Abstract

Water-borne viral diseases are a significant concern for public health. In particular, they threaten the health of people and animals in countries that lack proper water treatment facilities. Novel water treatment technology may efficiently improve water quality and prevent the spread of waterborne viral pathogens. Laser-induced graphene (LIG) has been shown to inactivate viruses and bacteria with its photothermal properties, electrochemical reaction, and rough surface texture. However, LIG's activity to prevent virus transmission via contaminated water has not been fully explored. Here, we demonstrated that enveloped and non-enveloped viruses in seawater could be rapidly inactivated by LIG technology. After being activated by 3 V of electricity, the LIG electrodes inactivated both types of viruses spiked in water within 30 min. In addition, the electrolyzed seawater exhibited virucidal effects even after the cessation of the electrical charge. The generation of different oxidants, such as chlorine, chlorine dioxide, and hydrogen peroxide, may play an essential role in the antiviral mechanism of the LIG electrodes. Furthermore, after 10 min of electrolysis, the pH of the seawater dropped from approximately 8–5, which may also have contributed to the virucidal effects of the LIG technology. The virucidal activity of LIG technology highlighted its potential for preventing the spread of viral infections via seawater systems which may have public health implications in areas where seawater is used in the sewage system. It may also have applications in aquaculture, where viral diseases do not have treatments and can cause high fish mortality.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Viral infections claim millions of human lives annually (Morens et al. 2004), especially since the emergence of the coronavirus disease 2019 (COVID-19) caused by severe acute respiratory syndrome-coronavirus-2 (SARS-CoV-2) (Walls et al. 2020). Contaminated water is a common route of transmission for viruses among humans and animals, including norovirus (Jacqueline et al. 2022), hepatitis A and E viruses (Farkas et al. 2020), coxsackievirus (Tiwari and Dhole 2018), and avian influenza virus (Sedlmaier et al. 2009). In Hong Kong, the spread of coronavirus through sewage lines within apartment complexes has been documented several times (Peiris et al. 2003; Xu et al. 2021). Animal coronaviruses, such as feline infectious peritonitis virus, is also spread to terrestrial animals via water (Addie et al. 2020). In addition, fish viruses are common in aquatic systems and can cause high mortality (Crane and Hyatt 2011). Thus, better measures to prevent viral transmission via contaminated water, whether for public or veterinary health, are needed (Webby et al. 2004).

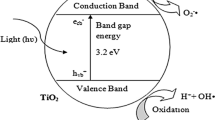

Electrolysis has been used to create in situ chlorine in salt water systems and effectively disinfect water for some time; however, issues with electrode corrosion and mineral build-up have been problematic (Kraft et al. 1999). In recent years with the discovery of new electrode materials this disinfection technology has gained popularity (Huo et al. 2020). Graphene and its derivatives have recently received significant attention owing to their potential virucidal activity in air (Luo et al. 2018; Perreault et al. 2015; Power et al. 2018; Yang et al. 2021; Zou et al. 2016), and their relatively inexpensive cost of production (Cheng et al. 2021). Direct contact with the nanosized sharp edges of the graphene-based materials is thought to lead to the rupture of the microbial cell membranes (Akhavan and Ghaderi 2010; Perreault et al. 2015). In addition, cellular components are oxidized by graphene oxide, resulting in cell death (Pelin et al. 2018; Xie et al. 2020). Furthermore, when electricity is applied to these materials, the physicochemical and electrochemical effects are enhanced, resulting in an improved disinfection effect. For example, direct oxidation (Qi et al. 2022), indirect oxidation via the generation of different oxidant species (Biswas et al. 2017; Chen et al. 2019), bubble generation (Lee et al. 2022), heating (Huo et al. 2022), and local pH change (Qi et al. 2022) have been reported to contribute to inactivation of different pathogens by graphene-based materials. Recent studies conducted on a small scale suggest when LIG is used in electrolysis of salt water it is very effective at killing bacteria in a short period (Zhang et al. 2023b). There is limited information as to whether electrolysis with LIG can kill viruses. However, the antibacterial mechanism of LIG electrodes appears to be associated with highly localized chlorine species generated during treatment (Zhang et al. 2023a) therefore it is likely also to have antiviral effects. If this was the case, this type of system would have several uses. For example, salt water pools, which already often use electrolysis for the disinfection of water (Gao et al. 2022) could explore this material. Salt water aquaculture recirculating systems could also adopt graphene-based electrolysis if it worked against both viruses and bacteria. This industry is very vulnerable to both of these types of pathogens. Lastly, in Hong Kong and a few other cities in Asia where the sewage system uses salt water instead of fresh water, electrolysis could be useful in the treatment of waste. In this study, we evaluated the disinfection properties of LIG electrodes on enveloped and non-enveloped viruses, specifically in salt water, to remove viruses transmitted in saltwater systems.

