Abstract

The photocatalytic oxidation of methylene blue (MB) in aqueous media is explored using nanoscale ZnO nanoparticles (ZnO NPs) for maximal dye removal within the high-surface-area nanoparticle photocatalyst. The operating parameters such as illumination time, initial MB load, ZnO NP dose, solution flow rate and pH were examined. The experimental results revealed the alkaline pH (12.0) corresponding to the higher oxidation rate within only 20 min of reaction time; however, increasing the initial MB load decreased the reaction rate at the optimum circulation flow rate of 460 mL/min and ZnO NP dose of 0.4 g. Additionally, for providing maximum performance, the interaction between the most effective independent parameters (ZnO NP dose, flow rate, and initial pH) were explored using Box–Behnken experimental design based on the response surface methodology. The results showed a good fitness of the model (R2 = 96.86%) with the experimental data. The optimum values were recorded after 20 min of reaction time with the values: 0.45 g/L for ZnO NP dose, 370 mL/min for flow rate and pH 11, showing a 94% maximum dye removal compared to 92% using manual optimization. Finally, the kinetic models were applied and the data were described by second-order kinetic model.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

As a result of industrialization, water recourses are polluted from several industrial streams. Textile industry, among several other industries, is considered a major source of dye-polluted wastewater, producing a huge amount of dye-containing wastewater. Discharging such dyes to the environment causes a massive deterioration to human and aquatic system. Dyes are considered one of the most problematic groups of pollutants because they can be easily identified by the human eyes once they are released to the water bodies but are not easily removed. Furthermore, most synthetic dyes are properly non-degradable even with sunlight (Mogharabi et al. 2012). Additionally, most of them are dangerous (Gupta et al. 2011; Saleh and Gupta 2012; Saravanan et al. 2013a, Sareen et al. 2014; Ghaedi et al. 2015). Recently, there has been an increase in public awareness and concern regarding environmental pollution. Most organic chemicals and pathogens, which are present in aqueous waste effluents discharged from industrial or domestic sources, should essentially be treated or removed prior to the final discharge to the watercourses. Hence, a promising treatment technique is required to overcome such challenge for a safe disposal. Oxidation of such dyes from aqueous industrial discharges is considered a difficult technique since dyes show resistance to various oxidants, chemicals, UV light and heat besides being non-biodegradable (Kargi and Ozmıhc 2004; Akar et al. 2006; Gupta et al. 2011; Saleh and Gupta 2012; Sareen et al. 2014; Tony and Bedri 2014; Saravanan et al. 2015a).

Conventionally, various techniques were applied for wastewater treatment such as coagulation, reverse osmosis, biological treatment techniques and adsorption methods (Beydoun et al. 1999; Ashour et al. 2014; Tony et al. 2018). However, those methods are not widely recommended as they are expensive, transferring the pollutants phase, or they are not effective with high organic loads (Rahman et al. 2009; Tony and Mansour 2019). For example, low-cost techniques, which are confirmed to be efficient as adsorption by activated carbon, are producing large quantities of solid wastes, which need further disposal, therefore adding to the environmental threats. However, the other sufficiently promising methods are not economically effective (Azbar et al. 2004; Tony et al. 2016). Thus, it is crucial to explore a novel alternative treatment technique that is more efficient in removing dye-water streams.

