Abstract

Oil industry suffers from flow assurance problems that occur both in upstream and downstream operations. One of the common flow assurance issues arises from precipitation and deposition of asphaltenes in various locations along the oil production path including near wellbore region in the reservoir, production tubing, flowlines and separation unit at the surface. Asphaltene particles precipitate out of oil continuum due to changes in temperature, pressure or composition. Such changes in operating conditions occur during different recovery processes (natural depletion, gas injection, chemical injection, etc.) as well as production and blending of different oils during transportation. There are different experimental methodologies documented in the literature that describe how to determine onset of asphaltene precipitation. In this paper, a comprehensive review is performed on all the available procedures to measure onset of asphaltene precipitation. The advantages and limitations associated with all these methods are also documented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Because of the complex nature of oil mixture, its elemental examination is difficult. One of the best approaches to describe an oil mixture is SARA separation which is an analytical approach to categorize oil into four fractions based on their polarity as saturates, aromatics, resins and asphaltenes (Aske et al. 2001; Aske 2002; Fan and Buckley 2002; Goel et al. 2017). Asphaltene is the polyaromatic fraction of the crude oil with a wide range for molecular mass reported in the literature, to name a few, from 700 to 40,000 (Ratovskaya 1968), 1000–50,000 g/mol (Ali and Al-Ghannam 1981), 3200 ± 400 g/mol (Acevedo et al. 2005b) and 300–1400 g/mol (Akbarzadeh et al. 2007). However, the latest, and more probable value, was reported by Mullins et al. (2012) to be around 750 g/mol. Another approach to define asphaltenes is through solubility aspects; asphaltene is defined as the fraction of oil which precipitates upon mixing of oil sample with normal alkanes as pentane, hexane and heptane (Andersen 1994; Arya et al. 2015; Mozaffari et al. 2015). It was found that different alkanes (as the precipitants) result in various amounts of asphaltene precipitation for the same oil sample. The lighter precipitant results in greater mass of asphaltene precipitation (Kokal and Sayegh 1995; Hu and Guo 2001). In some publications, asphaltene solubility in aromatic solvents such as toluene and benzene is also considered when “solubility” of the particulates is considered for classification (Speight and Moschopedis 1981; Kawanaka et al. 1991; Browarzik et al. 1999; Speight 2004; Akbarzadeh et al. 2007; Mozaffari et al. 2017). As stated, several classification criteria were proposed in the literature (including molecular mass, molecular structure, solubility, etc.) to define asphaltenes; however, there is no universal and standard definition for this fraction of the crude oil. Another interesting point about structure of asphaltenes is the presence of significant amounts of heteroatoms such as nitrogen, oxygen and sulfur (Speight 2004; Aquino-Olivos et al. 2013; Guzmán et al. 2017). In addition, asphaltenes contain some amounts of metals such as Ni, Fe, and V (Leontaritis 1996; Luo et al. 2010; Maqbool et al. 2011).

Asphaltene precipitation and subsequent deposition in porous medium as well as in the flowlines causes expensive flow assurance issues worldwide. Changes in pressure, temperature and composition of oil may cause asphaltene precipitation and deposition (Leontaritis and Mansoori 1987; Zahedi et al. 2009; Rassamdana et al. 1996; Branco et al. 2001; Mofidi and Edalat 2006; Eskin et al. 2016; Kord et al. 2014). These changes could happen during different in situ recovery processes such as natural depletion, gas injection, and chemical flooding as well as during production and transportation of the produced crude in flowlines (Mansoori 1997; Zanganeh et al. 2012; da Silva Oliveira et al. 2014). Asphaltene precipitation has also been reported during well workover and acidizing operations (Jacobs and Thorne 1986; Kokal and Sayegh 1995).

One of the first steps to prevent asphaltene precipitation is acquiring knowledge about the asphaltenic fluid, and how it behaves under various operating conditions from the thermodynamic point of view. The beginning point of separation of asphaltenes from oil is called onset of asphaltene precipitation. To know how the asphaltenic fluid behaves under varying operating conditions, one may refer to asphaltene phase envelope, APE (Escobedo and Mansoori 1995; Chandio et al. 2015; Mahmoudi and Zare-Reisabadi 2015; Lei et al. 2015). When asphaltene precipitation from reservoir fluid under high pressure and temperature is concerned, APE can provide valuable information on how to avoid asphaltene precipitation by tailoring production conditions. Under isothermal pressure depletion, asphaltenes precipitate when reservoir pressure drops below onset of asphaltene precipitation pressure, which is below the reservoir pressure but most of the times much higher than the saturation pressure of the live reservoir fluid (Fig. 1). As pressure decreases below the onset precipitation pressure, the amount of asphaltene precipitation increases and reaches to its maximum value when pressure approaches the bubble point pressure. As pressure declines below the saturation pressure, solution gas is liberated from the live oil, making it denser. This will cause the already precipitated asphaltenes to dissolve back into the remaining oil phase because of a shift in asphaltene solubility in the denser oil (De Boer et al. 1995; Kokal and Sayegh 1995; Hammami et al. 2000). APE consists of two distinct regions. The first region is the pressure–temperature conditions for asphaltene precipitation above the bubble point, which is called upper boundary of asphaltene precipitation. The second region of precipitation is related to P–T conditions below the bubble point, which is known as lower boundary of asphaltene precipitation (Fig. 1).

Schematic of asphaltene phase envelope (Akbarzadeh et al. 2007)

De Boer et al. (1995) presented an interesting graph in which the difference between the initial pressure and bubble point pressure was plotted versus the reservoir fluid density (Fig. 2). This figure was used to predict the risk of asphaltene precipitation.

Risk of asphaltene precipitation as a function of difference between the initial pressure and bubble point pressure as well as the reservoir fluid density (de Boer et al. 1995)

A review on techniques for determining onset of asphaltene precipitation

There are several experimental methods to measure onset of asphaltene precipitation. Depending on the mechanism triggering asphaltene precipitation, this onset precipitation is attributed to the pressure at which asphaltene particles precipitate out (i.e., onset precipitation pressure) or the concentration of precipitant at which asphaltene precipitation occurs (i.e., onset precipitation concentration). The former terminology is applied when a live oil sample is depressurized, whereas the latter one is used for both live oil and dead oil titration with a precipitant, i.e., the onset point is defined as the threshold amount of precipitant used to titrate a known amount of oil when asphaltene particles precipitate out of the solution. The advantages and limitations of the laboratory techniques are also documented in this section.

Gravimetric method

This method is used to obtain the asphaltene onset pressure (AOP) associated with a live oil sample when it undergoes an isothermal depressurization process in a PVT cell from initial reservoir pressure to a pressure well below the saturation pressure. The live oil sample is transferred from the sample cylinder into the PVT cell at constant reservoir pressure and temperature. Care should be taken for the transfer lines and connections to be heat traced so that sample temperature does not change during charge into the PVT cell. The live oil sample is then conditioned at reservoir temperature and pressure for homogenization. After sample conditioning, it goes through discrete depressurization stages. At the end of each pressure step, the sample is agitated for a fixed duration of time for homogenization. The homogenized sample is then allowed to stabilize at the new pressure and reservoir temperature. A sub-sample is then taken from the top portion of the PVT cell and brought to atmospheric conditions by bleeding off the pressure and liberating the solution gas. Once the dead oil is obtained, it goes through analytical tests such as IP-143 or ASTM D-3279 for asphaltene content measurement. This procedure is continued until reaching the saturation pressure of the live oil sample where solution gas is released upon further depressurizing. At each pressure step below, the saturation pressure, the released solution gas is first removed from the PVT cell, followed by further homogenization of the live oil before sub-sampling for asphaltene content measurement. When upper boundary pressure of asphaltene precipitation at the desired temperature is reached, asphaltenes separate from the oil continuum and concentrate more at the bottom of the PVT cell. The amount of precipitated asphaltenes at the bottom of the cell increases gradually until bubble point pressure. Below the bubble point, gas is liberated from the live oil, hence the remaining oil dissolves back the precipitated asphaltenes; therefore, the asphaltene content of the live oil sample in the PVT cell increases. Using this method, an indicator for asphaltene precipitation is obtained by comparing asphaltene content of sub-samples collected at various pressure steps with the asphaltene content of the original oil sample. This process is schematically shown in Fig. 3. This technique was used by several authors such as Burke et al. (1990), Zendehboudi et al. (2013) and Jamaluddin et al. (2001). The experimental conditions for the study performed by Jamaluddin et al. (2001) are presented in Table 1.

Burke et al. (1990) used gravimetric method to study the effect of temperature and pressure on asphaltene precipitation. They also investigated the effect of mole fraction of precipitant in several oil–precipitant mixtures. The gravimetric method was also used by Zendehboudi et al. (2013) to examine the effect of various precipitant/oil ratios (1–50) for n-pentane and n-heptane on asphaltene precipitation at reservoir conditions for two oil samples.

