Abstract

Poor raw water quality has led science and technology research to explore more environmentally friendly water treatment methods, such as advanced oxidation processes. Ferrate (VI) salts have been regarded as a new green oxidant, cost-effective, and coagulant/flocculent in a single mixing and dosing unit in wastewater treatment. This research aimed to synthesize calcium ferrate (CaFeO4), a benign green chemical that can be utilized to treat water and wastewater through a facile wet oxidation process, with minimal increase in electrical conductivity. This study used the wet oxidation approach to synthesize stable aqueous calcium ferrate in an alkaline media using distilled water. During process optimization, CaFeO4 was synthesized and named 60-CaFeO4, 70-CaFeO4, 80-CaFeO4, and 90-CaFeO4, where the numbers represent the synthesis temperature. The prepared CaFeO4 was characterized using XRD, FT-IR, UV–Vis, TEM, SEM, Raman, and redox titration. FT-IR analysis confirmed the presence of the Fe–O stretching vibrations in all the freeze-dried CaFeO4 powders, signifying the successful preparation of the materials. The physicochemical characteristics of raw water, such as turbidity, color, COD, pH, EC, and TDS, were analyzed before and after treatment with CaFeO4. A jar test was performed to evaluate the reactivity and efficiency of the CaFeO4 toward wastewater treatment through coagulation/flocculation processes. After coagulation using CaFeO4, the pollutants levels were reduced COD (43.56–71.56%) and turbidity (97–99%), signifying the effectiveness of the as-prepared materials. CaFeO4 was successfully produced at various temperatures and was stable enough to be stored at room temperature for over six months without significantly decomposing.

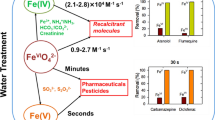

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water quality in some natural water sources has deteriorated due to rapid urbanization and industrialization, making it imperative to develop highly efficient and low-cost water treatment technologies with the capacity to deal with high loads of pollutants. The most conventional coagulants for wastewater or drinking water treatment are ferric chloride, aluminum, and ferric sulfates (Chorghe et al. 2017; Talaiekhozani et al. 2017). These coagulants reduce sensory indicators (turbidity, chromaticity, and others) of raw water and remove microorganisms, oxidize organic and inorganic contaminants, and remove colloidal/suspended particles and heavy metals (Ghernaout and Elboughdiri 2019). Ferrate (VI) salts in the form of calcium ferrate (CaFeO4) can serve as a chemical reagent to meet the abovementioned requirements. Historically, potassium ferrate and the metal ferrate family in groups I and II have been known for a long time (Kooti et al. 2010).

Iron often exists in + 2 and + 3 oxidation states, and a high oxidation state of + 6 (Ferrate VI) is formed under strongly oxidizing and alkali conditions (Tiwari and Lee 2014). Researchers have discovered that ferrate (VI) is an effective oxidant across a wide pH range, with its highly acidic and basic redox potential of + 2.20 V and + 0.70 V, respectively, when compared to other oxidants such as chlorine (1.36 V), hypochlorite (1.48 V), chlorine dioxide (0.95 V), hydrogen peroxide (1.78 V), dissolved oxygen (1.23 V), and permanganate (+ 1.68 V) (Delaude and Laszlo 1996; Jiang and Lloyd 2002; Rai et al. 2018; Sharma 2002; Wood 1958). Due to this factor of having one of the most positive redox potentials, ferrate (VI) makes an ideal environmentally friendly chemical for drinking water and wastewater treatment. However, ferrate (VI) can be a tailor in wastewater treatment at the chlorination stage as it can act as a sterilant.

Comparing ferrate (VI) with other coagulants/flocculants in terms of effectiveness and cost for treating wastewater requires examining their performance in different aspects of wastewater treatment. In this investigation, the initial concentration of phenol varied within the range of 0.5–5.0 mg L−1. Three distinct iron sources were utilized in separation: FeCl3 as a conventional coagulant, Fe(OH)3 derived from exclusively reducing Fe(VI) solution in water of Fe(VI) solution in water. The amount of each of the iron sources was varied to maintain a consistent iron to phenol ratio of 20:1. Polyaluminum chloride (PAC) was utilized as a coagulant at a concentration of 5 mg L−1 (Sun et al. 2016). In the conducted experiments involving the utilization of coagulants, the pH level was appropriately adjusted to a value of 7.0. The percentage of phenol removed by FeCl3 ranged from 4.2% to 4.8%. The percentage of phenol removed by Fe(OH)3 ranged from 5.5 to 5.8%. The removal efficiency of phenol by Fe(VI) was observed to be 59.1%, 67.6%, and 69.2% at concentrations of 0.5, 2.0, and 5.0 mg L−1, respectively. In the instance of PAC, the removal percentage was recorded as 5.0 Sun's (2016) research demonstrates strong proof that the predominant mode of phenol removal using Fe(VI) was oxidation, as indicated in the study by (Sun et al. 2016).

Ferrate (VI) exhibits multiple treatment mechanisms such as Oxidant, disinfectant, and coagulation. The ferrate (VI) ions are further reduced to Fe (III) ions or ferric hydroxide (which are non-toxic by-products), and this simultaneously generates a coagulant or flocculent with a single dose and mixing unit (Jiang and Lloyd 2002; Sharma 2002). Terminal oxo ligands are the most stable among all Fe (VI) materials. However, ferrate (FeO42−) is a more potent oxidant under acidic conditions when compared to other oxidants. Hence, it has the potential to be applied in several fields, such as the oxidation of organic substrates (Kooti et al. 2010), the disinfection of water, and the degradation of organic synthetic pollutants (Jiang 2007; Kooti et al. 2010; Tiwari and Lee 2014).

In wastewater treatment, ferrate (VI) exhibits multiple treatment mechanisms (coagulant, disinfectant, and oxidant) and can simultaneously remove turbidity, dissolved organic carbon, and particulate matter, lowering residual iron and microbial activity while also lowering the concentrations of SS, COD, BOD, phosphorus, and micro-pollutants (Jiang 2013). Moreover, ferrate (VI) is considered as natural and friendly water treatment chemical and does not form toxic by-products (Anon 2020). Ferrate (VI) does excellent work than other coagulants and disinfectants cannot do. Another advantage about ferrate is that it is synthesized using the least expensive chemicals, such as hypochlorite, alkali hydroxides such as (NaOH and KOH), and ferric chloride, which makes ferrate the best option for wastewater and water treatment. In acidic conditions, the redox potential (+ 2.20 V) of Fe (VI) ions is more potent than that of O3 (2.08 V), and it is a powerful water chemical treatment reagent as compared to other reagents such as chlorine, hydrogen peroxide, ozone, dissolved oxygen, etc. In addition, during the oxidation or disinfection process, Fe (VI) ions are reduced to Fe (III) ions or Fe (OH)3, which also leads to the production of coagulants within a single dose (Jiang 2013).

