Abstract

This work studied the removal of paracetamol through the adsorption process using the granular activated carbon. The results indicated that it was possible to obtain 95% of removal under the experimental conditions of pH 6, 120 min of process and 5 g L−1 of solid adsorbent. The kinetic model that best fit the experimental data was the pseudo-first order. The isotherm model that best fit the experimental data was the Sips. The thermodynamic tests indicated that the adsorption process was favorable and spontaneous and confirmed the endothermic nature of the process. In fixed bed column adsorption, the best operating condition found was obtained using the flow rate of 3 mL min−1 and bed mass equal to 0.5 g. In this case, the system presented the highest volume of treated PAR effluent, of 810 mL per gram of carbon in the bed, besides a longer rupture time and bed saturation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pharmaceuticals are complex molecules that are developed for the preservation of human and animal health. However, even those products being needed by people must be properly discarded after consumption. Drugs are excreted in the urine and feces of humans and animals in their unaltered form or as their active metabolites (intermediates of metabolic reactions that occur in living organisms). They have become a constant concern since the effect of this exposure on humans and aquatic organisms is not yet fully understood (Najjar et al. 2014).

The pharmaceutical compounds can be divided according to their therapeutic class (antibiotics, antihistamines, antifungals, analgesics) or according to their anatomo-therapeutic classification (medicines of the neurological system, cardiovascular system, etc.). Among these, the classes with the lowest removal efficiency in effluent treatment plants (ETP) (between 30 and 50%) are analgesics, antibiotics, contrast media, lipid regulators, β-blockers and diuretics (Deblonde et al. 2011).

Paracetamol (PAR), also known as acetaminophen, is one of the most widely used medications worldwide. As an analgesic and antipyretic agent, it acts in the fight against pain and fever (Nunes et al. 2014). Approximately 90% of this drug is metabolized by the body, and only 5% is excreted unchanged in urine (Najjar et al. 2014). Drugs are designed to be persistent by maintaining their chemical structure unchanged long enough for their therapeutic action. Thus, due to its high consumption, even though it is almost totally metabolized by the organism, paracetamol is found as a micropollutant in effluents from sewage treatment plants and hospital effluents (Papageorgioua et al. 2016).

Although it is considered a safe drug because it does not present immediate side effects and also because it does not interact with most drugs, when ingested in high concentrations PAR can cause liver toxicity and renal failure (Nunes et al. 2014). Such problems can occur due to the accumulation of metabolites and toxic intermediates, such as phenolic compounds. Other studies have also shown that the high intake of this drug may decrease interpersonal empathy, increase frustration and decrease the ability to assess errors as well as cause blood disorders and form tumors in parts of the body (Randles et al. 2016).

Among the techniques used to treat effluents containing paracetamol, the adsorption process is generally considered better in water treatment due to ease of operation and simplicity in the process (Alalm et al. 2016; Shakir et al. 2016). In addition, this process can eliminate or reduce the different types of organic and inorganic pollutants from water or wastewater and therefore have wide application in the control of water pollution. Thus, adsorption becomes an interesting alternative for the treatment of water contaminated with pharmaceuticals (Pezotoi et al. 2016; Franco et al. 2017; Haro et al. 2017).

In this context, the present work aims to evaluate the removal of paracetamol, a drug used worldwide, through the adsorption technique in batch model and fixed-bed column, using granular activated carbon (GAC) as solid adsorbent, analyzing the behavior of the process through the kinetic, adsorption isotherms and thermodynamic study.

Materials and methods

Materials

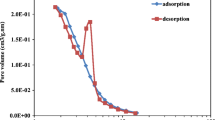

The adsorbate used, paracetamol, was supplied by Sigma-Aldrich. As solid adsorbent, the commercial active carbon with particle size between 1.4 and 2 mm (Exodus) was used. The surface area (BET) of the adsorbent, pore diameter and water content were estimated at 543.4 m2 g−1, 20.6 Å and 0.05%, respectively (Haro et al. 2017). The zeta potential of the adsorbent was measured on the Zeta Plus Brookhaven Instruments Corporation (ZEE) model 500.

