goal is to totally eliminate the use of acids in metal naphthenate inhibition formulations and replace them with surfactant inhibitors, as has been exemplified in the success stories of two West African oilfields where metal naphthenate formation has been effectively mitigated using only low-dose surfactant inhibitors (Igwebueze et al. 2013; Hurtevent and Ubbels 2006).

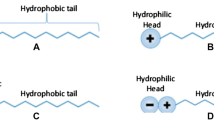

Surfactant inhibitors

Non-acid naphthenate inhibitors are monomeric or polymeric surfactants. They can be water or oil soluble and usually act at much lower dosages than acids by interacting with naphthenic acids at the oil–water interface. They are quick-acting, but their effect wanes with time (Nordgård et al. 2010). Ideally, a metal naphthenate inhibitor should simultaneously inhibit metal naphthenate formation and destabilize emulsions without need for pH adjustment (Vindstad et al. 2003; Debord and Srivastava 2009; Bretherton et al. 2005). However, depending on its chemistry, a naphthenate inhibitor can have no effect on crude oil water content or influence it in either direction. The hydrophile–lipophile balance of a naphthenate inhibitor is critical to its effect on water content of oil. A hydrocarbon portion consisting of a hydrotrope is favourable for better oil dehydration because, being relatively poor aggregators, they will rarely form emulsions compared to compounds with straight-chain aliphatic hydrocarbon tails. Figure 9 shows some generic naphthenate inhibitors: sulphosuccinate (1); diphosphate ester (2); and an amino phosphonate (3). The ‘R’ group may be any of alkyl, aryl, alky/aryl blends or oxyalkylenes, offering a wide variety of possible structures (Ubbels 2005). In many field cases, naphthenate inhibitor packages consists of an acid/naphthenate inhibitor/demulsifier blend or a naphthenate inhibitor/demulsifier blend (Vindstad et al. 2003; Debord and Srivastava 2009; Gallup and Star 2004; Melvin et al. 2008). A formulation composed of a naphthenate inhibitor and a demulsifier was used to successfully break naphthenate-stabilized emulsions and prevent the formation of sludge without the need for acid injection (Hurtevent and Ubbels 2006). Also, a low-dose naphthenate inhibitor effectively inhibited CaN formation in a Nigerian offshore field without any negative effect on water content (Igwebueze et al. 2013).

Optimized naphthenate inhibitor packages and treat rates are field specific and vary with time in a given field as variables such as water cut and brine composition change in the course of production, such that re-optimization is necessary from time to time (Nichols et al. 2014; Melvin et al. 2008). Treat rates from 9 ppm to as high as 600 ppm have been reported in the field (Igwebueze et al. 2013; Shepherd et al. 2006). In most cases, naphthenate inhibitors are effective at low doses and could be counterproductive if they are in excess, promoting naphthenate formation (Nordgård et al. 2010; Bertelli et al. 2014). It is speculated that naphthenate inhibitors may exhibit selectivity in inhibition of naphthenic acid depending on the acid molecular weight. This selective inhibition may result in change in the composition, texture and behaviour of calcium naphthenates formed post-treatment (Shepherd et al. 2006). Therefore, naphthenate inhibitor packages should be robust. Figure 10 presents the chemical structure of some naphthenate inhibitors, showing monomeric dodecylbenzene sulphonic acid (1), as well as copolymeric and terpolymeric members (Vijn 2015). The polymers, composed of 2-ethylhexylacrylate (EHA), 2-acrylamido-2-methyl-1-propane sulphonic acid (AMPS), hydroxyethylmethacrylate (HEMA) and styrene, include: poly(EHA-co-AMPS) (2); poly(EHA-co-styrene-co-AMPS) (3); and poly(EHA-co-HEMA-co-AMPS) (4).

Naphthenate inhibitors do not totally prevent the formation of metal naphthenates rather they slow down the kinetics of the process (Nichols et al. 2014). Also they are usually not capable of removing already formed calcium naphthenate deposits (Vindstad et al. 2003). Therefore, inhibitors should be injected before significant degassing and as far upstream as practically possible to the point of metal naphthenate formation.

