Abstract

The present study focuses on the preparation of activated carbon (AC) from grape leaves as a low cost, non-toxic, efficient and available adsorbent for the removal of methylene blue (MB) from aqueous solution. The experimental design and data modeling have been carried out using response surface methodology (RSM) through DoE software version 8.0.0. The effect of independent variables including initial dye concentration (100–500 mg/L), pH (3–11), contact time (10–90 min) and adsorbent dosage (0.25–12.25 g/L) on dye removal was determined using the response surface methodology (RSM). The results of analysis of variance (ANOVA) displayed high R2 value of 0.91% for dye removal that shows the developed model has acceptable accuracy. The highest removal efficiency of MB (97.4%) was obtained at optimum condition (pH: 11, adsorbent dosage 12.5 g/L, MB concentration 100 mg/L and contact time 90 min). The results indicated that the initial dye concentration and adsorbent dosage play an important role in increasing the adsorbent efficiency for adsorption of MB. The equilibrium data onto the adsorption of MB were measured using Langmuir and Freundlich, isotherm models. The experimental data obtained follow the Langmuir model (R2 = 0.88). In addition, the second-order kinetic model is more consistent with the adsorption data.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, the use of synthetic dyes in various industries such as silk, paper, cotton, textile, rubber, leather, plastics, pharmaceuticals cosmetics, food industries and ink has increased (Mondal 2008; Mahamad et al. 2015). According to estimates, more than 100,000 types of dyes are used in various industries and about 7 × 105 tons of dyes is produced annually in the world. Researchers estimate that about 2% of the dye produced annually is discharged into wastewater (Allen and Koumanova 2005). Therefore, dyes as an important group of pollutants discharge into industrial wastewater (Garg et al. 2003).

Dyes in wastewater are often resistant to oxidizing agent, and microbial attack and temperature due to their complex (aromatic) molecular structures and are difficult to decompose in the environment (Nekouei et al. 2015). Therefore, the discharge of dyes into the environment, even in very small amounts (less than 1 ppm), for toxicological and aesthetic reasons is in terms of very concern for researchers (Cherifi et al. 2013). In addition to creating an unpleasant appearance in the environment, colored effluents can prevent light from penetrating into the water and as a result may disrupt biological processes in the aquatic environment (Malik 2004). In addition, most dyes discharged into the environment are toxic, carcinogenic and mutagenic (Mahmoudi et al. 2015). Among the dyes used in industry, methylene blue (MB) is widely used today in various fields, including the textile industry, silk fabrics, paper staining, chemicals agent in printing and dyeing companies (Ghosh and Bhattacharyya 2002; Guo et al. 2014; Yang et al. 2017). MB can cause burns and may even cause permanent damage to the eyes of humans and animals. On the other hand, excessive oral intake may cause burning sensation, vomiting, nausea, mental impairment and excessive sweating (Sartape et al. 2015).

In order to remove dye from industrial wastewater, various methods such as electrochemical methods (Carneiro et al. 2005), coagulation and flocculation (Riera-Torres et al. 2010), reverse osmosis (Abid et al. 2012) and ozone oxidation (Szpyrkowicz et al. 2001) can be used. However, many of treatment methods are restricted because of high capital and operating costs, sludge production and the complexity of treatment processes (Toor and Jin 2012). Adsorption is one of the most promising methods compared to other water treatment methods to remove dyes from water solutions (Mittal et al. 2013). The adsorption process has more advantages than other methods, including the high potential for dyes removal, high flexibility in design and process production, simple design, and comfortable performance (Seidmohammadi et al. 2015). Adsorption with activated carbon (AC) is currently the most common dye removal process from wastewater (Robinson et al. 2002). For the past few years, scientists have been trying to use agricultural waste to build inexpensive adsorbents to remove various types of pollutants from water and wastewater. The advantages of using agricultural wastes as the raw material for AC production have been highlighted that they are renewable, biodegradable and environmentally friendly (Hameed et al. 2017). Some studies have shown that agricultural ancillary products such as durian shell (Hameed and Daud 2008), mango seed kernel powder (Kumar and Kumaran 2005) and grape stalks (Ozdemir et al. 2014) can be used to make low-cost adsorbents dye removal from wastewater.

