Abstract

At present, chemical flooding is one of essential enhanced oil recovery methods. In this study, three core flooding experiments (brine flooding, Alkaline, and Alkaline + Ionic Liquid slug flooding) were selected for history matching using CMG-STARS. Depending on the composition of the chemical slug, two pore volumes were injected into the porous medium to enhance the RF of heavy oil (14° API). We observed that the most challenging part of building up the model was relative permeability curves. So, the relative permeability values were tuned to end up with a successful match of cumulatively produced oil and water cut. Finally, history matching is significant to apply a wide range of assumptions and upscale the experimental results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The high volume of hydrocarbons remained unrecovered using the conventional oil recovery techniques was the main reason for seeking new scenarios. The application of efficient methods (e.g., EOR) and chemical types is necessary to improve the extraction process. But it is needed to test the new techniques using the experimental/simulation results before applying them in the field. Implementing both experimental and simulation outcomes would help well in understanding the applicability of the chosen solutions and techniques industrially.

The simulation of chemical flooding experimental results is significant to predict the ability to employ these chemicals under different conditions. One of the great simulators for modeling the laboratory results is Computer Modeling Group Ltd. (CMG). This model developed a three-phase multi-component thermal and steamed additive simulator, known as STARS (Bondino et al. 2011). STARS is the unquestioned application standard in thermal and advanced processes reservoir simulation. Besides, the grid systems can be set as Cartesian, cylindrical, or with different depth/thickness (Advanced Process and Thermal 2009). STARS is recognized for its capability to represent both experimental and field results, while it also can model complicated chemical performance (Norris 2011). However, one of the STARS restrictions is the differential pressure profile that gave misleading responses to the sensitivity analysis (AlSawafi 2015).

In this study, the history matching of experimental results was investigated using STARS. The history match is provided for waterflooding and chemical (Alkali/Ionic Liquid) flooding experiments. The production oil profile, oil cut, water cut, liquid production rate and pressure drop curves were recognized for history matching. After obtaining a suitable history match, a sensitivity study was performed to investigate the effect of chemical concentrations and oil viscosity on the RF.

Method

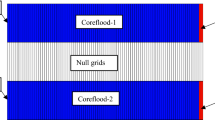

A Cartesian grid system was used to represent the sand pack samples. Grid blocks were sat as follows: ninety blocks in the flow direction were chosen to develop the simulation accuracy, and the number of the grids in the other two directions was set equal to whole to simulate 1-D flow, as shown in Fig. 1. The experimental values that were kept the same in the simulator are porosity, absolute permeability, initial water saturation and oil saturation. Table 1 represents both the rock and fluid properties of the model that have the same dimensions and characteristics of the experimental core sample. History matching is the applied method to perform a sensitive study.

Results and discussion

Simulation of chemical flooding experiment

In this study, the combinations of the chemical slugs of the experiments that were planned to be simulated are 0.7 wt% Na2CO3 (Alkaline flooding), and 0.7 wt% Na2CO3 + 1000 ppm [EMIM][Ac] (Alkaline + Ionic Liquid flooding).

The sand pack samples were modeled as a Cartesian grid to present chemical flooding experiments. The locations of injector and producer are in first and ninety blocks, respectively. The selected core flooding experiments, in this study, were presented by Tunnish (2016). Experimentally, about 6.6 PVs of brine (SPB) were injected, followed by 2 PVs of chemical slugs, and finally, two PVs of brine (SPB) were injected to flush the core sample, as detailed in Table 2. Constant injection rate (0.75 ml/min), temperature (22.5 °C), and pressure (14.7 psi) were used.