Mechanism of chemical inhibition of metal naphthenates

Metal naphthenate formation may be chemically inhibited via interfacial crowding, solubilization of ARN acids in the bulk phase, surfactant–reactant interactions and surfactant–particle interactions. Metal naphthenate inhibition is mainly via interfacial crowding where the interface-active inhibitor self-assembles at the oil–water interface and hinders contact between the tetraacids and the metal cation. Interfacial dilution is the principle for metal naphthenate inhibition by interfacial crowding. Here the inhibitor or its complex is at least as interfacially active as the naphthenic acid (Bertelli et al. 2014). The inhibitor molecules interspersed between the naphthenic acid monomers increase the lateral distance between dissociated acid monomers. Thus, there is need for interfacial rearrangement of naphthenate anion for the completion of the reaction with Ca2+. In essence, the naphthenate inhibitor blocks the 2:1 complexation of ARN with calcium ion. 1:1 reaction of ARN acid and divalent calcium ion does not allow for the formation of sticky polymeric naphthenate deposit (Hurtevent and Ubbels 2006). The overall effect is a decrease in the rate of metal naphthenate formation (Hanneseth et al. 2006).

Naphthenate inhibitors may also contribute to the stability of the bilayer conformation of ARN at the interface, where a pair of the carboxylic groups are directed to the aqueous phase and the other pair to the oil phase. The naphthenate inhibitor complexes and entraps the two carboxylic acid groups of ARN that are directed to the oil phase, making them unavailable for complexation with calcium cation (Nordgård et al. 2010). The bilayer conformation is also favourable to inhibitor activity as the interfacial area occupied by the tetraacid is reduced by half, creating more space for greater inhibitor packing, resulting in greater depression of the interfacial tension.

While it is usually expected that a naphthenate inhibitor should have greater interface activity than the naphthenic acid, an inhibitor that is less interfacially active than the tetraacids will still be effective if the complex formed by the tetraacid and the inhibitor is more interfacially active than the ARN acid (Nordgård et al. 2010). On the other hand, an increase in the interfacial tension on additization does not necessarily suggest inactivity. Rather, it might indicate that the inhibitor adopts a different mechanism involving either solubilization of the tetraacid in the oil phase, hence reducing its (tetraacid) concentration at the interface or complexation of the acid in the bulk or at the interface, thereby inactivating it towards complexation with calcium ions (Bertelli et al. 2014). However, an inhibitor that exhibits poor interfacial activity will likely be ineffective if there is no significant change in its interfacial properties in the presence of tetraacids.

The differing effect of inhibitors on the interfacial tension is as a result of their effect on monomer–dimer equilibrium of the tetraacid. ARN monomers are interfacially active, but the dimers are not. If an inhibitor in the oil phase breaks up ARN dimers, equilibrium position is shifted towards the monomer and the interaction between ARN acids and the inhibitor will likely result in a decrease in interfacial tension. Thus, the inhibitor exhibits a mechanism dominated by interfacial crowding. Conversely, an inhibitor that promotes ARN dimer formation will act more by dissolving the ARN acids in the bulk oil (Nordgård et al. 2010). Optical density studies have shown that surfactant inhibitors can effectively reduce the size of calcium naphthenate particles by promoting disintegration and/or dispersion of solid calcium naphthenate into smaller aggregates, thereby counteracting the agglomeration process (Nordgård et al. 2012).

