Abstract

Membrane Fenton-like process with cobalt–copper spinel catalyst is proposed to degrade nitrogenous organic hazardous in wastewater. Cu-auxiliary cobalt oxide (CuxCo3–xO4) was synthesized with the dispersion co-precipitation method. As-prepared CuCo2O4 performed as the best catalyst for Fenton degradation on nitrogen-containing organic compound as methylene blue (C16H18N3ClS) in water and N,N-dimethylacetamide [CH3CON(CH3)2] in industrial wastewater. Lattice substation of Cu2+ to Co2+ ion increased the oxygen vacancies and catalytic activity. The catalyst stability was improved owing to hybrid polarization confinement (total metal elution less than 0.8 mg/L). Methylene blue in water (C0 = 100 mg/L) was completely decolorized in 50 min using 0.6 g/L CuCo2O4 and 0.09 M H2O2 at intrinsic pH 6.7. Degradation reaction rate constant was increased by two folds as k = 0.076 min−1 catalyzed by CuCo2O4 over k = 0.039 min−1 by Co3O4. DMAc-contaminant wastewater of high CODs 19,080 mg/L was treated using 2.4 g/L CuCo2O4 and 2.4 M H2O2 at intrinsic pH = 7.6. Removal rate of DMAc was enhanced from 81 to 99% in the ceramic membrane reactor when H2O2 was activated, and self-sweeping effect was suppressed. As a result, Total Organic Nitrogen (2900 mg/L) in the wastewater was mineralized by 99.9% with a fast transformation to inorganic NO3− ion. Biodegradability of the resistant organic wastewater was remarkably improved, and BOD/COD was increased by 18 folds.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Degradation of resistant harmful organic pollutants in industrial wastewater imminently demands advanced treatment technology. Nitrogenous hazardous compounds in water are largely persistent to biological treatment because of bio-toxicity to the bacteria (Bhat and Gogate 2021). The nitrogen-containing dyes and organic solvents are often found in textile, agriculture, fibers, leather and pharmaceutic industrial wastewater. The widely-used aprotic solvent N,N-dimethylacetamide (DMAc) for polymer dissolution could cause damages to human liver, skin and neural system (Ghazali and Inayat-Hussian 2014). Conventional biological nitrification is applicable to low-concentration nitrogenous wastewaters (e.g., NH4+-N < 50 mg/L) mainly using the ammoniaoxidizing and nitriteoxidizing bacteria. One study reported that DMAc-contaminate wastewater via bacteria digestion released odor gas ammonia (NH3), and the membrane fouling was inevitable in the membrane bioreactor (MBR) (Zhou et al. 2018a). DMAc (C0 = 200 mg/L) was removed by 95.4% in water solution with a reaction rate constant k = 0.0258 min−1 using CuFe2O4/O3 catalyzed-ozone process (Zhang et al. 2018). In the electrolysis catalyzed-ozone process of ECO-Na2SiO3/Fe/O3, the rate constant increased to k = 0.112 min−1 in degradation reaction of DMAc compound in water (Xiong et al. 2021).

Advanced Oxidation Processes (AOPs) is an effective approach to decontaminate high-concentration nitrogenous organic wastewaters. The Fenton/Fenton-like wastewater treatment has been reviewed on ferrous and non-ferrous heterogeneous Fenton processes (Thomas et al. 2021) and Cu-based heterogeneous and homogenous Fenton-like processes (Li et al. 2020a). The Cu–Fe spinel ferrites (e.g., CuFe2O4) was found with superior performance over the mono-metal oxides in Fenton applications (Albuquerque et al. 2012; Sharma et al. 2015; Dang and Le 2016). With the reduced CuFe2O4 catalyst, methylene blue (C0 = 50 mg/L) in water solution was decolorized by 74% in 25 min with the heterogeneous Fenton process working at pH = 3.2 (Qin et al. 2018). Using Cu/CuFe2O4 nanocomposite (Cu0 loaded on surface) as Fenton catalyst, methylene blue was degraded by 99% over initial 50 mg/L in 5 min working at pH = 2.5 (Li et al. 2018). And Cu2O/CuFe2O4 microparticles were studied for phenol degradation among which Cu2O was found having a key function in the composite Fenton catalyst (Faheem et al. 2018). Nanocrystalline ferrite photocatalyst of CuFe2O4 was synthesized, and methylene blue (10 mg/L) in water was removed by 99.5% in 90 min using visible/CuFe2O4/H2O2 photocatalytic Fenton process (Vinosha et al. 2018).

