Abstract

Distillery industry is amidst the top source of surface water pollution owing to its very high content of recalcitrant organics, inorganics, and persistent turbidity contents. Melanoidins are the chief dark brown-colored complex contaminant existing in the distillery generated effluent with a very high organic load. The present investigation examined the melanoidin elimination from a model wastewater system utilizing Cu-impregnated activated carbon derived from waste leaves of Mangifera indica. With the initial surface characterization utilizing SEM equipped with EDX and FTIR, the Box-Behnken design of experiments was engaged for determining the influence of different factors for the melanoidin removal from the aqueous system. Adsorbent dose, initial melanoidin concentration, and contact time have imposed the maximum effect on to the melanoidin removal (73%) using the synthesized activated carbon, clearly showing its ability for the melanoidin removal from the aqueous contaminated system.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Melanoidins, a heterogeneous polymer (high molecular weight), formed during the last stage of Millard reaction due to the reaction between reducing sugars carbonyl group and amino acids peptide or amino group (Diaz-Morales et al. 2020). During cooking, thermal treatment or preservation non-enzymatic browning alteration occurs in food and provides organoleptic characteristics in processed food. Thus, they are brown-colored, polymeric complex with chemical oxygen demand and are present in various food such as cocoa beans, beer, sweet wine, coffee, honey, bakery products (Alves et al. 2020; Goulas et al. 2018). These industries generate large amount of wastewater mainly characterized by brown color with high chemical oxygen demand (COD), biological oxygen demand (BOD), dissolved organic nitrogen, phenolics, total dissolved solid, phosphates, and sulfates (Kumari et al. 2020; Goswami et al. 2018a, 2019). They are also known to have antioxidant, antimicrobial, cytotoxic, and anti-hypertensive activities (Kushwaha et al. 2022; Hussain et al. 2021; Liakos and Lazaridis 2016). Also, metal ions interact with melanoidin and form stable complexes which further contributes in environmental pollution (Chandra et al. 2008; Gautam et al. 2021). Furthermore, it reduces the alkalinity and manganese availability in soil, thereby, impeding the seed propagation which leads to abridged crop yield (Gupta et al. 2020; Lata et al. 2021; Bajgai et al. 2022). In water, it lessens the sunlight dissemination causing less oxygen level and ultimately death of aquatic life (Sathe et al. 2021, 2020; Devi et al. 2021).

Earlier, several conventional technologies (biological and chemical) have been implemented for the elimination of melanoidin from aqueous wastewater (Borah et al. 2021; Liakos and Lazaridis 2016). These methods are effective in melanoidin removal but are time-consuming, require a large area, generate perilous by-products, and a large amount of sludge; thus, not suitable for treating such effluents (Gupt et al. 2020, 2021; Kushwaha et al. 2016; Goswami et al. 2022). To assuage the limitations of conventional technologies, physico-chemical methods utilizing various adsorbents particularly bioadsorbents (activated carbon, biochar, and coal-fired fly ash) are effective techniques (Goswami et al. 2020, 2017; Kumar et al. 2019; Bind et al. 2019). Bioadsorption is a simple, easy, cost-effective, squat energy requirement, eco-friendly, and constancy in employing a wide range of adsorbents due to their specificity toward the pollutant (Yadav et al. 2021a, b; Singh et al. 2019; Kushwaha et al. 2020, 2017a).

Recently, the use of activated carbon (AC) for removal of perilous contaminants has gained attention because of their assorted form with diverse ostensible properties attained via surface modifications (physical and chemical) such as pore size and volume, functional groups, surface area, and high reactivity (Singh et al. 2022; Goswami et al. 2019; Hoarau et al. 2018). Additionally, the properties of AC are governed by the type of raw material used, precursor, temperature, method used, and activating agent (Goswami et al. 2021). The adsorption of contaminants (micropollutants, heavy metals, phosphates, and nitrates) was carried via precursors prepared aboriginal from oil palm, peanut shells, mango kernels, date stones, endocarp, etc. (Kumari et al. 2020; Kushwaha et al. 2021a, b; Kumar et al. 2021). Further, some recent literature reported the Fe ions doping to increase the sorption ability/affinity toward the melanoidin elimination along with its revival as a biosorbent (Shah et al. 2015). The surface modifications are carried out using different oxidizing agents trailed by doping with Fe/Cu precursor.