Inhibitor screening and management of compatibility issues

A calcium naphthenate inhibitor may not completely prevent calcium naphthenate formation but must be able to significantly reduce the deposition of solid on process equipment, improve oil–water separation process without imparting negatively on the quality of the oil and also be environmentally friendly. In selecting a calcium naphthenate inhibitor, it must also be proved that it is compatible with the existing portfolio of production chemicals (Igwebueze et al. 2013). Hence, laboratory screening of naphthenate inhibitors is necessary not only to ascertain the efficiency of the product but to estimate the dosage for field tests and evaluate its compatibility with other production chemicals such as corrosion inhibitors and scale inhibitors. Bottle test remains a popular method for screening of naphthenate inhibitors, but there are several other methods including interfacial shear/dilational rheometry, pendant drop tensiometry, gravimetry, Langmuir balance technique, light-scattering near-infrared spectroscopy and dynamic flow tests (Subramanian et al. 2017; Debord and Srivastava 2009; Hanneseth et al. 2006; Havre 2004; Brandal et al. 2004, 2006; Rosseau et al. 2001).

In addition to eliminating or reducing solid precipitation at the interface, the impact of the inhibitor on demulsification efficiency is an important performance index (Nichols et al. 2014; Goldszal et al. 2002). Small amount of minerals in naphthenates can lead to mixed scale deposition. Therefore, to prevent emulsion stabilization and solid deposition in the oilfield, it is often necessary to simultaneously counteract emulsion stabilization, inhibit the formation of mineral scale and disperse naphthenate from the interface (Moreira and Teixeira 2009; Goldszal et al. 2002).

Compatibility issues often arise between mineral scale inhibitors and metal naphthenate inhibitors. Scale inhibitors are ineffective against metal naphthenates and, except a few such as sulphonates, are mostly incompatible with acidic crude oil, often causing calcium loading and high water content in oil (Goldszal et al. 2002; Pogessi et al. 2002). Choice of solvent is an important consideration in the development of inhibitor formulations. A useful approach for effective metal naphthenate inhibition, devoid of problems arising from chemical incompatibility, is to develop synergistic and fully compatible single solvent blend of surfactants for simultaneous naphthenate inhibition, demulsification and mineral scale inhibition (Goldszal et al. 2002; Pogessi et al. 2002).

Conclusion

The formation of metal naphthenates in the oilfield by reaction of naphthenic acids in oil and metal cations in brine is a rapid and disruptive process that can only be effectively managed by proactive action. Tetraprotic ARN acids are the main culprits in formation of insoluble calcium naphthenate deposits. Knowledge of the physical drivers of metal naphthenate formation can be exploited to develop mitigative measures for a particular field. However, operating the production process under physical conditions unfavourable to naphthenate formation, as a method of naphthenate control, gives limited results and is difficult to achieve especially when the naphthenate problem is not discovered before facilities design. The conventional method of inhibiting metal naphthenates by injection of organic acids has costly consequences, making non-acid inhibitors an appealing option. Non-acid inhibitors are oil- or water-soluble surfactants, which can be monomeric or polymeric and are able to interact with naphthenic acids and naphthenate particles via a number of inhibitive mechanisms. Use of surfactant inhibitors for oilfield naphthenate control is advantageous because the additives are effective at low doses and hold the potential of totally eliminating the need for pH adjustment using acids. Use of low-dose surfactants alone as metal naphthenate inhibitors is ideal and feasible. However, for it to become the convention, work remains to be done in the development of more specialized surfactants for metal naphthenate inhibition and elucidating surfactant structure–activity relationships for improved inhibitor design.

References

Bai J, Fan W, Nan G, Li S, Yu B (2010) Influence of interaction between heavy oil components and petroleum sulfonate on the oil-water interfacial tension. J Dispers Sci Technol 31(4):551–556

Baugh TD, Grande KV, Mediaas H, Vindstad JE, Wolf NO (2005) The discovery of high molecular-weight naphthenic acids (ARN acid) responsible for calcium naphthenate deposits, SPE 93011. In: SPE international symposium on Oilfield scale, Aberdeen

Bertelli JN, Rocío MM, Renata VP, Albuquerque FC, Lucas EF (2014) Shear rheology using De Nouy ring to evaluate formation and inhibition of calcium naphthenate at the water/oil interface. Energy Fuels 28:1726–1735