The Cu–Co spinel has a similar crystalline structure to Cu–Fe spinel as cobalt and iron are the neighbor elements in the periodic table. The CuCo2O4 spinel are yet mostly focused on battery materials as the active anode or cathode for the lithium ion batteries (Xu et al. 2019; Liu et al. 2014). CuCo2O4 microflower was experimented as the catalyst over the noble metal catalysts for oxygen evolution reactions (Du et al. 2018). Bisphenol was degraded in peroxymonosulfate oxidation process catalyzed by nanocomposite CuCo2O4/GO (Xu et al. 2020). Deactivation of antibiotics in water was catalyzed by pine-needle-like CuCo2O4 in microwave-assisted Fenton process (Qi et al. 2019).

Green-synthesis of nanocatalysts and nanomaterials faces some current challenges for large-scale environmental technology (Nasrollahzadeh et al. 2020). Nanoparticles (NPs) synthesis often involves toxic redox compounds such as hydroxylamine, hydrazine and sodium borohydride. And shaping the nanoparticles normally requires the use of costly organic surfactants. For instance, sodium dodecyl sulfate (SDS) was used to obtain hexapod nanoparticles (Ho and Huang 2009); polyvinyl pyrrolidone (PVP) for octahedral and nanospheric nanoparticles (Sang et al. 2017; Sui et al. 2010) and cetyltrimethyl ammonium bromide (CTAB) for bi-pyramid nanoparticles (Jimenez-Cadena et al. 2010). Membrane dispersion has advantages on the control synthesis of nanoparticles, for instance, SiO2 nanoparticles and ZnO nanocrystals were precipitated in flat-sheet metal membrane micro-reactors (Zhang et al. 2014; Wang et al. 2010). And microparticles and nanoparticles of Cu2O were deposited and shaped in a ceramic membrane reactor (Li et al. 2020b). Additionally, the membrane rector could be integrated to advanced oxidation processes for oxidant activation. Degradation efficiency of paper-milling wastewater (Zhou et al. 2018b) and polymeric membrane wastewater (Li et al. 2020b) have been enhanced with the membrane Fenton-like process of Cu2O/H2O2.

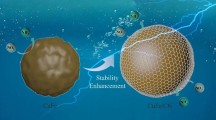

In this work, Cu–Co hybrid spinel nanocatalysts were synthesized with the aim of the improved activity and stability for nitrogenous wastewater treatment. Lattice substation of Cu2+ to Co2+ ion, having similar ionic radius, could increase oxygen vacancies and catalytic activity. The Cu–Co hybrid polarization confinement could improve catalyst stability in aqueous environment. A serious of CuxCo3−xO4 nanoparticles were prepared using the membrane dispersion co-precipitation method. Their performances evaluated for degradation efficiency of nitrogenous organic compounds in water and wastewater. Operational conditions including catalyst, oxidant, pH and temperature were optimized in the batch reactor. It was attempted to enhance degradation efficiency in the membrane reactor for the cobalt-based process. DMAc-contaminant industrial wastewater of high-concentration and low-biodegradability was treated with the proposed membrane Fenton-like process of CuCo2O4/H2O2.

Experimental

Chemicals and wastewater

All the chemicals were of analytical grade and used without further purification. Laboratory-made deionized water was used in all the experiments. Sodium carbonate (Na2CO3), sodium citrate (Na3C6H5O7·2H2O), copper acetate [Cu(CH3COO)2·2H2O], cobalt acetate [Co(CH3COO)2·4H2O], hydrogen peroxide (H2O2, 30 wt%), methylene blue (C16H18N3ClS) and N,N-dimethylacetamide [CH3CON(CH3)2] were purchased from Sinopharm Chemical Reagent company. Methylene blue was dissolved in water solution with initial concentration 100 mg/L as nitrogen-containing model pollutant.

The industrial wastewater was supplied from a polymeric membrane manufacturer in Nanjing, China. CODCr of the organic wastewater was measured as 19,080 mg/L with N,N-dimethylacetamide as the main organic pollutant. It was used for polymer dissolution in the membrane production line. Concentration of DMAc was measured as 18,000 mg/L, and concentration of inorganic ions (e.g., chloride and sulfate) was low in the wastewater. The intrinsic pH of wastewater was 7.6, and pH effect was studied as adjusting with sulfuric acid or sodium hydroxide. The organic wastewater was resistant to bio-degradation with a low value of BOD/COD = 0.04. Properties of the industrial wastewater are listed in Table 1.