Therefore, the present investigation deals with the gaps in the literature stated above by concurrently probing the removal of melanoidins by exploring copper-impregnated AC derived from Mangifera indica florae leaves. Earlier, we have examined three different kinds of AC prepared from leaf waste (Rizvi et al. 2020). Here, the efficacy of copper-impregnated AC for melanoidin removal was assessed. Furthermore, the copper-impregnated AC loaded with melanoidin after the adsorption process was evaluated by using scanning electron microscopy (SEM) equipped with energy-dispersive spectroscopy (EDX) for detecting the change in morphology, and Fourier transform infrared spectroscopy (FTIR) analyses were employed to detect the melanoidin binding functional groups present on the AC surface that were responsible for its removal. Nevertheless, the present investigation deals with melanoidins but can also be considered a prototypical system for other pollutant elimination by adsorption.

Materials and methods

Chemicals

Glucose was procured from HiMedia (Mumbai, India) with > 98% purity. Analytical grade chemicals for preparing the melanoidin stock solution were obtained from HiMedia (Mumbai, India). MilliQ water was utilized throughout the experiments. A copper metal stock solution of 0.5 mol/L concentration was prepared from Cu(NO3)2 and was diluted accordingly using MilliQ water (Hu et al. 2017).

Stock preparation

The stock solution of melanoidin was made as described by Rafigh and Soleymani (2020) with slight modifications. Briefly, in 100 mL MilliQ water, glycine, glucose, and NaHCO3 were mixed and heated at 80 ℃ for 8 h and kept aside to cool. The working solution of melanoidin was prepared by diluting appropriate amount of melanoidin solution in MilliQ water (Yaylayan and Kaminsky 1998).

Synthesis of copper-impregnated activated carbon

The waste leaves of M. indica were cumulated nearby from Kanpur, Uttar Pradesh, India. All three types of leaves were converted to AC by following Rizvi et al. (2020). In brief, initially, leaves were laved and dried in an oven at 105 ℃ for 24 h. The samples were grounded, sieved, and stored in a desiccator to avoid surplus moistness. The homogenized samples were amalgamated with HCl (1:2) and kept for 12 h (overnight) for digestion and subsequently, washed and dehydrated at 105 °C for 8 h, and kept at 600 °C for 90 min in a muffle furnace for carbonization.

Further, the copper doping was carried out with the definite amount to the respective selected AC in 50 mL of 0.5 M Cu (NO3)2 and kept in a shaker (200 rpm) for 2 h at room temperature (Park et al. 2015). The pH was adjusted accordingly to 7.0 with NaOH to attain copper-impregnated AC. The excess salts from adsorbents were removed by washing with deionized water. The prepared AC was dried and stored in a desiccator until further analysis.

The adsorbents morphological characterization was accomplished via SEM (Carl Zeiss EVO 50) (Kushwaha et al. 2017b). For SEM–EDX analysis AC and copper-impregnated AC were vacuum-dried and mounted on aluminum stubs over double-sided carbon tape followed by double coating with a thin gold layer by sputter coater (Borah et al. 2019). The most distinctive characteristic of adsorbent is functional group occurrence, which is important for binding with pollutants primarily characterized by FTIR (Bruker Tensor 27) with five scans in the range 450–4000 cm−1 (Goswami et al. 2019).