Adsorption tests in batch mode

Batch experiments were performed with 100 mL of paracetamol solution at 298 K in 250 mL of glass vials. In order to simulate a concentrated hospital effluent, the paracetamol concentration used was 20 mg L−1. The equipment used to determine the parameters (pH, residence time and solid adsorbent concentration) was the Wagner Agitator model MA160BP from Marconi. The concentration of paracetamol was analyzed in the Thermo Scientific spectrophotometer model Genesis 10S UV–VS at wavelength of 243 nm. The removal of atenolol was analyzed by the difference between the ATN concentration of the initial solution and the final solution already treated with the solid adsorbent.

Kinetic tests

In the kinetic tests, the vials were shaken at predetermined times (5–210 min). The experimental data were analyzed using the kinetic models of pseudo-first order (Eq. 1), pseudo-second order and intraparticle diffusion (Eq. 3).

where k1 (min−1), k2 (g mg−1 min−1) and kid are the pseudo-first rate, psdo-cond order and intraparticle diffusion constants (mg.g−1 min−0.5), respectively; qe and qt correspond, respectively, to the amount of solute adsorbed (mg.g−1) at equilibrium and at time t; and C is constant related to diffusion resistance (mg.g−1).

Adsorption isotherms

For these experiments, 5 g.L−1 of GAC was used and the adsorption time was 240 min. The experiments were carried out in bench refrigerated incubator shaker (CIENTEC—model CT-71RN) at temperatures of 288, 298 and 308 K. The equilibrium data were analyzed by Langmuir (Eq. 4), Freundlich (Eq. 5) and Sips (Eq. 6) models.

where qe is quantity sorbed at equilibrium (mg.g−1); qmáx is the maximum adsorption capacity (mg.g−1); KL is the Langmuir adsorption equilibrium constant (L.mg−1); KF is the Freundlich constant representing the adsorption capacity [(mg.g−1) (L.mg−1)1/n]; n is the constant that represents the adsorption intensity (dimensionless), b equilibrium constant (L.mg−1), and γ is the parameter that characterizes the heterogeneity of the system.

Adsorption thermodynamics

The thermodynamic parameters ΔH and ΔS are determined from the van't Hoff equation (Eq. 7), and the Gibbs free energy was calculated according to Eq. 8.

where KL is the Langmuir constant, R is the universal constant of the ideal gases, whose value is 8.314 J.mol−1.K−1, and T is the temperature in Kelvin.

Continuous system—fixed bed column

Paracetamol adsorption on activated carbon in continuous system was studied through tests in fixed bed column too. Experiments were realized in glass column with dimensions of 1.2 cm internal diameter and 20 cm total height. A peristaltic pump (MS Tecnopon BP 200) gave the plow rate in 3 and 5 mL.min−1. Carbon bed had a mass between 0.5 and 1 g with 0.5 and 1 cm of height, respectively. Paracetamol solution was 20 mg.L−1 in natural pH at 298 K with a concentration in the output of 95% of initial concentration.

Results and discussion

The XRD pattern by activated carbon before and after paracetamol adsorption is shown in Fig. 1.

Figure 1 shows X-ray patterns before and after adsorption. It can be seen 2 picks in about 25° and 45°, this phases corresponding to amorphous phase related to the carbon structure and a crystalline phase related to the presence of other compounds as calcite, lime and quartz (Benedetti et al. 2018). These picks correspond to the (002) planes and (001) planes of the graphitic carbon (Rawall et al. 2018).

The X-ray diffraction analysis showed that after paracetamol adsorption the intensity of the phases declined which can be caused by implying that paracetamol molecules were replacing the ions of the adsorbents and altering the structure of the solid. Results shown in Fig. 1 demonstrate that adsorption of paracetamol did not change structure space of solid and therefore the adsorption process occurred on the surface.