Materials and methods

Cells and viruses

Both enveloped and non-enveloped viruses were used in this study to assess the effect of the LIG technology on different types of viruses in seawater. We chose feline infectious peritonitis virus (FIPV, ATCC.VR-990), which belongs to the family Coronaviridae, as a surrogate model for enveloped viruses. FIPV was propagated in Crandell-Rees feline kidney (CRFK) cell lines (ATCC.CCL-94). A stock solution of ~ 2 × 106 plaque forming unit (pfu)/mL (viral titer) of FIPV was stored at − 80 °C until use. All cells were cultured in Dulbecco's Modified Eagle Medium (DMEM) medium (GiBCO, USA) supplemented with 10% heat-inactivated fetal bovine serum (FBS) (GiBCO, USA), 100 units/mL penicillin and 100 µg/mL streptomycin in a 5% CO2 humidity incubator at 37 °C.

Coxsackievirus B3 virus (CVB3, ATCC VR-30), belonging to the family Picornaviridae, was used as a surrogate model for non-enveloped viruses. The virus was propagated in rhesus monkey kidney epithelial (LLC -MK2, ATCC CCL-7) cells. A stock solution of ~ 107.2 tissue culture infective dose (TCID50)/mL (viral titer) of CVB3 was stored at − 80 ℃ until use. Cells were cultured in DMEM medium (GiBCO, USA) supplemented with 10% heat-inactivated FBS (GiBCO, USA), 100 units/mL penicillin, and 100 µg/mL streptomycin in a 5% CO2 humidity incubator at 37 °C.

Electrochemical disinfection cups

A day before the experiments, a stock solution of 31 ppt seawater was prepared using sea salt according to the manufacturer's instructions (Marinium, Mariscience International Co., Thailand). A refractometer was used to confirm the salinity each time the salt water was made. Water was autoclaved and stored at room temperature until use. The disinfection systems were constructed using a pair of LIG strips, a pair of conductive graphite paper with a thickness of 1 mm (Jinglong Co Ltd, Beijing, China), a direct-current (DC) power supply (Uni-Trend Technology, China), double-sided carbon conductive tape (Nisshin EM Co Ltd, Japan), and sterilized cups (width = 2.5 cm, height = 8 cm). In brief, the LIG strips were fabricated by lasering polyimide (PI) film as described by Huang et al. (Huang et al. 2020). Conductive graphite paper, which was used to hold the LIG strips, was attached to the top of LIG strips using double-sided carbon conductive tape. Alligator clips were attached to the top of the graphite sheet to convey the electricity. The LIG strips were placed 2.5 cm apart and suspended 2 cm below the water line to act as working electrodes (2 cm × 2 cm) (Fig. 1). The disinfection systems were operated in a biosafety level (BSL)-2 cabinet following standard laboratory biosafety procedures.

Direct virucidal effects of LIG electrodes

Virus stocks were diluted with sterilized seawater to achieve viral concentrations of ~ 2 × 105 pfu/mL and ~ 106.2 TCID50/mL of FIPV and CVB3, respectively. The virus working solutions were vortexed and distributed separately into three sterile cups for the treatment group and three for the control group for each virus. Each cup contained 10 mL of virus-infected seawater. For the treatment cups (n = 3), a direct 3 V current was applied to the LIG electrodes for 30 min. No electricity was given to the control group (n = 3), but LIG strips were included in the solution.

The inactivation of FIPV by the LIG electrodes was assessed using plaque assay (see 2.4.1). Samples (1 mL) were collected at 5 min, 10 min, 15 min, and 30 min after the LIG treatment and filtered using a 0.2 μm syringe filter before virus titration by plaque assay. Similarly, the virucidal effect of LIG electrodes against CVB3 was assessed using the TCID50 assay (see 2.4.2). Samples (2 mL) were collected at 5 min, 15 min, and 30 min, filtered using a 0.2 μm syringe filter and used for TCID50 assay.

Virus titration

Plaque assay FIPV

Infectious FIPV titers were determined by plaque assays with modifications (O'Brien et al. 2018). Briefly, CRFK cells were seeded in 6-well plates at 5 × 105 cells/well and cultured overnight at 37 °C in a 5% CO2 incubator. Cells were inoculated with five tenfold serially diluted cell culture supernatant containing the virus in duplicate for 1 h at 37 °C. After adsorption, cells were washed with phosphate-buffered saline (PBS) (Invitrogen™, USA) and overlaid with DMEM containing 0.5% low-melting-point agarose (Invitrogen™, USA) and 2% FBS. At 3 days post-infection (d.p.i), viral plaques were visualized by staining with 0.2% crystal violet solution.

Tissue culture infectious dose (TCID50) CVB3 virus

CVB3 virus titers were determined by 50% tissue culture infectious dose (TCID50) (He et al. 2013). Briefly, 96-well plates were seeded with a density of 2 × 104 cells/ well in DMEM supplemented with 10% FBS and incubated at 37 °C. After 24 h, cells were inoculated with eight tenfold dilutions (100 μL/well) of the virus in triplicate. The cytopathic effect was evaluated after three days of infection. The TCID50 values were calculated using the Reed–Muench method (Reed and Muench 1938).

Indirect virucidal effects of the electrolyzed seawater

The virucidal effect of the electrolyzed seawater, collected after the activation of the LIG electrodes with electricity, was investigated to understand better the longevity of the disinfection potential of electrolyzed seawater. Briefly, 60 mL of autoclaved stock seawater (without the virus) was distributed into six sterile cups. Then, 3 V was applied to the LIG electrodes for the treatment groups (n = 6) to generate the electrolyzed seawater. Based on preliminary work, we used seawater treated for 30 min (n = 3) on the non-enveloped virus and water treated for 15 min (n = 3) on the enveloped virus. Water was also exposed to LIG without current for the control group (n = 3).

