Abstract

The effluents generated by textile industries are extremely toxic and dangerous to the environment. In fact, new treatment technologies for recalcitrant effluents have been tested for high dye removal efficiency. Among these technologies, electrocoagulation has been highly promising, due to its excellent results coupled with a low operating cost. This study evaluated the electrocoagulation/electroflotation process efficiency on the removal of Eriochrome Black textile dye from aqueous solution. All the experiments were carried out using aluminum electrodes due to their availability and low cost. The parameters investigated during the experiment were: electrolysis experiment time, NaCl concentration, aqueous solution pH and electric potential. In this context, the best results considering the operational parameters studied were electric potential of 7 V, values of pH low to neutral (2–7) and NaCl concentration of 2 g L−1. It has also been observed that a time of 55 min of electrolysis is sufficient for a satisfactory result, reaching a color removal efficiency of 98.5%.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Synthetic dyes from the textile industry are used on a large scale, generating several problems in the environment (Forgacs et al. 2004; Gupta and Suhas 2009). The textile sector stands out due to the high demand of water required in its processes and the consequent generation of large volumes of effluents, and it is estimated that in the production of cotton fabric, for example, water consumption may range from 100 to 300 L Kg−1 of cotton fabric (Arslan et al. 2016). In fact, when these dyes are dumped without proper treatment in aqueous effluents, they immediately interfere with the aquatic ecosystem in several ways (Joshi et al. 2004). One of the great difficulties for the treatment of this type of industrial waste is the fact that it is very refractory to conventional treatments, persistent and carcinogenic (Verma et al. 2012), besides being bactericidal, which makes its treatment difficult through biological methods. An alternative to conventional methods of treatment of effluents is precisely the electrochemical methods. The basis of these processes is the application of an electric field between anodes and cathodes, resulting in different chemical reactions: oxidation–reduction reactions, molecular rupture reactions and chemical and electrochemical absorption (Moussa et al. 2017). The reactions that occur are responsible for the destabilization of the contaminating molecules, resulting in their precipitation and/or oxidation, transforming them into biodegradable compounds (Garcia-Segura et al. 2017).

The process of electroflotation (EF) and electrocoagulation (EC) is an example of an electrochemical process, being this process well known and detailed in the literature (Yang et al. 2018; Zongo et al. 2009; Mouedhen et al. 2008). This technique is based on the formation of the coagulating agent that occurs due to the electrolytic dissolution of sacrificial anodes, aluminum or iron. Gas bubbles—O2 and H2—are formed in parallel with the electrolysis of the water molecules, and thus, the electroflotation is coupled to the electrocoagulation process. The chemical reactions established for this process are:

where (1) is the metal dissolution in anode and (2) is the water reduction at the cathode. It is important to emphasize that in the anode occurs simultaneously the reaction (3):

The Al 3+(aq) is essential for the electrocoagulation process, because through this it is possible to form the species monomeric soluble hydroxides by reaction with 2OH −(aq) . All these reactions are pH-dependent. The H2(g) and O2(g) are responsible for the electroflotation process.

The electrocoagulation/electroflotation process has been used with great success in several types of effluents, for example, textile dyes (Gonçalves et al. 2016; Assemian et al. 2018), plating (Adhoum et al. 2004), microalgae (Cestarolli 2017), heavy metals (Merzouka et al. 2009), nitrates from groundwater (Lacasa et al. 2011), industrial wastewater and perfluorooctanoic acid (Yang et al. 2018), among others.

Thus, the objective of this study was the investigation of the influence of functional parameters of electrocoagulation, such as pH, amount of electrolyte and applied potential, in the removal of dye color of aqueous solution.

Experimental

All solutions investigated were produced in order to simulate a textile industrial wastewater. For this purpose, samples containing the dye Eriochrome Black (PROQUIMIOS) were prepared. The molecular formula of Eriochrome Black is shown in Fig. 1.