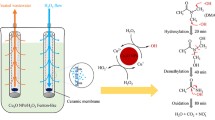

Membrane reactor

Ceramic membrane reactor could be supplemented for either catalyst synthesis experiment or wastewater degradation experiment as presented in Fig. 1. The ceramic membranes were provided from Jiangsu Jiuwu Co. Ltd. (China). The membrane was composed of zirconia outer-layer (mean pore size 50 nm) on top of alumina support. The outer diameter, inner diameter and length of the applied membrane tube were 1.2, 0.8 and 15 cm, respectively. The membrane was immersed in reactor with one end sealed. A dispersing phase was the reactant(s) permeating the membrane, and a continuous phase was the reactant(s) containing in the reactor. For the synthesis of catalyst, alkaline solution was the dispersing phase, and metal precursor was the continuous phase. For the Fenton-degradation experiment of organic pollutant, hydrogen peroxide solution was the dispersing phase, and wastewater was the continuous phase.

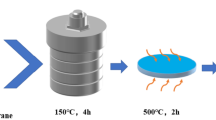

In preparation of Cu–Co oxide catalyst, precursor of copper acetate and cobalt acetate was stirring at 300 rpm in water solution at 25 °C. Alkaline sodium carbonate (0.2 M) with complexing agent sodium citrate (0.1 M) was mixed in water and dispersed via ceramic membrane at flowing with 30 mL/min. Membrane dispersion could improve the mixture homogeneity of metal precursor and the agent. Bluish-purple flocks of carbonate metal compound 2MCO3·3 M(OH)2 (M=Co and Cu) were deposited in the co-precipitation reaction. The deposition was filtered (using 0.22-um filter), washed (using water and then ethanol) and dried at 60 °C. Then the solid was heated to 500 °C (5 °C/min heating rate) and maintained for 3 h so that the binary metal oxide CuxCo3−xO4 was formed. Different molar proportion of Cu(CH3COO)2 and Co(CH3COO)2 was experimented to obtain a serious of oxide product.

The volume of water/wastewater was 20 mL being treated in each test. It was suspended with catalyst and stirring with 450 rpm at 25 °C in the reactor. Hydrogen peroxide solution (30 wt%) could be added to the reactor with either direct or indirect (membrane dispersion) manner. Catalysis performance of CuxCo3−xO4 was first characterized in decolorization test on methylene blue in water solution (C0 = 100 mg/L), and the kinetics was accordingly studied. DMAc-contaminated industrial wastewater (CODs 19,080 mg/L) was then treated with CuxCo3−xO4/H2O2 process in batch reactor and membrane reactor. Optimal structure of catalyst and optimal operational conditions including catalyst loading, oxidant dosage, pH and temperature were studied and determined. Degradation efficiency enhancement by ceramic membrane dispersion of H2O2 was investigated.

Characterization and calculation

Morphology of as-prepared catalyst was investigated with Scanning Electron Microscope (SEM, Hitachi S-4800, Japan). Crystalline structure was examined with X-ray Diffractometer (XRD, Mini Flex 600, Japan). Elemental valence states of copper, cobalt and oxygen in the catalyst were analyzed with X-ray Photoelectronic Spectroscopy (XPS, Thermo ESCALAB 250XI, USA). Concentration of methylene blue in water solution was calculated from the maximum absorbance at 664 nm with UV/Vis spectrometry (Lambda 950, Perkin Elmer, USA). Concentration of N,N-dimethylacetamide in wastewater was calculated from the maximum absorbance at 218 nm with UV/vis spectrometry. Chemical Oxygen Demands (CODs) of the wastewater were measured using the dichromate oxidation method on with an optical spectrometer (DR2800, Hach, USA). The 5-day Biological Oxygen Demand (BOD) of the wastewater was measured with BODTrak™ II (Hach, USA). Total nitrogen/total organic nitrogen (TN/TON) in the wastewater was measured with Nitrogen Analyzer multi N/C 3100 (Analytik Jena, Germany). Concentration of metal ions in water/wastewater was determined with Inductively Coupled Plasma spectrometry (ICP, Optima 7000DV, USA).

The removal rate (R) of organic pollutant in water/wastewater is calculated according to Eq. (1). The apparent reaction rate constant (k) can be known from Eq. (2).

where C0 is the initial concentration of organic pollutant in water; Ct is the instant concentration at degradation time t; V0 and V are the initial and instant volume of the treated effluent; and k is the apparent reaction rate constant.

Results and discussion

Preparation of Cu–Co bimetallic oxides

The metal precursor of copper acetate and cobalt acetate was mixed in water solution. Carbonate metal compound was co-precipitated upon dispersing and mixing agent solution with the precursor. CuxCo3−xO4 was obtained with post-heating treatment at 500 °C. In the preparation, the dispersing phase consisted of alkaline solution (sodium carbonate 0.2 M) and complexing agent (sodium citrate 0.1 M) with a flowing rate 30 mL/min. The continuous phase consisted of copper acetate and cobalt acetate of a constant total concentration 0.066 M in the reactor. But the molar ratio of Cu:Co in precursor was adjusted from 0, 1:4 and to 4:1 in the synthesis reaction. The preparation conditions for 8 samples of metal oxide using the membrane dispersion method are listed in Table 2.