To assess the indirect virucidal effect of LIG treatment against FIPV, 1 mL of 15 min electrolyzed (n = 3) or non-electrolyzed seawater (n = 3) was collected and mixed with 100 μL of FIPV to achieve the final titer of ~ 2 × 105 pfu/mL. These mixtures were incubated at room temperature for another 15 min and then filtered through a 0.2 μm syringe filter before conducting plaque assay. Similarly, to assess the indirect virucidal effects on CVB3, 1.8 mL of the 30 min electrolyzed (n = 3) or non-electrolyzed (n = 3) seawater was collected and mixed with 200 μL of CVB3 to achieve the final titers of ~ 106.2 TCID50/mL. The mixtures were incubated at room temperature for another 30 min and then filtered through a 0.2 μm syringe filter before conducting the TCID50 assay. During the incubation, the direct virucidal effects of LIG electrodes (virus present during the electrolysis of LIG) were also evaluated, as described above, to compare the indirect disinfection activity of the LIG technology.

pH and oxidant measurements

The total residual oxidants (i.e., Cl2), chlorine dioxide, and hydrogen peroxide were measured while evaluating the direct and indirect virucidal effects of LIG electrodes. The oxidants were measured at each sampling point using test strips for chlorine, chlorine dioxide, and hydrogen peroxide (Huankai biological Co., Ltd., Guangzhou, China).

The pH of the electrolyzed water was measured independently at 0, 5 min, 10 min, 15 min, and 30 min after the 3 V treatment of the LIG electrodes. A pH probe (ECO pH + , Trans Instruments (S) Pte Ltd, Japan) was used to measure this water quality parameter.

Statistical analysis

To compare the direct virucidal effects of LIG electrode treatment over time, we used two-way repeated measures ANOVA. Data from the experiments using FIPV and CVB3 were analyzed separately. To compare the direct and indirect virucidal effects of the electrochemical treatment with LIG electrodes, we used a one-way ANOVA. Data from the FIPV and CVB3 experiments were analyzed separately. All statistical analyses were performed using GraphPad Prism software (Version 8.0.1, GraphPad Software, San Diego, USA). All values were expressed as mean ± standard deviation (S.D.) of triplicate cups in each treatment. Differences were considered statistically significant when p < 0.05.

Results

Direct virus inactivation by LIG electrodes

The application of 3 V of electricity to the LIG electrodes inactivated both FIPV (enveloped virus) and CVB3 (non-enveloped virus) in seawater within 30 min of electrolysis (Fig. 2). The virucidal effect was more pronounced with prolonged treatment time. For FIPV, approximately a 2.5-log reduction in viral titer (p = 0.0122) was observed after 5 min of LIG treatment. After 10 min of LIG treatment, no infectious FIPV was detected by plaque assay. In contrast, the viral titers remained unchanged in control groups exposed to the LIG strip without electricity (Fig. 2 A).

In comparison, CVB3 appeared less susceptible to the effects of electrochemical treatment. There was no significant virucidal activity after 15 min of the 3 V LIG treatment, with only a slight reduction in viral titers measured by TCID50 assay (Fig. 2 B). However, a significant decrease (p = 0.0022) in CVB3 titers appeared after 30 min of the LIG treatment, with an average of more than 5-log reduction (Fig. 2 B).

Indirect virus inactivation of the electrolyzed water

There was significant inactivation of FIPV and CVB3 in contact with LIG-electrolyzed seawater. The FIPV exposed to electrolyzed seawater for 15 min decreased in titer by 4 logs (pfu/ml) compared to the control group (Fig. 3A) (p < 0.001). Consistent with previous results, direct LIG electrolysis of seawater spiked with the virus for 15 min completely inactivated the FIPV (Fig. 3A). Similarly, electrolyzed seawater significantly inactivated CVB3 (p = 0.0274) after 30 min compared to the control group; however, the virucidal effect was lower than that of direct LIG electrode treatment (Fig. 3B). Taken together, the data showed that the virucidal activity of the electrolyzed seawater in contact with the virus was less effective than that of direct electrolysis of the seawater containing the virus using LIG electrodes activated with 3 V of electricity.

Indirect virucidal effects of the electrolyzed seawater and direct virucidal effects by the LIG electrodes activated at 3 V. A Electrolysed seawater (15 min treatment) and LIG electrodes against FIPV; B Electrolysed seawater (30 min treatment) and LIG electrodes against CVB3. Black bar: control; grey bar: LIG-treated. UD: undetected

pH and oxidants

The pH of electrolyzed water decreased with the treatment time. As shown in Fig. 4, the pH dropped from 8 to an average of 5.28 after 30 min of treatment with the LIG electrodes using a current of 3 V (Fig. 4).