Determination of pH and adsorption mechanisms

The effect of pH on paracetamol adsorption on GAC is shown in Fig. 2.

In Fig. 2, it can be observed that the best removal obtained (approximately 65 ± 0.5%) occurred at pH 6. Removal rates higher occurred at pH 6 possibly due to the electrostatic forces attractive that occur between the drug and the solid adsorbent at this pH. The PAR shows dissociation constant (pKa) equal to 9.5. Therefore, the species of this drug when in solution at pHs ranging from 2 to 9.5 have predominantly positive charge and at pHs higher than 9.5 have a neutral charge (Huguet et al. 2014). As the GAC presents negatively charged surface at all pH values (see Fig. 2), there will be an electrostatic interaction between PAR and GAC favoring the adsorption process. At pHs below 4 and above 9, there is a decrease in paracetamol removal. This behavior may be a result of the decrease in attractive electrostatic force established between PAR and GAC. At pHs lower than 6, the carbon has a less intense negative charge than the other pHs, resulting in weaker electrostatic interactions between GAC and PAR. The decrease in this interaction hinders the adsorption process and, consequently, the removal of this pollutant will be smaller. At pHs higher than 9.5, the paracetamol molecules are in their neutral form, so their interaction with the adsorbent will be impaired, which decreases the removal of this drug at these pHs. In addition to the electrostatic interaction established between the adsorbates and the adsorbent, other weaker interactions such as the van der Waals and London forces may be additional mechanisms that contribute to the adsorption process of the PAR in the GAC (Haro et al. 2017).

Determination of adsorption time

The effect of drug adsorption time is shown in Fig. 3.

According to Fig. 3, it can be seen that from 120 min the removal efficiency did not increase representatively (93 ± 2 and 96 ± 0.1% at 120 and 150 min, respectively). A statistical analysis (ANOVA, with a significance level of 5%) was performed on these data, and it was verified that there was no significant difference in these results. The adsorption time was then set at 120 min where an adsorption capacity of 3.6 mg.g−1 was obtained.

Rad et al. (2015) evaluated the effect of contact time on paracetamol adsorption by NaX nanozeolite in aqueous systems using 20 mg.L−1 of the drug, 0.2 g.L− 1 of solid and pH 4. The results obtained showed that the adsorption process of the drug was faster up to about 60 min and the adsorption equilibrium was reached after 120 min of the process. These results are similar to those found in the present study.

Determination of solid adsorbent concentration

Figure 4 shows the effect of adsorbent concentration on the removal of paracetamol by granular activated carbon.

It can be seen from Fig. 4 that with increasing adsorbent concentration in the system, drug removal gradually increased until, from a given solid concentration, the removal percentage was approximately constant. The highest removal was achieved with 5 g.L−1 of solid adsorbent. At this concentration, the removal reaches a maximum value of 95 ± 0.5% which corresponds to a residual concentration below 1.2 mg L−1. The results obtained can be explained by evaluation of the behavior of the total adsorption area. The increase in the amount of solid in the system allows the increase in the adsorption area, that is, with a greater amount of solids there is a greater number of available active sites for the adsorption. When the system comes into equilibrium (concentrations of adsorbent above 5 g.L−1), there is an increase in the amount of solid, which no longer has a great influence on the paracetamol removal. This occurs because the solute–solute interactions in low concentrations are stronger than the solute–adsorbent interactions. This behavior is observed in batch systems due to the equilibrium between the adsorbate held on the adsorbent and the solute in solution (Gupta and Nain 2019).

Dutta et al. (2015) evaluated the effect of activated carbon concentration from tea leaves on paracetamol removal. The adsorbent dosage effects were studied with an initial concentration of 60 mg.L−1 of the drug, solid concentration ranging from 1 to 2 g.L−1, pH 3 and temperature of 308 K. The results showed that, contrary to what is expected, increasing the adsorbent concentration the amount of adsorbed PAR decreased. The authors concluded that the decrease in adsorption with increasing amount of adsorbent occurred due to the overlapping of the pores resulting from the agglomeration of the adsorbent particles present in solution.