The as-prepared metal oxide samples were first characterized with Scanning Electron Microscope (SEM) and X-ray diffraction (XRD) as presented in Figs. 2, 3. Mono-metal oxide of Co3O4 was formed with the absence of copper precursor in the preparation solution. With the addition of copper acetate in precursor, the binary metal oxide of CuxCo3−xO4 formed with an increased ratio of Cu in the spinel lattice. According to SEM observation, the samples formed with Cu:Co ratio close to the stoichiometric ratio were found with better mono-dispersion (particle dimension ca. 30 nm) as seen in Fig. 2d–f. The oxide products tended to agglomerate in clusters when either copper or cobalt precursor exceeded in preparation as seen in Fig. 2b, c, g, h. With the largest amount of Cu precursor, rod-shaped aggregates formed (Fig. 2h), and the composite structure of CuO·CuxCo3−xO4 would be transformed form to XRD in Fig. 3. Quantity of Cu precursor in preparation, as the auxiliary ion in the lattice, could affect the nucleation phase in the co-precipitation reaction.

Unit cells of CuCo2O4 and Co3O4 having the similar spinel structure are presented in Fig. 3. Divalent Cu2+ ions can substitute to Co2+ ions on the top roof of octahedral in the symmetry. Since the ionic radius of Cu2+ (73 pm) is slightly smaller than that of Co2+ (74.5 pm), X-ray diffraction patten of CuCo2O4 was right shifted to the unsubstituted Co3O4. Characteristic crystal planes of (220), (111), (311), (222), (422), (511), (440) and (533) are present in the standard card of CuCo2O4 (Fig. 3). Bimetallic oxide prepared with stoichiometric ratio Cu:Co = 1:2 was found in the consistent spinel crystalline structure with good particle dispersion. As increasing copper precursor in synthesis, CuO (111) and (20-2) planes have appeared, and CuCo2O4 (311) plane has reduced in the composite oxide made of Cu:Co = 3:1 and 4:1.

Element analysis and valence state of copper and cobalt in the as-prepared sample of CuCo2O4 were studied with X-ray Photoelectron Spectroscopy (XPS). In the general scan, carbon, oxygen, copper and cobalt were detected in the sample in Fig. 4a. Co 2p spectrum was assigned the divalent ion Co2+ and trivalent ion Co3+ with binding energy 776.5 eV and 779.5 eV in Fig. 4b. It found that the divalent ion Cu2+ in two forms as Cu–O in the oxide (CuA, 934.3 eV) and Cu-OH on surface (CuB, 937.8 eV) in Cu 2p spectrum (Fig. 4c). The lattice CuA was the main form of copper ions in the metal oxide. Oxygen element existed in the oxide with three types including the lattice oxygen (OA, 529.6 eV), surface hydroxyl (OB, 531.5 eV) and chemical-adsorbed water (OC, 533.7 eV). It found that OB had the largest portion of oxygen, and it could cause "oxygen vacancy" formation in the sample. Such vacancy can play an important role in chemo-adsorption and active sites for the catalyst.

Decolorization test

Catalytic performance of the samples was examined in decolorization test using the nitrogen-containing dye of methylene blue (C16H18N3ClS) in water (Fig. 5a). Decolorization efficiency of methylene blue was apparently improved as using the catalyst CuxCo3−xO4 (with Cu:Co ≤ 2:1) instead of Co3O4. But the decolorization efficiency would decline as using the catalyst form of CuO·CuxCo3−xO4 (with Cu:Co ≥ 3:1) in comparison to Co3O4. Among these samples, as-prepared CuCo2O4 (with Cu:Co = 1:2) performed with the highest degradation efficiency for methylene blue (100 mg/L) with a complete decolorization in 50 min in water. The kinetics study was made for the eight catalysts as seen the inert graph in Fig. 5a. The result pointed out that CuCo2O4 catalyst had the apparent reaction rate constant k = 0.076 min−1. It was almost two folds higher than the mono-metal oxide Co3O4 with k = 0.039 min−1 in the Fenton-like reaction.

Leaching of copper and cobalt ions in water solution was measured by Inductively Coupled Plasma spectrometry (ICP) as presented in Fig. 5b. The total amount of copper and cobalt in precursor was constant as 0.066 M in the preparation for catalyst. Dissolution of copper in the treated solution was generally stronger with the increased amount of copper acetate in precursor. In particular, copper leaching sparked for the two samples of CuO·CuxCo3−xO4 with the highest ratios as Cu:Co = 3:1 and 4:1. Metal ion dissolution was well confined for the metal oxides made with Cu:Co ≤ 1:2. As for as-prepared CuCo2O4, the total metal elution was measured as the lowest less that 0.8 mg/L including 0.31 mg/L copper ions and 0.43 mg/L cobalt ions. It could comply to the national standard GB 25,467-2010 on the industrial emission with discharge limit of copper 1.0 mg/L and cobalt 1.0 mg/L in water.