Oxidants such as Cl2, ClO2, and H2O2 were detected in the direct and indirect virucidal experiments. During the direct virucidal experiment, the concentration of the different oxidant species was generally low at the 5 min treatment time point, but the concentration increased in later sampling time points (Fig. 5A, B). During the direct treatment of FIPV with the LIG electrodes, the concentrations of Cl2, ClO2, and H2O2 in the solution were below 10 mg/L after 5 min, but these increased after 10 min of treatment (Fig. 5A). During the experiment using CVB3, the concentrations of Cl2, ClO2, and H2O2 were even lower in the solution, with an average concentration below 5 mg/L after 5 min of LIG treatment (Fig. 5B). However, the three oxidants increased above 5 mg/L after 15 min of treatment (Fig. 5B).

The concentration of different oxidant species during direct and indirect virus inactivation experiments. A the concentrations of Cl2, ClO2, and H2O2 during the direct LIG treatment against FIPV at 5 min, 10 min, 15 min, and 30 min; B the concentrations of Cl2, ClO2, and H2O2 during the direct LIG treatment against CVB3 at 5 min, 15 min, and 30 min; C the concentration of Cl2, ClO2, and H2O2 in the electrolyzed seawater treated for 15 min (left panel) and in the solution containing FIPV after treated for 15 min by LIG electrodes at 3 V (right panel); (D) the concentration of Cl2, ClO2, and H2O2 in the electrolyzed seawater treated for 30 min (left panel) and in the solution containing CVB3 after treated for 30 min by LIG electrodes at 3 V (right panel)

The concentrations of the oxidant species in the electrolyzed seawater (without the virus) used in indirect virucidal experiments were generally higher than those in the solution used in direct virucidal experiments (Figs. 5C, D). For example, the concentrations of Cl2, ClO2, and H2O2 in the 15 min-treated seawater were above 10 mg/L (left panel; Fig. 5C), while it was less than 5 mg/L in the solution containing FIPV after 15 min of treatment with the LIG electrodes using 3 V of electricity (right panel; Fig. 5C). Similarly, the concentration of Cl2, ClO2, and H2O2 in the 30 min-treated seawater were above 20 mg/L, while there were lighter color changes on the test strips in the solution containing CVB3 after 30 min treatment by LIG electrodes at 3 V (Fig. 5 D).

Discussion

Laser-induced graphene technology significantly reduced viral titers of FIPV and CVB3 in seawater after 5 and 30 min of electrochemical treatment, respectively, in our study (Fig. 2A, B). We chose to use these two model viruses because they represent groups of viruses (i.e., enveloped and non-enveloped viruses) that are transmitted via water and are important for public and/or veterinary health (Sin et al. 2015). For example, CVB3 has been frequently detected from wastewater surveillance in Italy and China (Pennino et al. 2018; Zheng et al. 2013). The FIPV, although more unstable, has also been shown to survive in wastewater for 2–3 days (Gundy et al. 2009). The latter is also a coronavirus (Decaro and Lorusso 2020) and shares similar pathogenic features as SARS-CoV-2 (Jo et al. 2021) in feline species. Potential transmission of SARS-CoV-2 via wastewater was raised during the COVID-19 pandemic in Hong Kong when clusters of infections were linked to saltwater sewage lines in apartment buildings (Cook et al. 2022; Gonçalves et al. 2021; Gormley et al. 2020). Greater transmission risk may be present in developing countries where wastewater is less well-treated (Adelodun et al. 2021). Therefore, the preliminary findings about the rapid and efficient inactivation of viruses in seawater by electrochemical disinfection using LIG electrodes may be very important for future applications in preventing waterborne viral diseases in these settings.

Our results showed that the use of LIG electrodes for electrolysis of salt water could effectively inactivate enveloped and non-enveloped viruses. In addition, indirect treatment by electrolyzed seawater appears to maintain virucidal properties after the electrolysis is halted. However, the inactivation effect was quicker and more significant (i.e., titer reduction) for the enveloped virus (i.e., FIPV) compared to the non-enveloped virus (i.e., CVB3) in both the direct and indirect disinfection process. The different disinfection efficiency noted for FIPV and CVB3 may be ascribed to the nature of the presence or absence of the viral envelope. Enveloped viruses are generally considered fragile and less stable than non-enveloped viruses (Bibby et al. 2015; Casanova and Weaver 2015; Ye et al. 2018). For example, non-enveloped viruses, such as bacteriophage MS2 and M13, were more resilient than the enveloped viruses, such as Ebola and Phi6 bacteriophage, upon exposure to chlorine disinfectants (0.5% NaOCl) (Gallandat and Lantagne 2017).

The virucidal activity of LIG technology is likely multifactorial. We detected several oxidants after the electrolysis of seawater, which may account for the observed virucidal effect. For instance, the concentrations of Cl2, ClO2, and H2O2 in the 15 min-treated seawater were above 10 mg/L (left panel; Fig. 5C), and this electrolyzed seawater could significantly reduce viral titers of FIPV and CVB3 (Fig. 3). Similarly, the electrolyzed water containing mixed oxidants was reported to show virucidal effects (Chen and Wang 2022; Hricova et al. 2008). Moreover, we observed that the pH of seawater after 10 min of electrolysis dropped from approximately 8–5 (Fig. 4). Previously, it has been reported that chlorine may be present as hypochlorous acid (HOCl) at the pH range of 5.0–6.5 (Ampiaw et al. 2021), which is 80–100 times stronger than the equivalent concentration of hypochlorite ion (ClO−) in commercial liquid bleach (Cao et al. 2009; Jackson et al. 2006). In addition, HOCl is also relatively safe for use in humans, material surfaces, equipment, and the environment (Nguyen et al. 2021). Due to its significant virucidal activity and relative safety, HOCl was recommended by the US Food and Drug Administration (FDA) as a disinfectant.

