Abstract

The diminishing oil resources make the exploration and development of heavy oil reservoirs more and more important. Heavy oil reservoirs need steam stimulation or other thermal development methods; temperature increasing during the thermal recovery process will inevitably affect the reservoir compressive characteristics. In order to study the variation of the compression coefficient of heavy oil reservoirs in the multi-round steam stimulation process, the compression coefficients of the reservoirs after different temperature and pore pressure cycles were tested. The results show that the compression coefficient of heavy oil reservoir decreases with the increase in effective confining pressure and increases with the increase in test temperature; After the temperature and pore pressure cycle, the compression coefficient of the rock is greatly reduced; the decrease in range of compression coefficient of the reservoir after the temperature and pore pressure cycle increases with the increase in the test temperature, and increases with the increase in maximum effective confining pressure. The dynamic variation of the reservoir compression coefficient must be taken into account in the prediction of the production capacity of multi-round steam stimulation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the increasing demands for energy resources and the declining of oil resources, more and more attentions are paid to the exploration and development of heavy oil reservoirs. Due to high density and viscosity as well as poor mobility of heavy oils, it is difficult to have recovery rate with conventional development methods (Guo and Su 2013; Bera and Babadagli 2015). Thermal recovery methods need to be used in the production to improve the recovery efficiency of heavy oil reservoirs. At present, steam stimulation is an effective thermal recovery method for heavy oils (Hamedi Shokrlu and Babadagli 2014). In steam stimulation, the oil field is produced by depleted development after the end of shut in well. The value of reservoir compression coefficient is significant for the improvement in heavy oil recovery. Compression coefficient is an important parameter which reflects the elastic energy can be provided by reservoir rocks, and high rock compressibility indicates sufficient elastic driving energy of oil reservoirs with which oil reservoirs can be easily exploited.

At present, empirical formula methods and experimental measurement methods are generally used to determine rock compressibility. The former mainly includes Hall plot method and Newman empirical formula method. The Hall plot method put forth the incorrect logical relationship that rock compression coefficient decreases with the increase in porosity and ignores the different compressibilities of different lithologies (Li 2013). Newman method only considers the relationship between rock compression coefficient and single factors, so the operating errors are large (Li et al. 2009). However, the latter obtains rock compression coefficient mainly by measuring the fluid volume flowing out due to the changes in pore volume under certain confining and pore pressure (Sun 1992). Xiao et al. (2015) and Xu et al. (2015) invented and improved the experimental device of rock compression coefficient. Based on the regression analysis on the test results of multiple groups of rock samples, Wang et al. (2007) obtained the change laws of rock compression coefficient based on the compression processes and concepts of rock compression coefficient. Liu et al. (2009) analyzed the change laws of rock compression coefficient based on the experiment and studied the factors influencing the changes in rock compression coefficient. In addition, by using the experimental method, Sadeghazad and Beiranvand (2003) researched the relationship between stress changes and rock compression coefficient. Ding and Ma (2012) and Li et al. (2009) conducted a large number of researches on rock compression coefficient and got the sensitive factors of compression coefficient.

However, the current research on the compression coefficient of rock is mainly carried out at room temperature, and the reservoir temperature is much higher than room temperature; especially for the thermal recovery reservoirs, the injection of high-temperature fluid will significantly increase the temperature of the reservoir. The temperature change can affect the deformation characteristics of rock such as elastic modulus and Poisson’s ratio (Ferrero and Marini 2001; Wu et al. 2012; Brotons et al. 2013; Li et al. 2015; Nicolas et al. 2016), but the effect of temperature variation on rock compression coefficient is lack of research. And steam stimulation will carry out multiple cycles of development; after each cycle of development, it will be accompanied by the temperature and pore pressure reduction; the effect of this cyclic change in temperature and pore pressure on the reservoir compression coefficient needs to be researched. In order to study the change laws of compression coefficient of heavy oil reservoirs in the late stage of multi-cycle steam stimulation, the authors carried out experiments on the influences of temperature, especially temperature and pore pressure cyclic changes in rock compression coefficient.

Test methods

In the oil and gas production, due to the gradual extraction of fluids in pores, the pore pressure in reservoirs will decrease and the effective stresses will increase, which result in the gradual compression of reservoirs. As reservoirs are compressed, the reduction in pore volume squeezes the fluids in pores, thus increasing the production of oil and gas. Therefore, only the changes in pore volume with pore pressure are concerned in oil and gas engineering, so traditionally the pore volume compression coefficient of rocks is named as rock compression coefficient in oil and gas engineering. Compression coefficient of pore volume, that is, rock compression coefficient, is defined as the change in unit pore volume when unit pore pressure is changed (Liu et al. 2009), and expressed as

where C p is the pore volume compression coefficient of rocks (simplified as rock compression coefficient below) (MPa−1). P and V p are the pore pressure (MPa) and the pore volume (cm3), respectively.