This study aimed to investigate the methylene blue (MB) removal using prepared activated carbon from leave wastes of grape as low-cost adsorbent from aqueous solution. To achieve the optimal conditions for methylene blue adsorption, the effects of contact time, initial dye concentration, adsorbent dosage and pH solution were investigated using central composite designs (CCD) through the response surface methodology (RSM). The physical and chemical properties of the prepared activated carbon were investigated using SEM and FT-IR analysis. Then, the adsorption mechanism was considered through isotherm and kinetics studies to investigate the nature of MB adsorption on the surface of activated carbon.

Materials and methods

Chemicals and reagents

Applied reagents including MB with 98% purity (C16H18ClN3S), H2SO4 (98%) and NaOH with the analytical reagent grade were purchased from Merck (Germany, Merck). The dye specifications of the purchased MB are given in Table 1 (Kuang et al. 2020). The pH of the solutions was adjusted using NaOH (1 mol l−1) and H2SO4 (1 mol l−1).

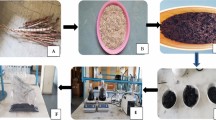

Adsorbent preparation

In order to prepare the adsorbent, wastes of grape leaves were collected from Kermanshah rural area in the western region of Iran. The raw material has been transferred to the laboratory for further works. At first, in order to remove any contaminants or impurities such as debris and dust, the grape leaves are thoroughly washed with distilled water and then dried at 150° C for 3 h in Oven (Germany, Mammoth 854). In next phase, the thermal activation carried out by electric furnace (Naberthem 11. s27 Germany) at 500 °C for 2 h under nitrogen atmosphere. Finally, after completing the steps, in order to prevent moisture adsorption, the grape leaves activated carbon (GLAC) was kept in a desiccator.

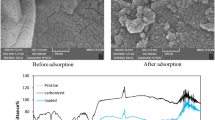

Characterization of activated carbon

Microscopic characteristics and chemical properties of GLAC were determined by scanning electron microscopy (SEM) and Fourier Transform Infrared (FTIR) method. Adsorption microscopy images were obtained to study the surface morphology and to investigate the porosity (Jeol JSM 840A, Japan). Fourier transform infrared spectroscopy was used to determine the vibration frequency changes in the activated carbon functional groups. The spectra were determined by FTIR (Shimadze IR Prestige, Japan model) in the range of 400–4000 cm−1.

Batch adsorption process

This empirical study carried out at a laboratory bench scale by using activated carbon prepared from grape leaves waste for removing MB from aqueous solution. First, a series of batch experiments were performed to evaluate the efficiency of prepared activated carbon to remove MB dye from synthetic wastewater. In the second stage, batch experiments of the adsorption process were designed in different values of independent variables. In this study, four variables, pH (3 to 11), adsorbent dosage (0.25 to 12.5 g/L), MB concentration (100 to 500 mg/L) and contact time (10 to 90 min), have been selected to evaluate the efficiency of GLAC. All run adsorption processes were performed using a series of Pyrex glass with a total volume of 250 ml and a working volume of 100 ml. In addition, in all stages, ambient temperature and mixing speed were constant during the process of 25 ± 2 °C and 100 rpm, respectively. NaOH or H2SO4 was used to adjust the initial pH of the dye solutions. At the end of the adsorption time, the GLAC was separated by centrifugation (Shimi fan, Iran) at 3800 rpm for 7 min. Finally, the residual concentration of the dye was calculated by measuring its absorbance in an UV–Visible spectrophotometer (Germany, Jenway 6305) at a maximum wavelength of 665 nm (λmax = 665 nm) (Eq. 1, 2). Also, the experiment was repeated when an error higher than 5% was observed in the samples (Idris et al. 2012).

where C0 and Ce are the initial, and final dye concentrations (mg/L), respectively; qe is the amount of adsorbate per mass of the adsorbent (mg/g), V is the volume of solution (L); and W is the mass of adsorbent (g).