There may be several advantages of using LIG technology for water electrochemical disinfection over chemical disinfectants. Firstly, unlike disinfectants such as bleach, methanol, and hydrogen peroxide which need to be purchased in advance and require storage, electrolyzed seawater could be generated as needed. Secondly, LIG technology may reduce the likelihood of the emergence of resistant pathogens due to multiple mechanisms of action by different oxidant species in the electrolyzed seawater (Eggers 2019). The potential benefit of using LIG as the electrode material in the electrolysis process over other materials is that it is relatively inexpensive to generate compared to platinum and titanium-based electrodes (Moon et al. 2014; Tayel et al. 2018). The commercialization and scale of producing LIG electrodes are still to be determined, but the short-term effectiveness against bacteria (Zhang et al. 2023b) and viruses seems promising. Large-scale electrochemical disinfection of water is gaining interest from different industries as it reduces the need to store and handle large quantities of hazardous disinfectants on-site (Kraft 2008). Further, the use of this technology was evaluated on the health of medaka in an earlier study in our laboratory and no deleterious effects were noted on the health or behaviour of the fish after 8 days of intermitted exposure to low voltage LIG electrolysis (Zhang et al 2023b).

Although the findings of this study are promising, the results were obtained under controlled laboratory conditions, so before this technology is applied to large-scale applications, it needs to be further evaluated. For example, larger volumes of contaminated water may require higher voltages and a larger working surface area for the LIG electrodes. Therefore, large-scale studies are required to better understand the water ratio to the surface area of LIG electrodes for efficient disinfection. The durability of the LIG technology should also be assessed to understand its commercial potential as we have not tested the system for longer than 8 days and our studies showed that the stability of the LIG electrodes may decline after 4 days (Zhang et al. 2023b); however, in this study, we did not reverse the polarity of the system so it is possible that the mineralization of the cathode played a partial role in the loss of current across the system. The durability of the LIG technology should be determined if this material is to be considered for commercial use in electrolysis. Additional studies are also needed to confirm the safety of LIG technology on aquatic life and human health if it is to be used continuously in a system.

Conclusions

Despite these limitations, our study provides preliminary findings that both enveloped and non-enveloped viruses can be directly inactivated during the electrochemical disinfection using LIG electrodes and indirectly inactivated by electrolyzed seawater. These findings support other researchers who also have found LIG technology to have virucidal activity in air and water (Gu et al. 2021; Gupta et al. 2021; Huang et al. 2021). Importantly, this technology shows promise for potential public health implications and the treatment of seawater aquaculture systems, which is often limited by viral diseases. This technology may facilitate the mitigation of infectious diseases in aquatic environments and thus improve the sustainability of intensive aquaculture facilities.

Data availability

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy reasons.

References

Addie DD, Curran S, Bellini F, Crowe B, Sheehan E, Ukrainchuk L, Decaro N (2020) Oral Mutian® X stopped faecal feline coronavirus shedding by naturally infected cats. Res Vet Sci 130:222–229. https://doi.org/10.1016/j.rvsc.2020.02.012

Adelodun B, Ajibade FO, Ighalo JO, Odey G, Ibrahim RG, Kareem KY, Bakare HO, Tiamiyu AO, Ajibade TF, Abdulkadir TS et al (2021) Assessment of socioeconomic inequality based on virus-contaminated water usage in developing countries: a review. Environ Res 192:110309. https://doi.org/10.1016/j.envres.2020.110309

Akhavan O, Ghaderi E (2010) Toxicity of graphene and graphene oxide nanowalls against bacteria. ACS Nano 4:5731–5736. https://doi.org/10.1021/nn101390x

Ampiaw RE, Yaqub M, Lee W (2021) Electrolyzed water as a disinfectant: a systematic review of factors affecting the production and efficiency of hypochlorous acid. J Water Process Eng 43:102228. https://doi.org/10.1016/j.jwpe.2021.102228

Bibby K, Fischer RJ, Casson LW, Stachler E, Haas CN, Munster VJ (2015) Persistence of ebola virus in sterilized wastewater. Environ Sci Technol Lett 2:245–249. https://doi.org/10.1021/acs.estlett.5b00193

Biswas A, Khandelwal P, Das R, Salunke G, Alam A, Ghorai S, Chattopadhyay S, Poddar P (2017) Oxidant mediated one-step complete conversion of multi-walled carbon nanotubes to graphene quantum dots and their bioactivity against mammalian and bacterial cells. J Mater Chem B 5:785–796. https://doi.org/10.1039/C6TB02446G