The asphaltene content of the oil sample versus pressure is depicted in Fig. 4. It is seen that the variation of asphaltene content with pressure is independent of the type of precipitant; however, greater amounts of asphaltene content for each sub-sample were obtained when n-pentane was used as the precipitant. In addition, four distinct trends were observed for the effect of pressure on asphaltene content: the first trend is a constant asphaltene content behavior from reservoir pressure to about 42.75 MPa. The asphaltene content of the sample was then decreased from 42.75 MPa down to 22.24 MPa where the minimum amount of asphaltene content was achieved. Therefore, the upper pressure boundary for asphaltene precipitation and saturation pressure of the sample was obtained at 42.75 MPa and 22.24 MPa, respectively. This observation was independently confirmed with a saturation pressure measurement conducted on the same live oil sample in a CCE test. Upon further depressurization of the sample below the bubble point pressure, the asphaltene content increased which is an expected trend until reaching the lower pressure boundary for asphaltene precipitation (i.e., 13.51 MPa) when the already precipitated asphaltenes were dissolved back in the denser live fluid. The fourth region is below the lower pressure boundary for asphaltene precipitation where no change in asphaltene content of the fluid is observed when pressure was further reduced.

Asphaltene content versus pressure (Jamaluddin et al. 2001)

The accuracy of the gravimetric technique for AOP pressure measurement of a live oil sample depends on the selection of pressure intervals and precision of analytical technique used for quantification of asphaltene content. If very coarse pressure steps were selected, the onset point may be missed in these wide intervals. On the other hand, excessive refinement of the pressure steps may elongate the measurement process. Another drawback of the gravimetric technique is the large volumes of the live oil needed.

Viscosity measurement

This method is established based on the idea of describing an asphaltenic crude as a “colloidal suspension” when asphaltene particles precipitate out of the solution. Based on the extensive research conducted in the literature on properties of colloidal solutions (Einstein 1956; Sherman 1964; Goldsmith and Mason 1964; Graham 1981; Gillespie 1983; Hirchberg 1988), one can implement viscosity measurement approach and characterize the crude oil when it is passed the onset of asphaltene precipitation. There are some influential parameters that control suspension viscosity including fluid-particle and particle–particle interactions, particle size distribution, particle shape, and particle concentration. Sometimes, suspended particles interact with each other and may form numerous sizes of aggregation. It has been shown that aggregation phenomenon in colloidal suspensions forms a distribution of greater particle sizes that results in increased suspension viscosity (Escobedo and Mansoori 1995; Gillespie 1983).

Numerous studies show that asphaltenes in crude oil have a colloidal nature (Kawanaka et al. 1989; Wen et al. 1978; Lichaa and Herrera 1975; Ray et al. 1957; Leontaritis 1988). In this approach, asphaltenes are considered as dispersed particles in crude oil which are stabilized by a resin layer on their surfaces. This condition of stabilization may be disturbed by adding a precipitant. The precipitant causes desorption of resins preserver layer from the asphaltene surfaces. In the absence of the resin layers, the asphaltene particles may interact with each other and aggregation will occur. This aggregation of suspended particles in a suspension will increase the viscosity. Thus, measurement of crude oil viscosity at different percentages of added precipitant can be a method for detecting the onset of asphaltene precipitation during a titration test for stock tank oils. This method was presented originally by Escobedo and Mansoori in 1995. Reverse or opaque Cannon–Fenske viscometer was the type of glass viscometer used in this study. Since each Cannon–Fenske viscometer tube size is only useful for a specific range of viscosity values, various tube sizes of this viscometer should be used to cover the entire viscosity range. One of the advantages of this method is its applicability for the light and heavy, opaque and transparent, and dead and live oil samples. However, if capillary tubes are used for viscometry, they may be plugged by deposited asphaltenes during the measurements. This method has been widely used in the literature. For instance, Shadman et al. (2012) and Firoozinia et al. (2016) used it to study the effect of inhibitors and dispersants on asphaltene precipitation from dead oil samples. Turta et al. (1997) used this method to determine onset of asphaltene precipitation in live oil samples at reservoir conditions during gas flooding process.

The overall procedure for viscometry of mixture of asphaltenic crude with a precipitant is presented here: first, several diluted samples of oil with different volumetric ratios of precipitant to oil need to be prepared. The number of samples is chosen in such a manner that covers the entire range of precipitant concentration. Escobedo and Mansoori (1995) used 30 samples for their viscometry study. Then, sufficient time should be allotted to prepare samples at thermal equilibrium with environment. After equilibration, viscosity of all the samples should be measured. The next step is to prepare solutions of crude oil in a polar and non-precipitating solvent such as toluene or benzene with the same volume proportions as those of the precipitant in the first step, and then measure the viscosity of oil–non-precipitating solvent mixture. These latter solutions are considered as references with which viscosity of mixtures of crude oil and precipitant is compared. This comparison highlights the point of onset on a graph of viscosity versus solvent or precipitant concentrations. In the end, each sample of oil–precipitant solution is examined under microscope to visually confirm the onset point. The onset of asphaltene precipitation is defined as the lowest precipitant concentration at which the suspended asphaltene could be visually detected.

Figures 5 and 6 are borrowed from Escobedo and Mansoori (1995) that show how kinematic viscosity of mixtures of oil–precipitant as well as oil–non-precipitating solvent change with solvent concentration. The n-alkanes used are n-C5, n-C7 and n-C9 and the non-precipitating solvents for the reference mixtures are toluene and a mixture of 64.33% tetrohydrofuran (THF) in toluene (known as THF-S). In both figures, the viscosity of oil–non-precipitating solvent mixtures continuously decreases with increasing solvent concentration. Note that in Fig. 5, viscosity of crude oil with n-C7 and n-C9 decreases until reaches a deviation point, the so-called onset of asphaltene precipitation. The titration data for oil and n-C5 mixture are shown in Fig. 6. For the case of n-pentane as the precipitant, great amounts of asphaltenes precipitate after reaching the onset point. The precipitated asphaltenes plugged the capillary tube of viscometer and as a result, no more data could be collected. Escobedo and Mansoori (1995) confirmed the viscosity measurement data with analyzing all the samples under microscope. The optical microscopy confirmed that the first precipitated asphaltene particles appeared right after the corresponding deviation point on the plots shown in Figs. 5 and 6.

Kinematic viscosity of Maya crude–solvent mixture versus weight fraction of solvent (n-C7, n-C9, Toluene, THF-S) (Escobedo and Mansoori 1995)

Kinematic viscosity of Maya crude–solvent mixture versus weight fraction of solvent (n-C5, Toluene, THF-S) (Escobedo and Mansoori 1995)

The same methodology was used for other crude oils by Escobedo and Mansoori (1995) and the results are summarized in Table 2.

As seen in Table 2, the volume of precipitant needed to induce asphaltene precipitation was obtained greater using optical microscopy method compared to those obtained using viscometry method. The origin of the difference is attributed to the detection mechanisms by which asphaltene precipitation in the mixture was identified. For the viscometry method, the viscosity of mixture changes suddenly as soon as the precipitation occurs. This of course depends on the precision of the viscosity measurement. However, for the optical microscopy method, there might be a delay in detecting the precipitation onset due to the fact that the first precipitated particles need to grow in size through the agglomeration process to be visible by microscope. This, of course, would be dependent on the accuracy and magnification ratio of the employed microscope. Therefore, slightly more precipitant volumes appeared to be needed to induce asphaltene precipitation when optical microscopy was used. Overall, the viscometry method seems to be a more accurate method compared to optical microscopy for asphaltene onset precipitation measurements during titration experiments.

Built upon the concept of viscometry method, Turta et al. (1997) developed a modified version of the procedure for detecting onset of asphaltene precipitation (and the associated volume of precipitant needed) using a capillary tube viscometer for oil and a miscible solvent mixture at reservoir conditions. This technique allowed to detect the onset of asphaltene precipitation at high-pressure conditions. In addition, the viscometry method does not need the use of any reference fluids. Shadman et al. (2012) also applied the viscometry method for evaluating the performance of asphaltene precipitation inhibitors.

To sum up, the applicable pressure range of the viscometry method for live oil systems depends on the type of viscometer. Cannon–Fenske viscometer is used for atmospheric pressure conditions, whereas high-pressure capillary viscometer allows onset detection for live oil samples. Unlike the photometric methods, the viscometry technique can be applied for all types of oils regardless of their color.

Optical microscopy technique

Optical microscopy was used by several researchers to detect onset of asphaltene precipitation when a crude oil is titrated with increasing concentration of a precipitant at ambient conditions (Hirschberg et al. 1984; Buckley 1996; Junior et al. 2006; Maqbool 2011; Rabbani et al. 2011; Hoepfner et al. 2013; Goual et al. 2014; Firoozinia et al. 2016). In this approach, the process of titration of a crude oil with precipitant is monitored in high magnifications with an optical microscope equipped with digital camera for image capturing and further processing. A detailed procedure for optical microscopy technique is illustrated in Fig. 7.