The main chemical characteristics of this dye are shown in Table 1.

All experiments were performed in order to evaluate the color removal efficiency CR (%) using the formula:

where Abs0 is the initial absorbance of dye and Abs is the absorbance after electrocoagulation/electroflotation process. The experiments were monitored by an UV/VIS spectrophotometer Shimadzu model UV3600, at a wavelength with the best absorbance of Eriochrome Black (maximum absorbance λ = 537 nm). A Hanna pH meter model 21 (0.05 precision) was used to measure the pH of the solutions. In order to simulate the actual properties of the effluent, the value adopted for the concentration of the solution was 0.20 g L−1. In studies where the initial concentration of the dye was varied, the values used were 0.20 to 1.00 g L−1.

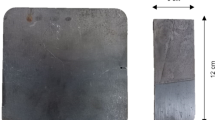

The electrocoagulation system consisted of a rectangular-shaped reactor with a capacity of 1.0 L (Fig. 2). Four aluminum electrodes (two anodes and two cathodes) with dimension of 30 cm2 each one (3.0 cm wide and 10.0 cm long) were used for the experiments, being connected by bipolar mode. A digital DC power supply (ICEL model) providing 0–15 V (0–5 A) with potentiostatic operational option was used for potential control.

Results

Effect of time of electrolysis on the efficiency of dye removal

As already reported by several authors, time is a very important parameter in the electrocoagulation process (Daneshvar et al. 2007; Zaroual et al. 2006). In fact, there is a direct relationship between the amount of aluminum ions dissolved and the time of electrolysis. The process can be described as follows: the main chemical reactions occur as seen in Eqs. (5) to (6) (Chen 2004):

At the anode:

The aluminum cations and their hydrolyzed derivatives are the coagulant species. The Al3+ ions combine with water and OH− ions to immediately undergo further spontaneous hydrolysis reactions to form monomeric species such as Al(OH)2+, Al(OH)2+ and Al(OH) −4 , polymeric species as Al2(OH) 4+2 and Al2(OH)5+, which finally transform into Al(OH)3(s) and less soluble species as Al2O3.

Thus, in an electrocoagulation process the coagulating ions are produced ‘in situ,’ and the greater the electrolytic time the greater the amount of coagulant species electrogenerated. As can be seen from Fig. 3, an increase in the electrocoagulation time causes an increase in the efficiency of the color removal, from 5 to 97%.

Efficiency of color removal as a function of applied potential

In order to verify the effect of the potential value applied in the electrocoagulation process, the following potential values were investigated: 2.0 to 9.0 V. In fact, it is known (Gonçalves et al. 2016; Aoudj et al. 2016) that increasing the potential implies an increase in the formation of the coagulating agent, which results in a higher CR efficiency. Figure 4 presents the results obtained as a function of the applied potential.

As can be seen from Fig. 4, the potentials that presented the best results in terms of CR were 7.0 and 8.0 V. It is important to note that, at these potential values, it took only about 20 min to reach about 98% of CR. More dissolved species of aluminum are electrogenerated at higher potentials and formation rate of Al(OH)3 and Aln(OH)3n increased. It is important to note that higher potential (9.0 V) obtained lower value of dye removal (78%) in the first 100 min of electrolysis. After about 100 min, a high efficiency was obtained for all potential investigated. However, considering the electrolysis time allied to the result of CR, it was concluded that the potentials of 7.0 V and 8.0 V were the most efficient. In order to obtain a high efficiency with a lower cost, it was chosen to use the potential of 7.0 V in the following studies.

Efficiency of color removal as a function of the initial concentration of Eriochrome Black

It is known (Cestarolli 2017; Daneshvar et al. 2004) that the initial concentration of the dye has a direct influence on the CR values. It is also interesting to note that in actual effluents from the textile industry the pigment concentrations in the generated wastes are not constant. Thus, the initial concentration of Eriochrome Black was investigated between 0.20 and 1.0 g L−1. The results are shown in Fig. 5.