Cao W, Zhu ZW, Shi ZX, Wang CY, Li BM (2009) Efficiency of slightly acidic electrolyzed water for inactivation of Salmonella enteritidis and its contaminated shell eggs. Int J Food Microbiol 130:88–93. https://doi.org/10.1016/j.ijfoodmicro.2008.12.021

Casanova LM, Weaver SR (2015) Inactivation of an enveloped surrogate virus in human sewage. Environ Sci Technol Lett 2:76–78. https://doi.org/10.1021/acs.estlett.5b00029

Chen B-K, Wang C-K (2022) Electrolyzed water and its pharmacological activities: a Mini-Review. Molecules 27:1222. https://doi.org/10.3390/molecules27041222

Chen S, Xie W, Guo B, Pan T, Chen W (2019) Revealing the role of graphene in enhancing the catalytic performance of phthalocyanine immobilized graphene/bacterial cellulose nanocomposite. Cellulose 26:7863–7875. https://doi.org/10.1007/s10570-019-02670-z

Cheng L, Guo W, Cao X, Dou Y, Huang L, Song Y, Su J, Zeng Z, Ye R (2021) Laser-induced graphene for environmental applications: progress and opportunities. Mater Chem Front. https://doi.org/10.1039/D1QM00437A

Cook S, Castillo D, Williams S, Haake C, Murphy B (2022) Serotype I and II feline coronavirus replication and gene expression patterns of feline cells—building a better understanding of serotype I FIPV biology. Viruses 14:1356. https://doi.org/10.3390/v14071356

Crane M, Hyatt A (2011) Viruses of fish: an overview of significant pathogens. Viruses 3:2025–2046. https://doi.org/10.3390/v3112025

Decaro N, Lorusso A (2020) Novel human coronavirus (SARS-CoV-2): a lesson from animal coronaviruses. Vet Microbiol 244:108693. https://doi.org/10.1016/j.vetmic.2020.108693

Eggers M (2019) Infectious disease management and control with povidone iodine. Infect Dis Ther 8:581–593. https://doi.org/10.1007/s40121-019-00260-x

Farkas K, Walker DI, Adriaenssens EM, McDonald JE, Hillary LS, Malham SK, Jones DL (2020) Viral indicators for tracking domestic wastewater contamination in the aquatic environment. Water Res 181:115926. https://doi.org/10.1016/j.watres.2020.115926

Gallandat K, Lantagne D (2017) Selection of a Biosafety Level 1 (BSL-1) surrogate to evaluate surface disinfection efficacy in Ebola outbreaks: comparison of four bacteriophages. PLoS ONE 12:e0177943. https://doi.org/10.1371/journal.pone.0177943

Gao F-Y, Yu P-C, Gao M-R (2022) Seawater electrolysis technologies for green hydrogen production: challenges and opportunities. Curr Opin Chem Eng 36:100827. https://doi.org/10.1016/j.coche.2022.100827

Gonçalves J, Koritnik T, Mioč V, Trkov M, Bolješič M, Berginc N, Prosenc K, Kotar T, Paragi M (2021) Detection of SARS-CoV-2 RNA in hospital wastewater from a low COVID-19 disease prevalence area. Sci Total Environ 755:143226. https://doi.org/10.1016/j.scitotenv.2020.143226

Gormley M, Aspray TJ, Kelly DA (2020) COVID-19: mitigating transmission via wastewater plumbing systems. Lancet Glob Health 8:e643. https://doi.org/10.1016/S2214-109X(20)30112-1

Gu M, Huang L, Wang Z, Guo W, Cheng L, Yuan Y, Zhou Z, Hu L, Chen S, Shen C et al (2021) Molecular engineering of laser-induced graphene for potential-driven broad-spectrum antimicrobial and antiviral applications. Small 17:2102841. https://doi.org/10.1002/smll.202102841

Gundy PM, Gerba CP, Pepper IL (2009) Survival of coronaviruses in water and wastewater. Food Environ Virol 1:10–14. https://doi.org/10.1007/s12560-008-9001-6

Gupta A, Sharma CP, Thamaraiselvan C, Pisharody L, Powell CD, Arnusch CJ (2021) Low-voltage bacterial and viral killing using laser-induced graphene-coated non-woven air filters. ACS Appl Mater Interfaces 13:59373–59380. https://doi.org/10.1021/acsami.1c20198

He J, Yue Y, Dong C, Xiong S (2013) MiR-21 confers resistance against CVB3-induced myocarditis by inhibiting PDCD4-mediated apoptosis. Clin Investig Med. https://doi.org/10.25011/cim.v36i2.19573

Hricova D, Stephan R, Zweifel C (2008) Electrolyzed water and its application in the food industry. J Food Prot 71:1934–1947. https://doi.org/10.4315/0362-028X-71.9.1934

Huang L, Gu M, Wang Z, Tang TW, Zhu Z, Yuan Y, Wang D, Shen C, Tang BZ, Ye R (2021) Highly efficient and rapid inactivation of coronavirus on non-metal hydrophobic laser-induced graphene in mild conditions. Adv Func Mater 31:2101195. https://doi.org/10.1002/adfm.202101195

Huang L, Xu S, Wang Z, Xue K, Su J, Song Y, Chen S, Zhu C, Tang BZ, Ye R (2020) Self-reporting and photothermally enhanced rapid bacterial killing on a laser-induced graphene mask. ACS Nano 14:12045–12053. https://doi.org/10.1021/acsnano.0c05330