Recently, advanced oxidation processes, AOPs, have been emerged as promising techniques for wastewater treatment (Saravanan et al. 2015b). These processes are mainly dependent on highly reactive hydroxyl radicals (\(^{ \cdot } {\text{OH}}\)); those radicals are effective on initiating the oxidation of the organic pollutants and then mineralizing them. The complete removal of pollutants leads to harmless end products, CO2− and H2O (Sobczynski and Dobosz 2001; Saravanan et al. 2013d; Ashour et al. 2014; Azbar et al. 2004; Tony et al. 2016). AOPs include several photocatalytic techniques such as the combination between a semiconductor (ZnO, TiO2) and UV-induced light (Legrini et al. 1993; Daneshvar et al. 2004). Semiconductor photocatalysis techniques are recently established as AOPs and can be used to oxidize dyes conveniently (Sobczynski and Dobosz 2001). Compared to other purification techniques, photocatalytic oxidation is an economic method that can oxidize various complex organic pollutants (Daneshvar et al. 2004; Tony et al. 2011). Moreover, when the semiconductor-based materials are used as photocatalysts, a complete oxidation is secured with environmentally friendly products, without generation of dangerous waste by-products. Besides, other advantages of photoactivated semiconductors are: its activity, reusability and being easily generated (Dieckmann and Gray 1998; Saravanan et al. 2013b, c, 2014; Rajendran et al. 2016). Additionally, according to the literature, ZnO has been suggested to be more effective than TiO2 as it absorbs large fraction of UV illumination and absorbs more light quanta (Lee and Abd Hamid 2015). In recent years, nanoscale semiconductor photocatalytic materials are gaining more attention because of their physical and chemical properties besides their high catalytic efficiency (Zhao and Zhang 2008).

The major reaction of the semiconductor photocatalytic dye oxidation is based on the production of an electron–hole pair on of the semiconductor surface after it is initiated by the UV light according to the following equation (Jeni and Kanmani 2011):

where e −cb : conduction band electron and h +vb : valence band electron vacancy.

Therefore, these two objects can migrate to the catalyst surface. Generally, h +vb reacts with surface-bound H2O to generate the hydroxyl (\({\text{OH}}^{ \cdot }\)) radicals; however, e −cb reacts with O2 to generate the anion of oxygen called a superoxide radical (\({\text{O}}_{2}^{ - \cdot }\)). Consequently, both radicals \({\text{OH}}^{ \cdot }\) and \({\text{O}}_{2}^{ - \cdot }\) can afterward react with the dye in the aqueous solution to produce other species which are responsible of the dye oxidation (Jeni and Kanmani 2011).

A statistical method usually called the response surface methodology (RSM), as a dominant factorial experimental design tool, has been applied to optimize the performance of a multi-variable system that might affect the response. Several authors (Suarez-Escobar et al. 2006; Duc 2014; Elboughdiri et al. 2015) have applied the RSM in the wastewater treatment to evaluate the dependent variables as a function of their independent factors or response.

The present investigation handles the treatment of methylene blue dye (MB) wastewater treatment by ZnO NPs as a source of photocatalytic oxidation, the process parameters are studied, and a statistical optimization is conducted based on Box–Behnken design method. Furthermore, the kinetics of the photocatalytic reaction is produced.

Materials and methods

Materials

Wastewater

A simulated dyestuff wastewater is prepared by using Methylene blue (MB) dye which is commonly used in industry as a colorant for cotton, silk and wool (Rafatullah et al. 2010). MB has the formula: C16H18N3SCl∙3H2O. It is supplied by Ciba Giegy and used as received.

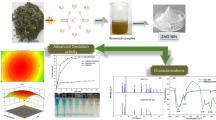

Nanostructured photocatalyst

ZnO NPs with particle size < 100 nm are used as photocatalyst for the catalytic oxidation of the pollutant, Methylene blue dye (MB), in the synthetic wastewater. The catalyst is prepared and supplied by Centre of Nanotechnology Lab, Faculty of Postgraduate Studies for Advanced Sciences, Beni-Suef University, Egypt.

X-ray diffraction (XRD) was conducted with X’Pert Pro PANalytical X-ray diffractometer apparatus supplied with a X’Pert High Score software with an X-ray wavelength of λ = 1.5406 Å, which is operated at a 40 kV voltage and a 40 mA current. The diffracted intensities were recorded using a step scan with a step size of 0.01 2θ which ranged from 10 to 80°. Then, the crystallite ZnO nanoparticle size (Dp = 62 nm) was estimated via Scherrer’s equation, from the XRD dominating peak (Eq. 2), where β is the full width at half maximum intensity of the peak and θ is the diffraction angle (Bindu and Thomas 2014).