Procedure for optical microscopy technique (Maqbool 2011)

With focusing on optical microscopy technique, Wang and Buckley (2001) stated that growth of asphaltene aggregates is a continuous process. The size at which asphaltene aggregates become large enough to be distinguished with an optical microscope is regarded as the threshold at which asphaltene precipitation onset occurs. Based on the resolution of available systems, a threshold asphaltene particle size of 0.2–0.5 microns was widely suggested in the literature. This threshold is also comparable to the typical pore size of the reservoir rock, and thus has practical implications especially for the asphaltene-induced formation damage. In the optical microscopy technique of asphaltene onset precipitation measurement, two of the most influential parameters that can affect the end results are residence time and precipitant concentration. It is possible to monitor how asphaltene particles precipitate out and agglomerate at constant precipitant concentration as a time-dependent process, or fix the residence time and study how precipitation occurs at different concentrations of the precipitant. The time-dependent optical microscopy of a crude oil–heptane system at fixed heptane concentration is shown in Fig. 8 that clearly shows the dynamics of precipitation process as a function of time (Maqbool 2011).

Micrographs showing the time dependence of asphaltene precipitation for a 50:50 vol.% K-1 crude oil–heptane mixture (Maqbool 2011)

Particles of 0.5 microns in size appeared after about 1.4 h; however, smaller asphaltene particles appeared sooner (at 0.9 h) but were not recognizable in size due to the microscope limitations (Maqbool 2011). The smaller particles were called as “haze” in his study. The onset of asphaltene precipitation (with threshold particle size of 0.5 microns) and that of haze precipitation was measured for two different crudes subject to titration with different heptane concentrations and the data are presented in Fig. 9. It was concluded that the onset time was reduced exponentially with respect to precipitant concentration (Maqbool 2011). This figure demonstrates that based on 24 h of contact time of crude oil K-1 and precipitant (i.e., common time for asphaltene precipitation tests), all solutions composed of a precipitant concentration of less than 46.5% (vol/vol) are stable solutions. This statement is of course valid considering only 24 h of residence time. It should be noted that if the exposure time was extended, more precipitation would have happened. The results could also be analyzed from the precipitant concentration point of view. In other words, if less concentration of precipitant (i.e., lower than 46.5% by volume) was used, it would have taken more time to attain precipitation and aggregation to the extent of achieving a 0.5-micron particle size, capable of being detected by optical microscopy. This proves that the dynamics of asphaltene precipitation matter, and a combination of residence time and precipitant concentration plays the essential role in onset of asphaltene precipitation.

Change of onset time with respect to precipitant concentration, detected using optical microscopy technique at ambient conditions (Maqbool 2011)

Prechshot et al. (1943) used electron microscopy as a new tool to study asphaltic substances in stock tank crude oil. Witherspoon and Munir (1958) used electron microscopy method to study size and shape of asphaltic substances centrifuged from different crude oils. They concluded that the asphaltene particles are spherical with an average diameter of 40 Å. They confirmed the previous findings that asphaltene substances are present in crude oil as particles of colloidal dimensions. Buckley (1996) combined microscopic observations of particulate formation in mixtures of oil and precipitant with measurement of mixture refractive index to determine onset of asphaltene precipitation for stock tank crude oil.

Microscopy technique was also used to visualize onset of asphaltene precipitation pressure when a sample of live oil went through depressurization. For this purpose, a high-pressure microscope (HPM) is utilized which is composed of a high-pressure high-temperature (HPHT) cell, with a light source in one side of the cell and a camera mounted on the other side. The captured images are transferred to a data acquisition unit for further image processing. A schematic of a HPM setup is provided in Fig. 10. Zhou and Sarma (2012) experimentally investigated different gas injection scenarios with the aid of a high-pressure microscope. They concluded that the depressurization rate and gas injection ratio influence the asphaltene onset precipitation pressure. Karan et al. (2003) also used high-pressure microscopy to examine the performance of asphaltene precipitation inhibitors. They combined three complimentary techniques: solid detection system (SDS) with particle size analyzer (PSA) and high-pressure microscopy (HPM) to screen asphaltene inhibitors at field conditions of pressure, temperature and composition. Abdallah et al. (2010) applied high-pressure microscopy for determination of onset of asphaltene precipitation. Based on their study, sample D had higher sulfur and asphaltene content compared to sample B. In addition, sample D’s density was greater than that of sample B. They tried to design more effective remedial treatments to prevent asphaltene deposition using live oil samples from four different reservoirs. Results of HPM in their works on fluids B and D are depicted in Fig. 11. For fluid B, there is no evidence of precipitated asphaltene particles, which is in agreement with no observation of asphaltene problem in the field. However, the images from sample D show formation of asphaltene particles during isothermal depressurization.

Results of high-pressure microscopy from Abdallah et al. (2010)

In summary, optical technique and HPM are two widely accepted and commercialized methods for determination of asphaltene onset precipitation. Accuracy of these methods depends on the opacity of the oil sample. It is expected that optical techniques give better and more precise results for oils with lower gravity and asphaltene content.

Refractive index measurement

Refractive index (RI) measurement is a powerful tool in determining onset of asphaltene precipitation when a crude oil sample is titrated with a precipitant. It is also a useful method for creating correlations with other properties of crude oil such as solubility parameter and density. Because of the polarizability root of solubility parameter and RI, there is a similarity between these two parameters (Buckley 1996). Solubility parameter is a measurable parameter only for pure substances; however, it can be calculated for simple mixtures. However, for complex mixture such as crude oil, solubility parameter is an unknown factor. On the other hand, RI can be simply measured for light to medium crude oil systems (Buckley 1999).

The Lorentz–Lorenz equation relates the optical properties such as RI to the microscopic properties such as polarizability of a solution:

where f(n) is the refractive index function, n is the refractive index of crude oil, NA is the Avogadro’s number, ρ is the density, α is the polarizability, and M is the molecular weight.

The effective density (\({\rho }_{\text{e}}\)) and molecular weight (\({M}_{\text{e}}\)) of homogenous multicomponent mixtures are defined based on volume fraction \(\left( {{\phi _i}} \right)\) and mass fraction \(\left( {{m_i}} \right)\) of each component i as follows:

The effective refractive index of a mixture is then expressed as a volumetric average of refractive index of its components in the form of the following equation:

Substitution Eqs. 2 and 3 in Eq. 4 gives the following equation:

where \({ \alpha }_{\text{e}}\)is the effective polarizability.

A crude oil mixed with a precipitant can be assumed as a binary mixture in which crude oil and chemical are each treated as single components. According to Eq. (4), \(\left( {\frac{{n_{i}^{2} - 1}}{{n_{i}^{2}+2}}} \right)\) is linearly related to the volume fraction of either of the components (Buckley 1999; Castillo et al. 2009). The more polarity of a structure, the more polarizability (α) of that structure; hence, such a structure would have higher RI value. This expression suggests that in a crude oil mixture, paraffinic compounds have the lowest RI, whereas the polar molecules of resins and asphaltenes have the highest RI values. RI values of aromatic compounds are between these two extremes as illustrated in Figs. 12 and 13.

RI of various components of oil: paraffins, aromatics, and cycloparaffins (Buckley 1999)

RI of resins and asphaltenes (in toluene solutions) from Prudhoe Bay oil sample (Buckley 1999)

Precipitation of asphaltenes reduces the polarity properties of the remainder of the oil phase and based on Eq. 5, the RI value of the crude oil will be reduced. Addition of a precipitant to a crude oil reduces the RI of mixture in a linear trend. This behavior continues until the onset of asphaltene precipitation. After this point, the polarity of the remaining oil is reduced due to the reduction of suspended asphaltene particles; therefore, RI deviates from its linear trend. According to the data published by Wattana et al. (2003), a jump will be observed in the RI curve at onset of asphaltene precipitation if the asphaltene precipitation process occurs suddenly and completely. After hitting this stage, the declining trend of RI versus volume fraction of precipitant would remain linear as shown in Fig. 14. It is reported that the amount of deviation of RI values from the initial linear trend depends on the crude oil nature and differs from one type to another.

RI of CLA oil and heptane mixture versus volume fraction of heptane (Wattana et al. 2003)

The effect of precipitant type can also be examined by RI measurement of crude oil–precipitant mixture. Wattana et al. (2003) studied how precipitant type affects the RI values of the mixture (Fig. 15). The onset of asphaltene precipitation occurs over a wide range of the RI values for several types of precipitants (Buckley 1996; Buckley et al. 1998).