Experiment set-up

The batch experiment was conducted in 250-mL Erlenmeyer flasks with a working volume (100 mL) of the respective adsorbate concentration. Primarily, all the adsorbents were studied, opting for its potential final dosage for optimization of adsorbate removal studies. The effect of adsorbent on adsorbate adsorption was attained by reaction, 500 mg/L of starting melanoidin concentration with 50 mg/L adsorbent dosage. The suspension was agitated at pH 3 for 2 h. Later, depending on the result, the adsorbent showing maximum removal was selected (M. indica) for further studies. The effect of factors affecting melanoidin removal was determined. Similar parameters were followed for the experiment as per our previous experiment (Rizvi et al. 2020): adsorbent dosage (A: 25–100 mg/L); adsorbate amount (B: 100–1000 mg/L); temperature (C: 30–50℃); and contact time (D: 30–120 min), and iron/adsorbent ratio (E: 20–40%). The experimental trials were carried out at pH 4. The optimization of parameters was performed using Box-Behnken design via Design Expert (Version 11, USA) depending on the literature accessible so far. Supplementary Table S1 represents the different experimental runs for optimizing the removal process. Based on the literature available for all the studies, pH was kept at 4.0 to elude the doped Cu-particles leaching. The percentage melanoidin removal was calculated as stated in equation:

where Co and Ce signify the initial and final melanoidin concentrations, respectively.

Analytical methods

At the end of the adsorption process, the adsorbents were removed by centrifugation at 8000 rpm for 15 min. The supernatant was collected and examined for adsorbate concentration via a UV–visible spectrophotometer (Systronics UV 22,300) (475 nm) (Rafigh and Soleymani 2020). All the experiments were executed in triplicates, and the values are expressed as mean ± standard deviation.

Results and discussion

Characterization of prepared Cu-impregnated activated carbon

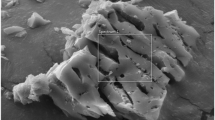

The micrographs for both of the prepared adsorbents are presented in Fig. 1. The micrographs clearly show that the morphologies have maintained the lignocellulosic herald shape. This technique has led to eliminating the non-carbonaceous substances showing the relative homogenous cavities onto the external surfaces. In addition, the SEM–EDX analysis (Fig. 1) demonstrates the copper doping onto the prepared AC adsorbent surface, further confirming the extra Cu peak in all the EDX spectra.

FTIR spectra of both the activated carbon and Cu-impregnated AC are represented in Fig. 2. Primarily, it is affirmed from the FTIR spectra that the surface of AC has numerous oxygenated groups such as -COOH and -OH (Rodrigues et al. 2020). Also, it could well be detected that all the band intensities dropped owing to the doping of copper for almost at all the stretch bands (Rizvi et al. 2020). The band in between 635 and 648 cm−1 (i.e., ~ 640 cm−1) resembles the saturated carbon stretching of –CH2 group. The minute peaks -C=O and –CH2 bands were clearly observed at 1265 and 1028 cm−1, respectively (Goswami et al. 2017), along with the -C=O asymmetric stretches at 1690 cm−1 (Rizvi et al. 2020). Furthermore, in most cases, a wide spectrum is usually observed at 3500 cm−1, confirming the presence of -OH bonds (Bind et al. 2019).

Melanoidin removal

Earlier, we performed the melanoidin adsorption experiments and examined that the AC prepared from M. indica leaf wastes had performed better than others in the batch process (Rizvi et al. 2020). Hence, the Cu-impregnated AC prepared from M. indica was nominated for further experiment.

Experimental design

For performing the optimization experiments, five different parameters were evaluated for the melanoidin removal utilizing Cu-impregnated AC. The parameters mentioned above (in Sect. Experiment set-up) were selected to determine the effect on the removal process. The experiments were carried out in triplicates, and average results were described. Maximum removal of 73.29% was attained at all the central points of the operational parameters (Fig. 3). The present removal was on the lower side in comparison with our earlier study performed with the Fe-impregnated AC (Rizvi et al. 2020).