Kinetics of adsorption

The comparison of the kinetic models of pseudo-first order and pseudo-second order and the values of the kinetic parameters, qe calculated, coefficient of determination (R2) and experimental error are presented in Table 1.

According to Table 1, it is possible to verify that the pseudo-first-order and pseudo-second-order models presented the same adjustment (R2 = 0.993). In order to define which of the models was that best fitted the experimental data, it was necessary to make an analysis of the value of qe estimated by the model and the value of qexp determined experimentally. Thus, it was possible to conclude that the pseudo-first-order model best fitted to the experimental data since the values of qe estimated by this model (qe = 3.8 mg.g−1) are closer to the results obtained experimentally (qexp = 3.9 ± 0.01 mg g−1).

The value for the rate constant obtained by this model was 0.033 min−1. This result indicates that drug removal rate versus time is directly proportional to the difference between the amount adsorbed at equilibrium and the amount adsorbed at any time.

This same tendency was observed in the adsorption of PAR in NaX nanozeolites by Rad et al. (2015). In this study, the values of the coefficients of determination were also very similar, 0.990 and 0.993 for the pseudo-first-order and pseudo-second-order models, respectively. However, the authors assumed that the model that best fit the experimental data was the pseudo-second order since the R2 value was slightly higher in this model.

The applied kinetic models (pseudo-first and pseudo-second order) assume that adsorption kinetics are controlled by external diffusion. However, they do not identify the mechanisms of diffusion within the particle. In this way, the intraparticle diffusion model was applied to verify the influence of mass transfer resistance in the paracetamol adsorption process. If this phenomenon is the stage that controls the process, the amount of drug adsorbed (qt) should be directly proportional to t0.5. Figure 5 shows the graph obtained through the model (qt as a function of t0.5). The parameters of the intraparticle diffusion model are presented in Table 2.

As can be seen in Fig. 5, the application of this model does not result in a linear response throughout the process. However, through the graphical representation, it is possible to define three distinct regions representing the different stages of mass transfer. The first region (phase I) is related to the adsorption on the outer surface of the adsorbent and represents the boundary layer effect. The second region (phase II) is attributed to intraparticle diffusion, and the third region (phase III) represents equilibrium, in which the amount adsorbed is constant (Souza et al. 2019).

For intraparticle diffusion to be the step that controls the speed of the process, the graph of the model must be linear and pass through the origin. As can be seen from Fig. 5 and by the value of parameter C (see Table 2), the linear curves of the drug did not pass through the origin. This deviation from the origin may be due to the difference in the mass transfer rate in the initial and final phases of the adsorption. The values of the determination coefficients (R2 = 0.86) confirm that the intraparticle diffusion model was not able to fit the experimental data obtained for paracetamol. These results indicate that intraparticle diffusion is not the determinant step of the process speed and that other interaction mechanisms must act simultaneously in the control of the adsorption process. In general, intraparticle diffusion is not a limiting step in the drug adsorption process (Pei et al. 2017; Souza et al. 2019).

Adsorption isotherms

In Fig. 6, the adsorption isotherm of paracetamol obtained at 288, 298 and 308 K is shown. The adjustments of the Freundlich, Langmuir and Sips models are presented in Table 3.

It is possible to verify in Fig. 6 that the slope of the isotherm does not increase with the increase in solute concentration in the solution (Giles et al. 1960). This result indicates that the adsorbent has high affinity with the solute in the three temperatures studied and presents particularly strong intermolecular attraction. It can also be verified that with the increase in temperature, the adsorption process was favored even though at temperatures of 288 and 298 K this effect was not very expressive. This demonstrates that the paracetamol adsorption process on activated carbon is endothermic in nature. The increase in temperature can increase the rate of diffusion of the adsorbate molecules through the outer and inner boundary layers in the pores of the adsorbent particle increasing the adsorption of the drug (Yang et al. 2019).