In order to study the compression coefficient of reservoirs under high temperature and high pressure, an experimental device for measuring rock compression coefficient at high temperature and high pressure was established. This experimental device mainly included a high-temperature and high-pressure core holder, a confining pressure system, a pore pressure system and temperature and pressure sensors. The flowchart of the device is shown in Fig. 1. Experimental equipment is shown in Fig. 2.

Flowchart of the experimental device for rock compression coefficient (1: heating device; 2: core holder; 3: vent valve for confining pressure; 4: temperature controller; 5: vent valve for pore pressure; 6: vacuum cutoff valve; 7: cutoff valve for pore pressure; 8: cutoff valve for confining pressure; 9: EDC servo control system)

The flange sealing structure was used in a core holder under high temperature and high pressure. The overall upstream and downstream plunger pistons were located in the chamber for confining pressure test, so that the end face of a rock was effectively contacted with the piston of the holder. Using the flexible graphite to seal the confining pressure in the rock samples and holder overcomes the shortage of traditional equipments that they cannot be applied for testing at high temperature when rubber is used for sealing. Furthermore, the copper casing subjected to thermal treatment in the vacuum was used to isolate the rock samples and confining pressure, which can effectively transfer confining pressure and reliably resist high temperature and pressure, so as to work continuously. The pore pressure and confining pressure were loaded by utilizing the EDC servo control system, which can automatically control the pressure. When pore pressure or confining pressure changed, the servo control system was able to compensate pressure, so that pressure was maintained at a certain value and did not change with temperature or other conditions.

This study measured the compression coefficient of rocks by measuring the changes in pore volume of rocks. In the measurement, the rock sample was placed in the envelope of the holder, and pore pressure and confining pressure were loaded in the sample and outside the envelope to stabilize the sample under confining pressure and pore pressure. After that, confining pressure was unchanged, while pore pressure would be decreased, so as to compress and decrease pore volume of the sample and force the fluids in pores to flow out. Through Eq. (2), the compression coefficient of rocks was calculated. When the test was finished, pore pressure reached the lowest and showed the maximum difference with confining pressure. Therefore, the difference between confining pressure and pore pressure at this moment was called the maximum effective confining pressure.

In the extraction of heavy oil reservoirs, multi-round steam stimulation needs to be carried out which brings about cyclic increase and decrease in reservoir temperature and pore pressure. To study the changes in compression properties of reservoirs in multi-round steam stimulation, the method with unchanged confining pressure and decreased pore pressure was used to measure the reservoir compression coefficient at high temperature. After each test, the temperature decreased to the initial temperature of reservoirs and stabilized for 2 h, before elevating the temperature and pore pressure. Then the next cycle test was carried out after the temperature and pressure systems stabilize (as shown in Fig. 3). Owing to the pore pressure of core needed to be reduced in the test, the pore pressure after finishing each test represented the reservoir pressure after finishing each round of steam stimulation. Such cycle was conducted for many times to simulate the changes in reservoir properties in multi-round steam stimulation.

Influences of temperature and pore pressure cycle on the compression coefficient

Rock samples made by sand that collected from a heavy oil reservoir buried 1540 m underground in Bohai Bay, China, were used in the test. At room temperature, the compression coefficient was 6 × 10−4 MPa−1 when the effective confining pressure was 9 MPa.

Figure 4 shows the change curves of the compression coefficient with the effective confining pressure under different cycles at 280 °C. It can be seen from the test results that the compression coefficient of rocks decreased with the increase in effective confining pressure and cycles.

When the effective confining pressure is 9 MPa and the cycle temperature is 280 °C, the change laws of the compression coefficient with cycles are demonstrated in Fig. 5. The test results display that after temperature cycles and cyclic loading of pore pressure, the compression coefficient of rocks decreased significantly. Particularly, in the 2nd cycle, the compression coefficient decreased most prominently to become merely 39.1% of that in the 1st cycle. Then, the decrease in amplitude of the compression coefficient gradually reduced and finally tended to be stable. In addition, the test results of compression coefficients after the 5th and 6th cycles only have a difference of 2%.