A wet oxidation method was adopted in this study with some reaction conditions modifications since it was found to be relatively easy to deploy, following the Thompson process (Munyengabe et al. 2021; Thompson et al. 1951; Tong et al. 2021). All preparation steps and conditions must be carefully monitored and controlled throughout the process to produce ferrate (VI) of high quality and reactivity. This method can have stable and high-purity Ferrate (VI) (Jiang and Lloyd 2002). This work focuses on synthesizing CaFeO4 using ferric chloride and calcium hypochlorite (oxidizing agent) under alkaline conditions (Calcium hydroxide). Ferrate (VI) in CaFeO4 has solely been investigated toward wastewater treatment. Previous studies shows the successful preparation of calcium ferrate (IV) by mixing sodium/potassium ferrate with calcium ferrate (Maghraoui et al. 2020; Xu et al. 2007).

Herein this study, a slightly modified wet oxidation approach was employed for the synthesis of CaFeO4. To investigate the effect of temperature on the formation of the CaFeO4, a series of CaFeO4 were prepared at different temperatures (60, 70, 80, and 90 °C), and were represented as 60-CaFeO4, 70-CaFeO4, 80-CaFeO4, and 90-CaFeO4, respectively. The as-synthesized series of CaFeO4 samples were characterized using X-ray diffraction (XRD), Fourier transform infrared (FT-IR), scanning electron microscopy (SEM), transmission electron microscopy (TEM), Ultraviolet–visible (UV–Vis), Raman techniques, and redox titration to validate their successful preparation. The performances of the as-prepared samples were evaluated using real wastewater samples by performing a simple jar test.

Synthesizing CaFeO4 at various temperatures offers significant advantages by allowing the manipulation of material properties and applications. This controlled synthesis permits the customization of crystal structure, morphology, and composition, improving functional attributes for specific purposes. Elevated temperatures facilitate efficient crystallization and the formation of a distinct ferrate phase. The resulting highly crystalline phases at high temperatures enhance stability and catalytic activity. This process also enhances crystallinity and phase purity by eliminating impurities and amorphous phases. Particularly in water treatment applications, CaFeO4 is an oxidizing agent to eliminate pollutants, organic compounds, and heavy metals from water sources (Jiang and Lloyd 2002). The effectiveness of CaFeO4 in this role depends on its oxidation state, particle size, and surface reactivity. Varying synthesis temperatures can modify these properties, optimizing the material for efficient water treatment. Higher temperatures may lead to smaller particle sizes and increased surface reactivity, bolstering its ability to effectively oxidize contaminants. Calcium ferrate is a promising, eco-friendly oxidant and water treatment agent, garnering attention for its advantages over conventional water treatment techniques (Sharma 2002; Sharma et al. 2005).

The efficiency of the samples in water treatment were investigated by evaluating the physical and chemical properties such as chemical oxygen demand (COD), electrical conductivity (EC), turbidity, and total dissolved solids (TDS) of the treated wastewater samples. This work paves the way toward using green and straightforward techniques with environmentally friendly nanomaterials for wastewater treatment. The synthesized CaFeO4 nanomaterials will reduce the need to use harsh chemical and energy-demanding approaches toward improving water quality.

Experimental

Chemicals reagents

Ferric chloride (FeCl3, 43% m/m) was purchased from NCP Chlorchem Pty. Ltd. (Kempton Park, South Africa). Calcium hypochlorite (Ca(OCl)2, 70% m/m) was purchased from HTH (Kempton Park, South Africa), and Calcium hydroxide (Ca(OH)2) was purchased from Protea Laboratory Solutions (Pty) Ltd (Midrand, South Africa). Ammonium ferrous sulfate hexahydrate ((NH4)2Fe(SO4)2·6H2O), analytical reagent) was purchased from ACE Chemicals (Johannesburg, South Africa), and Oxalic acid dehydrate (99%) was purchased from Sigma-Aldrich (Missouri, United States). H93754C COD (HR). Reagent Vials (0–15,000 mg/L) were purchased from Hanna instruments (Bedfordview, South Africa).

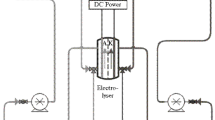

Synthesis of CaFeO4

A literature procedure was used for synthesizing calcium ferrate (CaFeO4) with modifications (Munyengabe et al. 2021; Tong et al. 2021). Briefly, appropriate ratios of Ca(OCl)2 and Ca(OH)2 was dissolved in 500 mL and 250 mL of ultra-water, respectively. These solutions were then mixed, followed by the introduction of FeCl3. The used volume ratio in the mixture was 1:5:10 (v:v:v), corresponding to FeCl3, Ca(OH)2, and Ca(OCl)2. The reaction vessel was kept in an ice water to avoid initial overheating of the exothermic reaction. The resulting solution was then transferred into 100 mL of hot water set at temperatures of 60, 70, 80, and 90 °C. The formation of CaFeO4 was accelerated by the constant stirring of the mixture (350 rpm) for 15 min to assess the effect of temperature on the production yield of the CaFeO4. The resulting CaFeO4 solutions 60-CaFeO4, 70-CaFeO4, 80-CaFeO4, and 90-CaFeO4 were then freeze-dried to obtain dried powders (Fig. 1). To optimize the equivalent ratios of the reactants (FeCl3, Ca(OH)2, and Ca(OCl)2), a series of different ratios of 1:5:20, 1:10:40, 1:10:60, 1:20:20 and 1:30:20 (v:v:v) of FeCl3, Ca(OH)2, and Ca(OCl)2 were also employed at the optimum temperature of 90 ℃ to prepare as series of test products: 90-CaFeO4, to evaluate the influence of FeCl3, Ca(OH)2, and Ca(OCl)2 concentration toward the formation of CaFeO4. The synthesis calcium ferrate proceeded theoretically, as shown in Eq. 1.