Huo Y, Guo D, Yang J, Chang Y, Mu C, Nie A, Wang B, Xiang J, Zhai K, Xue T (2022) Flexible graphene/bacterial celluloses Janus structure film with excellent electromagnetic interference shielding and Joule heating performance. Mater Chem Phys. https://doi.org/10.1016/j.matchemphys.2022.126318

Huo Z-Y, Du Y, Chen Z, Wu Y-H, Hu H-Y (2020) Evaluation and prospects of nanomaterial-enabled innovative processes and devices for water disinfection: a state-of-the-art review. Water Res 173:115581

Jackson DS, Crockett DF, Wolnik KA (2006) The indirect detection of bleach (sodium hypochlorite) in beverages as evidence of product tampering. J Forensic Sci 51:827–831. https://doi.org/10.1111/j.1556-4029.2006.00160.x

Jacqueline C, del Valle Arrojo M, Bellver Moreira P, Rodríguez Feijóo MA, Cabrerizo M, Fernandez-Garcia MD (2022) Norovirus GII. 3 [P12] outbreak associated with the drinking water supply in a rural area in galicia, Spain, 2021. Microbiol Spectr 10:e01048-e11022. https://doi.org/10.1128/spectrum.01048-22

Jo WK, de Oliveira-Filho EF, Rasche A, Greenwood AD, Osterrieder K, Drexler JF (2021) Potential zoonotic sources of SARS-CoV-2 infections. Transbound Emerg Dis 68:1824–1834. https://doi.org/10.1111/tbed.13872

Kraft A (2008) Electrochemical water disinfection: a short review. Platin Met Rev 52:177–185. https://doi.org/10.1595/147106708X329273

Kraft A, Stadelmann M, Blaschke M, Kreysig D, Sandt B, Schröder F, Rennau J (1999) Electrochemical water disinfection Part I: hypochlorite production from very dilute chloride solutions. J Appl Electrochem 29:859–866

Lee JH, Yun E-T, Ham S-Y, Kim H-S, Sun P-F, Park H-D (2022) Electrically conductive carbon nanotube/graphene composite membrane for self-cleaning of biofouling via bubble generation. Desalination 535:115841. https://doi.org/10.1016/j.desal.2022.115841

Luo Z, Yang D, Yang C, Wu X, Hu Y, Zhang Y, Yuwen L, Yeow EKL, Weng L, Huang W (2018) Graphene quantum dots modified with adenine for efficient two-photon bioimaging and white light-activated antibacteria. Appl Surf Sci 434:155–162. https://doi.org/10.1016/j.apsusc.2017.10.121

Moon G-H, Kim D-H, Kim H-I, Bokare AD, Choi W (2014) Platinum-like behavior of reduced graphene oxide as a cocatalyst on TiO2 for the efficient photocatalytic oxidation of arsenite. Environ Sci Technol Lett 1:185–190. https://doi.org/10.1021/ez5000012

Morens DM, Folkers GK, Fauci AS (2004) The challenge of emerging and re-emerging infectious diseases. Nature 430:242–249. https://doi.org/10.1038/nature02759

Nguyen K, Bui D, Hashemi M, Hocking DM, Mendis P, Strugnell RA, Dharmage SC (2021) The potential use of hypochlorous acid and a smart prefabricated sanitising chamber to reduce occupation-related COVID-19 exposure. Risk Manag Healthc Policy. https://doi.org/10.2147/RMHP.S284897

O’Brien A, Mettelman RC, Volk A, André NM, Whittaker GR, Baker SC (2018) Characterizing replication kinetics and plaque production of type I feline infectious peritonitis virus in three feline cell lines. Virology 525:1–9. https://doi.org/10.1016/j.virol.2018.08.022

Peiris JSM, Chu C-M, Cheng VC-C, Chan K, Hung I, Poon LL, Law K-I, Tang B, Hon T, Chan C (2003) Clinical progression and viral load in a community outbreak of coronavirus-associated SARS pneumonia: a prospective study. The Lancet 361:1767–1772. https://doi.org/10.1016/S0140-6736(03)13412-5

Pelin M, Fusco L, Martín C, Sosa S, Frontiñán-Rubio J, González-Domínguez JM, Durán-Prado M, Vázquez E, Prato M, Tubaro A (2018) Graphene and graphene oxide induce ROS production in human HaCaT skin keratinocytes: the role of xanthine oxidase and NADH dehydrogenase. Nanoscale 10:11820–11830. https://doi.org/10.1039/2040-3372/2009

Pennino F, Nardone A, Montuori P, Aurino S, Torre I, Battistone A, Delogu R, Buttinelli G, Fiore S, Amato C, Triassi M (2018) Large-scale survey of human enteroviruses in wastewater treatment plants of a metropolitan area of Southern Italy. Food Environ Virol 10:187–192. https://doi.org/10.1007/s12560-017-9331-3

Perreault F, De Faria AF, Nejati S, Elimelech M (2015) Antimicrobial properties of graphene oxide nanosheets: why size matters. ACS Nano 9:7226–7236. https://doi.org/10.1021/acsnano.5b02067