According to Fig. 5, it is possible to verify that the increase in the initial concentration of the dye does not favor the electrocoagulation process. Indeed, under constant potential, there will be always the same amount of aluminum hydroxides present (Daneshvar et al. 2004; Modirshahla et al. 2007), and thus, it is expected that the efficiency of CR actually decreases with increasing the concentration of the dye.

Efficiency of color removal as a function of the initial pH

It is well known in the literature that pH exerts a great influence on the electrocoagulation process (Rahmani et al. 2013; Pajootan et al. 2012; Gonçalvez et al. 2016). Monomeric and polymeric Al species vary at different pH, and the coagulation mechanism is dependent on pH. The influence of pH in the EC process was investigated by adjusting the initial pH in the interval from 2 to 11. These results are presented in Fig. 6.

According to Fig. 6, it is possible to verify that the electrocoagulation process presents better results with acid pH of 2, 5 and 7. The calculated values for CR (%) were 97.9 (pH 3), 93.6 (pH 5) and 98.5 (pH 7), respectively. In low values of pH (from 2 to 3), the cationic species are converted into soluble species such as Al(OH) +2 , Al(OH)2+ and Al(OH)3 (Essadki et al. 2008). At pH between 5 and 7, it is possible to obtain monomeric cations which can be converted into Al2(OH) 4+2 and Al6(OH) 3+15 , which, in this case, facilitated the electrochemical coagulation process.

Efficiency of color removal as a function of concentration of supporting electrolyte

A highly conductive electrolyte favors the electrocoagulation process, and, in this sense, the influence of the NaCl concentration on the color removal efficiency of the dye was investigated. In fact, NaCl was chosen not only for being a good electrolytic conductor, but also because it is widely used in the textile industry with the aim of favoring the absorption of dye molecules in the fibers (Kabdasli et al. 2009). The effect of concentration of NaCl as supporting electrolyte on dye removal efficiency was studied using concentration range from 1.0 to 4.0 g L−1. The results are reported in Fig. 7.

As can be seen from Fig. 7, there was no significant variation of CR values as a function of NaCl concentration in the investigated range. However, it is necessary to emphasize that the lower the NaCl concentration, the longer the durability of the aluminum electrodes. In fact, a higher concentration of Cl− can produce the pitting corrosion phenomenon, which is a disadvantage (Chen 2007).

Conclusions

The electrocoagulation process was quite efficient for removing the color of the Eriochrome Black dye, reaching values of CR 98.5% with optimized parameters. The investigated parameters resulted in the following conclusions: The electroflotation time process is a very important parameter for electrocoagulation process, and, in this study, it was observed that 60 min was sufficient for a satisfactory color removal. It was not observed, at higher values of pH, for satisfactory results with respect to decolourization. The optimal investigated values of pH are 2, 5 and 7. With respect to the applied potential, the better EC results were obtained with 7.0 V, beyond which no real improvement may be observed. The lower is the dye concentration, the better is the decolourization efficiency. A low concentration of NaCl (1.0 g L−1) is sufficient for the color removal process to be efficient.

References

Adhoum N et al (2004) Treatment of electroplating wastewater containing Cu2+, Zn2+ and Cr(VI) by electrocoagulation. J Hazard Mater 112:207–213

Aoudj S et al (2016) Removal of fluoride and turbidity from semiconductor industry wastewater by combined coagulation and electroflotation. Desalin Water Treat 57:18398–18405

Arslan S et al (2016) A review of state-of-the-art technologies in dye-containing wastewater treatment—the textile industry case. Text Wastewater Treat. https://doi.org/10.5772/64140

Assemian AS et al (2018) Water Air Soil Pollut 229:184

Cestarolli DT et al (2017) Removal of microalgae from water medium by electrocoagulation process. Glob J Eng Sci Res Manag 4(12):18–23