Instrumentation

The synthesized liquid calcium ferrate was freeze-dried at -70 °C and dried in a vacuum for two days to remove moisture and water from hydration. X-ray diffraction patterns of the dried sample of calcium ferrate were obtained on a Panalytical X'Pert X-ray Diffractometer operating with Cu Kα radiation at a wavelength of 0.1540 nm (40 kV, 40 mA). XRD patterns were scanned to evaluate the crystal structures of the as-synthesized materials in the 2-theta (2θ) range of 4.0°–80.0°. For functional group identifications, FT-IR spectra of the prepared calcium ferrate samples were obtained in the frequency range of 500–4000 cm−1 using a Perkin-Elmer Spectrum 100 spectrometer (Perkin-Elmer, USA). Scanning electron microscopy (SEM, TESCAN VEGA 3 XMU, LMH instrument, Czech Republic) instrument coupled with energy dispersive x-ray spectroscopy (EDX) were employed to evaluate the morphology and elemental distribution of the materials at an accelerating voltage of 20 kV under nitrogen gas. Transmission electron microscopy (TEM) images were acquired using a JOEL-JEM, 2010 microscope with an accelerating voltage of 200 kV, and the samples were spotted on carbon-coated copper grids using ethanol as a dispersant solvent. The Raman spectra were obtained with a Raman Micro 200 Perkin Elmer configured with a laser wavelength of 532 nm, a laser power of 8.0 mW, and a wavenumber range of 50 to 1500 cm−1. Calcium ferrate (VI) optical absorption spectrum was recorded with a Genesys 180 UV–visible absorption spectrophotometer (Thermo Fisher Scientific, America). pH meter (Ohaus Starter ST20 Pen pH Meter with Thermometer), conductivity (Ohaus Starter ST20 Pen Conductivity Meter with an in-built Thermometer), water color (HI96727 Platinum Cobalt Colorimeter (PCU) supplied by Hanna), turbidity (EPA) (Portable Meter), chemical oxygen demand (COD). Photometer-HI83399 and COD Test Tube Heater–HI839800 supplied by Hanna, and the ICP-OES (iCAP 6500 Duo, Thermo Scientific, UK) were used to monitor the physico-biochemical quality parameters of the water before and after treatment with Ferrate (VI).

Redox titration procedure

-

Preparation of 1 M sulphuric acid: exactly 27.77 mL of concentrated H2SO4 (18.0 M) was diluted with ultra-pure water into a volumetric flask of 500 mL.

-

Preparation of 0.1 M oxalic acid solution: A mass of 12.607 g of oxalic acid was weighed, dissolved in ultra-water, transferred to a 1 L volumetric flask, and diluted accordingly.

-

Preparation of 0.5 M Mohr salt (NH4)2Fe(SO4)2·6H2O) standard solution: A mass of 9.8 g of Mohr salt was weighed, dissolved in ultra-water, transferred to a 500 mL volumetric flask, and made up to the mark. Data was used to calculate the molar concentration of the prepared CaFeO4 under the aforementioned conditions.

-

Titration of oxalic acid with CaFeO4 solution: A 10.00 mL aliquot of the 0.100 M oxalic acid standard solution followed by 5 mL of 1 M H2SO4. Afterward, the solution was heated to about 50 – 60 °C and titrated with until the color of the hot solution changed from colorless to pale pink. Data was used to calculate the molar concentration of the prepared CaFeO4 under the aforementioned conditions.

-

Titration of Mohr salt with CaFeO4 solution: the molar concentration of CaFeO4 was determined by another titrimetric method using the Mohr as standard. Exactly 10.00 mL of Mohr salt solution was transferred to a conical flask and 5 mL of 1.0 M H2SO4 to make the solution acidic. The acidic solution was titrated with CaFeO4 until the color changed from colorless to pale pink.

Water sampling and site description

Five samples of raw water were collected from Hartbeespoort dam at three different sites and stored in the refrigerator at 4 °C. Hartbeespoort Dam, which is situated 40 km west of Pretoria between Daspoort Hill on the South end and the Magaliesburg Mountains on the North end and was used as the study site. This dam has a surface area of 20 km2, a volume of 192.8 × 106 m3, a maximum depth of 45 m, and a mean depth of 9.6 m, and a maximum depth of 45 m (Carroll and Curtis 2021). At its inception, the Hartbeespoort Dam was indeed constructed for irrigation purposes. The dam is located in the North West Province of South Africa and was built on the Crocodile River in the 1920s. It was officially completed in 1925. The primary objective of constructing the Hartbeespoort Dam was to provide a stable and reliable water supply for irrigation in the surrounding agricultural areas. The dam was intended to help boost agricultural productivity and support the local farming communities by ensuring a consistent water source during dry periods. Over the years, the demand for water in the region increased due to population growth and industrial development. As a result, the usage of the Hartbeespoort Dam evolved, and it began to be utilized for various other purposes beyond irrigation [8], [86–87]. In South Africa, Hartbeespoort Dam ranks as one of the most polluted dams due to its high levels of phosphates, nitrates, heavy metals, and chemical oxygen demand (COD). The dam is now swamped by water hyacinths an indication of the worsening extent of eutrophication and general contamination due to the incipient nutrients and other pollutants from its catchment basin.

Jar flocculation test methodology

The objective of jar test experiments is to determine the optimal conditions for the removal of specific substances, such as color due to humic compounds, turbidity, COD, and TDS using a coagulant called CaFeO4. Jar test experiments are a common procedure used in water treatment plants and laboratories to assess the effectiveness of coagulants in removing impurities from water.

A jar test was conducted to evaluate the coagulation process and oxidative capabilities of the prepared CaFeO4 material on the removable pollutants from the untreated water from Hartbeespoort dam. Five portions of 100 mL of water raw samples were transferred to five 250 mL flasks and labeled according to their sampling site and to the temperature (60, 70, 80, 90 °C) used to synthesize the calcium ferrate test samples. The pH, electric conductivity, turbidity, color, COD, and TDS were measured before adding the as-prepared calcium ferrate (coagulant and oxidant/disinfectant). A volume of 40, 50, 60, 70, and 90 µL, as-prepared CaFeO4 sample (i.e., 60-CaFeO4, 70-CaFeO4, 80-CaFeO4, 90-CaFeO4) was added to the dam wastewater and stirred vigorously with a magnetic stirrer for 4 min and then slowly for 8 min. After allowing the samples to settle (sedimentation and clearance of the supernatant) for about 3 h, the optimum performing CaFeO4 (based on the extent of flocs formation) was noted and selected for further pre-oxidation the water as well as evaluating the best equivalence ratio of the reactants. The flocculated residues were then removed by decanting and filtered through a 0.45 μm filter. All the physicochemical parameters of the treated and filtered wastewater were evaluated. A pre-oxidation of 100 mL of sewage in a jar test was conducted (same procedure mentioned above) with 90 µL of the best performing CaFeO4 solution for the removal of all oxidizable, including algae.