Bertheussen A, Simon SC, Sjoblom J (2018) Equilibrium partitioning of naphthenic acid mixture part 2: crude oil extracted naphthenic acids. Energy Fuels 32(9):9142–9158

Brandal Ø, Sjöblom J (2005) Interfacial behavior of naphthenic acids and multivalent cations in systems with oil and water. II: formation and stability of metal naphthenate films at oil-water interfaces. J Dispers Sci Technol 26(1):53–58

Brandal Ø, Sjöblom J, Øye G (2004) Interfacial behavior of naphthenic acids and multivalent cations in systems with oil and water. I. A pendant drop study of interactions between n-dodecyl benzoic acid and divalent cations. J Dispers Sci Technol 25(3):67–374

Brandal Ø, Hanneseth AD, Hemmingsen PV, Sjöblom J, Kim S, Rodgers RP, Marshall AG (2006) Isolation and characterization of naphthenic acids from a metal naphthenate deposit: molecular properties at oil-water and air–water interfaces. J Dispers Sci Technol 27(3):295–305

Bretherton N, Smith R, Keilty G, Ubbels S (2005) Naphthenate control: is acetic acid injection the answer? SPE 95115. In: International symposium on Oilfield corrosion, Aberdeen

Brocart B, Hurtevent C (2008) Flow assurance issues and control with naphthenic oils. J Dispers Sci Technol 29(10):1496–1504

Brocart B, Bourrel M, Hurtevent C, Volle J, Escoffier B (2007) ARN-type naphthenic acids in crudes: analytical detection and physical properties. J Dispers Sci Technol 28(3):331–337

Celesie A, Parnis JM, Mackay D (2016) Impact of temperature, pH and salinity changes on the physico-chemical properties of model naphthenic acids. Chemosphere 146:40–50

Chakravarthy R, Naik GN, Savalia A, Sridharan U, Saravanan C, Das AK, Gudasi KB (2016) Determination of naphthenic acid number in petroleum crude oils and their fractions by mid-FTIR spectroscopy. Energy Fuels 30(10):8579–8586

Clemente JS, Fedorak PM (2004) Evaluation of the analyses of tert-butyldimethylsilyl derivatives of naphthenic acids by gas chromatography–electron impact mass spectrometry. J Chromatogr A 1047:117–128

Debord J, Srivastava P (2009) Development and field application of a novel non-acid calcium naphthenate inhibitor. SPE 123660. In: SPE annual technical conference and exhibition, Louisiana

Dohkholyan BK, Magomedov AK (1984) Effect of sodium naphthenate on survival and some physiological-biochemical parameters of some fishes. J Ichthyol 23:125–132

Dyer SJ, Graham GM, Arnott C (2003) Naphthenate scale formation—molecular control in idealised systems. SPE 80395. In: SPE 5th international symposium on Oilfield scale, Aberdeen

Dyer SJ, Williams HL, Graham GM, Cummine C, Melvin KB, Haider F, Gabb AE (2006) Simulating calcium naphthenate formation and mitigation under laboratory conditions. SPE 100632. In: SPE Oilfield scale symposium, Aberdeen

Dzidic I, Somerville AC, Raia JC, Hart HV (1988) Determination of naphthenic acids in california crudes and refinery wastewaters by fluoride ion chemical ionization spectrometry. Anal Chem 60(13):1318–1322

Fan T (1991) Characterization of naphthenic acids in petroleum by fast atom bombardment mass spectrometry. Energy Fuels 5:371–375

Gabryelski W, Froese KL (2003) Characterization of naphthenic acids by electrospray ionization high-field asymmetric waveform ion mobility spectrometry mass spectrometry. Anal Chem 75:4612–4623

Gallup DL, Curiale JA (2007) Characterization of sodium emulsion soaps formed from production fluids of Kutel Basin, Indonesia. Energy Fuels 21:1741–1759