In addition, the ANOVA outcome from the experimental process, the quadratic model reported 46.97 of the F-value, inferring the significance of the model. Moreover, the projected R2 (0.8963) agrees with the adjusted R2 (0.9533), describing that all the exploratory and projected values were lying inside the constricted interval (Supplementary Table S2). Most of the model terms were substantial that validate the accuracy and reliability of the optimization process (Supplementary Table S3). Also, the lack of fit analysis was observed to be irrelevant. The linear effects of three parameters, i.e., adsorbent dosage, initial melanoidin concentration, and temperature, were inferred as the major interacting factors having P values < 0.001. Similarly, adsorbent dosage–adsorbate concentration (AB), adsorbent dosage–contact time (AD), and adsorbate concentration–contact time (BD) were examined to be the most significant interrelating parameter depicting the elliptical nature of the contour plot (Fig. 3).

It is also important to evaluate the factors that have substantial effects on melanoidin removal. The perturbation plot helps in determining the impact of various factors on the response. Figure 4a is plotted for all five factors. Now, the influence of each factor is plotted at a definite point, while the other parameters are kept fixed for melanoidin removal. Here, the mid-point of two extreme values of every factor was selected as the reference point (Das et al. 2014). Adsorbent dosage, initial melanoidin concentration, and temperature were primarily observed as noteworthy following the center points.

Figure 4b depicts the correlation between experimental and projected values. It further confirms the response scattering amidst the data points and the diagonal lines demonstrating the satisfactory agreement between the actual and projected data (Ab Ghani et al. 2017). Further, the Box-Cox plot was employed to examine the λ-value, which is generally used to envisage the change in the experimental numerals to enhance the model impact. In accordance with the λ-value of 1.62 generated from the plot, a natural log transformation was utilized (Fig. 4c).

Various literature has utilized different adsorbents for the melanoidin removal, viz. natural oxides, waste biomaterials, agro-based adsorbents, waste-derived chitin, AC prepared from waste materials, nanosheets, etc. Arimi et al. (2015) used natural manganese oxides for color and COD removal, where a strong pH dependence was observed. Further, the removal mechanism includes chemical transformation, precipitation, and adsorption. Some researchers had explored the melanoidin removal by graphene oxide nanosheets and reported 18.3 g/g of the adsorption capacity for the actual industrial melanoidin-contaminated wastewater (Rafigh and Soleymani 2020). Tsiakiri et al. (2020) prepared Baker’s yeast cells via immobilizing on to the alumina/silica particles. Around 80 and 100% removal (degradation) were achieved in 48 h for alumina and silica support, respectively. Here, the secretion of laccase and peroxidase activity plays an important role in melanoidin degradation.

Further, Wongcharee and Aravinthan (2020) examined the mesoporous magnetic nanosorbent prepared from Macadamia nutshell residues for dissolved organic carbon (DOC) removal. Approximately 68.4% of removal was reported with the removal phenomena following pseudo-second-order kinetic model and Langmuir isotherm. Susree et al. (2013) efficiently removed 83.2% of COD using an electrochemical reactor in batch mode with simultaneous enhancement in current density and electrolyte concentration. Additionally, Navgire et al. (2012) synthesized MoO3–TiO2 nanocrystalline composite material via the sol–gel method. The prepared catalytic material was efficient in degrading melanoidin (molasses) under UV–visible exposure.

Mechanism involved in the treatment process

Figure 5 depicts the different kinds of bonds available on to the surface of the prepared AC, which is plausibly involved in the contaminant removal from the wastewater. Diffusion and attraction are primarily engaged in the physical removal process by adsorption (Rizvi et al. 2020). The various bond including hydrogen bonding, π–π interactions, cationic electrostatic attraction, interparticle diffusion, anionic–cationic electrostatic bonding, pore-filling, hydrophobic effect, and intersphere complexation, etc., plays an imperious role in melanoidin elimination from wastewater (Goswami et al. 2018b; Ab Ghani et al. 2017; Tan et al., 2015). Further, the carboxylic and lactonic groups present on the AC surface can extract the π-electrons leading to electron shortage (Liu et al. 2015).