According to Table 3, it is possible to verify, through the empirical term of Freundlich, n, that the obtained experimental isotherm is favorable, because according to Giles et al. (1960) the analysis of the term n indicates that: when n > 1, the curve qe versus Ce will have a concave shape in relation to the abscissa axis, thus, the isotherm is satisfactory to the sorption; when n = 1, qe will present linear form with the variation of Ce; when n < 1, the isotherm will be convex in relation to the abscissa axis and is characterized as unfavorable. The values of n obtained were 3.5, 3.6 and 3.4 at temperatures of 288, 298 and 308 K, respectively. However, considering the obtained values of R2 and experimental error (χ2) (see Table 3) the Freundlich model did not fit any of the parameters (R2 and χ2), at any temperature analyzed, when compared to other isotherms (Langmuir and Sips).

The results obtained indicate that the best fit to the experimental data is given by the Sips model in all studied temperatures, since it presented higher coefficient of determination (0.985, 0.961 and 0.980 at 288, 298 and 308 K, respectively) and lower χ2 (0.114, 0.319; 0.261 at 288, 298 and 308 K, respectively) when compared to the Freundlich and Langmuir models. This result indicates that the PAR adsorption behavior does not change at the different temperatures analyzed and that, at low concentrations of PAR, the experimental data follow the Freundlich isotherm, while at high concentrations of PAR the adsorption capacity occurs in monolayer, which characterizes the Langmuir isotherm.

Adsorption thermodynamics

In order to investigate the behavior of the adsorption process of the drugs used, a study was carried out on the thermodynamics of the adsorption process. The values obtained for ΔG, ΔH and ΔS are presented in Table 4.

According to Table 4, the negative values of ΔG obtained indicate that the PAR adsorption in GAC is favorable and spontaneous at all temperatures studied in this work indicating that the drug has high affinity with the adsorbent. It is also possible to observe that the Gibbs free energy variation decreased with increasing temperature, indicating that the adsorption process is more favorable at higher temperatures. This can occur due to a possible expansion of the pores of the adsorbent that occurs at a higher temperature, resulting in larger pores which provides a greater diffusion of the paracetamol molecules inside the adsorbent (Pei et al. 2017).

The endothermic nature was confirmed from the positive value calculated for the ΔH, confirming the results obtained in the analysis of the adsorption isotherms (Sect. 3.6) where it is possible to notice an increase in the adsorbed quantity with increasing the temperature. The ΔH value obtained for PAR, 10.8 kJ mol−1, indicates that the adsorption process is of physical origin. Dutta et al. (2015) verified that the adsorption process of paracetamol in activated carbon from tea leaves is physical in nature. The ΔH obtained in this study was 9.48 kJ mol−1.

The positive value of ΔS suggests an increase in disorder in solid/solute interface during the adsorption of the drugs on the activated carbon. In this study, the value of ΔS obtained was 75.0 J.mol−1.T−1. Positive values of indicate strong affinity of the drugs with the GAC (Zanella et al. 2016).

Fixed-bed column

In the study of paracetamol adsorption in continuous regime were realized rupture curves of fixed-bed column to evaluate influence of the variables of feed rate and bed mass. The operation column was conducted to reach the saturation point in about 95% of initial concentration. The performance of the column was evaluated in terms of the breaking time, saturation time and volume of treated effluent per gram of solid.

In the rupture curves, the behavior of adsorption can be associated with speed of superficial saturation of carbon with the paracetamol molecules along the plane. Mass transfer zone was reached in the maxims point of fixed-bed with once pass (Geankoplis 2016). Starting this point, the pollutants that were adsorbed more slowly in the carbon bed provided for the spatial reorganization of paracetamol molecules. This result can be seen during the gradual increasing of last point to final saturation in the curve, and it can be implicated by the slowly Restauration molecular process (Giles et al. 1960).