Gallup DL, Star J (2004) Soap sluges: aggravating factors and mitigation measures. SPE 87471. In: 6th International symposium on Oilfield scale, Aberdeen

Gallup DL, Smith PC, Chipponeri J, Abuyazid A, Mulyono D (2002) Formation & mitigation of “metallic soap” sludge, Attaka, Idonesia field. SPE 73960. In: SPE international conference on health and safety and environment in oil and gas exploration and product, Kuala Lumpur

Gallup DL, Smith PC, Star JF, Hamilton S (2005) West Seno deepwater development case history—production chemistry. SPE 92696. In: International symposium on Oilfield chemistry, Texas

Goldszal A, Hurtevent C, Rousseau G (2002) Scale and naphthenate inhibition in deep offshore fields. SPE 74661. In: SPE Oilfield scale symposium, Aberdeen

Hanneseth AD, Brandal Ø, Sjöblom J (2006) Formation, growth, and inhibition of calcium naphthenate particles in oil/water systems as monitored by means of near infrared spectroscopy. J Dispers Sci Technol 27(2):185–192

Haoa C, Headley JV, Peru KM, Frank R, Yang P, Solomon KR (2005) Characterization and pattern recognition of oil–sand naphthenic acids using comprehensive two dimensional gas chromatography/time-of-flight mass spectrometry. J Chromatogr A 1067:277–284

Havre TE (2004) Near-IR spectroscopy as a method for studying the formation of calcium naphthenate. Colloid Polym Sci 282:270–279

Havre TE, Ese M, Sjöblom J, Blokhus AM (2002) Langmuir films of naphthenic acids at different pH and electrolyte concentrations. Colloid Polym Sci 280:647–652

Havre TE, Sjöblom J, Vindstad JE (2003) Oil/water-partitioning and interfacial behavior of naphthenic acids. J Dispers Sci Technol 24(6):789–801

Holowenko FM, Mackinnom MD, Fedorak PM (2002) Characterization of naphthenic acids in oil sands wastewaters by gas chromatography–mass spectrometry. Water Res 36:2843–2855

Hsu CS, Dechert GJ, Robbins WK, Fukuda EK (2000) Naphthenic acids in crude oils characterized by mass spectrometry. Energy Fuels 14:217–223

Hurtevent C, Ubbels S (2006) Preventing naphthenate stabilised emulsions and naphthenate deposits on fields producing acidic crude oils. SPE 100430. In: SPE International Oilfield scale symposium, Aberdeen

Igwebueze C, Oduola L, Smith O, Vijn P, Shepherd AG (2013) Calcium naphthenate solid deposit identification and control in offshore Nigerian fields. SPE 164055. In: SPE international symposium on Oilfield chemistry, Texas

Jones DM, Watson JS, Meredith W, Chen M, Bennett B (2001) Determination of naphthenic acids in crude oils using nonaqueous ion exchange solid-phase extraction. Anal Chem 73:703–707

Junior J, Borges L, Carmelino C, Hango P, Milliken JD, Asomaning S (2013) Calcium naphthenate mitigation at Sonangol’s Gimboa field. SPE 164069. In: SPE international symposium on Oilfied chemistry, Texas

Juyal P, Mapolelo MM, Yen A, Rodgers RP, Allenson SJ (2015) Identification of calcium naphthenate deposition in South American oil fields. Energy Fuels 29:2342–2350

Kamaluddin M, Zwiazek JJ (2002) Naphthenic acids inhibit root water transport, gas exchange and leaf growth in Aspen (Populus tremuloides) seedlings. Tree Physiol 22:1265–1270

Lutnaes BF, Brandal Ø, Sjoblom J, Krane J (2006) Archaeal C80 isoprenoid tetraacids responsible for naphthenate deposition in crude oil processing. Org Biomol Chem 4:616–620

Lutnaes BF, Krane J, Smith BE, Rowland SJ (2007) Structure elucidation of C80, C81 and C82 isoprenoid tetraacids responsible for naphthenate deposition in crude oil production. Org Biomol Chem 5:1873–1877