Effect of different precipitants on RI of Mars crude oil–precipitant mixture (Wattana et al. 2003)

It should be mentioned that direct RI measurement of heavy dark crude oils is impossible. It is suggested that RI of a solution of heavy dark crude in a solvent (such as toluene) would be measured at different oil and solvent volume fractions. Then the results can be extrapolated to calculate the RI of the crude oil (Castillo et al. 2009). Taylor et al. (2001) used extrapolation of the RI of asphaltene–toluene mixtures to calculate the RI of asphaltenes. Their estimation for the RI of asphaltenes was 1.708. They also showed that Eq. 4 is applicable for calculating bitumen’s RI. For this case, maltenes and asphaltenes are considered as two components of bitumen. Evdokimov and Losev (2007) stated that extrapolating approach for determining the RI of oil is valid only for mixtures with high concentration of oil. They also showed that there is a considerable deviation of the RI from linear trend in dilute solution of oil. Fan et al. (2002) defined \(\Delta {\text{RI}}=\text{RI}{_{{\text{oil}}}} - {({\text{R}}{{\text{I}}_{{\text{oil}}}}{\text{)}}_{{\text{at onset}}}}\) as a measure of oil sample stability. They believed that it cannot be considered a distinct boundary between stable and unstable oil; however, they proposed the following regions based on this parameter: oils with \(\Delta {\text{RI}}\;<\;0.04~\;{\text{or}}\;~0.05\) are unstable and oils with \(\Delta {\text{RI}}\;>\;0.06\) have stable asphaltenes.

In summary, the RI measurement is a relatively fast method for detection of asphaltene precipitation onset. This method can be applied at HPHT conditions. The RI value of light and medium oil samples can be measured directly but those of the heavy opaque oils are too difficult or even impossible to measure. The RI values of the mixture of heavy opaque oils and precipitants can be estimated by extrapolating the RI trend (vs. different solvent concentrations) to zero concentration of solvent.

Interfacial Tension (IFT) measurement method

It is believed that the presence of heteroatoms such as oxygen, nitrogen and sulfur in asphaltenes makes it possible to consider this fraction of oil to have a “surfactant-like structure”. This is the reason that several researchers used measurements of IFT between water and mixture of crude oil and a precipitant as a viable technique to detect onset of asphaltene precipitation. IFT can be measured using different equipment. Kim et al. (1990) measured IFT between water and mixture of oil and n-heptane by Du Nouy ring method. Mousavi-Dehghani et al. (2004) also used Du Nouy ring method for measuring IFT between water and various mixtures of crude oil and n-heptane. This method is used at atmospheric pressure. Acevedo et al. (2005a) studied the presence of asphaltenes at the interface of toluene and water mixture via IFT measurements using Du Nouy ring method as well as pendant drop method. Fossen et al. (2007) performed a series of pendant drop experiments to measure IFT between asphaltene–toluene mixtures and water. They observed that the presence of asphaltene in the mixture decreased the IFT. The authors related this behavior to the surfactant role of asphaltenes at the interface of oil mixtures and water.

The basic idea behind this methodology is that there should be a sudden change in the IFT value versus precipitation factor (pressure, temperature or concentration of precipitant) as a sign of onset of asphaltene precipitation. An example of such a study is published by Mousavi-Dehghani et al. (2004) where the IFT between water and mixtures of precipitant and various oil samples were measured at 25 °C. Figure 16 shows that there is a slight change in the IFT value with increasing precipitant concentration. This oil sample is a light one with a very small asphaltene content (0.8 wt%). Therefore, IFT was relatively constant at 21 dyne/cm over a wide range of precipitant concentration.

IFT between water and light oil–heptane mixture (Mousavi-Dehghani et al. 2004)

The authors also conducted asphaltene precipitation tests on Sohio oil sample which contained 4.2 wt% of asphaltenes using both n-pentane and n-heptane as precipitant. It was found that IFT was approximately constant up to a certain concentration for each precipitant after which it was suddenly increased (Fig. 17). This point of sudden change on IFT versus precipitant concentration plot was defined as the asphaltene onset precipitation point in terms of the minimum volume (or concentration) of precipitant needed to attain precipitation in the titration experiments. The authors concluded that the precipitated polar molecules of asphaltenes moved to the interface between water and the oil–precipitant mixture. These precipitated asphaltenes then formed a film at the interface which resulted in an increase in the IFT values. The authors’ justification for additional instabilities in the IFT values at higher concentrations of precipitants is the adhesion or deposition of precipitated asphaltenes at the interface. No evidence was provided by the authors to support this claim. Some other researchers observed different behaviors for asphaltene at the interfacial region. The presence of polyaromatic and heterocyclic molecules in the structure of asphaltenes and their adsorption at the interface causes different interfacial behaviors (Rane et al. 2012; Darjani et al. 2017; Liu et al. 2017).

IFT between water and Sohio oil–precipitant mixture (Mousavi-Dehghani et al. 2004)

Heat transfer technique

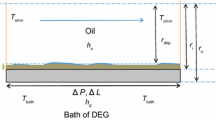

Clarke and Pruden (1996) used heat transfer analysis for predicting onset of asphaltene precipitation. The basic idea behind Clarke and Pruden’s work is that thermal resistance of an oil sample or mixture of oil sample and a precipitant is increased due to precipitation of asphaltenes. They designed a special cell to conduct asphaltene precipitation tests at conditions up to 2000 psi and 400 °C (Fig. 18).

Schematic of heat transfer cell for determining onset of asphaltene precipitation (Clarke and Pruden 1996)

In this setup, heat was supplied by heating tapes around the cell. The top and bottom of the cell were isolated from the walls by gaskets. This isolation facilitated conduction heat transfer through the deposited asphaltene layer which would form at the proximity of the cell bottom. The cell was placed on an aluminum plate, which acted as a heat sink. Path of the heat began from the heating tapes. Generated heat passed through the walls of the cell and reached to the bulk of the fluid sample via inner film of the fluid on the walls. Heat was transferred from the base of the cell through a fluid film and deposited layer of asphaltenes. There was a line for precipitant injection and a stirrer. Six thermocouples were also located at various parts of the cell for detecting local temperatures. The locations of these thermocouples are indicated in Table 3. The outer wall temperature was maintained constant, and T3 was located 1 mm above the inner base of the cell for measuring temperature of the lower layer of the fluid and/or that of the deposited asphaltenes layer.

A summary of the test performed by Clarke and Pruden (1997) is mentioned here: the sample was placed in the vessel. The vessel’s top plate and walls were held at constant temperature of 115 °C, whereas the circulator fluid to the aluminum plate was at a much lower temperature of 28 °C. The sample was stirred and heated for a fixed time. Then, several cycles of fixed duration were performed. For every cycle, the stirrer was on for the initial 5 min, then was turned off to allow the temperature profiles to reach their steady state values. Over the last 10 min of each cycle, the measured temperatures were averaged to obtain the average steady state temperature for the given cycle. For all the runs, no solvent was added for the very first cycle. The temperature from this first cycle was then treated as the reference temperature which facilitated the comparison of runs. A fixed volume of chemical, n-heptane and toluene, was injected during the stirring portion of each cycle following the first cycle. The volume of the solvent added in each cycle was typically 0.4–0.5 times that of the original sample. Clarke and Pruden (1996) found that the thermocouple located at the smallest distance from the cell bottom can represent the temperature for the deposited layer of asphaltenes (if any). It was hypothesized that this deposited layer of asphaltenes creates an additional thermal resistance.

Results of the Clarke and Pruden’s study (1997) are illustrated in Fig. 19. When toluene was added to the crude oil sample in the cell, viscosity of the mixture reduced. Therefore, thermal resistance of the solution dropped and temperatures increased. This can be seen in the monotonous increase of the temperature measured by the thermocouple closest to the cell bottom (Fig. 19). However, addition of the precipitant resulted in a different behavior for temperature of the region closest to the cell bottom. At first, addition of n-heptane resulted in viscosity decrease for the mixture, hence the temperature of the region nearby the cell bottom increased. However when proper ratio of precipitant to oil was reached in the cell, asphaltene particles precipitated out of the solution, hence forming a deposit layer at the bottom of the cell during the stabilization period. This deposit layer formed a new thermal resistance which caused reduction of temperature associated with the region close to the cell bottom. Using this method, the concentration of precipitant needed to achieve onset precipitation of asphaltenes could be measured. The oscillating behavior of the temperature plot after reaching asphaltene onset precipitation was attributed to the competing roles of viscosity reduction and asphaltene deposit layer formation. In 1998, Clarke and Pruden also studied the effectiveness of different additives on delaying asphaltene precipitation from Cold Lake bitumen using the same heat transfer approach. They examined the performance of toluene, naphthalene, phenanthrene, indole, quinolone, benzothiophene, 2-methoxy-4-methylphenol, tetralin and decalin as additives to delay asphaltene precipitation. Clarke and Pruden (1998) concluded that phenanthrene had the greatest effectiveness, whereas indole and quinolone had the slightest efficiency.