Experimental design and data analysis

In this study, Design-Expert software (version 8.0.0) was applied for the design of experiments and data analysis through response surface methodology (RSM) using CCD technique. RSM is a statistical method that uses the quantitative data from experiments to examine the interaction of the several parameters affecting the process and study the responses of various factors by varying them simultaneously (Zahangir et al. 2007; Jaiswal et al. 2011). In the present study, the optimization and effects of four main independent variables including contact time (A), pH (B), adsorbent dosage (C) and initial concentration (C) on MB removal using central composite design (3-level-4-factor) were examined. The levels and range of variables that affect the removal efficiency of MB are listed in Table 2, which consist of low level (− 1), central (0) and high level (+ 1). The effect of input factors on the responses was investigated by analysis of variance (ANOVA) through statistical evaluation of P-value and F-value of regression coefficients (P < 0.05). In addition, the validity of the model was reported in terms of the coefficient of determination (R2), adjusted coefficient of determination (R2adj.) and sufficient accuracy (AP). Finally, the three-dimensional response level diagrams have been developed to show the interrelationship between independent factors and their related effects on the response.

With the suggestion of DOE (version 8.0.0) software, the experiments were carried out at 78 runs (with three repetitions). The average of each run, except for the 6 central run, is presented in Table 3.

The quadratic equation model (Eq. 3), which includes all interaction terms, was used to calculate the predicted response (Shahbazi et al. 2020).

The quadratic model based on Eq. (3) was applied to evaluate the coefficients of the statistical model, where Y is the response, βo is the constant coefficient, βi is the linear coefficients, βij is the interaction coefficients, βii is the quadratic coefficients, xi and xj are the coded values of the investigated variables and e is the statistical error term.

Result and discussion

Adsorption mechanisms: SEM and FT-IR

The SEM method was used to observe the surface physical morphology of the raw material and the prepared activated carbon (Yang and Qiu 2010). As shown in Fig. 1, after activating the porosity and honeycomb pores, the level of activated carbon has increased. As a result, as the porosity level of activated carbon increases, the adsorbents ability to remove dye from the aqueous solution increases.

The FT-IR spectrum is used to characterize the functional groups of the adsorbent surface as well as their changes during the adsorption process. The FT-IR spectra of the adsorbent after MB adsorption are shown in Fig. 2. The band at 3200 to 3600 cm−1 with O–H stretching vibration is in accordance with the hydroxyl functional groups. The strong peak about 1400 cm−1 and 1500 cm−1 is associated with carboxyl structures (Mousavi et al. 2017). The peak at 1600–1700 cm−1 associated with C=O stretching vibrations (Mousavi et al. 2020). The peak around 960 cm−1 may be due to C–C or C–H groups stretching vibration (Mousavi et al. 2017).

Process analysis and modeling of the MB removal

In order to study the relationship between response value and four parameters including initial concentration of MB, initial pH, adsorbent dosage and contact time, multiple regression analysis was used. The results of analysis of variance (ANOVA) are summarized in Table 4. Based on the evaluation of F and P values of the variables studied in this study, adsorbent dosage, initial dye concentration, contact time and pH indicated a positive effect on the removal efficiency of MB. In addition, the P value of AC, BD, AD and CD is less than 0.05, which indicates that the effect of these variables is significant on MB removal. The adsorbent dosage and initial dye concentration have the most effect on dye removal. Adjusted R2 and correlation coefficients (R2) for the MB removal are 0.90 and 0.9178, respectively, which confirms that there is a good correlation between the predicted and experiment data. On the other hand, the Model F-value (50.85) indicates that the model was significant for MB removal. Interpreting values of Prob > F less than 0.05, it means that the model terms were significant, while values greater than 0.05 indicate that the model terms are not significant. The lack of fit value 3.53 is not significant and confirms that the model is adequate. Adequate precision measured the signal to noise ratio that a value of this parameter greater than 4 is generally essential (Mousavi and Ibrahim 2016). In this work, obtained adequate precision was 29.696 for the degradation of MB that confirmed an adequate signal, thus obtained model in this work could be used to navigate the design space (Eq. 4).