Results and discussion

CaFeO4 was synthesized at various temperatures and molar ratios by the wet oxidation method and the highest was 90 ℃, refer to Table 1. All products showed greater stability over six months (Fig. 2) compared with other ferrates like K2FeO4 and Na2FeO4 (Talaiekhozani et al. 2017). The ratio of the reactants also influenced the molar concentration of the CaFeO4 that was produced. Initially, a ratio 1:5:10 of FeCl3; Ca(OH)2; Ca(OCl)2 was used to prepare CaFeO4, which resulted in a pink-colored solution signifying the formation of the expected CaFeO4. Moreover, CaFeO4 samples were synthesized at 90 ℃ (to yield a series of 90-CaFeO4 using different ratios (i.e., 1:5:20, 1:10:40, 1:10:60, 1:20:20 and 1:30:20 (v:v:v)) to evaluate the effect of mole ratio of FeCl3 Ca(OH)2 and Ca(OCl)2 toward the molar yield of CaFeO4. Based on the color intensity of the prepared solutions of CaFeO4 (at an optimum temperature of 90 ℃ and different ratios)yielded lower concentrations of the products.

The solution where the molar ratio, FeCl3:Ca(OCl)2, exceeded 4, i.e., the 1:5:20, resulted in a very faint pink colored solution than the 1:5:10. This could be attributed to the low concentration of Ca(OCl)2, being in lower molar ratio limits the oxidation of Fe (III) to Fe (VI). Moreover, an excess amount of Ca(OCl)2 also results in observable CaCl2 precipitates, and the solution becomes more heterogeneous, which limits the reaction between Fe(III) and OCl− ions (Tong et al. 2021). In contrast, the OCl− ions decompose at temperatures beyond the optimal (~ 90 °C), which results in Fe(III) is not properly oxidized into Fe(VI) (Tong et al. 2021).

Phase structure

The crystal structure of the as-synthesized CaFeO4 was assessed using XRD. The XRD patterns of CaFeO4 prepared at 60 °C, 70 °C, 80 °C, and 90 °C temperatures are exhibited in Fig. 3. The XRD diffractograms of CaFeO4 were obtained by scanning 2Ө (degree) values ranging from 4 to 80°. All the as-prepared CaFeO4 materials exhibits sharp characteristic crystalline peaks at 28.10°, 31.7°, 38.28°, 45.36°, and 46.94°, corresponding to (101), (200), (103), (220), and (110), respectively. The observed XRD patterns are in accordance with previous studies, signifying the successful preparation of the material (Xu et al. 2007). The XRD spectrum of Na2FeO4 matches closely with the XRD spectra of BaFeO4 (Koltypin et al. 2006), as well as with the XRD spectra of calcium ferrate (Fig. 3) (Maghraoui et al. 2013; Munyengabe et al. 2021). The close resemblance between Na2FeO4 and BaFeO4 XRD spectra indicates that the synthesized material likely possesses a crystal structure similar to that of calcium ferrate. Calcium ferrate is known to exhibit an orthorhombic polymorphic phase, which is consistent with the crystal structure observed in the synthesized Na2FeO4 material. This agreement aligns with findings in the existing literature (Xu et al. 2007).

Phase structures of CaFeO4 samples were further evaluated using Raman spectroscopy. The Raman spectra in Fig. 4 shows seven distinctive characteristic peaks corresponding to CaFeO4 active optical vibrations. The intense symmetrical peaks at 742.68 and 728.93 cm−1 are ascribed to the A1 vibrational mode of Fe–O bonds highlighted in yellow (Cheung et al. 2021). The set of peaks at 674.27 and 593.16 cm−1 corresponds to T2 (υ3 depolarized), highlighted in cyan, peaks at 477.08 and 428.03 cm−1 correspond to T2 (υ2 depolarized) highlighted in pink, and lastly, the peaks at 347.82 cm−1 correspond to T2 (υ4 depolarized) highlighted in green (Cheung et al. 2021).

Microstructure and morphology

The morphological structures of the prepared CaFeO4 samples were evaluated using SEM and TEM. Figure 5a shows the SEM images of the materials prepared at different temperatures, where nanoparticles with intertwined ultrathin nanosheets were observed. However, the dominating observed morphologies were nanoparticles, and this can be observed on the magnified SEM images on the supporting information (SI) in Fig. S1. The prepared CaFeO4 exhibits a similar SEM morphological structure to a previously reported CaFe2O4 (Wang et al. 2019). TEM analyzes were further conducted to ascertain for the observed morphology and also to calculate the particle sizes of the prepared CaFeO4. Figure 5b clearly shows spherical nanoparticles with an average size distribution of 7, 7, 7, and 9 nm for 60 °C CaFeO4, 70 °C CaFeO4, 80 °C CaFeO4, and 90 °C CaFeO4, respectively. The data shows a fairly similar average size distribution irrespective of the temperature used to prepare the material. The average size distribution curve for 70 °C CaFeO4 and 80 °C CaFeO4 are shown on the SI in Fig. S2.

Spectral and chemical composition data

EDS, elemental mapping, and FT-IR were used to investigate the spectral and elemental composition and functional groups of the prepared CaFeO4 materials, respectively. Figure 6a exhibits the elemental compositions for 60 °C CaFeO4 and 90 °C CaFeO4 as examples. Peaks of the expected elements from CaFeO4 were observed, other elements, such as carbon (C) and Cl, are due to coating and the used FeCl3 reagent, correspondingly. Elemental mapping for the optimal 90-CaFeO4 sample exhibited in Fig. 6b shows a uniform dispersion of the expected elements.