Prediction of chemical flooding performance under different conditions

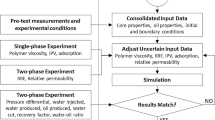

In this section, the modeled Alkaline + Ionic Liquid (AIL) experiment was chosen to perform the history matching. The effect of changing the properties of displacing phase and relative permeability curves was addressed. Adjusting the viscosity of the displacing liquid, maintaining the same concentration of chemicals in the slug, the same slug size and relative permeability curves as resulted from the experimental data was the first trial, as presented in Fig. 2. It is evident that neither the waterflooding curve nor the chemical slug additional recovery factor (RF) is close to the experimental cumulative oil recovery. For that, some properties are required to be tuned to approach the most suitable match. Previously, it was noticed that the final simulation was based on physically practical input values. These parameters involved viscosity, the performance of the relative permeability and saturation curves, and adsorption performance (Norris 2011). In another study, various relative permeability curves were required to history match the production profile of different well patterns (Tavallali 2013). So the first parameter that was chosen to vary is the pure Alkali viscosity. A range of viscosities were tested starting from the experimental (0.7 wt% Na2CO3 + SPB) mixture viscosity (1 cP) and concluding with 15 cP. Figure 3 displays the cumulative oil production curve of varying the viscosity. Also, the krw and kro curves were tuned, and the resulted cumulative oil recovery curves are presented in Figs. 4 and 5, respectively. As a conclusion, we need to work on both pure Alkali viscosity and the relative permeability curves (Fig. 6a) together to fulfill a proper history matching. Figure 6b represents a successful history matching, after tuning both pure Alkali viscosity (10 cP) and relative permeability curves (Fig. 6a). Due to the different shapes of the experimental (cylindrical) and simulator (rectangular) core sample, the bulk and pore volume of the simulator sample (80.59 cm3) are bigger than the experimental core sample (63.3 cm3). The reason for building a rectangularly shaped design in the simulator is to ensure having 1-D flow as we have in the laboratory flooding experiments. The history match of the water cut, oil cut, and pressure drop curves, as shown in Fig. 7, reported that the match was good except the pressure drop curve at the point when Alkali and Alkali + Ionic Liquid slugs were injected. Regardless of the pressure drop curve, it was clear that the match by altering the relative permeability curves, pure Alkali viscosity and maintaining the same Ionic Liquid viscosity was victorious, as the oil production profiles of both experimental and simulator results were almost overlapped. The same properties that concluded with the proper history matching were employed to make a history matching for a simulator core sample (rectangular) that has the same capacity of the experimental core sample (63.3 cm3 and with a smaller simulator diameter, 2.925 cm). The results of oil profile were excellent, as presented in Fig. 8. So the history matching of various core sample sizes is an easy challenge as long as the proper match was already performed for one of those sizes.

Simulation of waterflooding

Waterflooding results (liquid production rate, water cut, oil cut, pressure drop and cumulative oil production) were history matched by modifying oil–water relative permeability curves and keeping the original rock properties such as porosity and absolute permeability the same. Adjusting the relative permeability curves was significant to achieve a good history match of total liquid production rate curve, as can be seen in Fig. 9, and of water cut, oil cut, and pressure drop curves as shown in Fig. 10. The successful match of these parameters resulted in a satisfactory equivalent of the cumulative oil production, as presented in Fig. 11. It is clear that the simulator can easily handle the waterflooding data comparing with chemical flooding results since in waterflooding results we need to adjust the relative permeability curves only. However, the adjustment of both the relative permeability curves and viscosity of pure chemical compound is required in the case of chemical slug flooding.

Simulation of experimental chemical flooding

Five components (water, oil, Alkali, Ionic Liquid, and salts “Na, Cl, Mg2, and Ca2”) were formed to model the chemical flooding experiments. Two phases displayed in the simulation are aqueous and oleic phases. During history matching, relative permeability curves and viscosity of pure Alkali, the changeable parameters, were tuned to match the sand pack flood results. The adsorption potential of rock to the chemicals was based on the data given in the software templates.

The history-matched model was applied for various flood processes. Different experiments with different chemical slug compositions were matched. Two runs formed with 2 PV slugs of an Alkali, and 1 PV of Alkali and 1 PV of an Alkali + Ionic Liquid were simulated and history matched. For Alkaline flooding, the water–oil relative permeability curves to successfully match waterflooding (secondary flood mode), and Alkali viscosity to perfectly match the additional RF (tertiary flood mode) were tuned. According to Figs. 12 and 13, the total production rate curves, water cut and oil curves, and pressure drop curve were successfully matched, which ended with good history matching for the cumulative oil production curves, as can be depicted from Fig. 14. The cumulative oil production at the end of the first step (waterflooding) for experimental and STARS results are 45.83 and 46.00 [% OOIP], respectively. After chemical flooding and the chase water of both the experimental and simulation results, the total produced oil recoveries are 50.39 and 50.88 [% OOIP], respectively. Therefore, the CMG-STARS and experimental incremental RFs of applying chemical flooding are 4.88 [% OOIP] and 4.56 [% OOIP], respectively. The results proved the ability of CMG-STARS simulator to model chemical flooding experiments.