Henceforth, Cu-impregnated AC has shown a substantial amount of melanoidin removal from the contaminated wastewater. The Box-Behnken optimization has further impacted a positive effect on the removal process. All the process parameters have their key role in melanoidin removal. Overall, to enhance the removal, we can further explore and optimize various other biowaste materials or industrial waste to make the removal process more efficient.

Conclusions

Overall, the synthesized Cu-impregnated AC was found efficient in treating melanoidin-contaminated wastewater. The utilization of the optimizing tool for the optimization of different process parameters has certainly played a crucial role in melanoidin removal. Adsorbent dosage, melanoidin concentration, and contact time have played a substantial role. In addition, the up-scaling to determine the efficiency of the adsorbent and the real wastewater containing melanoidin could be preferred to have a clear insight and performance of the removal process.

References

Ab Ghani Z, Yusoff MS, Zaman NQ, Zamri MFMA, Andas J (2017) Optimization of preparation conditions for activated carbon from banana pseudo-stem using response surface methodology on removal of color and COD from landfill leachate. Waste Manage 62:177–187

Alves G, Xavier P, Limoeiro R, Perrone D (2020) Contribution of melanoidins from heat-processed foods to the phenolic compound intake and antioxidant capacity of the Brazilian diet. J Food Sci Technol 57(8):1–13

Arimi MM, Zhang Y, Geißen SU (2015) Color removal of melanoidin-rich industrial effluent by natural manganese oxides. Sep Purif Technol 150:286–291

Bajgai RC, Tamang DT, Kushwaha A, Goswami L (2022) Strategic consideration as feedstock resource for biofuel production as a holistic approach to control invasive plant species. Waste-to-energy approaches towards zero waste. Elsevier, pp 245–268

Begum SS, Muthukumar S, Yacin SM (2013) Biosorptional studies on heavy metals in an up-flow packed bed reactor using biomaterials. Int J Environ Eng 5(4):423–437

Bind A, Kushwaha A, Devi G, Goswami S, Sen B, Prakash V (2019) Biosorption valorization of floating and submerged macrophytes for heavy-metal removal in a multi-component system. Appl Water Sci 9(4):95

Borah SN, Sen S, Goswami L, Bora A, Pakshirajan K, Deka S (2019) Rice based distillers dried grains with solubles as a low cost substrate for the production of a novel rhamnolipid biosurfactant having anti-biofilm activity against Candida tropicalis. Coll Surf B Biointerfaces 182:110358

Borah SN, Goswami L, Sen S, Sachan D, Sarma H, Montes M, Peralta-Videa JR, Pakshirajan K, Narayan M (2021) Selenite bioreduction and biosynthesis of selenium nanoparticles by Bacillus paramycoides SP3 isolated from coal mine overburden leachate. Environ Pollut 285:117519

Chandra R, Bharagava RN, Rai V (2008) Melanoidins as major colourant in sugarcane molasses based distillery effluent and its degradation. Biores Technol 99(11):4648–4660

Das D, Vimala R, Das N (2014) Biosorption of Zn (II) onto Pleurotus platypus: 5-Level Box-Behnken design, equilibrium, kinetic and regeneration studies. Ecol Eng 64:136–141

Devi G, Goswami L, Kushwaha A, Sathe SS, Sen B, Sarma HP (2021) Fluoride distribution and groundwater hydrogeochemistry for drinking, domestic and irrigation in an area interfaced near Brahmaputra floodplain of North-Eastern India. Environ Nanotechnol Monitor Manag 16:100500

Diaz-Morales N, Cavia-Saiz M, Salazar G, Rivero-Pérez MD, Muñiz P (2020) Cytotoxicity study of bakery product melanoidins on intestinal and endothelial cell lines. Food Chem 343:128405

Gautam Aishvarya, Kushwaha Anamika, Rani Radha (2021) Microbial remediation of hexavalent chromium: an eco-friendly strategy for the remediation of chromium-contaminated wastewater. The future of effluent treatment plants. Elsevier, pp 361–384