Figure 7 shows that for the same mass of the bed, the curve corresponding to bigger flow of 5 mL.min−1 presented a less dispersion in the final of curve comparing with 3 mL.min−1 of flow. The fact that the saturation process occurs faster in higher flow has been explicated (Aljeboree et al. 2017). The increase in flow rate makes the fluid have less residence time in the column and consequently the solute disposes of less contact time with the surface, causing difficulty in reaching the equilibrium. This does that rupture point be reached quickly in big flows because the mass transference zone approximates to final of fixed-bed (Khadhri et al. 2019). However, for the same time period, the higher flow auspicious the contact with higher solute amounts with the fixed-bed, anticipating the saturation.

According to Fig. 8, for a fow rate of 5 mL.min−1 the bed of 0.5 g is practically saturated after of treat 200 mL, but with 1 g in the bed yet exist surface available that continues adsorbing paracetamol. As the flow rate is the same for both cases, due to surface availability, saturation is expected to occur more slowly in the larger bed, which can be confirmed by the rupture curves (Khadhri et al. 2019). The increase in the amount of solid in the bed, at constant flow, caused that the rupture time be greater when the fixed-bed was increasing as well as the sites available by adsorption. Moreover, the small difference presented in the inclinations of the curves suggests that the variation between the axial dispersion and back-mixing between the cases is negligible (Garcia-Mateos et al. 2015). However, this increase in the bed cannot be infinitely large because at some point the operation will be limited by the dispersion generated with the increase in the interstitial spaces of the adsorbent (Srivastava et al. 2008).

Column behavior

In the study of paracetamol adsorption on activated carbon in a fixed bed column with paracetamol on activate carbon, was adopted as parameter the treat volume by carbon gram. Table 5 shows the parameters of behavior by the column in conditions tested.

It was observed that cases 1 and 3 present larger volumes larger volumes per gram that was treated until was arrived the saturation. However, curve stretching after rupture indicates that much of the effluent volume using higher flow (5 mL.min−1) left the column at high concentrations, between 90 and 94% of the initial concentration. This effect may be related to the greater dispersion that occurs in larger beds (Dunlop et al. 1976). In addition, it was verified that although the experiments using bed mass of 0.5 g are very similar, it is noticed that the smaller flow rate of 3 mL.min−1 allowed a greater adsorption, possibly for facilitating the balance of the system when increasing the residence time of the fluid in the column (Khadhri et al. 2019).

Conclusions

In this work, the removal of paracetamol through the adsorption process in activated carbon was studied. According to the results, it was possible to obtain a drug removal of 95 ± 0.5% at pH 6, process time of 120 min and using 5 g.L−1 of solid adsorbent. In relation to the kinetic study, the results obtained showed that the model that best fit the experimental data was pseudo-first order. This information suggests that the removal rate of paracetamol as a function of time is directly proportional to the difference between the quantity adsorbed at equilibrium and the amount adsorbed at any time. The isotherm model that best fitted the experimental data was the Sips at all temperatures studied, indicating that, for low concentrations of the drug, the experimental data follow the Freundlich isotherm, whereas for higher concentrations of adsorbate, the experimental data follow the Langmuir isotherm. The thermodynamic study showed that the adsorption process is favorable and spontaneous and that its nature is endothermic, that is, the adsorption is favored by the temperature increase proving the results obtained by adsorption isotherms. The results also indicated that there is an increase in disorder in solid/solute interface during adsorption of paracetamol on activated carbon.

In the evaluation of fixed bed column adsorption, the best operating condition found was obtained using the flow rate of 3 mL.min−1 and bed mass equal to 0.5 g. In this case, the system presented the highest volume of treated paracetamol effluent of 810 mL per gram of carbon in the bed, besides a longer rupture time and bed saturation, obtaining a favorable relation between the mass transfer and the proximity of the equilibrium of adsorption.

Thus, it was concluded that both batch adsorption and fixed bed column adsorption using activated carbon as an adsorbent solid have been shown to be effective alternatives to solve the problem of contamination of water and effluents containing drugs such as paracetamol.