Effect of initial pH

pH is one of the important parameters in the adsorption process that can have a significant effect on the adsorption capacity of the adsorbent(El Qada et al. 2006). The pH of the solution plays an important role in the ionization rate of acidic and alkaline compounds, which in turn can affect the ionic forms of the adsorbent molecule, the electric charge of the adsorbent surface and the dissociation of different functional groups in the active sites of the adsorbent (Almasi et al. 2017a, b). In order to evaluate the adsorbent efficiency, the initial pH of the solution was examined at 5 levels (3, 5, 7, 9, and 11). As shown in Fig. 3, with increasing the pH from 3 to 11, the adsorbent efficiency in MB removal increases. Increasing the pH of the solution increases the number of hydroxyl groups, which makes the AC surface tends to increase the proton loss and reaction with hydroxyl ions. As a result, the negatively charged surface of the adsorbent is reinforced. Then, the amount of electrostatic force between MB and the adsorbent surface increased (Lai and Chen 2001). The results of Hassan et al. (2017) study show that by increasing the pH, the adsorbent efficiency prepared from waste carpets in removing MB from aqueous solutions increases. The researchers attribute this to a decrease in the electrostatic repulsion force between the positively charged MB and the surface of the activated carbon (Hameed et al. 2017). According to a study by Mousavi et al. in 2017 on the adsorption of MB by using activated carbon prepared from N. microphyllum, it was observed that with increasing pH, the dye adsorption efficiency increased (Mousavi et al. 2017).

Effect of adsorbent dosage

Adsorbent dosage plays an important role on the adsorbent efficiency in removing dye from aqueous solutions. In this study, in order to determine the effect of adsorbent dosage on the adsorption process, 0.25 to 12.25 g/L of adsorbent GLAC was used for adsorption tests. The results of the effect of adsorbent dosage on the adsorption process are shown in Fig. 3. As shown in the figure, the percentage removal of MB is increased with increasing the amount of adsorbent dosage. According to the results of Table 3, the highest amount (97.4%) of MB adsorption was obtained in 12.25 g/L of activated carbon. Because with increasing the adsorbent dosage, the pores of the adsorbent surface increase to adsorb the dye, so there are more active sites for adsorption, and saturation of adsorption sites occurs over longer periods of time (Mousavi et al. 2017). Mulugeta and Lelisa 2014 and Hassan et al., in 2017 confirmed that by increasing the amount of adsorbent, the MB removal efficiency increased (Mulugeta and Lelisa 2014; Hameed et al. 2017).

Effect of initial dye concentration

Evaluations show that the percentage removal of dye depends on the initial value of dye concentration (100–500 mg/L) in the solution. The effect of the initial dye concentration depends on the immediate relationship between the dye concentration in the solution and the binding sites on the adsorbent surface. The results showed that with increasing dye concentration, the adsorbent efficiency in dye removal decreased (Fig. 4). For example, by increasing the initial dye concentration from 100 to 500 mg/L the efficiency of GLAC adsorbent in dye removal decreased from 97.4% to 33.86% when the pH, adsorbent dosage and contact time were 11 and 12.25 g/L and 90 min, respectively. This result may be due to the fact that at low concentrations of dye, there are vacant adsorbent sites for dye adsorption, and when the initial concentration of dye increases, the active sites required to adsorb dye molecules are not available and therefore, saturation take place very fast (Etim et al. 2016). Kumar et al. (2010) used cashew nut shell to make activated carbon as a new low-cost adsorbent to remove methylene blue from aqueous solutions. The results of this study indicate that by increasing the initial dye concentration from 50 to 250 mg/L, the dye removal value decreases from 89.91% to 60.89% (Kumar et al. 2011).

Effect of contact time

To determine the equilibrium time for maximum adsorption and recognition of the kinetics of the adsorption process, the contact time between the dye and the prepared adsorbent has been investigated. Figure 4 showed 3D diagram of the relationship between the efficiency of GLAC adsorbent in removing methylene blue dye in times between 10 and 90 min. According to Table 3, by increasing the contact time from 10 to 90 min at concentration of 100 mg/L with initial solution pH 11, the adsorbent efficiency in MB removal increased from 83.66% to 97.4%. The study of Kuang et al (2020) showed that by increasing the contact time the efficiency of adsorption process increased (Kuang et al. 2020).