CMG-STARS gave an excellent history match of cumulative oil recovery profiles, water cut, oil cut, and pressure drop curves in cases of waterflooding and Alkali flooding. Besides, all curves were successfully matched, except pressure drop curve, for Alkaline-Alkaline + Ionic Liquid flooding.

Sensitivity study

The sensitivity of altering the concentrations of the chemicals in the slug and oil viscosity on the RF was investigated. The predicted results will assist us to estimate the effectiveness of employing these chemical slugs under different flooding conditions.

Effect of chemical concentration

The effect of the chemical concentrations in the injected slugs on the RF was studied. For the Alkaline + Ionic Liquid flooding, the fractions of Alkali and IL were considered separately. As shown in Fig. 14, the concentration of Na2CO3 was from 0.1 to 3 wt% It is clear that the additional RF of Alkaline slug noticeably improves as the ratio increases. Notably, the efficiency of the Alkaline slug appeared in an earlier time as the ratio advances. Regarding the additional RF of both slugs, as shown in Fig. 15, a significant enhancement in the RF as the proportion of Na2CO3 increases from 0.1 to 0.4 wt% was noticed, and slight improvement was observed as the ratio raised from 0.3 to 3 wt% Na2CO3. On the other side, when the IL concentration was examined, as can be depicted in Fig. 16, it was found that the growth in additional RF was limited as the level increased from 1000 to 10,000 ppm [EMIM][Ac], and noticeable as the concentration raised to 100,000 ppm [EMIM][Ac].

Effect of oil viscosity

To study the efficiency of AIL slug on the RF of several oil grades were considered. The range of oil viscosity from 12 to 12,000 cP was examined. Figure 17 exhibits the cumulative oil production of various oil viscosities, and it is noticed that the sweep efficiency of pure brine flooding grows as the viscosity of oil viscosity decreases, due to the reduction in oil–water mobility ratio. It is clear that the additional RF increases as the viscosity of oil increases from 12 to 1200 cP. However, the effectiveness of the chemical slug declines as the viscosity has risen from 1200 to 12,000 cP.

Conclusion

By employing the chemical simulation abilities, which are currently accessible in the simulation software, CMG-STARS, three sets of experimental results have been simulated and history matched applying physically realistic input parameters. The figures of injected PV versus water cut, oil cut, pressure drop and cumulative oil production curves display the ability of CMG-STARS to successfully history match by tuning oil–water relative permeability curves and the viscosity of Alkali. The results confirm the capability to conclude with a proper history matching of waterflooding, Alkaline, Alkaline + Ionic Liquid flooding experiments, and different core flooding sample sizes.

Abbreviations

- [EMM][Ac]:

-

1-Ethyl-3-methylimidazolium acetate

- Ka:

-

Absolute permeability

- kro:

-

Oil relative permeability

- krw:

-

Water relative permeability

- NaCl:

-

Sodium chloride

- Na2CO3 :

-

Sodium carbonate

- ppm:

-

Parts per million

- PV:

-

Pore volume

- PVinj :

-

Injected pore volume

- RF:

-

Recovery factor

- \(\emptyset\) :

-

Porosity

References

Advanced Process and Thermal Reservoir Simulator (2009) CMG STARS, version 2009. Computer Modelling Group Ltd., Calgary, AB

AlSawafi M (2015) Simulation of enhanced heavy oil recovery: history match of waterflooding and polymer injection at adverse mobility ratio. M.Sc. thesis, University of Bergen

Bondino I, Nguyen R, Hamon G et al (2011) Tertiary polymer flooding in extra heavy oil: an investigation using 1D and 2D experiments, core scale simulation and pore scale network models. In: International symposium of the society of core analysts, Austin, Texas, USA 18–21 Sept

Norris UL (2011) Core-scale simulation of polymer flow through porous media. M.Sc. thesis, University of Stavanger

Tavallali M (2013) Physical and numerical modeling of SAGD under new well configurations. Ph.D. thesis, University of Calgary

Tunnish A (2016) Study of ionic liquids as effective solvents for enhanced heavy oil recovery. Ph.D. thesis, University of Regina

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Tunnish, A., Shirif, E. & Henni, A. History matching of experimental and CMG-STARS results. J Petrol Explor Prod Technol 9, 341–351 (2019). https://doi.org/10.1007/s13202-018-0455-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-018-0455-2