The reason why the compression coefficient of rocks gradually decreased with the increase in cycles mainly is that heavy oil reservoirs generally have loose cementation and easily undergo plastic deformation under stresses. Therefore, in the 1st cycle, even though the external stresses were relieved completely, the rock cannot recover to that before plastic deformation and pore space shrank, thus greatly decreasing the compression coefficient in the 2nd cycle. In the cyclic loading, due to the strain hardening effects of rocks, the elastic limit increased and the deformation resistance gradually strengthened. Therefore, with the increase in cycles, the difference in compression coefficients of two adjacent cycles gradually reduced. When the elastic limit of rocks rose to the maximum effective confining pressure, the compression coefficients of two adjacent cycles were basically the same.

With the decrease in pore pressure, the fluid in the rock pores is gradually discharged, and the porosity of the sample decreases gradually during the experiment. Take the 1st cycle of the test process as an example (Fig. 6); when the effective confining pressure increased from 3 to 15 MPa, the porosity decreased by 35%, indicating that in the process of oil production, the reservoir is gradually being compacted.

As the pore is the flow channel of the oil in the reservoir, the decrease in the porosity will inevitably hinder the flow of oil in the reservoir, resulting in the decrease in the reservoir permeability. The relationship between the porosity and the permeability of sand stone can be generally expressed as follows (Guo et al. 2006):

where ϕ is the porosity of the sample under a certain effective confining pressure, ϕ 0 is the porosity of the sample before the experiment; K is the permeability of the sample under a certain effective confining pressure, K 0 is the permeability of the sample before the experiment.

Using the porosity change in Fig. 6 and Eq. (2), the permeability of the sample during the experimental process was analyzed (Fig. 7). It was found that the permeability of the sample decreased gradually with the increase in the effective confining pressure. When the effective confining pressure increases from 3 to 15 MPa, the permeability decreased by 62%, and the reduction rate is higher than the reduction rate of porosity, which show that the permeability is more sensitive than porosity to pore pressure change. With the increase in the effective confining pressure, the plastic deformation of the sample is larger, and the plastic deformation is gradually accumulated with the increase in cycles of steam stimulation. The decrease in permeability due to plastic deformation cannot be restored even if the fluid is re-injected into the reservoir to increase the pore pressure. Therefore, in the steam stimulation of heavy oil, the greater the degree of pressure depletion in each round of production, the more detrimental to the flow of oil in the reservoir in subsequent development process.

Effects of cyclic temperature on the compression coefficient

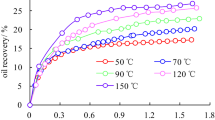

Figure 8 demonstrates the change laws of the compression coefficients at different cyclic temperatures when the effective confining pressure is 9 MPa. As shown in the figure, before the temperature cycles, the compression coefficient of rocks increased with temperature and rose by 19.5 and 25.5 times at 200 and 280 °C, respectively, compared with that at room temperature. It is obvious that the increase in reservoir temperature not only decreases the viscosity of heavy oils, but also greatly raises the elastic energy of the heavy oil reservoir, which is conducive to heavy oil recovery.

There are many defects and micro-cracks in rocks, and rocks are composed of various types of mineral particles. Under the effects of temperature, due to the differences in thermal expansion coefficients of different mineral particles, the internal structure of rock changes. Moreover, the fractures and defects are extended and connected with the increase in temperature effects (Fig. 9), affecting the physical characteristics of rocks, thus changing rock mechanical and deformation characteristics (Wu et al. 2012). The changes in the physical structure produced by high temperature undermine the original structure stability of the sample, and under the action of external effective confining pressure, the sample is more likely to deform along the defects such as these newly generated cracks. The higher the temperature, the more serious the physical structure of the sample damage, the higher the compression coefficient. So when the pore pressure decreases, the sample is more likely to deform under compression, resulting in a greater decrease in porosity and permeability in the process of production with pressure depletion in higher temperature. In addition, the rise in temperature decreased the stiffness of rock cement and increased the slippage of particles (Zhang et al. 1991; Yin et al. 2014). Finally, the deformation resistance of rocks was weakened and the compression coefficient increased.