Adsorption isotherms

Adsorption isotherm data are very important to find a suitable correlation of equilibrium data in order to optimize the design of an adsorption system (Almasi et al. 2017b). In this study, different isotherm equations such as Langmuir and Freundlich isotherms were used to investigate the balance of MB dye adsorption in GLAC.

The Langmuir isotherm describes the adsorption of dye molecules in the adsorbent monolayer coating and in homogeneous sites with a limited number. With this description, once the dye molecule occupies a site of the adsorbent, no further adsorption can take place on that site (Yakout et al. 2013; Cheng et al. 2015). The Langmuir isotherm model can be plotted based on Eq. 5.

where Ce (mg/L) is the equilibrium concentration of MB dye in the solution, qe (mg/g) is the adsorption capacity at equilibrium, Qm (mg/g) is the maximum adsorption capacity and K (L/mg) is the effective dissociation constant that relates to the affinity binding site. The values of Qm and K are obtained from the intercept and the slope of the linear plot of Ce/qe against Ce.

Unlike the Langmuir isotherm, the Freundlich isotherm describes the heterogeneous adsorption of dye molecules at different sites with different surface energy. Therefore, the amount of dye adsorption changes with the exponential distribution of sites and adsorption energies. The linear form of the Freundlich isotherm is given as (Eq. 6) (Yakout et al. 2013).

where n and KF are Freundlich adsorption isotherm constants, which indicate adsorption intensity and adsorption capacity, respectively. The Freundlich isotherm constants KF and 1/n can be reported based on the plot of lnqe versus lnCe, which is presented in Fig. 5. If the value of \({\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 n}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$n$}}{ }\) < 1, then the adsorption intensity and the type of isotherm to be required and the adsorption capacity increase with the appearance of new adsorption sites. Nonetheless, if.

\({\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 n}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$n$}}\) > 1, the adsorption bond weakens and its adsorption is very challenging that decreases the adsorption capacity.

The experimental data for the MB removal were tested with Langmuir and Freundlich isotherms Fig. 5 a, b. Correlation coefficient (R2) has been used to evaluate the suitability of isotherm models in the present study. The results show that the constant equilibriums of dye removal are conformed to Langmuir isotherm with correlation coefficient R2 = 0.88, so monolayer type adsorption was obtained. The parameters obtained from Fig. 5 are summarized in Table 5.

Kinetic study

Kinetics is one of the effective parameters in controlling the adsorption process. Using adsorption kinetics, the amount of solute adsorption at different retention times or adsorption reaction time can be described (Nekouei et al. 2015).

The kinetic parameters obtained from the analysis of experimental data can be used to design and model the adsorption processes (Shariati-Rad et al. 2014). In order to determine the adsorption kinetics, pseudo-first-order and pseudo-second-order models were examined.

The pseudo-first-order model

The nonlinear form of the quasi-first order equation can be obtained using the following Eq. 7:

where, qe is the amount of dye adsorbed at equilibrium (mg/g), qt is the amount of dye adsorbed at any time t (mg/g), and K1 is the first-order rate constant (min−1).

The pseudo-second-order model

The pseudo-second-order equilibrium adsorption model can be calculated using Eq. 8:

where: K2 (g mg−1 min−1) is the rate constant of second-order adsorption.

Based on Fig. 6, the experimental results at different times show that the data follow a pseudo-second-order model (R2 = 0.88).

Conclusion

In the present study, the efficiency of activated carbon made from grape leaves was investigated by thermal activation method and its optimal operating conditions such as adsorbent dosage, pH, contact time and initial dye concentration were determined by RSM method in removing MB dye. For characterization of activated carbon, FTIR and SEM tests were used. The results showed that activated carbon made from grape leaves waste can be a promising and efficient adsorbent for removing MB from aqueous solution. According to different responses, the optimum condition was obtained at pH = 11, contact time = 90 min, MB concentration = 100 mg/L and adsorbent dosage = 12.5 g/L. The maximum adsorption capacity is 97.4%. The results of this study show that the adsorption of MB dye on GLAC as an adsorbent is consistent with Langmuir model. Also, the obtained kinetic data follow the pseudo-second-order kinetic model. Accordingly, the prepared adsorbent has a good adsorption capacity and could be used as a natural and cost-effective adsorbent to remove MB dye.