Mapolelo MM, Stanford LA, Rodgers RP, Yen AT, Debord JD, Asomaning S, Marshall AG (2009) Chemical speciation of calcium and sodium naphthenate deposits by electrospray ionization FT-ICR mass spectrometry. Energy Fuels 23:349–355

Melvin K, Cummine C, Youles J, Williams HL, Graham GM, Dyer SJ (2008) Optimising calcium naphthenate control in the Blake field. SPE 114123. In: SPE international scale conference, Aberdeen

Meredith W, Kelland SJ, Jones DM (2000) Influence of biodegradation on crude oil acidity and carboxylic acid composition. Org Geochem 31:1059–1073

Mohammed MA, Sorbie KS (2009a) Naphthenic acid extraction and characterization from naphthenate field deposits and crude oils using ESMS and APCI-MS. Colloids Surf A: Physicochem Eng Asp 349:1–18

Mohammed MA, Sorbie KS (2009b) Spectroscopic determination of naphthenic acid composition from various calcium naphthenate field deposits. SPE 121633. In: SPE international symposium on Oilfield chemistry, Texas

Mohammed MA, Sorbie KS (2010) Thermodynamic modelling of calcium naphthenate formation: model predictions and experimental results. Colloids Surf A: Physicochem Eng Asp 369(1–3):1–10

Mohammed MA, Sorbie KS, Shepherd AG (2009) Thermodynamic modeling of naphthenate formation and related pH change experiments. SPE Product Oper 24:466–472

Moradi M, Topchiy E, Lehmann TE, Alvarado V (2013) Impact of ionic strength on partitioning of naphthenic acids in water–crude oil systems—determination through high-field NMR spectroscopy. Fuel 112:236–248

Moreira APD, Teixeira AMRF (2009) An investigation on the formation of calcium naphthenate from commercial naphthenic acid solutions by thermogravimetric analysis. Braz J Petrol Gas 3(2):51–56

Nichols DA, Rosario FF, Bezerra MCM, Gorringe SE, Williams HL, Graham GM (2014) Calcium naphthenates in complex production systems—evaluation and chemical inhibition challenges. SPE-169756-MS. In: SPE international Oilfield scale conference and exhibition, Aberdeen

Nordgård E, Sjoblom J (2008) Model compounds for asphaltenes and C-80 isoprenoid tetraacids, part 1: synthesis and interfacial activities. J Dispers Sci Technol 29(8):1114–1122

Nordgård EL, Hanneseth AD, Sjöblom J (2010) Inhibition of calcium naphthenate. Experimental methods to study the effect of commercially available naphthenate inhibitors. J Dispers Sci Technol 31(5):668–675

Nordgård EL, Ahmad J, Simon S, Sjöblom J (2012) Oil–water partitioning of a synthetic tetracarboxylic acid as a function of pH. J Dispers Sci Technol 33(6):871–880

Oliveira MCK, Rosario FF, Bertelli JN, Pereira RCL, Albuquerque FC, Marques LCC (2013) Flow assurance solutions to mitigate naphthenates problems in crude oil production. SPE 166235. In: SPE annual technical conference and exhibition, Louisiana

Passade-Boupat N, Gonzalez MR, Brocart B, Hurtevent C, Palermo T (2012) Risk assessment of calcium naphthenates and separation mechanism of acidic crude oil. SPE 155229. In: SPE international conference and exhibition on oilfield scale, Aberdeen

Pauchard V, Sjöblom J, Kokal S, Bouriat P, Dicharry C, Muller H, Al-Hajji A (2009) Role of naphthenic acids in emulsion tightness for a low-total-acid-number (TAN)/high asphaltenes oil. Energy Fuels 23:1269–1279

Pogessi G, Hurtevent C, Buchart D (2002) Multifunctional chemicals for West African deep offshore fields. SPE 74649. In: SPE Oilfield scale symposium, Aberdeen