Gautam A, Kushwaha A, Rani R (2022) Reduction of Hexavalent Chromium [Cr (VI)] by heavy metal tolerant Bacterium Alkalihalobacillus clausii CRA1 and its toxicity assessment through flow cytometry. Curr Microbiol 79(1):1–12

Goswami L, Kumar RV, Manikandan NA, Pakshirajan K, Pugazhenthi G (2017) Simultaneous polycyclic aromatic hydrocarbon degradation and lipid accumulation by Rhodococcus opacus for potential biodiesel production. J Water Process Eng 17:1–10

Goswami L, Kumar RV, Borah SN, Manikandan NA, Pakshirajan K, Pugazhenthi G (2018a) Membrane bioreactor and integrated membrane bioreactor systems for micropollutant removal from wastewater: a review. J Water Process Eng 26:314–328

Goswami L, Manikandan NA, Dolman B, Pakshirajan K, Pugazhenthi G (2018b) Biological treatment of wastewater containing a mixture of polycyclic aromatic hydrocarbons using the oleaginous bacterium Rhodococcus opacus. J Clean Prod 196:1282–1291

Goswami L, Kumar RV, Pakshirajan K, Pugazhenthi G (2019) A novel integrated biodegradation—microfiltration system for sustainable wastewater treatment and energy recovery. J Hazard Mater 365:707–715

Goswami L, Pakshirajan K, Pugazhenthi G (2020) Biological treatment of biomass gasification wastewater using hydrocarbonoclastic bacterium Rhodococcus opacus in an up-flow packed bed bioreactor with a novel waste-derived nano-biochar based bio-support material. J Clean Prod 256:120253

Goswami L, Kushwaha A, Goswami S, Sharma YC, Kim T, Tripathi KM (2021) Nanocarbon-based-ZnO nanocomposites for supercapacitor application. Nanostructured zinc oxide. Elsevier, pp 553–573. https://doi.org/10.1016/B978-0-12-818900-9.00008-5

Goswami S, Kushwaha A, Goswami L, Singh N, Bhan U, Daverey A, Hussain CM (2021) Biological treatment, recovery, and recycling of metals from waste printed circuit boards. Environmental management of waste electrical and electronic equipment. Elsevier, pp 163–184

Goswami L, Kushwaha A, Singh A, Saha P, Choi Y, Maharana M, Patil SV, Kim BS (2022) Nano-biochar as a sustainable catalyst for anaerobic digestion: a synergetic closed-loop approach. Catalysts 12:186

Goulas V, Nicolaou D, Botsaris G, Barbouti A (2018) Straw wine melanoidins as potential multifunctional agents: insight into antioxidant, antibacterial, and angiotensin-I-converting enzyme inhibition effects. Biomedicines 6(3):83

Gupt CB, Bordoloi S, Sekharan S, Sarmah AK (2020) Adsorption characteristics of Barmer bentonite for hazardous waste containment application. J Hazard Mater 396:122594

Gupt CB, Kushwaha A, Prakash A, Chandra A, Goswami L, Sekharan S (2021) Mitigation of groundwater pollution: heavy metal retention characteristics of fly ash based liner materials. In: Gupta PK, Bharagava RN (eds) Fate and transport of subsurface pollutants. Springer, Singapore, pp 79–104

Gupta PK, Kumar A, Goswami L, Yadav B (2020) Rhizospheric treatment of hydrocarbons containing wastewater. In: Arora PK (ed) Microbial technology for health and environment. Springer, Singapore, pp 289–301

Hoarau J, Caro Y, Grondin I, Petit T (2018) Sugarcane vinasse processing: toward a status shift from waste to valuable resource: a review. J Water Process Eng 24:11–25

Hu X, Zhang H, Sun Z (2017) Adsorption of low concentration ceftazidime from aqueous solutions using impregnated activated carbon promoted by iron, copper and aluminum. Appl Surf Sci 392:332–341