Abbreviations

- b :

-

Constant related to the affinity of the binding sites (L/mg)

- C 0 :

-

Liquid-phase concentrations of dye at initial (mg/L)

- C e :

-

Liquid-phase concentrations of dye at equilibrium (mg/L)

- C t :

-

Liquid-phase concentrations of dye at any time (mg/L)

- K L :

-

Langmuir constant (L/mg)

- K F :

-

Freundlich constant (mg/g)

- n :

-

Dimensionless exponent of Freundlich equation

- q t :

-

Amount of dye adsorbed on the adsorbent at any time t (mg/g)

- q e :

-

Amount of dye adsorbed on the adsorbent at equilibrium (mg/g)

- q m :

-

Maximum amount of the adsorbed dye per unit mass of adsorbent (mg/g)

- AC:

-

Activated Carbon

- RSM:

-

Response Surface Methodology

- MB:

-

Methylene blue

References

Abid MF, Zablouk MA, Abid-Alameer AM (2012) Experimental study of dye removal from industrial wastewater by membrane technologies of reverse osmosis and nanofiltration. Iranian J Environ Health Sci Eng 9(1):1–9

Allen S, Koumanova B (2005) Decolourisation of water/wastewater using adsorption. J Uni Chem Tech Met 40(3):175–192

Almasi A, Rostamkhani Z, Mousavi SA (2017a) Adsorption of reactive red 2 using activated carbon prepared from walnut shell: batch and fixed bed studies. Desalin Water Treat 79:356–367

Almasi A, Navazeshkha F, Mousavi SA (2017b) Biosorption of lead from aqueous solution onto nasturtium officinale: performance and modeling. Desalin Water Treat 65:443–450

Carneiro PA, Osugi ME, ClS F, Boralle N, Furlan M, Zanoni MVB (2005) Evaluation of different electrochemical methods on the oxidation and degradation of Reactive Blue 4 in aqueous solution. Chemosphere 59(3):431–439. https://doi.org/10.1016/j.chemosphere.2004.10.043

Cheng Z, Zhang L, Guo X, Jiang X, Liu R (2015) Removal of lissamine rhodamine B and acid orange 10 from aqueous solution using activated carbon/surfactant: process optimization, kinetics and equilibrium. J Taiwan Inst Chem Eng 47:149–159. https://doi.org/10.1016/j.jtice.2014.09.032

Cherifi H, Fatiha B, Salah H (2013) Kinetic studies on the adsorption of methylene blue onto vegetal fiber activated carbons. Appl Surf Sci 282:52–59. https://doi.org/10.1016/j.apsusc.2013.05.031

El Qada EN, Allen SJ, Walker GM (2006) Adsorption of methylene blue onto activated carbon produced from steam activated bituminous coal: a study of equilibrium adsorption isotherm. Chem Eng J 124(1–3):103–110. https://doi.org/10.1016/j.cej.2006.08.015

Etim U, Umoren S, Eduok U (2016) Coconut coir dust as a low cost adsorbent for the removal of cationic dye from aqueous solution. J Saudi Chem Soc 20:S67–S76. https://doi.org/10.1016/j.jscs.2012.09.014

Garg V, Gupta R, Yadav AB, Kumar R (2003) Dye removal from aqueous solution by adsorption on treated sawdust. Bioresour Technol 89(2):121–124. https://doi.org/10.1016/S0960-8524(03)00058-0

Ghosh D, Bhattacharyya KG (2002) Adsorption of methylene blue on kaolinite. Appl Clay Sci 20(6):295–300. https://doi.org/10.1016/S0169-1317(01)00081-3

Guo JZ, Li B, Liu L, Lv K (2014) Removal of methylene blue from aqueous solutions by chemically modified bamboo. Chemosphere 111:225–231. https://doi.org/10.1016/j.chemosphere.2014.03.118

Hameed B, Daud F (2008) Adsorption studies of basic dye on activated carbon derived from agricultural waste: hevea brasiliensis seed coat. Chem Eng J 139(1):48–55. https://doi.org/10.1016/j.cej.2007.07.089