Industrial wastewater treatment

Bulk feeding Fenton-like process

The high-concentration organic wastewater was supplied from a polymeric membrane manufacturer. Chemical Oxygen Demands (CODs) were 19,080 mg/L with the total organic nitrogen up to 2900 mg/L in the industrial wastewater. The main pollutant was N,N-dimethylacetamide (DMAc) with the initial concentration measured as 18,000 mg/L. Catalytic performance of CuxCo3−xO4 samples was examined in DMAc compound degradation with a direct addition of H2O2. In a good consistence to the previous result, as-prepared CuCo2O4 performed as the best catalyst. Removal rate of DMAc compound was RDMAc = 81% in 120 min reaction using bulk-solution CuCo2O4/H2O2 process of (Fig. 6).

Mono-dispersion of particle morphology and spinel crystalline structure were observed for the as-prepared CuCo2O4 (SEM and XRD in Figs. 2, 3). The oxide lattice was also found with abundant oxygen vacancies (XPS in Fig. 4). These factors were advantageous for chemo-adsorption and active site formation in the CuCo2O4 sample. The uneven distribution of surface electron would improve catalytic activity in the hybrid metal oxide. Meanwhile, the catalyst stability could be enhanced because of hybrid polarization confinement of Cu–Co spinel couple. For the actual wastewater, RDMAc was only 46% using mono-metal oxide Co3O4 as the catalyst. RDMAc has reduced to 38% using a composite form of CuO CuxCo3−xO4 as preparation Cu:Co ratio was far exceeding the stoichiometric ratio in the catalyst synthesis.

Operational conditions optimization

In heterogeneous Fenton/Fenton-like process, ·OH radical, as the main active oxidant species, is generated at the interface of catalyst and oxidant. Operational conditions of catalyst, oxidant, pH and temperature would influence the oxidative degradation reaction. In the Fenton-like process, CuCo2O4 loading (0.6–3.6 g/L), H2O2 dosage (0.8–4.0 M), reaction pH (3–11) and temperature (25–55 °C) were investigated in DMAc-contaminate wastewater treatment. Removal rate of DMAc (RDMAc) gradually increased from 68 to 81% as increasing catalyst loading from 0.6 to 2.4 g/L with 2.4 M H2O2 at intrinsic at pH = 7.6 and 25 °C (Fig. 7a). The more active sites of catalyst the higher degradation efficiency of organic pollutant could be. And then RDMAc has insignificant change as further adding the catalyst from 2.4 to 3.6 g/L. The specific surface and active sites did not further increase when powder agglomeration occurred upon overloading.

Concentration of H2O2 solution from 0.8 to 4.0 M with the direct addition was studied in industrial wastewater degradation (Fig. 7b). RDMAc has increased from 57 to 81% as increasing the concentration of H2O2 from to 2.4 M. There was a larger amount of ·OH radical being formed with the increased concentration of oxidant reactant. Then RDMAc dropped down to 76% at higher concentration of H2O2 as 4.0 M. Depletion of H2O2 molecules could be caused by self-reaction of extra H2O2. In addition, the excessive H2O2 molecules would react with ·OH radical and form less active HO2· radical. The frequent collision could also accelerate the quench of ·OH radical at higher concentration. These reasons could explain the reduction of DMAc degradation efficiency with the over-dosed oxidant.

Reaction pH affects Fenton/Fenton-like process especially in the ferrous Fenton which requires the operational pH from 3 to 5. Effect of pH on DMAc degradation efficiency of the nitrogenous wastewater is presented in Fig. 7c. The intrinsic pH was 7.6 of the raw wastewater. Removal rate of DMAc (RDMAc) organic pollutant was slightly increased by 5% from the intrinsic neutral condition (pH = 7.6) to alkalinity condition of (pH = 11) using 2.4 g/L CuCo2O4 and 2.4 M H2O at 25 °C. Unlikely, RDMAc dramatically decreased to 34% for the acidified wastewater of pH = 3 with the other conditions kept constant. The conjugate forms of N,N-dimethylacetamide (DMAc) transfer under alkalinity and acidity condition as described in the equations of Fig. 8. DMAc compound hydrolyzes to the counterpart of CH3COO− and NH(CH3)2 under alkalinity condition. High electron density of acetic acid (–COO−) makes it vulnerable to ·OH radical attack. On the contrary, the lone-pair electron of amide nitrogen can interact with proton and reduce the electron density so that the molecule is protected from radical attack under acidity condition. It explained the reduced degradation efficiency of DMAc compound in the wastewater with acidification treatment.