References

Alalm MG, Tawfik A, Ookawara S (2016) Enhancement of photocatalytic activity of TiO2 by immobilization on activated carbon for degradation of pharmaceuticals. J Environ Chem Eng 4:1929–1937. https://doi.org/10.1016/j.jece.2016.03.023

Aljeboree AM, Alshirifi AN, Alkaim AF (2017) Kinetics and equilibrium study for the adsorption of textile dyes on coconut shell activated carbon. Arab J Chem 10:S3381–S3393. https://doi.org/10.1016/j.arabjc.2014.01.020

Benedetti V, Patuzzi F, Baratieri M (2018) Characterization of char from biomass gasification and its similarities with activated carbon in adsorption applications. Appl Energy 227:92–99. https://doi.org/10.1016/j.apenergy.2017.08.076

Deblonde T, Cossu-Leguille C, Hartemann P (2011) Emerging pollutants in wastewater: a review of the literature. Int J Hyg Environ Heal 214:442–448. https://doi.org/10.1016/j.ijheh.2011.08.002

Dunlop EH, Gazzard BG, Langley PG, Weston MJ, Cox LR, Williams R (1976) Design features of haemoperfusion columns containing activated charcoal. Med Biol Eng 14(2):220–226. https://doi.org/10.1007/BF02478752

Dutta M, Das U, Mondal S (2015) Adsorption of acetaminophen by using tea waste derived activated carbon. Int J Environ Sci 6:270–281. https://doi.org/10.6088/ijes.6031

Franco MAE, Carvalho CB, Bonetto MM, Soares RP, Féris LA (2017) Removal of amoxicillin from water by adsorption onto activated carbon in batch process and fixed bed column: kinetics, isotherms, experimental design and breakthrough curves modeling. J Clean Prod 161:947–956. https://doi.org/10.1016/j.jclepro.2018.01.138

Garcia-Mateos FJ, Ruiz-Rosas R, Marqués MD, Cotoruelo LM, Rodríguez-Mirasol J, Cordero T (2015) Removal of paracetamol on biomass-derived activated carbon: modeling the fixed bed breakthrough curves using batch adsorption experiments. Chem Eng J 279:18–30. https://doi.org/10.1016/j.cej.2015.04.144

Geankoplis CJ (2016) Transport processes and unit operations, 3rd edn. Prentice-Hall International, New Jersey

Giles CH, Macewans TH, Nakhwa N, Smith D (1960) Studies in adsorption: part XI—a system of classification of solution adsorption isotherms, and its use in diagnosis of adsorption mechanisms and in measurement of specific areas of solids. J Chem Soc. https://doi.org/10.1039/JR9600003973

Gupta J, Nain AK (2019) Physicochemical study of solute-solute and solute-solvent interactions of homologous series of α-amino acids in aqueous-isoniazid solutions at temperatures from 293.15 to 318.15 K. J Mol Liq 278:262–278. https://doi.org/10.1016/j.molliq.2019.01.036

Haro NK, Del Vecchio P, Marcilio NR, Féris LA (2017) Removal of atenolol by adsorption: study of kinetics and equilibrium. J Clean Prod 154:214–219. https://doi.org/10.1016/j.jclepro.2017.03.217

Huguet M, Simon V, Gallard H (2014) Transformation of paracetamol into 1,4-benzoquinone by a manganese oxide bed filter. J Hazard Mater 271:245–251. https://doi.org/10.1016/j.jhazmat.2014.02.017

Khadhri N, Saad MEK, Mosbah MB, Moussaoui Y (2019) Batch and continuous column adsorption of indigo carmine onto activated carbon derived from date palm petiole. J Environ Chem Eng 7:102775. https://doi.org/10.1016/j.jece.2018.11.020

Najjar NH, Touffet A, Deborde M, Journl R, Leitner KV (2014) Kinetics of paracetamol oxidation by ozone and hydroxyl radicals, formation of transformation products and toxicity. Sep Purif Technol 136:137–143. https://doi.org/10.1016/j.seppur.2014.09.004