The characteristic functional groups of CaFeO4 prepared at different temperatures are presented in the FT-IR spectra (Fig. 7). Typical vibrational modes of ferrate were observed at 676 and 876 cm−1 credited to the Fe–O (asymmetric stretching) bond (Cheung et al. 2021). These peaks were observed in all the CaFeO4 materials. The peak at 729 cm−1 corresponds to the symmetric bending mode and further confirms the presence of the Fe–O bond in the as-prepared CaFeO4. Furthermore, the peaks observed at 1472 cm−1 and 1638 cm−1 are attributed to the characteristic peaks of the C-O and C=O bond stretching vibration, respectively, which could be triggered by the CO2 in the air (Martinez-Tamayo et al. 1986). The peaks shown between 3262 and 3654 cm−1 are attributed to the O–H stretching vibration of adsorbed moisture (Lei et al. 2013; Peleyeju et al. 2017). The FT-IR analysis shows that the CaFeO4 structure is maintained throughout the different synthetic temperatures. In addition, variations in peak intensity observed in Fourier-transform infrared spectroscopy (FTIR) measurements for different samples can be attributed to concentration differences. Variations in the concentration of the compounds in the sample can lead to variations in peak intensities.

Ultraviolet–visible (UV–Vis)

The UV–Vis absorption spectra of the as-prepared CaFeO4 are depicted in Fig. 8 as having two maxima absorption peaks at 524.98 and 544.99 nm, with shoulder absorption peaks located at 505.3 and 569.97 nm. Despite this, the wavelength of Ferrate (VI) in various research is around 505–510 nm (Cheung et al. 2021; Jiang 2013). CaFeO4 solutions synthesized at various temperatures of 60 °C, 70 °C, 80 °C, 90 °C, and 100 °C have a purple color, indicating that Ferrate (VI) ions are formed for each the synthetic trial. However, the color intensity of the CaFeO4 60 °C and 70 °C is faint pink-purplish because the heat is insufficient to accelerate the production of Ferrate (VI) ions. At 80 °C and 90 °C, the CaFeO4 solution has the same and more intensity color, indicating that more CaFeO4 is formed, however, at 100 °C, the color became faint, which may be due to the decomposition of Ferrate (VI) ions.

Table 1 represents the temperature trend during the synthesis of CaFeO4. The concentration of Fe(VI) ions is increased from 0.1879 to 0.4716 M when the reaction temperature increases from 60 to 90 °C (oxalic acid titration). The concentration was reduced drastically when the temperature was elevated to 100 °C. The observations might be attributed to the fact that as the temperature increased, the activity of the reactants increased during the chemical reaction to accelerate the reaction rate (Tong et al. 2021). But, as the temperature increased, the hypochlorite ions would decompose because of the high temperature, which would result in inadequate oxidation of Fe (III) (Adam and Gordon 1999). At higher temperatures (100 °C), ferrate(VI) ions would similarly decompose more fast (Sharma et al. 2015; Tong et al. 2021).

Figure 9(a) shows absorption bands of CaFeO4 at 524.98 and 544.99 nm. Figure 9(a) is also similar to the spectra of CaFeO4 solutions which were prepared at the optimum temperature (90 °C) at different ratios of FeCl3, Ca(OH)2, and Ca(OCl)2. Those samples were prepared when calcium hypochlorite was in excess by using 60 mL, 120 mL, and 180 mL. When 60 mL of Ca(OCl)2 was used CaFeO4, the solution showed an intense bright purple and concentrated color compared to the other solutions, with high absorbance of 1.2109 at λ = 524.98 nm and 1.1611 at λ = 544.99 nm. For 120 mL of Ca(OCl)2, the intensity of the color of this solution was faint with a reduced absorbance value of 0.4173 at λ = 524.98 nm and 0.4038 at λ = 544.99 nm, which suggests a less concentrated solution compared to the initially prepared CaFeO4 using 60 mL of the Ca(OCl)2. For 180 mL, the solution was faded purple color, as shown in Fig. 9a inset, and has an absorbance of 0.2327 at λ = 524.98 nm and 0.2236 at λ = 544.99 nm. In summary, when the amount of Ca(OCl)2 is high, the absorbance, intensity of color, and concentration decrease (see Fig. 9a and the inset).

Moreover, Fig. 9b shows the spectra of CaFeO4 solutions, which were prepared at the optimum temperature (90 °C) and, however, varying the ratios of FeCl3, Ca(OH)2, and Ca(OCl)2. Calcium hydroxide was in excess with different volume measurements, such as 60 mL and 90 mL. Both CaFeO4 solutions have relatively the same intensity of color, however, with varying values of absorbance 0.3434 and 0.3311 at λ = 524.98 and λ = 544.99 nm for 60 mL, respectively, and 0.4433 and 0.4281 at λ = 524.98 and λ = 544.9 nm for 90 mL, correspondingly.

Redox titration

Redox titration was used in this study to determine the concentration strength of CaFeO4, a powerful oxidizing agent that is more potent than potassium permanganate. Ferrate works more strongly in an acidic medium than in a basic medium because of its higher reduction potential, which is 2.20 V in acidic media and 0.70 V in basic media (Rai et al. 2018). This is illustrated by the following equations.

In these titrations, diluted sulphuric acid was used to prevent the precipitation of iron (VI). The ferrate acts as its own indicator. Acidity is provided only by sulphuric acid because other acids, such as nitric acid, are potent oxidizing agents that will interfere with ferrate (VI) during titration (Anon 2019; Piskarev and Aristova 2020). Hydrochloric acid is also unsuitable for this titration since it oxidizes to chlorine (Anon 2019). In the present study, redox titrations of calcium ferrate (VI) were performed using Mohr salt and oxalic acid as the standard titrants.

For the first method, oxalic acid acts as a standard titrant and reducing agent and transfers 3 electrons per mole of FeO42− ion, as shown in Eq. 5. Redox reaction Eqs. (4–6) represent the titration of oxalic acid with CaFeO4.

Ionic equations

Mohr salt acts as a standard titrant and reducing agent and transfers 3 electrons per mole of FeO42− ion. Redox reaction equations represent the titration of oxalic acid with CaFeO4.

Ionic equations:

Titrations were performed at various temperatures of CaFeO4 (60, 70, 80, 90, and 100 °C), and the results of the redox titrations are shown in Table 1.