Experimental methodology

The experimental setup is conducted using a UV tubular reactor in which a UV lamp is used as the source of the photo-oxidation of the wastewater streams. The UV lamp is 10 cm in diameter and 40 cm long. It has a wavelength of 400 nm and 15 watts. A pump is used for circulating the polluted water. It is a peristaltic (dosing) pump, supplied by Cole Parmer Instrument Company System, Model No 7521-10. A magnetic stirrer is used to ensure good mixing of ZnO NPs with the polluted water. Hydrochloric acid and sodium hydroxide in analytical grade are used for the initial pH adjustment using a digital pH meter (model type pH2005). The experimental treatment steps are illustrated in Fig. 1.

After different time intervals, the samples are centrifuged (TDL 16B centrifuge type) to separate the NPs from the solution before the dye color removal is measured with a spectrophotometer (PG Instruments LTD, Model T80).

Box–Behnken design

Factorial experimental design is applied to optimize the performance and the operating parameters for the Methylene blue dye removal efficiency. RSM (response surface methodology) designs estimate the interaction and even quadratic effects, in order to locate the accurate optimum values. Hence, they illustrates the shape of the response surface under exploration.

Box–Behnken design is having the maximum efficiency for a RSM problem involving three factors, i.e. ZnO NP dose, pH and the solution flow rate and their three levels. Thus, the number of runs required is less compared to other designs such as a central composite design. As regards the measured response, we retained the amount adsorbed by removal of the dye (expressed in %) after 20 min of economic reaction time (see Fig. 2). According to the preliminary trials, the process parameters and its levels are given in Table 1.

In the RSM optimization process, the response (ƒ = % dye removal) can be related to the chosen variables by a second-order polynomial model given by the following Eq. (3) (Saggioro et al. 2011; Bindu and Thomas 2014):

where f is the response of the predicted dye removal rate (%); i = 1, 2, 3 and j = 1, 2, 3; βo, βi, βii and βij are the model regression coefficient parameters, while Xi is the input coded variable. The natural variables of the operating system (€i) are transferred to coded variables (Xi) according to Eq. 4 (Bindu and Thomas 2014; Tony et al. 2016). In addition, statistical analysis was conducted using the Statistical Analysis System (SAS) software (Montgomery 1991); thereafter, the data were analyzed by the analysis of variance (ANOVA) using SAS software. The response surface model is considered significant when the probability (p value) is lower than 0.05 (SAS 1990). The optimal values of the process (ZnO NP dose, pH and the aqueous solution flow rate) are estimated by the three-dimensional (3-D) response surface investigation and their dependent response and illustrated using MATLAB 7.0 software.

Results and discussion

Methylene blue degradation: preliminary investigation

Comparison of solo UV illumination and UV-ZnO NPs

Figure 2 shows the effect of the UV illumination time of irradiation on the photocatalytic degradation of 5 mg/L MB dye. Two sets of experiments were done: The first experiment is conducted in the presence of 0.4 g/L of ZnO NPs (at pH 12 and 460 mL/min flow rate) under UV irradiation, while the other one is conducted with the exposure to UV irradiation only. After an irradiation time of 90 min, the results revealed that the degradation reached to 97% in the presence of ZnO NPs. However, it is recorded 26% in the UV illumination solely. It is clear from Fig. 2 that the degradation becomes slow after almost 20 min of irradiation time. This result could be attributed to the presence of ZnO NPs which play an important role in the catalytic oxidation compared to the solo systems. Thus, the bonds in the MB dye are easily broken in the presence of ZnO NP catalyst which oxidizes the dye molecules either by the holes in the catalyst surface or by hydroxyl radicals (Saggioro et al. 2011; Tony and Mansour 2019).