Hussain CM, Singh S, Goswami L (eds) (2021) Waste-to-energy approaches towards zero waste: interdisciplinary methods of controlling waste. Elsevier

Kumar M, Goswami L, Singh AK, Sikandar M (2019) Valorization of coal fired-fly ash for potential heavy metal removal from the single and multi-contaminated system. Heliyon 5(10):e02562

Kumar M, Kushwaha A, Goswami L, Singh AK, Sikandar M (2021) A review on advances and mechanism for the phycoremediation of cadmium contaminated wastewater. Clean Eng Technol 5:100288

Kumari S, Jose S, Tyagi M, Jagadevan S (2020) A holistic and sustainable approach for recovery of phosphorus via struvite crystallization from synthetic distillery wastewater. J Clean Product 254:120037

Kushwaha A, Rani R, Kumar S, Thomas T, David AA, Ahmed M (2017) A new insight to adsorption and accumulation of high lead concentration by exopolymer and whole cells of lead-resistant bacterium Acinetobacter junii L. Pb1 isolated from coal mine dump. Environ Sci Pollut Res 24(11):10652–10661

Kushwaha A, Rani R, Patra JK (2020) Adsorption kinetics and molecular interactions of lead [Pb (II)] with natural clay and humic acid. Int J Environ Sci Technol 17(3):1325–1336

Kushwaha A, Goswami S, Hans N, Goswami L, Devi G, Deshavath NN, Yadav MK, Lall AM (2021) An insight into biological and chemical technologies for micropollutant removal from wastewater. In: Gupta Pankaj Kumar, Bharagava Ram Naresh (eds) Fate and transport of subsurface pollutants. Springer, Singapore, pp 199–226. https://doi.org/10.1007/978-981-15-6564-9_11

Kushwaha A, Rani R, Agarwal V (2016) Environmental fate and eco-toxicity of engineered nano-particles: current trends and future perspective. In: Advanced nanomaterials for wastewater remediation. 387–404

Kushwaha, A., Rani, R., & Kumar, S. (2017a). Mechanism of soil-metal-microbe interactions and their implication on microbial bioremediation and phytoremediation. Environmental science and engineering, p 8

Kushwaha A, Goswami L, Lee J, Sonne C, Brown RJC, Kim KH (2021a) Selenium in soil-microbe-plant systems: sources, distribution, toxicity, tolerance, and detoxification. Crit Rev Environ Sci Technol, 1–42

Kushwaha A, Hans N, Giri BS, Rene ER, Rani R (2022) Uncovering the phytochemicals of root exudates and extracts of lead (Pb) Hyperaccumulator Vetiveria Zizanioides (L.) in response to lead contamination and their effect on the chemotactic behaviour of rhizospheric bacteria.

Lata Kiran, Kushwaha Anamika, Ramanathan Gurunath (2021) Bacterial enzymatic degradation and remediation of 2,4,6-trinitrotoluene. Microbial and natural macromolecules. Elsevier, pp 623–659

Liakos TI, Lazaridis NK (2016) Melanoidin removal from molasses effluents by adsorption. J Water Process Eng 10:156–164

Liu H, Zhang J, Ngo HH, Guo W, Wu H, Guo Z, Zhang C (2015) Effect on physical and chemical characteristics of activated carbon on adsorption of trimethoprim: mechanisms study. RSC Adv 5(104):85187–85195

Navgire M, Yelwande A, Tayde D, Arbad B, Lande M (2012) Photodegradation of molasses by a MoO3–TiO2 nanocrystalline composite material. Chin J Catal 33(2–3):261–266

Park HS, Koduru JR, Choo KH, Lee B (2015) Activated carbons impregnated with iron oxide nanoparticles for enhanced removal of bisphenol A and natural organic matter. J Hazard Mater 286:315–324

Rafigh SM, Rahimpour Soleymani A (2020) Melanoidin removal from molasses wastewater using graphene oxide nanosheets. Sep Sci Technol 55(13):2281–2293