The molar concentrations of the as-prepared CaFeO4 samples yielded at various temperatures (all < / = 100 ℃) were determined by two redox titrations (Mohr salt and Oxalic acid), and results are presented in Table 1. The molar concentration of CaFeO4 determined by the double salt ammonium iron (II) sulfate titrations increased as the reaction temperature was increased from 60 to 80 °C but decreased from 90 to 100 °C. Nevertheless, titration results of the same samples by oxalic acid show an increase in the molar concentration of CaFeO4 as the temperature was increased from 60 to 90 °C, followed by a decrease at 100 °C, which agrees with the theory temperatures higher than 90 ℃ result in the decomposition of hypochlorite ions, resulting in insufficient oxidation of Fe (III) and thus lower yield of CaFeO4 (Tong et al. 2021).

Figure 10 illustrates the effect of temperature (T) on the molar concentration of CaFeO4 of the as-prepared samples. From 60 to 90 °C, CaFeO4 concentration progressively increased from 0.2719 M to 0.5291 M as determined by the Mohr salt titration and 0.1879 M to 0.4716 M (oxalic acid titration). However, CaFeO4 concentration decreased abruptly at 100 ℃ compared to 90 ℃. Thus 90 ℃ was considered optimal for maximum yield. Due to the elevated temperatures, the activity of the reactants increased during the chemical reaction, which accelerated the reaction rate. On the other hand, at high temperature, the hypochlorite ions begin to decompose rapidly (Adam and Gordon 1999; Tong et al. 2021), which lower the yield of CaFeO4. The ferrate(VI) also decomposes rapidly at higher temperatures (Sharma et al. 2015). Hence, 90 °C was considered the optimum temperature for synthesizing CaFeO4. This was also confirmed by the high absorbance of the 90-CaFeO4 solution (Fig. 9a, b) compared to samples produced at other temperatures. Figure 10 also shows that the CaFeO4 concentration at 90 °C is exceptionally high for oxalic.

Jar test results

The experimental assessment involved conducting jar tests on 100 mL samples of untreated dam water. These tests aimed to evaluate the impact of varying dosages of calcium ferrate (VI) solutions on the water's quality. The investigation encompassed a range of dosage values, precisely 36.71, 45.84, 54.96, 64.06, and 82.19 parts per million (ppm) of CaFeO4. These dosage levels were chosen to explore the treatment's effectiveness across different concentrations comprehensively. The CaFeO4 solutions were meticulously prepared at different temperatures, including 60 ℃, 70 ℃, 80 ℃, and 90 ℃. The choice of temperature allowed for an investigation into the potential influence of thermal conditions on the treatment process. All of these CaFeO4 solutions were prepared and had a consistent pH of 12.1, ensuring that the only variable being examined was the dosage and temperature of the treatment.

Figures 11 and 12 in the paper visually depict the jar test procedure. These figures present a side-by-side comparison of the untreated, or “raw,” dam water samples and the treated water samples using CaFeO4 prepared at 90 ℃. This dosage level was 90-CaFeO4 was selected to illustrate the impact of the treatment.

At a relatively higher concentration. The jar test beakers, as seen in the figures, provide a clear visual representation of the changes that occur because of the treatment process, where color changes and potential reductions in turbidity and other pollutants are evident. In Fig. 11, the untreated raw water is showcased in one beaker, allowing for direct comparison with the treated water in the adjacent beaker. The treated water is the outcome of subjecting the raw water to the CaFeO4 treatment at a dosage of 90 ppm. Similarly, Fig. 12 captures the visual contrast between the initial dam water and the water that underwent treatment with 90-CaFeO4, highlighting any observable differences in color, clarity, and overall appearance.

In the study, eliminating solutes from the initial water source took approximately three hours, maintaining consistent pH levels and concentrations. This purification process was effectively captured through images, showcasing a notable decrease in turbidity and coloration, accompanied by the formation of visible flocs settling at the bottom of the samples. The comprehensive data presentation in Tables 2 and 3 offered a thorough analysis of various water parameters, comparing untreated and treated samples (Fig. 13).

The physicochemical attributes of the untreated water were meticulously evaluated, encompassing factors such as turbidity, color, chemical oxygen demand (COD), pH, electrical conductivity, and total dissolved solids (TDS). The pH values measured in the Hartbeespoort water samples range from 7.83 to 8.29. The COD concentrations, a pivotal indicator of organic matter and pollutants varied between 289 and 668 mg/L, as indicated in Table 2. Focusing on the impact of treatment with 90-CaFeO4, results revealed that at a dosage of 45.84 ppm, a remarkable 71.56% of oxidizable substances were successfully extracted from the water, as inferred from COD analysis. This signifies a significant reduction in harmful compounds. However, at higher dosages of CaFeO4 (64.06 and 82.19 ppm), the efficiency of chemical oxygen demand removal reduced, with removal percentages ranging from 65.74 to 43.56%. This suggests that there exists an optimal dosage range for the treatment process. Of noteworthy importance was the exceptional performance of CaFeO4 in eliminating coloration from the water samples, irrespective of the dosage employed. This attests to the efficacy of the treatment process in achieving desirable esthetic outcomes.

A similar analytical approach was adopted for turbidity measurements. Prior to treatment, and after allowing the samples to remain undisturbed for three hours and subsequently filtering to eliminate settled flocs, the turbidity levels were assessed. Remarkably, the addition of 90-CaFeO4 resulted in a remarkable turbidity reduction of 97–99% across all dosages. This substantial improvement aligns with the drinking water standards outlined by the World Health Organization (WHO) (Organization 2017), thus reinforcing the efficacy and safety of the treatment approach. To conclude, the study highlighted the effectiveness of 90-CaFeO4 in treating water from the Hartbeespoort region. Through the removal of solutes, reduction in turbidity, and efficient removal of color and contaminants, the treatment process demonstrated promise in enhancing the quality of the water supply in compliance with international standards.

Total Dissolved Solids (TDS) concentrations in the five water samples collected from Hartbeespoort exhibited a range of values between 305 and 332 mg/L, alongside an associated electrical conductivity of 0.66 mS/cm, as presented in Table 2. The findings align with the information provided in the report by Davis in 2017, which sheds light on the ecological state of Hartbeespoort Dam. According to the report, the Crocodile River contributes the highest levels of both Electrical Conductivity (EC) and TDS to the dam, registering measurements of 619 mS/cm and 307 mg/L, respectively.