Temperature of the cell bottom in the presence of toluene and n-heptane (Clarke and Pruden 1997)

In summary, this approach is a relatively fast method, similar to the RI measurement technique. This method detects asphaltene precipitation onset at HPHT conditions. Accuracy of the heat transfer technique depends on the precision of temperature sensors. Moreover, the temperature changes during asphaltene precipitation is a function of the thickness of the deposited asphaltene layer at the bottom of the cell. Therefore, asphaltene content of the oil is another parameter affecting the accuracy of this method.

Density measurement method

Significant changes of the macroscopic properties of crude oil during asphaltene precipitation are not tangible because of the low concentration of asphaltenes in the crude oil. Amongst these properties, density and viscosity have the highest sensitivity with respect to asphaltene precipitation phenomenon. Ekulu et al. (2004) showed that different trends of crude oil density before and after onset of asphaltene precipitation can be considered as an indication of the onset point. A so-called “reduced density” parameter was defined by the authors as the difference between the density of mixture (i.e., crude oil, toluene and n-heptane) and the density of reference system (i.e., maltenes, toluene and n-heptane). The reduced density of mixture was then plotted against volume fraction of precipitant (Figs. 20, 21). The oil samples FC and FF in Figs. 20 and 21 were taken from an European oilfield as well as one in South America, respectively. Two intersecting straight lines with different slopes were obtained. The authors defined the intersection point as the asphaltene onset precipitation point for the given system. It is observed that before the intersecting point, the mixture density was higher than that obtained after onset point. As asphaltenes precipitate out of the fluid mixture, the crude oil density approaches that of the maltenes.

Reduced density of fluid FF {crude oil F (5 g) + cyclohexane (7.5 g) + n-heptane (Xg)} as a function of the ratio of n-heptane and available crude oil (Ekulu et al. 2010)

Reduced density of fluid FC {crude oil C (5 g) + cyclohexane (7.5 g) + n-heptane (Xg)} as a function of the ratio of n-heptane and available crude oil (Ekulu et al. 2010)

Electrical technique

Fotland et al. (1993) invented a new technique to determine onset of asphaltene precipitation. The supporting background of their work returns to Lichaa and Herrera’s experiment. Lichaa and Herrera (1975) placed two electrodes in an oil sample and applied a direct current across them. They observed some deposition on one of the electrodes which shows migration of charged particles. It is now known that the presence of heteroatoms, vanadium and nickel in asphaltene structure may generate dipole moments in asphaltenes fraction of the oil. Based on this background, Fotland et al. (1993) designed a special conductivity cell, consisted of concentric cylinders capable of being used for medium to high conductivity ranges by changing the space between the electrodes or electrode area. The electrodes were covered with a gold layer. During the test, a mixture of oil and a precipitant was injected from a dilution flask to the cell. A magnetic stirrer was used for mixing the solution. The setup was mounted in an air bath for isothermal testing. The conductivity and capacitance were measured using an impedance meter (Figs. 22, 23). The normalized conductivity was defined as conductivity per mass fraction of oil in the injected solution. The change of trends for both conductivity and normalized conductivity at a particular precipitant concentration was attributed to the onset of asphaltene precipitation. Comparing the upper and lower curves in Figs. 22 and 23 reveals that the onset of asphaltene precipitation is more clear in the normalized plot (i.e., upper curve). As the precipitant was added to the oil sample in the dilution flask, the fluid mixture’s viscosity was reduced. The viscosity reduction caused an increase in mobility of the conducting entities (i.e., asphaltenes). This trend continues up to a maximum point after which both graphs began a downward trend until they reached the conductivity of a 100% precipitant phase. Using this method, one can also estimate the amount of precipitated asphaltenes by extrapolating the data before precipitation to the point of pure precipitant. The detailed algorithm for this estimation is provided in the paper by Fotland et al. (1993).

Conductivity and normalized conductivity for crude A-precipitant mixture (Fotland et al. 1993)

Conductivity and normalized conductivity for crude B-precipitant mixture (Fotland et al. 1993)

Other researchers adapted this technique for measuring onset of asphaltene precipitation for crude oils when titrating with precipitants. MacMillan et al. (1995) measured conductivity of a crude oil and pentane mixture to determine the onset of asphaltene precipitation. They used electrical and optical methods to determine the onset of asphaltene precipitation and concluded that combining these two techniques improves the interpretation of experimental results. Behar et al. (1998) studied the effect of asphaltene concentration in solutions of asphaltenes in nitrotoluene and THF by conductivity measurements. They repeated their experiments on solutions of asphaltenes in nitrotoluene in the presence of resins. Their study showed that precipitation of asphaltenes depends on asphaltene concentration as well as properties of the bulk fluid phase.

In summary, the electrical conductivity for measuring asphaltene onset precipitation is also applicable to HPHT conditions for both light and heavy oils. The accuracy of this technique depends on the sensitivity of the measuring sensors. The asphaltene concentration of the oil sample affects detection of the onset point using this methodology since low asphaltene contents result in low conductivity values.

Acoustic resonance technique (ART)

This method is rooted in the differences of sonic wave speeds in various fluid phases. It is known that the denser the fluid is, the faster the sonic wave moves. Thus, it is expected that the phase transition (i.e., from liquid to solid, asphaltene precipitation, or from liquid to gas, gas liberation) could be detected from response of fluids to acoustic waves propagating through them. Using this technique, the onset of asphaltene precipitation pressure can be detected for a live oil system undergoing depressurization steps (Carrier et al. 2000). In ART for asphaltene onset precipitation measurement, the output response is in the form of resonance frequency. It is known that changes in sonic wave speed, which is associated with phase transition, influence resonance frequency and therefore acoustic response (Jamaluddin et al. 2002). This technique is schematically shown in Fig. 24. The main element of the setup is a HPHT cylindrical resonator. Acoustic wave is sent through the fluid in resonator via a transmitter which is located at the top end of the system. Response signals are detected in a receiver at the other end of the resonator. These responses pass through a low noise pre-amplifier and finally are processed through an analog to digital convertor. A data acquisition and recording system is used to control the whole setup, control the acoustic stimulation of transmitter, collect and record the operational variables such as pressure, volume, temperature, and response signals (Kabir and Jamaluddin 1999).

Schematics of the ART setup (Jamaluddin et al. 2002)

The operating procedure for this setup is borrowed from Jamaluddin et al. (2002): first, the system is heated up to the desired temperature. Next, the reservoir fluid is charged at constant pressure under isothermal conditions. The system is then allowed to stabilize at fixed pressure and temperature. A series of depressurization steps are performed with a decreasing rate change versus time. At each depressurization stage (after stabilization), the sonic frequency and associated operating conditions are captured and recorded. The normalized acoustic response can then be plotted versus pressure. An example of such measurement is shown in Fig. 25. There are two distinct trend changes observed in the plotted data: one is associated with the onset of asphaltene precipitation pressure and the second one is related to the saturation pressure. As the pressure decreases from right to left, the fluid density gradually decreases and as a result, the sonic speed decreases. These trends are continued until the onset of asphaltene precipitation was reached, shown by the big drop in the curve. The precipitated solid particles caused an increase in the sonic speed. After passing the AOP pressure, some oscillations were observed in the data which may be due to counteracting effects of viscosity reduction and further asphaltene precipitation on the magnitude of the acoustic response. Another sharp drop in acoustic response was experienced due to separation of gas from the live oil when the pressure passed the saturation pressure. According to Jamaluddin (2002), the lower boundary of asphaltene precipitation could not be detected using ART due to gradual change of re-solubilization of the asphaltene particles in oil below the bubble point pressure, which was not detected by resonance frequency.

Determination of AOP pressure for a live oil sample at 210 °F using ART (Jamaluddin et al. 2002)

De Boer et al. (1995) and Sivaraman et al. (1999) studied the effect of inhibitors on asphaltene precipitation using ART. Kabir and Jamaluddin (1999) found onset pressure of asphaltene precipitation and bubble point pressure using ART. This method can also be used to detect asphaltene onset conditions for crude oil samples under titration experiments. Carrier et al. (2000) investigated asphaltene precipitation for mixtures of crude oil/o-xylene/n-hexane and n-octane using acoustic technique in the ultrasound frequency range at 323 K and atmospheric pressure. Yarranton et al. (2000) and Chen (2000) also used ART to detect AOP pressure as well as saturation pressure for six oil samples.

To sum up, ART can be applied for light and dark oil samples at HPHT conditions. This method is a fast technique and requires low volume of reservoir fluids. This technique has no mixing mechanism. This causes inaccurate determination of the onset point due to heterogeneity in asphaltene distribution. It should be noted that changes in acoustic properties are not only related to asphaltene precipitation. The presence of other solids or gas phase also changes these properties. Moreover, ART is unable to detect lower boundary of asphaltene precipitation envelope. This is because of the gradual dissolution of the precipitated asphaltenes in the remaining oil below the bubble point pressure.