Hameed KS, Muthirulan P, Sundaram MM (2017) Adsorption of chromotrope dye onto activated carbons obtained from the seeds of various plants: equilibrium and kinetics studies. Arabian J Chem 10:S2225–S2233. https://doi.org/10.1016/j.arabjc.2013.07.058

Hassan AF, Elhadidy H (2017) Production of activated carbons from waste carpets and its application in methylene blue adsorption: kinetic and thermodynamic studies. J Environ Chem Eng 5(1):955–963. https://doi.org/10.1016/j.jece.2017.01.003

Idris S, Ndamitso MM, Iyaka YA, Muhammad EB, Gabriel U, Akinrotimi O, Kamaru M (2012) Sawdust as an adsorbent for the removal of methylene blue from aqueous solution: adsorption and equilibrium studies. J Chem Eng 1:11–24

Jaiswal N, Prakash O, Talat M, Hasan S, Pandey RK (2011) Application of response surface methodology for the determination of optimum reaction conditions(temperature and ph) for starch hydrolysis by alpha-amylase. Asian J Biochem 6(4):357–365

Kuang Y, Zhang X, Zhou S (2020) Adsorption of methylene blue in water onto activated carbon by surfactant modification. Water 12(2):587. https://doi.org/10.3390/w12020587

Kumar KV, Kumaran A (2005) Removal of methylene blue by mango seed kernel powder. Biochem Eng J 27(1):83–93. https://doi.org/10.1016/j.bej.2005.08.004

Kumar PS, Sathishkumar RS, K, (2011) Removal of methylene blue dye from aqueous solution by activated carbon prepared from cashew nut shell as a new low-cost adsorbent. Korean J Chem Eng 28(1):149–155

Lai C, Chen CY (2001) Removal of metal ions and humic acid from water by iron-coated filter media. Chemosphere 44(5):1177–1184. https://doi.org/10.1016/S0045-6535(00)00307-6

Mahamad MN, Zaini MAA, Zakaria ZA (2015) Preparation and characterization of activated carbon from pineapple waste biomass for dye removal. Int Biodeterior Biodegradation 102:274–280. https://doi.org/10.1016/j.ibiod.2015.03.009

Mahmoudi K, Hosni K, Hamdi N, Srasra E (2015) Kinetics and equilibrium studies on removal of methylene blue and methyl orange by adsorption onto activated carbon prepared from date pits-A comparative study. Korean J Chem Eng 32(2):274–283

Malik P (2004) Dye removal from wastewater using activated carbon developed from sawdust: adsorption equilibrium and kinetics. J Hazard Mater 113(1–3):81–88. https://doi.org/10.1016/j.jhazmat.2004.05.022

Mittal J, Thakur V, Mittal A (2013) Batch removal of hazardous azo dye Bismark Brown R using waste material hen feather. Ecol Eng 60:249–253. https://doi.org/10.1016/j.ecoleng.2013.07.025

Mondal S (2008) Methods of dye removal from dye house effluent—an overview. Environ Eng Sci 25(3):383–396

Mousavi SA, Ibrahim S (2016) Application of response surface methodology (RSM) for analyzing and modeling of nitrification process using sequencing batch reactors. Desalin Water Treat 57(13):5730–5739. https://doi.org/10.1080/19443994.2015.1007484

Mousavi SA, Mehralian M, Khashij M, Parvaneh S (2017) Methylene Blue removal from aqueous solutions by activated carbon prepared from N. microphyllum (AC-NM): RSM analysis, isotherms and kinetic studies. NEST J 19(4):697–705

Mousavi SA, Zangeneh H, Almasi A, Nayeri D, Monkaresi M, Mahmoudi A, Darvishi P (2020) Decolourization of aqueous Methylene Blue solutions by corn stalk: modeling and optimization. Desalin Water Treat 197:335–344. https://doi.org/10.5004/dwt.2020.25952

Mulugeta M, Lelisa B (2014) Removal of methylene blue (Mb) dye from aqueous solution by bioadsorption onto untreated parthenium hystrophorous weed. Mod Chem Appl 2(4):146