Despite employing significant amounts of CaFeO4, the reduction in TDS remains relatively modest. Table 2 reinforces this observation by displaying the outcomes of applying CaFeO4 as a coagulant and flocculent agent. Intriguingly, CaFeO4 has exhibited remarkable efficacy in reducing COD and addressing turbidity and coloration in the water samples. This data underscores the complex interplay between various water quality parameters and the diverse challenges of managing water quality. While CaFeO4 has proven effective in targeting specific aspects of water impurities, the relatively minor decrease in TDS (14.76%), despite its use, highlights the intricate nature of the interactions between different dissolved substances. Addressing elevated TDS concentrations, particularly those originating from the Crocodile River's contribution, necessitates a comprehensive approach that may involve multiple treatment methods to achieve desired outcomes.

Algae reduction

The study aimed to assess the effectiveness of utilizing calcium ferrate pre-oxidation to enhance algae removal through coagulation. This investigation involved a meticulous jar test, which provided valuable insights into the efficiency of this approach. Upon subjecting the water samples to calcium ferrate pre-oxidation, a remarkable trend emerged. A substantial reduction in algae content was observed within a remarkably short span of just an hour following the pre-oxidation process. This outcome highlighted the potency of calcium ferrate as an effective pre-oxidant and underscored its rapid action in facilitating algae removal.

Interestingly, the influence of calcium ferrate pre-oxidation extended beyond a mere reduction in algae content. It was noted that the process induced a unique phenomenon whereby the algae particles exhibited an increased tendency to agglomerate. This agglomeration, resulting from the interaction between the calcium ferrate and the algae, was pivotal in facilitating subsequent coagulation. The agglomerated particles presented a more significant and denser mass, rendering them more amenable to coagulation mechanisms and simplifying their removal through subsequent treatment processes.

These visual representations, coupled with the comprehensive range of dosage values and temperature variations explored in the jar tests, provide a multifaceted understanding of the treatment's effectiveness. The data collected from these experiments serve as the basis for interpreting the impact of CaFeO4 on various water quality parameters, offering valuable insights into the potential of this treatment for addressing pollutants and enhancing water quality.

Conclusion

Calcium ferrate (VI) was prepared using the wet oxidation method of Thompson at varying reaction temperatures and reactant mole ratios. The wet oxidation method employed in this study is facile and environmentally friendly, and the product obtained has fewer limitations. CaFeO4 was characterized using XRD, FT-IR, Raman, UV–Vis, and redox titration. According to data obtained from FT-IR, stretching vibrations at 676, 729, and 876 cm−1 confirm the presence of the Fe–O bond in calcium ferrate salt. XRD patterns of the as-prepared CaFeO4 samples show the samples to be isomorphous with sharp peaks at 31.7°. The UV–Vis spectra absorption of CaFeO4 confirms the formation of Ferrate (VI) ion by showing intense and characteristic at 524.98 and 544.99 nm. The solution absorbance data of the freeze dried CaFeO4 showed the solids could be kept for six months without a sign of alteration to their spectra due to degradation or side chemical reactions. Also, calcium ferrate can be used as a chemical reagent for drinking water and wastewater treatment due to its multiple treatment mechanisms (coagulant and oxidant/disinfectant). The used wastewater aliquot sample showed notable total dissolved solids, causing the water to appear turbid. In addition, the wastewater had a remarkably high chemical oxygen demand given the range. After coagulation-flocculation using as-prepared CaFeO4 samples, the pollutants levels were reduced, as noted by reduction of key pollution indicator parameters ranging from 97 to 99% for turbidity, 100% for color, from 43.56 to 71.56% COD, and TDS from 3.13 to 14.76%e. This study paves a way toward the use of efficient wastewater treatment chemicals prepared under moderate conditions. Herein, CaFeO4 demonstrates its potentials as a chemical reagent for the treatment of wastewater due to its multiple treatment mechanisms (coagulant and oxidant/disinfectant).

Future work

In light of the preceding, ferrate (VI) technology offers a promising alternative to existing water and wastewater treatment techniques. If CaFeO4 is to be used successfully in the water and wastewater industry, it is crucial that a technology for economically synthesizing large quantities of CaFeO4 be optimized based on bench scale conditions which were elucidated in this study. Once CaFeO4 can be generated economically in massive quantities, the performance of ferrate should be thoroughly evaluated in a pilot plant for water and wastewater treatment. In addition to all the analyzed parameters (turbidity, color, COD, EC, pH, and TDS), evaluation of the CaFeO4 performance should focus on a range of organics and other microorganisms, such as cryptosporidium. In addition, systematic investigations should be done to confirm that no mutagenic risks and effects develop due to use of water treated by Fe(VI) ions or residual ions.

References

Adam LC, Gordon G (1999) Hypochlorite Ion decomposition: effects of temperature, ionic strength, and chloride Ion. Inorg Chem. https://doi.org/10.1021/ic980020q

Anon (2019) Titrimetric analysis 1(19):1–5. Retrieved August 8, 2022. https://ncert.nic.in/pdf/publication/sciencelaboratorymanuals/classXII/chemistry/lelm106.pdf.

Anon (2020) Ferrate treatment technologies, LLC—The Future of Environmentally Friendly Water Treatment. Retrieved May 8, 2020. http://www.ferratetreatment.com/

Atta KPT, Maree JP, Onyango MS, Mpenyana-Monyatsi L, Mujuru M (2020) Chemical phosphate removal from Hartbeespoort Dam water, South Africa. Water SA 46(4):610–614. https://doi.org/10.17159/wsa/2020.v46.i4.9074

Carroll ASD, Curtis CJ (2021) Increasing nutrient influx trends and remediation options at Hartbeespoort Dam, South Africa: a mass-balance approach. Water SA 47(2):210–220. https://doi.org/10.17159/wsa/2021.v47.i2.10917

Cheung PCW, Williams DR, Barrett J, Barker J, Kirk DW (2021) On the origins of some spectroscopic properties of ‘purple iron’ (the tetraoxoferrate(vi) ion) and its pourbaix safe-space. Molecules 26(17):234. https://doi.org/10.3390/molecules26175266

Chorghe D, Sari MA, Chellam S (2017) Boron removal from hydraulic fracturing wastewater by aluminum and iron coagulation: mechanisms and limitations. Water Res 126:481–487

Davis A (2017) Hydrogeological characteristics of hartbeespoort dam 64

Delaude L, Laszlo P (1996) A Novel oxidizing reagent based on potassium ferrate (VI). J Org Chem 61(18):6360–6370

Ghernaout D, Elboughdiri N (2019) Communication water disinfection: ferrate (VI) as the greenest chemical-a review. Appl Eng 3(2):171–180. https://doi.org/10.11648/j.ae.20190302.24

Jarvis AC (1987) Studies on zooplankton feeding ecology and resource utilization in a sub-tropical hypertrophic impoundment (December).