Light scattering technique (LST)

When light passes through a fluid, any phase transition (i.e., formation of solids or gas phase) influences the power of the transmitted light (PTL). The light absorbance is inversely related to PTL. For the case of dark oil samples, near infrared (NIR) light can be used. This is because of absorbance of visible range wavelength in the dark oil medium. Based on these principles, the light scattering technique was developed to detect onset of asphaltene precipitation pressure for live oil samples. For the live oil systems, this methodology was developed in the form of designing a HPHT visual PVT cell equipped with an NIR source and detector. The general scheme of this setup is the same as a typical PVT cell with an impeller mixer for bringing the fluid to equilibrium conditions at target pressure and temperature along with sight glasses for visual capability, with an added element of an NIR emitter and detector. The intensity of the NIR light, passing through the live fluid at operating pressure and temperature, is measured at the detector based on which presence of solid particles in the fluid is determined. A schematic of this setup is shown in Fig. 26.

Schematic of HPHT PVT cell equipped with NIR source and detector for light scattering technique (Jamaluddin et al. 2002)

Hammami et al. (2000) used light scattering method for investigating asphaltene precipitation in live reservoir fluid systems. The experiments were performed at reservoir temperature, and a series of depressurization steps were done from a pressure greater than the reservoir pressure to close to atmospheric condition. Figure 27 depicts the results for two oil samples, namely Oil 1 and Oil 2. The properties for these two oils are summarized in Table 4.

Intensity of NIR light with respect to pressure for Oil 1 and Oil 2 (Hammami et al. 2000)

For Oil 1, there was no field-scale asphaltene deposition issues based on production reports. In both oils, the power of transmitted light increased by decreasing the pressure due to reduction in density of the single phase live fluid above the AOP. For Oil 1, the increase in PTL continued until it dropped to noise level at about 34 MPa. This drop was attributed to release of gas from the live oil, and the detected saturation pressure was independently confirmed by a CCE test. No asphaltene dropout was detected for this fluid at lab conditions which confirmed the field observations. For pressures lower than bubble point pressure, the evolved gas was then removed from the PVT cell. For \(p<{p_{\text{b}}}\), the power of transmitted light dropped by decreasing the fluid pressure. It is attributed to the increase in fluid density (i.e., loss of light gas components) as pressure was decreased below the saturation pressure. For Oil 2, however, there is a point at which PTL reached a plateau and then started to decrease gradually and continuously. The point at which the PTL deviated from the almost linear increasing trend (i.e., about 50 MPa) was considered as the AOP pressure. When the depressurization was continued below the AOP, the PTL gradually decreased until it completely dropped to zero at about 39 MPa (i.e., the suspected saturation pressure for Oil 2). For \(p<{p_{\text{b}}}\), the declining slope of the PTL curve is smaller than that of Oil 1. Two opposing mechanisms are competing in this pressure region which affect the PTL declining trend: in one hand, pressure drop below the saturation pressure results in density increase (hence PTL decrease), and on the other hand, it causes the re-dissolution of asphaltene particles back into the remaining fluid which increases the PTL intensity.

Buenrostro-Gonzalez et al. (2004) also used the light scattering technique to measure AOP pressure for a live oil sample (Fig. 28). Before the sudden drop of the light intensity, it increased linearly with pressure reduction (i.e., line 1) until it plateaued (i.e., line 2). The intersection of these two straight lines was defined as the AOP pressure for this live fluid system. The same approach for AOP measurement was also employed by Tavakkoli et al. (2013). Mahmoudi and Zare-Reisabadi (2015) used the light scattering technique to investigate the effect of temperature on AOP pressure of a live fluid system. Other applications of this technique include studies by Joshi et al. (2001), Gholoum et al. (2003), and Lei et al. (2015) that used LST for asphaltene deposition envelope (ADE) development.

Results of LST on Y3 oil sample at 413 K (Buenrostro-Gonzalez et al. 2004)

Using the same approach, Aske et al. (2002) studied the asphaltene precipitation process and its reversibility for several live oil samples and model systems of asphaltenes in toluene/pentane solvent mixture by means of NIR spectroscopy. The optical density was then plotted versus pressure or weight fraction of the precipitant. The minimum point in these graphs was then considered as asphaltene onset precipitation, in terms of pressure or concentration of precipitant. The optical density was calculated according to the following equation:

in which I0 and I are the power of incident and transmitted light, respectively.

The light scattering technique can be implemented in a slightly different manner to investigate asphaltene precipitation from crude oils during titration experiments. In this case, the absorbance of the transmitted light, and not the power intensity, is presented as a function of time. An example of such an application can be seen in the study performed by Fuhr et al. (1991). An initial decrease in the absorbance of light was observed during the initial stages of the titration experiment which is due to the dilution effect of the precipitant before its concentration reaches the threshold value needed for asphaltene precipitation (Fig. 29). At one point when this threshold concentration of precipitant was reached, the asphaltene particles precipitated out of the solution and absorbed the light passing through the solution, hence the measured absorbance started to increase by time. This local minimum point was referred as the onset of asphaltene precipitation. The absorbance ultimately plateaued after about 50 min which means that all the containing asphaltene content of oil was extracted by that time. The same approach was used by other researchers such as Hu and Guo (2001) and Chandio et al. (2014).

Absorbance of NIR light versus duration of titration (Fuhr et al. 1991)

Marugan et al. (2009) also applied NIR light to detect asphaltene particles in dead oil samples under titration. Horvath-Szabo et al. (2004) measured light scattered intensity instead of light transmitted intensity to measure onset of asphaltene precipitation in asphaltene/toluene/heptane mixture. They found that presenting light scattered intensity data versus heptane/toluene ratio formed two straight lines with different slopes. The authors proposed that the intersection point of these two straight lines shows the onset of asphaltene precipitation. Gorshkov et al. (2014) also plotted light scattered intensity versus volume fraction of the precipitant and observed that there are linear and exponential trends for low and high precipitant concentrations, respectively. They identified the intersection point of these two trends as the asphaltene precipitation onset. Kraiwattanawong et al. (2007) stated that selecting the minimum point of light absorbance versus volume fraction of precipitant plot results in an inaccurate determination of the asphaltene precipitation onset. They showed that plotting the derivative of light absorbance with respect to volume fraction of precipitant versus volume fraction of precipitant provides a more precise value of asphaltene precipitation onset. Mansur et al. (2009) used visible ultraviolet spectroscopy to observe the onset of asphaltene precipitation.

Some investigators also measured turbidity value of crude oil system to determine onset of asphaltene precipitation. The precipitation of asphaltenes due to temperature or pressure change or adding precipitant intensifies scattering of the emitted light. This is equivalent to an increase in turbidity value of the system. Thus, measurement of variation of this parameter can be applied as a technique for detecting onset of asphaltene precipitation. Chen et al. (2013) used this technique to determine onset of asphaltene precipitation for four oil samples. Turbidity variation versus ratio of n-heptane/oil sample is illustrated in Fig. 30. Before onset concentration of precipitant, the turbidity value of the mixture was approximately constant. Turbidity value increased sharply after beginning of asphaltene precipitation. Shadman et al. (2016) also used the turbidity measurement technique to investigate the effect of several dispersants on asphaltene precipitation.

Turbidity value versus added heptane for TP7 oil sample (Chen et al. 2013)

Summary

In this paper, a comprehensive literature review was performed on all the available procedures in the literature for measuring the onset of asphaltene precipitation. The major advantages and limitations associated with these methods are summarized in Table 5.