Power A, Chandra S, Chapman J (2018) Graphene, electrospun membranes and granular activated carbon for eliminating heavy metals, pesticides and bacteria in water and wastewater treatment processes. Analyst 143:5629–5645

Qi S, Grossman AD, Ronen A, Bernstein R (2022) Low-biofouling anaerobic electro-conductive membrane bioreactor: the role of pH changes in bacterial inactivation and biofouling mitigation. J Membr Sci 662:120960. https://doi.org/10.1016/j.memsci.2022.120960

Reed LJ, Muench H (1938) A simple method of estimating fifty per cent endpoints. Am J Epidemiol 27:493–497

Sedlmaier N, Hoppenheidt K, Krist H, Lehmann S, Lang H, Büttner M (2009) Generation of avian influenza virus (AIV) contaminated fecal fine particulate matter (PM2.5): genome and infectivity detection and calculation of immission. Vet Microbiol 139:156–164. https://doi.org/10.1016/j.vetmic.2009.05.005

Sin J, Mangale V, Thienphrapa W, Gottlieb RA, Feuer R (2015) Recent progress in understanding coxsackievirus replication, dissemination, and pathogenesis. Virology 484:288–304. https://doi.org/10.1016/j.virol.2015.06.006

Tayel A, Ramadan AR, El Seoud OA (2018) Titanium dioxide/graphene and titanium dioxide/graphene oxide nanocomposites: synthesis, characterization and photocatalytic applications for water decontamination. Catalysts 8:491

Tiwari S, Dhole TN (2018) Assessment of enteroviruses from sewage water and clinical samples during eradication phase of polio in North India. Virol J 15:157. https://doi.org/10.1186/s12985-018-1075-7

Walls AC, Park Y-J, Tortorici MA, Wall A, McGuire AT, Veesler D (2020) Structure, function, and antigenicity of the SARS-CoV-2 spike glycoprotein. Cell 181:281-292.e286. https://doi.org/10.1016/j.cell.2020.02.058

Webby R, Hoffmann E, Webster R (2004) Molecular constraints to interspecies transmission of viral pathogens. Nat Med 10:S77–S81. https://doi.org/10.1038/nm1151

Xie C, Zhang P, Guo Z, Li X, Pang Q, Zheng K, He X, Ma Y, Zhang Z, Lynch I (2020) Elucidating the origin of the surface functionalization—dependent bacterial toxicity of graphene nanomaterials: oxidative damage, physical disruption, and cell autolysis. Sci Total Environ 747:141546. https://doi.org/10.1016/j.scitotenv.2020.141546

Xu X, Zheng X, Li S, Lam NS, Wang Y, Chu DKW, Poon LLM, Tun HM, Peiris M, Deng Y et al (2021) The first case study of wastewater-based epidemiology of COVID-19 in Hong Kong. Sci Total Environ 790:148000. https://doi.org/10.1016/j.scitotenv.2021.148000

Yang W, Pan M, Huang C, Zhao Z, Wang J, Zeng H (2021) Graphene oxide-based noble-metal nanoparticles composites for environmental application. Compos Commun 24:100645

Ye Y, Chang PH, Hartert J, Wigginton KR (2018) Reactivity of enveloped virus genome, proteins, and lipids with free chlorine and UV254. Environ Sci Technol 52:7698–7708. https://doi.org/10.1021/acs.est.8b00824

Zhang J, Cheng L, Huang L, Ng PH, Huang Q, Marques AR, MacKinnon B, Huang L, Yang Y, Ye R (2023a) In situ generation of highly localized chlorine by laser-induced graphene electrodes during electrochemical disinfection. Chemosphere 335:139123. https://doi.org/10.1016/j.chemosphere.2023.139123

Zhang J, Huang L, Ng PH, Jahangiri L, Huang Q, Huang L, MacKinnon B, Yang Y, Nekouei O, Yang Y (2023b) Rapid and safe electrochemical disinfection of salt water using laser-induced graphene electrodes. Aquaculture 571:739479. https://doi.org/10.1016/j.aquaculture.2023.739479

Zheng H, Lu J, Zhang Y, Yoshida H, Guo X, Liu L, Li H, Zeng H, Fang L, Mo Y et al (2013) Prevalence of nonpolio enteroviruses in the sewage of Guangzhou city, China, from 2009 to 2012. Appl Environ Microbiol 79:7679–7683. https://doi.org/10.1128/aem.02058-13

Zou X, Zhang L, Wang Z, Luo Y (2016) Mechanisms of the antimicrobial activities of graphene materials. J Am Chem Soc 138:2064–2077. https://doi.org/10.1021/jacs.5b11411

Acknowledgements

We would like to thank International Development Research Centre for funding support.

Funding

This research was funded by International Development Research Centre (IDRC, Canada) (grant # 109050-001).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

We did not conduct any animal study in this manuscript,so there is no ethical standards statement.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, J., Gu, G., Liu, C. et al. Rapid and efficient inactivation of viruses in seawater by LIG electrodes. Appl Water Sci 14, 1 (2024). https://doi.org/10.1007/s13201-023-02040-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-023-02040-y