The temperature (25–55 °C) performed a minor effect on pollutant degradation in the industrial wastewater. RDMAc roughly maintained as the wastewater was treated in CuCo2O4/H2O2 process for 120 min at 25 and 35 °C. RDMAc increased slightly to 89% when the wastewater was heated to 45 °C. RDMAc was not raising anymore and maintained as 86% at 55 °C. Thermal motion and collision of the reactants would be frequent at higher temperature. On the other hand, self-decomposition of H2O2 and quench of ·OH radical became severe at higher temperature. The temperature-induced outcome was a result of reactant collision, self-decomposition and radical quench.

In a conclusion, the operational degradation conditions for industrial wastewater (DMAc organic pollutant ~ 18,000 mg/L) were optimized as loading catalyst of CuCo2O4 (2.4 g/L) and direct feeding of H2O2 (2.4 M) at the intrinsic pH = 7.6 and room temperature (25 °C) in the bath reactor.

Membrane Fenton-like process

The membrane Fenton process was then studied using the optimal operational conditions as previously but with H2O2 dispersion feeding as seen in the experiment set-up in Fig. 1. In the ceramic membrane reactor, H2O2 solution was pumped to the inner of membrane tube and permeated the membrane wall to reactor. In the control experiment, RDMAc was less than 5% for the wastewater and catalyst powder, and RDMAc was less than 10% for the wastewater and H2O2. It was caused by adsorption of the catalyst and weak oxidation of H2O2. With the other conditions constant, wastewater RDMAc was effectively enhanced from 81 to 99% just with H2O2 dispersion instead of bulk-solution feeding (Fig. 9a).

Activation of H2O2 in Fenton-like application was evidently strengthened with micro-streaming of oxidant through nano-scale pore channels in ceramic membrane. It could produce a great amount of ultrafine droplets of H2O2 with quick micro-mass transfer and large specific surface. It also improved the homogeneity of reactant mixture with continuous feeding. Self-depletion of H2O2 as so-called sweeping effect could be eliminated with high dosage through micro-streaming. In addition, surface hydroxyl of the ceramic membrane promoted ·OH radical formation at the interface. Life-time extension of ·OH radical was measured with EPR in the membrane Fenton reactor according to the previous work (Zhou et al. 2018a, b; Li et al. 2020a, b). Comparison of the literature with this work on degradation efficiency of nitrogenous organic contaminants in water/wastewater is summarized in Table 3. It is clear that the proposed CuCo2O4-based membrane Fenton-like process has a unique advantage for efficient denomination of the high-concentration nitrogenous industrial wastewater.

Chemical Oxygen Demands (CODs) of the organic wastewater were up to 19,080 mg/L, and the 5-day Biology Oxygen Demands (BOD5) were 718 mg/L. The nitrogenous wastewater was resistant to bio-degradation treatment. Biodegradability was as low as BOD/COD = 0.04. With CuCo2O4/H2O2 process, CODs decreased by 68% in the membrane reactor and by 60% in the batch reactor. As a result, BOD/COD index was increased by 18 folds from 0.04 to 0.72 with membrane-assisted Fenton treatment. A significant improvement of biodegradability was realized for the high-concentration organic wastewater.

Degradation of amide nitrogen in DAMc compound was studied in the membrane Fenton treatment. Total Nitrogen (TN) was 2906 mg/L, and Total Organic Nitrogen (TON) was 2900 mg/L in the industrial wastewater. Inorganic nitrogen was absent before the oxidative degradation treatment. Total Organic Nitrogen was significantly reduced by 99.9% in 120 min with membrane Fenton-like process (TON = 266 mg/L). In parallel, the inorganic nitrate nitrogen (NO3−-N) has increased to 2640 mg/L in the treated wastewater. It proved that acetamide nitrogen has been completely oxidized and nitrated. Degradation pathway of organic nitrogen and carbon is proposed in Fig. 10. Mineralization mechanism of DMAc to CO2, H2O and NO3− was studied with GC–MS spectrometry in the previous work (Li et al. 2020a, b).