References

Abdallah D, Al-Basry A, Zwolle S, Grutters M, Huo Z, Stankiewicz A (2010) Asphaltene studies in on-shore Abu Dhabi Oil fields, part II: investigation and mitigation of asphaltene deposition-a case study. In: Presented in Abu Dhabi international petroleum exhibition and conference, SPE 138039, Society of Petroleum Engineers

Acevedo S, Borges B, Quintero F, Piscitelly V, Gutierrez L (2005a) Asphaltenes and other natural surfactants from Cerro Negro crude oil. Stepwise adsorption at the water/toluene interface: film formation and hydrophobic effects. Energy Fuels 19(5):1948–1953

Acevedo S, Gutierrez L, Negrin G, Pereira J, Mendez B, Delolme F, Dessalces G, Broseta D (2005b) Molecular weight of petroleum asphaltenes: a comparison between mass spectrometry and vapor pressure osmometry. Energy Fuels 19(4):1548–1560

Akbarzadeh K, Hammami A, Kharrat A, Zhang D, Allenson S, Creek J, Kabir S, Jamaluddin A, Marshall A, Rodgers R (2007) Asphaltenes—problematic but rich in potential. Oilfield Rev 19(2):22–43

Ali L, Al-Ghannam K (1981) Investigations into asphaltenes in heavy crude oils. I. Effect of temperature on precipitation by alkane solvents. Fuel 60(11):1043–1046

Andersen S (1994) Effect of precipitation temperature on the composition of n-heptane asphaltenes. Fuel Sci Technol Int 12(1):51–74

Aquino-Olivos M, Grolier J-P, Randzio S, Aguirre-Gutiérrez A, García-Sánchez F (2013) Determination of the asphaltene precipitation envelope and bubble point pressure for a Mexican crude oil by scanning transitiometry. Energy Fuels 27(3):1212–1222

Arya A, von Solms N, Kontogeorgis G (2015) Determination of asphaltene onset conditions using the cubic plus association equation of state. Fluid Phase Equilib 400:8–19

Aske N (2002) Characterisation of crude oil components, asphaltene aggregation and emulsion stability by means of near infrared spectroscopy and multivariate analysis. Ph. D. Thesis, Norwegian University of Science and Technology

Aske N, Kallevik H, Sjöblom J (2001) Determination of saturate, aromatic, resin, and asphaltenic (SARA) components in crude oils by means of infrared and near-infrared spectroscopy. Energy Fuels 15(5):1304–1312

Aske N, Kallevik H, Johnsen E, Sjöblom J (2002) Asphaltene aggregation from crude oils and model systems studied by high-pressure NIR spectroscopy. Energy Fuels 16(5):1287–1295

Behar E, Hasnaoui N, Achard C, Rogalski M (1998) Study of asphaltene solutions by electrical conductivity measurements. Rev L’institut Fr Petrol 53(1):41–50

Boer R, de;Leerlooyer K, Eigner M, van Bergen A (1995) Screening of crude oils for asphalt precipitation: theory, practice, and the selection of inhibitors. SPE Prod Facil 10(01):55–61

Branco V, Mansoori G, Xavier L, Park S, Manafi H (2001) Asphaltene flocculation and collapse from petroleum fluids. J Petrol Sci Eng 32(2):217–230

Browarzik D, Laux H, Rahimian I (1999) Asphaltene flocculation in crude oil systems. Fluid Phase Equilib 154(2):285–300

Buckley J (1996) Microscopic investigation of the onset of asphaltene precipitation. Fuel Sci Technol Int 14(1–2):55–74

Buckley J (1999) Predicting the onset of asphaltene precipitation from refractive index measurements. Energy Fuels 13(2):328–332

Buckley J, Hirasaki G, Liu Y, Drasek S, von;Wang J, Gill B (1998) Asphaltene precipitation and solvent properties of crude oils. Pet Sci Technol 16(3–4):251–285

Buenrostro-Gonzalez E, Lira-Galeana C, Gil-Villegas A, Wu J (2004) Asphaltene precipitation in crude oils: theory and experiments. AIChE J 50(10):2552–2570

Burke N, Hobbs R, Kashou S (1990) Measurement and modeling of asphaltene precipitation (includes associated paper 23831). J Pet Technol 42(11):1440–1446

Carrier H, Plantier F, Daridon J-L, Lagourette B, Lu Z (2000) Acoustic method for measuring asphaltene flocculation in crude oils. J Pet Sci Eng 27(3):111–117

Castillo J, Gutierrez H, Ranaudo M, Villarroel O (2009) Measurement of the refractive index of crude oil and asphaltene solutions: onset flocculation determination. Energy Fuels 24(1):492–495

Chandio Z, Ramasamy M, Mukhtar H (2014) Investigation of effect of bulk temperature on dissolution and precipitation of asphaltenes using flocculation onset titration. J Appl Sci 14(10):1093–1096

Chandio Z, Ramasamy M, Mukhtar H (2015) Temperature effects on solubility of asphaltenes in crude oils. Chem Eng Res Des 94:573–583

Chen T (2000) Detection of phase transitions with acoustic resonance. M.Sc. Thesis, University of Calgary

Chen C, Guo J, An N, Ren B, Li Y, Jiang Q (2013) Study of asphaltene deposition from Tahe crude oil. Pet Sci 10(1):134–138

Clarke P, Pruden B (1996) The development of an onset-of-precipitation detection technique using heat transfer analysis. Fuel Sci Technol Int 14(1–2):117–137

Clarke P, Pruden B (1997) Asphaltene precipitation: detection using heat transfer analysis, and inhibition using chemical additives. Fuel 76(7):607–614

Clarke P, Pruden B (1998) Asphaltene precipitation from Cold Lake and Athabasca bitumens. Pet Sci Technol 16(3–4):287–305

da Silva Oliveira E, Neto Á, Júnior, V;Castro, E, de, Menezes S de (2014) Study of Brazilian asphaltene aggregation by nuclear magnetic resonance spectroscopy. Fuel 117:146–151

Darjani S, Koplik J, Pauchard V (2017) Extracting the equation of state of lattice gases from random sequential adsorption simulations by means of the Gibbs adsorption isotherm. Phys Rev E 96(5):052803

Einstein A (1956) Investigations on the theory of the Brownian movement. Courier Corporation, Chelmsford

Ekulu G, Magri P, Rogalski M (2004) Scanning aggregation phenomena in crude oils with density measurements. J Dispers Sci Technol 25(3):321–331

Ekulu G, Sadiki A, Rogalski M (2010) Experimental study of asphaltenes flocculation onset in crude oils using the densitometry measurement technique. J Dispers Sci Technol 31(11):1495–1503

Escobedo J, Mansoori G (1995) Viscometric determination of the onset of asphaltene flocculation: a novel method. SPE Prod Facil 10(02):115–118

Eskin D, Mohammadzadeh O, Akbarzadeh K, Taylor S, Ratulowski J (2016) Reservoir impairment by asphaltenes: a critical review. Can J Chem Eng 94(6):1202–1217

Evdokimov I, Losev A (2007) Effects of molecular de-aggregation on refractive indices of petroleum-based fluids. Fuel 86(15):2439–2445

Fan T, Buckley J (2002) Rapid and accurate SARA analysis of medium gravity crude oils. Energy Fuels 16(6):1571–1575

Fan T, Wang J, Buckley J (2002) Evaluating crude oils by SARA analysis. In: Presented in SPE/DOE improved oil recovery symposium, SPE 75228, Society of Petroleum Engineers

Firoozinia H, Abad K, Varamesh A (2016) A comprehensive experimental evaluation of asphaltene dispersants for injection under reservoir conditions. Pet Sci 13(2):280–291

Fossen M, Sj⊘blom, J, Kallevik H, Jakobsson J (2007) A new procedure for direct precipitation and fractionation of asphaltenes from crude oil. J Dispers Sci Technol 28(1):193–197

Fotland P, Anfindsen H, Fadnes F (1993) Detection of asphaltene precipitation and amounts precipitated by measurement of electrical conductivity. Fluid Phase Equilib 82:157–164

Fuhr B, Cathrea C, Coates L, Kalra H, Majeed A (1991) Properties of asphaltenes from a waxy crude. Fuel 70(11):1293–1297

Gholoum E, Oskui G, Salman M (2003) Investigation of asphaltene precipitation onset conditions for Kuwaiti reservoirs. In: Presented in middle east oil show, SPE 81571, Society of Petroleum Engineers

Gillespie T (1983) The effect of aggregation and particle size distribution on the viscosity of Newtonian suspensions. J Colloid Interface Sci 94(1):166–173

Goel P, Saurabh K, Patil-Shinde V, Tambe S (2017) Prediction of API values of crude oils by use of saturates/aromatics/resins/asphaltenes analysis: computational-intelligence-based models. SPE J 22(03):817–853

Goldsmith H, Mason S (1964) The flow of suspensions through tubes. III. Collisions of small uniform spheres. Proc R Soc Lond A 282:569–591

Gorshkov A, Shishmina L, Roslyak A (2014) New method for the onset point determination of the petroleum asphaltene aggregation. IOP Publishing, Bristol, p 21

Goual L, Sedghi M, Wang X, Zhu Z (2014) Asphaltene aggregation and impact of alkylphenols. Langmuir 30(19):5394–5403

Graham N (1981) Orthokinetic flocculation rates for amorphous silica microspheres with cationic polyelectrolytes. Colloids Surf 3(1):61–77

Guzmán R, Ancheyta J, Trejo F, Rodríguez S (2017) Methods for determining asphaltene stability in crude oils. Fuel 188:530–543

Hammami A, Phelps C, Monger-McClure T, Little T (2000) Asphaltene precipitation from live oils: an experimental investigation of onset conditions and reversibility. Energy Fuels 14(1):14–18

Hirschberg A (1988) Role of asphaltenes in compositional grading of a reservoir’s fluid column. J Pet Technol 40(01):89–94