Nekouei F, Nekouei S, Tyagi I, Gupta VK (2015) Kinetic, thermodynamic and isotherm studies for acid blue 129 removal from liquids using copper oxide nanoparticle-modified activated carbon as a novel adsorbent. J Mol Liq 201:124–133. https://doi.org/10.1016/j.molliq.2014.09.027

Ozdemir I, Şahin M, Orhan R, Erdem M (2014) Preparation and characterization of activated carbon from grape stalk by zinc chloride activation. Fuel Processing Technol 125:200–206. https://doi.org/10.1016/j.fuproc.2014.04.002

Riera-Torres M, Gutiérrez-Bouzán C, Crespi M (2010) Combination of coagulation–flocculation and nanofiltration techniques for dye removal and water reuse in textile effluents. Desalination 252(1–3):53–59. https://doi.org/10.1016/j.desal.2009.11.002

Robinson T, Chandran B, Nigam P (2002) Effect of pretreatments of three waste residues, wheat straw, corncobs and barley husks on dye adsorption. Bioresour Technol 85(2):119–124. https://doi.org/10.1016/S0960-8524(02)00099-8

Sartape AS, Patil SA, Patil SK, Salunkhe ST, Kolekar SS (2015) Mahogany fruit shell: a new low-cost adsorbent for removal of methylene blue dye from aqueous solutions. Desalin Water Treat 53(1):99–108. https://doi.org/10.1080/19443994.2013.839404

Seidmohammadi A, Asgari G, Leili M, Dargahi A, Mobarakian A (2015) Effectiveness of quercus branti activated carbon in removal of methylene blue from aqueous solutions. Arch Hyg Sci 4(4):217–225

Shahbazi D, Mousavi SA, Nayeri D (2020) Low-cost activated carbon: characterization, decolorization, modeling, optimization and kinetics. Int J Environ Sci Technol 17:1–12

Shariati-Rad M, Irandoust M, Amri S, Feyzi M, Ja’fari F, (2014) Magnetic solid phase adsorption, preconcentration and determination of methyl orange in water samples using silica coated magnetic nanoparticles and central composite design. Int Nano Lett 4(4):91–101

Szpyrkowicz L, Juzzolino C, Kaul SN (2001) A comparative study on oxidation of disperse dyes by electrochemical process, ozone, hypochlorite and Fenton reagent. Water Res 35(9):2129–2136. https://doi.org/10.1016/S0043-1354(00)00487-5

Toor M, Jin B (2012) Adsorption characteristics, isotherm, kinetics, and diffusion of modified natural bentonite for removing diazo dye. Chem Eng J 187:79–88. https://doi.org/10.1016/j.cej.2012.01.089

Yakout S, Daifullah A, El-Reefy S (2013) Adsorption of naphthalene, phenanthrene and pyrene from aqueous solution using low-cost activated carbon derived from agricultural wastes. Adsorp Sci Technol 31(4):293–302. https://doi.org/10.1260/0263-6174.31.4.293

Yang J, Qiu K (2010) Preparation of activated carbons from walnut shells via vacuum chemical activation and their application for methylene blue removal. Chem Eng J 165(1):209–217. https://doi.org/10.1016/j.cej.2010.09.019

Yang S, Qiang L, Sample A, Shah P, He YY (2017) NF-κB signaling activation induced by chloroquine requires autophagosome, p62 protein, and c-Jun N-terminal Kinase (JNK) signaling and promotes tumor cell resistance. J Biol Chem 292(8):3379–3388. https://doi.org/10.1074/jbc.M116.756536

Zahangir A, Muyibi SA, Toramae J (2007) Statistical optimization of adsorption processes for removal of 2, 4-dichlorophenol by activated carbon derived from oil palm empty fruit bunches. J Environ Sci 19(6):674–677. https://doi.org/10.1016/S1001-0742(07)60113-2

Acknowledgements

The authors gratefully acknowledge the Research Council of Kermanshah University of Medical Sciences for the financial support through mentorship number 50001233.

Funding

There is no funding for this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mousavi, S.A., Mahmoudi, A., Amiri, S. et al. Methylene blue removal using grape leaves waste: optimization and modeling. Appl Water Sci 12, 112 (2022). https://doi.org/10.1007/s13201-022-01648-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01648-w