Conclusion

The benefits of using the prepared CuCo2O4 nanocatalyst include the feasible synthesis and the improved catalytic performance for oxidative degradation of nitrogenous organic pollutants in water. Large-scale control synthesis of uniform nanoparticles could be realized using the membrane dispersing co-precipitation method. Neither strong redox or toxic surfactant should be required in the preparation. Cu–Co bimetallic oxide nanoparticles presented better catalytic performance over the mono-metal oxide (e.g., Co3O4 and Cu2O) owing to oxygen vacancies and hybrid polarization. Application of the prepared nanocatalyst in Fenton-like oxidation has unique treatment advantage to high-concentration nitrogenous wastewater, where bio-degradation method is ineffective. The Co-based Fenton-like process solved the problem of iron sludge and working window of pH. Membrane dispersion integration largely increased the H2O2 activation and degradation efficiency. Methylene blue (100 mg/L) in water was completely decolorized in 50 min with CuCo2O4/H2O2 process. Removal rate of N,N-dimethylacetamide (18,000 mg/L) in high-concentration nitrogenous wastewater increased from 81 to 99% with the membrane-assisted process. Miro-streaming of H2O2 through the ceramic membrane could effectively extend ·OH radical life time. The Total Organic Nitrogen (2900 mg/L) in the industrial wastewater transferred to NO3− by 99.9%. Biodegradability of the nitrogenous wastewater was significantly improved with the BOD/COD increase by 18 folds.

References

Albuquerque AS, Tolentino MVC, Ardisson JD, Moura FCC, De Mendonca R, Macedo WAA (2012) Nanostructured ferrites: structural analysis and catalytic activity. Ceram Int 38:2225–2231

Bhat AP, Gogate PR (2021) Degradation of nitrogen-containing hazardous compounds using advanced oxidation processes: a review on aliphatic and aromatic amines, dyes, and pesticides. J Hazard Mater 403:123657–123688. https://doi.org/10.1016/j.jhazmat.2020.123657

Dang HT, Le TK (2016) Precursor chain length dependence of polymeric precursor method for the preparation of magnetic Fenton-like CuFe2O4-based catalysts. J Sol-Gel Sci Technol 80:160–167

Du X, Zhang X, Xu Z (2018) CuCo2O4 microflowers catalyst with oxygen evolution activity comparable to that of noble metal. Int J Hydrog Energy 43(10):5012–5018. https://doi.org/10.1016/j.ijhydene.2018.01.142

Faheem M, Jiang X, Wang L, Shen J (2018) Synthesis of Cu2O–CuFe2O4 microparticles from Fenton sludge and its application in the Fenton process: the key role of Cu2O in the catalytic degradation of phenol. RSC Adv 8:5740–5748

Ghazali AR, Inayat-Hussain SH (2014) N,N-dimethylacetamide. In: Encyclopedia of toxicology, 3rd edn. p 594–597. https://doi.org/10.1016/B978-0-12-386454-3.01223-9

Ho J, Huang MH (2009) Synthesis of submicrometer-sized Cu2O crystals with morphological evolution from cubic to hexapod structures and their comparative photocatalytic activity. J Phys Chem C 113:14159–14164. https://doi.org/10.1021/jp903928p

Jimenez-Cadena G, Comini E, Ferroni M, Sberveglieri G (2010) Synthesis of Cu2O bi-pyramids by reduction of Cu(OH)2 in solution. Mater Lett 64:469–471. https://doi.org/10.1016/j.matlet.2009.11.051

Li Z, Lyu J, Ge M (2018) Synthesis of magnetic Cu/CuFe2O4 nanocomposite as a highly efficient Fenton-like catalyst for methylene blue degradation. J Mater Sci 53:15081–15095

Li J, Pham AN, Dai R, Wang Z, Waite TD (2020a) Recent advances in Cu-Fenton systems for the treatment of industrial wastewaters: role of Cu complexes and Cu composites. J Hazard Mater 392:122261–122279. https://doi.org/10.1016/j.jhazmat.2020.122261

Li WY, Chen M, Zhong Z (2020b) Hydroxyl radical intensified Cu2O NPs/H2O2 process in ceramic membrane reactor for degradation on DMAc wastewater from polymeric membrane manufacturer. Front Environ Sci Eng 14(6):102–114. https://doi.org/10.1007/s11783-020-1281-6

Liu Y, Cao LJ, Cao CW (2014) Facile synthesis of spinel CuCo2O4 nanocrystals as high-performance cathode catalysts for rechargeable Li-air batteries. Chem Commun 50(93):14635–14638. https://doi.org/10.1039/c4cc04682j

Nasrollahzadeh M, Sajjadi M, Iravani S, Varma R (2020) Green-synthesized nanocatalysts and nanomaterials for water treatment: current challenges and future perspectives. J Hazard Mater 401:123401–123425. https://doi.org/10.1016/j.jhazmat.123401

Qi Y, Mei Y, Li J (2019) Highly efficient microwave-assisted Fenton degradation of metacycline using pine-needle-like CuCo2O4 nanocatalyst. Chem Eng J 373:1158–1167. https://doi.org/10.1016/j.cej.2019.05.097