Rizvi S, Goswami L, Gupta SK (2020) A holistic approach for melanoidin removal via Fe-impregnated activated carbon prepared from mangifera indica leaves biomass. Biores Technol Rep 12:100591

Sankaran K, Premalatha M, Vijayasekaran M, Somasundaram VT (2014) DEPHY project: distillery wastewater treatment through anaerobic digestion and phycoremediation—a green industrial approach. Renew Sustain Energy Rev 37:634–643

Sathe SS, Goswami L, Mahanta C, Devi LM (2020) Integrated factors controlling arsenic mobilization in an alluvial floodplain. Environ Technol Innovat 17:100525

Sathe SS, Goswami L, Mahanta C (2021) Arsenic reduction and mobilization cycle via microbial activities prevailing in the Holocene aquifers of Brahmaputra flood plain. Groundwater Sustain Develop 13:100578

Shah I, Adnan R, Wan Ngah WS, Mohamed N (2015) Iron impregnated activated carbon as an efficient adsorbent for the removal of methylene blue: regeneration and kinetics studies. PloS one 10(4):e0122603

Singh PK, Kushwaha A, Hans N, Gautam A, Rani R (2019) Evaluation of the cytotoxicity and interaction of lead with lead resistant bacterium Acinetobacter junii Pb1. Braz J Microbiol 50(1):223–230

Singh A, Kushwaha A, Sen S, Goswami S, Katiyar S, Kumar A, Borah SN, Goswami L, Hussain CM (2022) Recent advancement in microwave-assisted pyrolysis for biooil production. Waste-to-energy approaches towards zero waste. Elsevier, pp 197–219

Susree M, Asaithambi P, Saravanathamizhan R, Matheswaran M (2013) Studies on various mode of electrochemical reactor operation for the treatment of distillery effluent. J Environ Chem Eng 1(3):552–558

Tan X, Liu Y, Zeng G, Wang X, Hu X, Gu Y, Yang Z (2015) Application of biochar for the removal of pollutants from aqueous solutions. Chemosphere 125:70–85

Tsiakiri EP, Sompatzi E, Voukia F, Sotiropoulos S, Pantazaki AA (2020) Biocatalytic and bioelectrolytic decolorization of simulated melanoidin wastewaters by saccharomyces cerevisiae cells suspended and conjugated on silica and alumina. J Environ Chem Eng 8(5):104078

Wongcharee S, Aravinthan V (2020) Application of mesoporous magnetic nanosorbent developed from macadamia nut shell residues for the removal of recalcitrant melanoidin and its fractions. Sep Sci Technol 55(9):1636–1649

Yadav APS, Dwivedi V, Kumar S, Kushwaha A, Goswami L, Reddy BS (2021) Cyanobacterial extracellular polymeric substances for heavy metal removal: a mini review. J Compos Sci 5:1

Yadav APS, Goswami L, Dwivedi V, Kumar S (2021) Leveraging the biosorption potential of Leptolyngbya boryana for Cr (VI) removal from aqueous solution. Clean Eng Technol 4:100198

Yaylayan VA, Kaminsky E (1998) Isolation and structural analysis of maillard polymers: caramel and melanoidin formation in glycine/glucose model system. Food Chem 63(1):25–31

Acknowledgements

The authors thank the Department of Chemical Engineering, HBTU, and Instrument facilities at IIT Kanpur for providing the necessary facilities to carry out the present study.

Funding

The author(s) received no specific funding for this work.

Author information

Authors and Affiliations

Contributions

SR was involved in conceptualization, data curation, writing original draft, and editing; Anju Singh helped in visualization supervision and editing; SKG helped in supervision, funding, visualization, and editing.

Corresponding author

Ethics declarations

Conflict of interest

All the authors do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rizvi, S., Singh, A. & Gupta, S.K. A parametric study using Box-Behnken design for melanoidin removal via Cu-impregnated activated carbon prepared from waste leaves biomass. Appl Water Sci 12, 81 (2022). https://doi.org/10.1007/s13201-022-01620-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01620-8