Morphology of sandstone at different temperatures (Yin et al. 2012). a 25 °C, b 200 °C, c 400 °C, d 600 °C

With the increase in test temperature, the influences of temperature on the compression coefficient of the reservoir after temperature cycles gradually rose, that is, the higher the temperature, the more greatly the compression coefficient of the reservoir decreased after the cyclic treatment. Compared with the test results of the first cycle, the compression coefficient in the second cycle ia reduced by 39.7, 55.9 and 60.9% at 100, 200 and 280 °C, respectively. Due to the large initial compression coefficient of the reservoir at high temperature, the difference in compression coefficients at different temperatures gradually reduced after multiple cycles of temperature and pore pressure. In other words, after multiple rounds of steam stimulation in the thermal recovery of heavy oil, the effects of temperature on the compression coefficient gradually decreased. Even though the sample of the reservoir at a high temperature underwent multiple temperature and pore pressure cycles, the compression coefficient was still far higher than that at room temperature.

The reason for the existence of differences in compression coefficients of two adjacent cycles mainly is that the plastic deformation of the rock occurred under high effective confining pressure, while the propagation of defects and cracks in the rock strengthened the plasticity under the effects of high temperature, thus enhancing the plastic deformation under stresses. The higher the temperature was, the less the rocks can recover from the deformation after the first test of compression coefficients, which therefore resulted in a larger difference in compression coefficients in the first and second cycles.

Impacts of the maximum effective confining pressure on the compression coefficient after the cycles

In order to further study the formation energy in the late stage of multiple rounds of steam stimulation, the influences of different maximum effective confining pressures on the compression coefficient of rocks were analyzed. Figure 10 shows the relationship between the compression coefficient of the rock and cycles under different maximum effective confining pressure. As demonstrated in the figure, when the temperature was the same, the larger the maximum effective confining pressure after each test, the more greatly the compression coefficient decreased with cycle times. At 280 °C, when the maximum effective confining pressure was 15 MPa, the compression coefficient after the first cycle showed a difference of 60.9% with that of the second test results and 74.2% with the final compression coefficient in the 6th cycle, while when the maximum effective confining pressure was 9 MPa, the compression coefficient in the first cycle had differences of 48.1 and 61.4% with that of the second cycle and the final compression coefficient in the 6th cycle. Therefore, in steam stimulation process, the more serious the reservoir pressure depletion in each round of steam stimulation, the more unfavorable it was to the next round of development.

In the compression coefficient test, the discharge of fluids in pores is mainly because of the compressive deformation of the rock resulting from the gradual increase in effective confining pressure. According to the stress–strain relationship of rocks in compressive test, when the stress loaded on rocks was small, the elastic deformation occurred at first. When the stress gradually rose and exceeded the elastic limit, the plastic deformation occurred and increased with stresses. Therefore, when the maximum effective confining pressure was low, the plastic deformation of the rock was small after each test of compression coefficient. After the reduction in the effective confining pressure, with the recovery of the rock from elastic deformation, there were still many pores. Therefore, the effects of temperature and pore pressure were relatively small. However, when the effective confining pressure is high, the plastic deformation will gradually accumulate with the increase in cycles, so that the pore space of the sample will become smaller and smaller, and the effect of the maximum effective confining pressure on the sample compression coefficient will increase with the increase in the number of cycles. Therefore, in the process of steam stimulation, the more serious the pressure depletion in every cycle of production, the smaller the elastic energy of the reservoir in the subsequent production process. At the same time, due to plastic deformation is too large, severe pressure depletion will lead to the decrease in porosity and permeability in the later stage of steam stimulation, which is not conducive to the ultimate recovery rate of the oilfield.

Conclusions

The compression coefficient of the heavy oil reservoir gradually decreased with the increase in the effective confining pressure, while it increased with the rise in experimental temperature.

After the temperature cycles and cyclic loading of pore pressure, the compression coefficient of the rock reduced significantly. In particular, the compression coefficient decreased the most significantly in the 2nd cycle, and afterward, it gradually decreased and then stabilized in the 6th cycle.

When the maximum effective confining pressure was same in the test, the decrease in amplitude of the compression coefficient of the reservoir gradually grew after the cycles with increasing test temperature. When the experimental temperature was the same, the larger the maximum effective confining pressure was after the test, the larger the decrease in amplitude of compression coefficients after the temperature cycles and cyclic loading of pore pressure. Therefore, in the steam stimulation, the more serious the reservoir pressure depletion in each round of development, the more unfavorable it was to the next round of development.

In the process of steam stimulation, the changes in temperature of injection steam and reservoir pressure in development will affect the compression coefficient of the reservoir. In the prediction of productivity in the late stage of multiple rounds of steam stimulation, the dynamic changes in the compression coefficient of reservoirs need to be considered.