Qin Q, Liu Y, Li X, Sun T, Xu Y (2018) Enhanced heterogeneous Fenton-like degradation of methylene blue by reduced CuFe2O4. RSC Adv 8:1071–1077

Sang W, Zhang G, Lan H, An X, Liu H (2017) The effect of different exposed facets on the photoelectrocatalytic degradation of o-chlorophenol using p-type Cu2O crystals. Electrochim Acta 231:429–436. https://doi.org/10.1016/j.electacta.2017.02.073

Sharma R, Bansal S, Singhal S (2015) Tailoring the photo-Fenton activity of spinel ferrites (MFe2O4) by incorporating different cations (M = Cu, Zn, Ni and Co) in the structure. RSC Adv 5:6006–6018

Sui Y, Fu W, Yang H, Zeng Y, Zhang Y, Zhao Q, Li Y, Zhou X, Leng Y, Li M, Zou G (2010) Low temperature synthesis of Cu2O crystals: shape evolution and growth mechanism. Cryst Growth Des 10:99–108. https://doi.org/10.1021/cg900437x

Thomas N, Dionysiou DD, Pillai SC (2021) Heterogeneous Fenton catalysts: a review of recent advances. J Hazard Mater 404(Part B):124082–124105. https://doi.org/10.1016/j.jhazmat.2020.124082

Vinosha PA, Xavier B, Anceila D, Das SJ (2018) Nanocrystalline ferrite (MFe2O4, M=Ni, Cu, Mn and Sr) photocatalysts synthesized by homogeneous co-precipitation technique. Optik 157:441–448

Wang Y, Zhang C, Bi S, Luo G (2010) Preparation of ZnO nanoparticles using the direct precipitation method in a membrane dispersion micro-structured reactor. Powder Technol 202(1–3):130–136. https://doi.org/10.1016/j.powtec.2010.04.027

Xiong ZK, Li JY, Li Y, Yuan Y, Jiang YN, Yao G, Lai B (2021) Simultaneously enhanced degradation of N,N-dimethylacetamide and reduced formation of iron sludge by an efficient electrolysis catalyzed ozone process in the presence of dissolved silicate. J Hazard Mater 406:124725–124735. https://doi.org/10.1016/j.jhazmat.2020.124725

Xu H, Song X, Zhang Y (2019) Facile preparation of porous erythrocyte-like CuCo2O4 as active material of lithium ion batteries anode. J Mater Sci 30(17):16308–16315. https://doi.org/10.1007/s10854-019-02001-9

Xu XQ, Feng YB, Chen ZH, Wang SB, Wu GH, Huang YL, Ma J, Wen G (2020) Activation of peroxymonosulfate by CuCo2O4-GO for efficient degradation of bisphenol A from aqueous environment. Sep Purif Technol 251:117351–117361. https://doi.org/10.1016/j.seppur.2020.117351

Zhang T, Wang Y, Luo G, Bai S (2014) Preparation of highly dispersed precipitated nanosilica in a membrane dispersion microreactor. Chem Eng J 258:327–333. https://doi.org/10.1016/j.cej.2014.07.027

Zhang M, Ji F, Zhang Y, Pan Z, Lai B (2018) Catalytic ozonation of N,N-dimethylacetamide (DMAc) in aqueous solution using nano-scaled magnetic CuFe2O4. Sep Purif Technol 19(3):368–377. https://doi.org/10.1016/j.seppur.2017.10.028

Zhou M, Olusegun KA, Zhang K (2018a) New insights into the treatment of real N,N-dimethylacetamide contaminated wastewater using a membrane bioreactor and its membrane fouling implications. RSC Adv 8:12799–12807. https://doi.org/10.1039/c8ra01657g

Zhou HJ, Kang L, Zhou M, Zhong ZX, Xing WH (2018b) Membrane enhance COD degradation of pulp wastewater using Cu2O/H2O2 heterogeneous Fenton process. Chin J Chem Eng 26:1896–1903. https://doi.org/10.1016/j.cjche.2018.01.007

Funding

This work was supported by the National Key R&D Program of China (Grant No. 2018YFE0203500), the Key Industrial R&D International Cooperation Project (Grant No. BZ2018004) and the Key R&D Program of Jiangsu Province (Grant No. BE2019117).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Human and animal participants

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhou, M., Li, W., Chen, M. et al. Synthesis of CuxCo3−xO4 nanocatalyst for degradation of nitrogenous organic wastewater in Fenton-like membrane reactor. Appl Water Sci 12, 57 (2022). https://doi.org/10.1007/s13201-022-01581-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-022-01581-y