Hirschberg A, DeJong L, Schipper B, Meijer J (1984) Influence of temperature and pressure on asphaltene flocculation. Soc Pet Eng J 24(03):283–293

Hoepfner M, Limsakoune V, Chuenmeechao V, Maqbool T, Fogler H (2013) A fundamental study of asphaltene deposition. Energy Fuels 27(2):725–735

Horvath-Szabo G, Masliyah J, Czarnecki J (2004) A novel photometric technique to detect the onset of asphaltene precipitation at low concentrations: the effect of maltenes and water. Can J Chem Eng 82(5):1089–1095

Hu Y-F, Guo T-M (2001) Effect of temperature and molecular weight of n-alkane precipitants on asphaltene precipitation. Fluid Phase Equilib 192(1):13–25

Jacobs I, Thorne M (1986) Asphaltene precipitation during acid stimulation treatments. In: Presented in SPE formation damage control symposium, SPE 14823, Society of Petroleum Engineers

Jamaluddin A, Creek J, Kabir, C;McFadden, J;D’Cruz, D, Joseph M, Joshi N, Ross B (2001) A comparison of various laboratory techniques to measure thermodynamic asphaltene instability. In: Presented in SPE Asia Pacific improved oil recovery conference, SPE 72154, Society of Petroleum Engineers

Jamaluddin A, Creek J, Kabir CS, McFadden JD D’Cruz D, Manakalathil J, Joshi N, Ross B (2002) Laboratory techniques to measure thermodynamic asphaltene instability. J Can Pet Technol 41(7):44–52

Joshi N, Mullins O, Jamaluddin A, Creek J, McFadden J (2001) Asphaltene precipitation from live crude oil. Energy Fuels 15(4):979–986

Junior L, Ferreira M, da Silva Ramos A (2006) Inhibition of asphaltene precipitation in Brazilian crude oils using new oil soluble amphiphiles. J Pet Sci Eng 51(1):26–36

Kabir C, Jamaluddin A (1999) Asphaltene characterization and mitigation in south Kuwait’s Marrat reservoir. In: Presenetd in middle east oil show and conference, SPE 53155, Society of Petroleum Engineers

Karan K, Hammami A, Flannery M, Artur Stankiewicz B (2003) Evaluation of asphaltene instability and a chemical control during production of live oils. Pet Sci Technol 21(3–4):629–645

Kawanaka S, Leontaritis K, Park S, Mansoori G (1989) Thermodynamic and colloidal models of asphaltene flocculation. ACS Publications, Washington, DC

Kawanaka S, Park S, Mansoori G (1991) Organic deposition from reservoir fluids: a thermodynamic predictive technique. SPE Reserv Eng 6(2):185–192

Kim S, Boudh-Hir M, Mansoori G (1990) The role of asphaltene in wettability reversal. In: Presented in SPE annual technical conference and exhibition, SPE 20700, Society of Petroleum Engineers

Kokal S, Sayegh S (1995) Asphaltenes: the cholesterol of petroleum. In: Presented in middle east oil show, SPE 29787, Society of Petroleum Engineers

Kord S, Mohammadzadeh O, Miri R, Soulgani B (2014) Further investigation into the mechanisms of asphaltene deposition and permeability impairment in porous media using a modified analytical model. Fuel 117:259–268

Kraiwattanawong K, Fogler H, Gharfeh S, Singh P, Thomason W, Chavadej S (2007) Thermodynamic solubility models to predict asphaltene instability in live crude oils. Energy Fuels 21(3):1248–1255

Lei H, Yang S, Qian K, Chen, Y;Li, Y, Ma Q (2015) Experimental investigation and application of the asphaltene precipitation envelope. Energy Fuels 29(11):6920–6927

Leontaritis K (1988) Asphaltene deposition: a thermodynamic-colloidal model. Ph. D. Thesis, Illinois Univ., Chicago, IL, USA

Leontaritis K (1996) The asphaltene and wax deposition envelopes. Fuel Sci Technol Int 14(1–2):13–39

Leontaritis K, Mansoori G (1987) Asphaltene flocculation during oil production and processing: A thermodynamic collodial model. In: Presented in SPE international symposium on oilfield chemistry, SPE 16258, Society of Petroleum Engineers

Lichaa P, Herrera L (1975) Electrical and other effects related to the formation and prevention of asphaltene deposition problem in Venezuelan crudes. In: Presented in SPE oilfield chemistry symposium, SPE 5304, Society of Petroleum Engineers

Liu F, Darjani S, Akhmetkhanova N, Maldarelli C, Banerjee S, Pauchard V (2017) Mixture effect on the dilatation rheology of asphaltenes-laden interfaces. Langmuir 33(8):1927–1942

Luo P, Wang X, Gu Y (2010) Characterization of asphaltenes precipitated with three light alkanes under different experimental conditions. Fluid Phase Equilib 291(2):103–110

MacMillan D, Tackett J Jr, Jessee M, Monger-McClure T (1995) A unified approach to asphaltene precipitation: laboratory measurement and modeling. J Petrol Technol 47(9):788–793

Mahmoudi B, Zare-Reisabadi M (2015) Experimental study of temperature effect on onset pressure of asphaltene in live oil. Pet Coal 57(4):p346

Mansoori G (1997) Modeling of asphaltene and other heavy organic depositions. J Petrol Sci Eng 17(1–2):101–111

Mansur C, Guimaraes A, Gonzalez G, Lucas E (2009) Determination of the onset of asphaltene precipitation by visible ultraviolet spectrometry and spectrofluorimetry. Anal Lett 42(16):2648–2664

Maqbool T (2011) Understanding the kinetics of asphaltene precipitation from crude oils. Ph. D. Thesis, University of Michigan

Maqbool T, Srikiratiwong P, Fogler H (2011) Effect of temperature on the precipitation kinetics of asphaltenes. Energy Fuels 25(2):694–700

Marugán J, Calles J, Dufour J, Giménez-Aguirre R, Peña J, Merino-García D (2008) Characterization of the asphaltene onset region by focused-beam laser reflectance: a tool for additives screening. Energy Fuels 23(3):1155–1161

Mofidi A, Edalat M (2006) A simplified thermodynamic modeling procedure for predicting asphaltene precipitation. Fuel 85(17):2616–2621

Mousavi-Dehghani SA, Riazi MR, Vafaie-Sefti M, Mansoori GA (2004) An analysis of methods for determination of onsets of asphaltene phase separations. J Pet Sci Eng 42(2):145–156

Mozaffari S, Tchoukov P, Atias J, Czarnecki J, Nazemifard N (2015) Effect of asphaltene aggregation on rheological properties of diluted Athabasca bitumen. Energy Fuels 29(9):5595–5599

Mozaffari S, Tchoukov P, Mozaffari A, Atias J, Czarnecki J, Nazemifard N (2017) Capillary driven flow in nanochannels—application to heavy oil rheology studies. Colloids Surf A 513:178–187

Mullins OC, Sabbah H, Eyssautier J, Pomerantz AE, Barré L, Andrews AB, Ruiz-Morales Y, Mostowfi F, McFarlane R, Goual L, Lepkowicz R (2012) Advances in asphaltene science and the Yen–Mullins model. Energy Fuels 26(7):3986–4003

Prechshot G, Dehisle N, Cottrell C, Katz D (1943) Asphaltic substances in crude oil. Trans AIME 151:188–205

Rabbani A, Gazanfari M, Najafi I (2011) A new analytical modeling of asphaltene-induced formation damage under ultrasonic stimulation. In: Presented in 6th congress of the Balkan geophysical society

Rane JP, Harbottle D, Pauchard V, Couzis A, Banerjee S (2012) Adsorption kinetics of asphaltenes at the oil–water interface and nanoaggregation in the bulk. Langmuir 28(26):9986–9995

Rassamdana H, Dabir B, Nematy M, Farhani M, Sahimi M (1996) Asphalt flocculation and deposition: I. The onset of precipitation. AIChE J 42(1):10–22

Ratovskaya A (1968) Determination of the molecular weight of asphaltenes by the thermoelectric technique. Chem Technol Fuels Oils 4(10):773–776

Ray B, Witherspoon P, Grim R (1957) A study of the colloidal characteristics of petroleum using the ultracentrifuge. J Phys Chem 61(10):1296–1302

Shadman M, Dehaghani, A;Sefti, M, Dehghanizadeh M (2012) The effect of inhibitors on asphaltene precipitation in crude oil using the viscometric method. Energy Sources Part A Recovery Util Environ Effects 34(9):827–838

Shadman M, Vafaie-Sefti M, Ahmadi S, Assaf M, Veisi S (2016) Effect of dispersants on the kinetics of asphaltene settling using turbidity measurement method. Pet Sci Technol 34(14):1233–1239

Sherman P (1964) The flow properties of emulsions. J Pharm Pharmacol 16(1):1–25