Chen G (2004) Electrochemical technologies in wastewater treatment. Sep Purif Technol 38:11–41

Chen G (2007) J Hazard Mater 141:653

Daneshvar N, Ashassi Sorkhabi H, Kasiri MB (2004) Decolorization of dye solution containing Acid Red 14 by electrocoagulation with a comparative investigation of different electrode connections. J Hazard Mater B112:55–62

Daneshvar N et al (2007) Decolorization of C.I. Acid Yellow 23 solution by electrocoagulation process: investigation of operational parameters and evaluation of specific electrical energy consumption (SEEC). J Hazard Mater 148:566–572

Essadki AH et al (2008) Chem Eng Process 47(2008):1211

Forgacs E, Cserhati T, Oros G (2004) Removal of synthetic dyes from wastewaters: a review. Environ Int 30(7):953–971. https://doi.org/10.1016/j.envint.2004.02.001

Garcia-Segura S et al (2017) Electrocoagulation and advanced electrocoagulation processes: a general review about the fundamentals, emerging applications and its association with other technologies. J Electroanal Chem 801:267–299. https://doi.org/10.1016/j.jelechem.2017.07.047

Gonçalves MVB et al (2016) Electrocoagulation/electroflotation process applied to decolourization of a solution containing the dye yellow Sirius K-CF. Int J Electrochem Sci 11:7576–7583

Gupta VK, Suhas (2009) Application of low-cost adsorbents for dye removal—a review. J Environ Manag 90(8):2313–2342. https://doi.org/10.1016/j.jenvman.2008.11.017

Joshi M, Bansal R, Purwar R (2004) Colour removal from textile effluents. Indian J Fibre Text Res 29:239–254

Kabdaslı IB et al (2009) Chem Eng J 148:89

Lacasa E et al (2011) Chem Eng J 171(2011):1012–1017

Merzouka B, Gourichb B, Sekki A, Madani K, Chibane M (2009) J Hazard Mater 164:215–222

Modirshahla N, Behnajady MA, Kooshaiian S (2007) Investigation of the effect of different electrode connections on the removal efficiency of Tartrazine from aqueous solutions by electrocoagulation. Dyes Pigm 74:249–257

Mouedhen G, Feki M, Wery MDP, Ayedi HF (2008) Behavior of aluminum electrodes in electrocoagulation process. J Hazard Mater 150:124–135

Moussa DT et al (2017) A comprehensive review of electrocoagulation for water treatment: potentials and challenges. J Environ Manag 186:24–41. https://doi.org/10.1016/j.jenvman.2016

Pajootan E, Arami M, Mahmoodi NM (2012) Binary system dye removal by electrocoagulation from synthetic and real colored wastewaters. J Taiwan Inst Chem Eng 43:282–290

Rahmani AR et al (2013) Continuous thickening of activated sludge by electroflotation. Sep Purif Technol 107:166–171

Verma AK, Dash RR, Bhunia P (2012) A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J Environ Manag 93(1):1

Yang L et al (2018) Chemosphere 201:303–309

Zaroual Z et al (2006) Contribution to the study of electrocoagulation mechanism in basic textile effluent. J Hazard Mater 131:73–78

Zongo I et al (2009) Removal of hexavalent chromium from industrial wastewater by electrocoagulation: a comprehensive comparison of aluminium and iron electrodes. Sep Purif Technol 66:159–166

Acknowledgements

This study was conducted at Universidade Federal de São João Del Rei. We also thank the FAPEMIG, CAPES and CNPQ foundations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Cestarolli, D.T., das Graças de Oliveira, A. & Guerra, E.M. Removal of Eriochrome Black textile dye from aqueous solution by combined electrocoagulation–electroflotation methodology. Appl Water Sci 9, 101 (2019). https://doi.org/10.1007/s13201-019-0985-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-019-0985-x