Nunes B, Antunes SC, Santos J, Martins L, Castro BB (2014) Toxic potential of paracetamol to freshwater organisms: A headache to environmental regulators? Ecotoxicology. Environ Saf 107:178–185. https://doi.org/10.1016/j.ecoenv.2014.05.027

Papageorgioua M, Kosmab C, Lambropoulou D (2016) Seasonal occurrence, removal, mass loading and environmental risk assessment of 55 pharmaceuticals and personal care products in a municipal wastewater treatment plant in central greece. Sci Total Environ 543:547–569. https://doi.org/10.1016/j.scitotenv.2015.11.047

Pei Y, Agostini F, Skoczylas F (2017) The effects of high temperature heating on the gas permeability and porosity of a cementitious material. Cem Concr Res 95:141–151. https://doi.org/10.1016/j.cemconres.2017.01.003

Pezoti O, Cazetta AL, Bedin KC, Souza LS, Martins AC, Silva TL, Júnior OOS, Visentainer JV, Almeida VC (2016) NaOH-activated carbon of high surface area produced from guava seeds as a high-efficiency adsorbent for amoxicillin removal: kinetic, isotherm and thermodynamic studies. Chem Eng J 288:778–788. https://doi.org/10.1016/j.cej.2015.12.042

Rad LR, Irani M, Divsar F, Pourahmad H, Sayyafan S, Haririan I (2015) Simultaneous degradation of phenol and paracetamol during photo-fenton process: design and optimization. J Taiwan Inst Chem Eng 47:190–196. https://doi.org/10.1016/j.jtice.2014.10.014

Randles D, Kam JWY, Heine SJ, Inzlicht M, Handy TC (2016) Acetaminophen attenuates error evaluation in cortex. Soc Cogn Affect Neurosci 11:899–906. https://doi.org/10.1093/scan/nsw023

Rawal S, Joshi B, Kumar Y (2018) Synthesis and characterization of activated carbon from the biomass of saccharum bengalense for electrochemical supercapacitors. J Energy Storage 20:418–26. https://doi.org/10.1016/j.est.2018.10.009

Shakir M, Faraz M, Sherwani MA, Al-Resayes SI (2016) Photocatalytic degradation of the Paracetamol drug using Lanthanum doped ZnO nanoparticles and their in-vitro cytotoxicity assay. J Lumin 176:159–167. https://doi.org/10.1016/j.jlumin.2016.03.027

Souza PR, Dotto GL, Salau NPG (2019) Experimental and mathematical modeling of hindered diffusion effect of cationic dye in the adsorption onto bentonite. J Environ Chem Eng 7:102891. https://doi.org/10.1016/j.jece.2019.102891

Srivastava VC, Prasad B, Mishra IM, Mall ID, Swamy MM (2008) Prediction of breakthrough curves for sorptive removal of phenol by bagasse fly ash packed bed. Ind Eng Chem Res 47:603–1613. https://doi.org/10.1021/ie0708475

Yang T, Chen P, Li B, Nie B, Ye Q (2019) Potential safety evaluation method based on temperature variation during gas adsorption and desorption on coal surface. Saf Sci 113:336–344. https://doi.org/10.1016/j.ssci.2018.11.027

Zanella O, Klein E, Haro NK, Cardoso MG, Tessaro IC, Féris LA (2016) Equilibrium studies, kinetics and thermodynamics of anion removal by adsorption. World Review of Science. Technol Sust Deve 12:193–218. https://doi.org/10.1504/WRSTSD.2016.078412

Acknowledgements

The authors the Coordination for the Improvement of Higher Education Personnel (CAPES) of the Brazilian Government for the financial support granted to carry out this work.

Funding

The authors received no specific funding for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Haro, N.K., Dávila, I.V.J., Nunes, K.G.P. et al. Kinetic, equilibrium and thermodynamic studies of the adsorption of paracetamol in activated carbon in batch model and fixed-bed column. Appl Water Sci 11, 38 (2021). https://doi.org/10.1007/s13201-020-01346-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-020-01346-5