Jiang JQ (2007) Research progress in the use of ferrate(VI) for the environmental remediation. J Hazard Mater 146(3):617–623. https://doi.org/10.1016/j.jhazmat.2007.04.075

Jiang J-q (2013) Advances in the development and application of ferrate (VI) for water and wastewater treatment. J Chem Tech Biotech. https://doi.org/10.1002/jctb.4214

Jiang JQ, Lloyd B (2002) Progress in the development and use of ferrate(VI) salt as an oxidant and coagulant for water and wastewater treatment. Water Res 36(6):1397–1408. https://doi.org/10.1016/S0043-1354(01)00358-X

Koltypin M, Licht S, Nowik I, Vered RT, Levi E, Gofer Y, Aurbach D (2006) Study of various (‘super Iron’) MFeO[Sub 4] compounds in li salt solutions as potential cathode materials for Li batteries. J Electrochem Soc 153(1):A32. https://doi.org/10.1149/1.2128121

Kooti M, Jorfi M, Javadi H (2010) Rapid chemical synthesis of four ferrate (VI) compounds. J Iran Chem Soc 7(4):814–819

Lei B, Zhou G, Cheng T, Jianshi Du (2013) Synthesis of potassium ferrate by chemical dry oxidation and its properties in degradation of methyl orange. Asian J Chem 25(1):27

MaghraouiZerouale AELA, Ijjaali M, Sajieddine M (2013) Synthesis and characterization of ferrate(VI) Alkali metal by electrochemical method. Adv Mater Phys Chem 03(01):83–87. https://doi.org/10.4236/ampc.2013.31013

Maghraoui AEL, Zerouale A, Ijjaali M, Harrach A (2020) Ambient-stable CaFeO4 synthesis process wet. SIJCMS 3:138–142

Martinez-Tamayo E, Beltrán-Porter A, Beltrán-Porter D (1986) Iron compounds in high oxidation states. II1 1 for Part I, See Ref. 1. Reaction between Na2O2 and FeSO4. Thermochim Acta 97(C):243–255. https://doi.org/10.1016/0040-6031(86)87024-1

Munyengabe A, Zvinowanda C, Ramontja J (2021) Treatment of acid mine drainage using low energy advanced oxidation processes

Peleyeju MG, Umukoro EH, Tshwenya L, Moutloali R, Babalola JO, Arotiba OA (2017) Photoelectrocatalytic water treatment systems: degradation, kinetics and intermediate products studies of sulfamethoxazole on a TiO2-exfoliated graphite electrode. RSC Adv 7(64):40571–40580

Piskarev IM, Aristova NA (2020) Processes in spark electric discharge in air, nitrogen and oxygen. IOP Conf Ser Mater Sci Eng 966(1):234. https://doi.org/10.1088/1757-899X/966/1/012100

Rai PK, Lee J, Kailasa SK, Kwon EE, Tsang YF, Ok YS, Kim KH (2018) A critical review of ferrate(VI)-based remediation of soil and groundwater. Environ Res 160:420–448. https://doi.org/10.1016/j.envres.2017.10.016

Sharma VK (2002) Potassium ferrate VI: an environmentally friendly oxidant. Adv Environ Res 6:143–156

Sharma VK, Kazama F, Jiangyong H, Ray AK (2005) Ferrates (Iron (VI) and Iron (V)): environmentally friendly oxidants and disinfectants. J Water Health 3(1):45–58

Sharma VK, Zboril R, Varma RS (2015) Ferrates: greener oxidants with multimodal action in water treatment technologies. Acc Chem Res 48(2):182–191

Sun X, Zhang Qi, Liang He, Ying Li, Xiangxu M, Sharma VK (2016) Ferrate (VI) as a greener oxidant: electrochemical generation and treatment of phenol. J Hazard Mater 319:130–136

Talaiekhozani A, Talaei MR, Rezania S (2017) An Overview on production and application of ferrate (VI) for chemical oxidation, coagulation and disinfection of water and wastewater. J Environ Chem Eng 5(2):1828–1842. https://doi.org/10.1016/j.jece.2017.03.025

Thompson GW, Ockerman LT, Schreyer JM (1951) Preparation and purification of potassium ferrate. VI. J Am Chem Soc 73(3):1379–1381

Tiwari D, Lee S-m (2014) Ferrate (VI) in the treatment of wastewaters : a new generation green chemical. https://doi.org/10.5772/15500

Tong R, Zhang P, Yang Y, Zhang R, Sun X, Ma X, Sharma VK (2021) On line continuous chemical synthesis of ferrate(VI): enhanced yield and removal of pollutants. J Environ Chem Eng 9(6):106512. https://doi.org/10.1016/j.jece.2021.106512

Wang J, Xinchao Xu, Cao F, Wang Y, Li S, Qin G (2019) In situ fabrication of α-Fe2O3/CaFe2O4 p–n heterojunction with enhanced VOCs photodegradation activity. Adv Powder Technol 30(3):590–595. https://doi.org/10.1016/j.apt.2018.11.027

Wittmann W, Forstner U (1975) Waters—the hartbeespoort dam I(2):76–82

Wood RH (1958) The heat, free energy and entropy of the ferrate (VI) ion. J Am Chem Soc 80(9):2038–2041

World Health Organization (2017) Guidelines for drinking-water quality: first addendum to the fourth edition

Xu Z, Wang J, Shao H, Tang Z, Zhang J (2007) Preliminary investigation on the physicochemical properties of calcium ferrate(VI). Electrochem Commun 9(3):371–377. https://doi.org/10.1016/j.elecom.2006.09.015

Acknowledgements

The authors wish to acknowledge the University of Johannesburg and the National research foundation (NRF) for support.

Funding

The author(s) received no specific funding for this work

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or any personal relationships that could have appeared to influence the work reported in this paper.

Ethical standard

No ethical standard required for this study as no human or other animal samples or tissues were used.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ndzungu, G., Zvinowanda, C. & Ngila, J.C. Novel synthesis, characterization, and application of calcium ferrate (VI) in water treatment. Appl Water Sci 14, 47 (2024). https://doi.org/10.1007/s13201-023-02069-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-023-02069-z