References

Bera A, Babadagli T (2015) Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: a review. Appl Energy 151:206–226

Brotons V, Tomás R, Ivorra S, Alarcón JC (2013) Temperature influence on the physical and mechanical properties of a porous rock: San Julian’s calcarenite. Eng Geol 167:117–127

Ding KW, Ma SG (2012) A method for a rapid calculation of reservoir rock compressibility. Spec Oil Gas Reserv 19(6):65–67

Ferrero AM, Marini P (2001) “Experimental studies on the mechanical behaviour of two thermal cracked marbles. Rock Mech Rock Eng 34(1):57–66

Guo T, Su Y (2013) Current status and technical development direction in heavy oil reservoir development in Bohai Oilfield. Chin Offshore Oil Gas 25(4):26–30

Guo X, Du Z, Zhou Z (2006) Fluid-solid coupled flow simulation in unconsolidated sandstone reservoir. J Southwest Pet Inst 28(4):53–56

Hamedi Shokrlu Y, Babadagli T (2014) Kinetics of the in situ upgrading of heavy oil by nickel nanoparticle catalysts and its effect on cyclic-steam-stimulation recovery factor. SPE Reserv Eval Eng 17(03):355–364

Li CL (2013) One more discussion on the compressibility of reservoir rocks: in reply to Dr. Gao Yourui. Chin Offshore Oil Gas 25(4):85–87

Li H, Wang D, Li J, Yang L, Li XA (2009) prediction method for reservoir rock compressibility. Fault-Block Oil Gas Field 16(1):45–47

Li C, Xie L, Chen S, Dou S, Xu B (2015) Experimental research on mechanical and thermal properties of oil sand. Rock Soil Mech. 36(8):2298–2306

Liu R, Feng W, Long L (2009) Experimental study on rock pore volume compressibility. Oil Drill Prod Technol 31(4):79–82

Nicolas A, Fortin J, Regnet JB, Dimanov A, Guéguen Y (2016) Brittle and semi-brittle behaviours of a carbonate rock: influence of water and temperature. Geophys J Int 206(1):438–456

Sadeghazad A, Beiranvand B (2003) Unusual Carbonate Rocks Showing Increasing Trends for Rock Compressibility as the Applied Net Stress Increases. In: SPE Asia Pacific Oil and Gas Conference and Exhibition, Society of Petroleum Engineers. https://doi.org/10.2118/80442-MS

Sun LT (1992) Reservoir physics experiment. Petroleum Industry Press, Beijing

Wang XH, Song Y, Fang HF (2007) Transforming laws of rock compressibility. J Oil Gas Technol 29(1):42–45

Wu G, Wang D, Zhai S, Li Y, Chen J (2012) Test research on mechanical properties of marble under high temperature. Chin J Rock Mech Eng 31(6):1237–1244

Xiao W, Zhou W, Li MA (2015) Real-time measuring device for measuring the permeability, porosity and compressibility of rock and its measuring method and calculating method. Chinese Patent, CN104713814A[P]

Xu X, Hu Y, Jiao CA (2015) Testing device of core pore compressibility and its testing method. Chinese Patent, CN104374683A[P]

Yin TB, Li XB, Yin ZQ, Zhou ZL, Liu XL (2012) Study and comparison of mechanical properties of sandstone under static and dynamic loadings after high temperature. Chin J Rock Mech Eng 31(2):273–279

Yin S, Li X, Yin Z (2014) Static and dynamic mechanical properties of sandstone after high temperature. In: Proceedings of the MTS materials testing conference of Central South China

Zhang Y, Chu Z, Chen Y (1991) Research status and prospect of thermal cracking of rock. Spec Oil Gas Reserv 16(2):1–5

Acknowledgements

This work is financially supported by the Changjiang Scholars and Innovative Research Team in University (Grant No. IRT_14R58), the State Key Laboratory Program of Offshore Oil Exploitation, the National Natural Science Foundation Project of China (Grant No. 51704311, 51504040), the Qingdao National Laboratory for Marine Science and Technology (QNLM2016ORP0212) and the Shandong Provincial Natural Science Foundation, China (ZR2017BEE073).

Author information

Authors and Affiliations

Corresponding author

Additional information

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Chuanliang, Y., Yuanfang, C., Ji, T. et al. The influence of steam stimulation on compression coefficient of heavy oil reservoirs. J Petrol Explor Prod Technol 8, 1287–1294 (2018). https://doi.org/10.1007/s13202-017-0404-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-017-0404-5