Rosseau G, Zhou H, Hurtevent C (2001) Calcium carbonate and naphthenate mixed scale in deep offshore fields. SPE 68307. In: SPE 3rd international symposium on Oilfield scale, Aberdeen

Runham G, Smith C (2009) Successful naphthenate scale and soap emulsion management. SPE 121522. In: SPE international symposium on Oilfield chemistry, Texas

Saab J, Mokbel I, Razzouk AC, Ainous N, Zydowicz N, Jose J (2005) Quantitative extraction procedure of naphthenic acids contained in crude oils. Characterization with different spectroscopic methods. Energy Fuels 19:525–531

Shepherd AG, Thomson GB, Westacott R, Sorbie KS, Turner M, Smith PC (2006) Analysis of organic field deposit: new types of calcium naphthenate scale or the effect of chemical treatment? SPE 100517. In: SPE international Oilfield scale symposium, Aberdeen

Shepherd AG, Dijk M, Koot W, Dubey S, Poteau S, Zabaras G, Grutters M (2012) Flow assurance in oil systems: on the role of naphthenic acids. SPE 157295. In: SPE international production and operations conference and exhibition, Qatar

Simon S, Nordgård E, Bruheim P, Sjoblom J (2008) Determination of C80 tetra-acid content in calcium naphthenate deposits. J Chromatogr A 1200:136–143

Simon S, Reisen C, Bersås A, Sjöblom J (2012) Reaction between tetrameric acids and Ca2+ in oil/water system. Ind Eng Chem Res 51:5669–5676

Sjöblom J, Simon S, Xu Z (2014) The chemistry of tetrameric acids in petroleum. Adv Colloid Interface Sci 205:319–338

Smith BE, Sutton PA, Lewis CA, Dunsmore B, Fowler G, Krane J, Lutnaes BF, Brandal Ø, Sjoblom J, Rowland SJ (2007) Analysis of ARN naphthenic acids by high temperature gas chromatography and high performance liquid chromatography. Sep Sci 30:375–380

Sorbie KS, Shepherd A, Smith PC, Turner M, Westacott RE (2005) Naphthenate formation in oil production: general theories and field observations. In: Chemistry in the oil industry IX, pp 289–350

Subramanian S, Simon S, Sjöblom J (2017) Interfacial dilational rheology properties of films formed at the oil/water interface by reaction between tetrameric acid and calcium ion. J Dispers Sci Technol 38(8):1110–1116

Sundman O, Simon S, Nordgård EL, Sjöblom J (2010) Study of the aqueous chemical interactions between a synthetictetra-acid and divalent cations as a model for the formation of metal naphthenate deposits. Energy Fuels 24:6054–6060

Taylor SE, Hiu TC (2018) Metal ion interactions with crude oil components: specificity of Ca2+ binding to naphthenic acid at an oil/water. Colloids Interfaces 2(40):1–21

Turnbull A, Slavcheva E, Shone B (1998) Factors controlling naphthenic acid corrosion. In: Corrossion/98, California

Turner MS, Smith PC (2005) Controls on soap scale formation, including naphthenate soaps—drivers and mitigation. SPE 94339. In: International conference on Oilfield scale, Aberdeen

Ubbels SJ (2005) Method for inhibiting naphthenate salt precipitates and naphthenate-stabilised emulsions, US patent US 777693082

Vijn JP (2015) Low dosage polymeric naphthenate inhibitors, European Patent Specification, EP 2705113 B1

Vindstad JE, Bye AS, Grande KV, Hustad BM, Hustvedt E, Nerdard B (2003) Fighting naphthenate deposition at the Heidrun field. SPE 80375. In: 5th international symposium on Oilfield scale, Aberdeen

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Eke, W.I., Victor-Oji, C. & Akaranta, O. Oilfield metal naphthenate formation and mitigation measures: a review. J Petrol Explor Prod Technol 10, 805–819 (2020). https://doi.org/10.1007/s13202-019-00797-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-019-00797-0