Effect of initial MB concentration

Experiments are implemented at different initial dye concentrations of 5–50 mg/L, 0.4 g/L ZnO NPs and at a pH value of 12, taking flow rate 460 mL/min as a constant value for 90-min reaction time. Results are shown in Fig. 3 and revealed that the MB oxidation is fast and complete in the low dye concentrations ranging from 5 to 15 mg/L, with percentage dye removal of 97 and 79% for 5 and 15 ppm dye concentrations, respectively. At higher concentrations, more than 15 ppm, the removal efficiency becomes slower: only 49 and 25% for initial dye concentrations of 30 and 50 mg/L, respectively. Thus, this means that the process is fairly good for the initial dye concentration ranging from 5 to 15 mg/L.

It is clearly shown in Fig. 3 that the dye oxidation is higher at the initial contact time followed by a decrease in the reaction rate. This finding agrees with the results of (Chakrabarti and Dutta 2004). This is explained by the fact that as the initial MB dye concentration is increased, the adsorbed MB dye molecules on the surface of ZnO NPs increase, and subsequently the active sites of the catalyst are occupied by dyes, and thus, the degradation efficiency decreases as the activity of active surface of the ZnO NPs decreased. This is due to the reduction in the hydroxyl radicals after the initial time which is mainly responsible for the reaction. However, the reduction due to the UV light could not be neglected, since in the high dye concentration the color deepness prevents the UV light penetration to the dye solution (Saggioro et al. 2011).

Effect of ZnO NP dose

A test was run for the decolorization of MB dye solution at various ZnO NP dosage; 0.1–0.4 g/L, at 5 mg/L MB, pH 12 and 460 mL/min flow rate. Experiments conducted with various concentrations of ZnO NPs presented that the photodegradation reaction efficiency increases with the increase in the ZnO NP concentration. Examination of results (Fig. 4) indicates that the highest oxidation rate (97.6%) is obtained when using catalyst concentration 0.4 g/L. This is followed by 96.0, 94.6 and 91.86% for catalyst concentrations 0.3, 0.2 and 0.1 g/L, respectively.

These findings can be illustrated in terms of the active sites available on the surface of ZnO NPs. Thus, the total available active surface area increases with increasing the ZnO NPs. This is previously described by Goncalves et al. (1999) in the treatment of azo dye using TiO2.

Effect of flow rate

To investigate the most suitable flow rate for the photocatalytic oxidation of MB dye on the ZnO NPs, series of sets of experiments were conducted at different flow rates ranged from 150 to 750 mL/min, while operating at the same initial MB dye concentration (5 mg/L) using the same catalyst dose (0.4 g/L). The % removal of the dye is observed to increase by increasing the flow rate up to 460 mL/min. Conversely, further increase in the flow rate decreases the % removal of the dye from 97% (for 460 mL/min) to 20% for 750 mL/min. Hence, a flow rate of 460 mL/min has been set for further studies.

Consideration of the data in Fig. 5 shows the optimum flow rate is related to the exposure time to the UV radiation. Thus, the dye removal increases when more OH radicals are produced. This could be attributed by the increase in organics conversion in the wastewater. However, at a higher flow rate rather than the optimum, the hydraulic retention time is reduced and the result is a reduction in the UV exposure time (Tony et al. 2015). Therefore, a reduction in the overall OH radicals produced. Thus, the dye oxidation rate is reduced. This observation is in accordance with previous observations concerning the sour wastewater phototreatment under photo-Fenton’s reagent under artificial UV light (Sareen et al. 2014).

Effect of initial pH value

The effect of pH value is considered an effective parameter especially on those reactions that are taking place on the surface of particulate solids, as in the case of ZnO NPs photocatalysis. The value of pH has its effect on the MB dye molecules adsorption on the ZnO NPs surface. Experiments were run on two different dye solutions concentrations of 5 and 50 mg/L in order to check the effect of pH at various values in acidic, neutral and alkaline media, i.e., 3, 7 and 12 pH values. However, the other operating conditions are kept constant (0.4 g/L ZnO NPs and 460 mL/min flow rate).

It is observed from the results shown in Fig. 6 that rate of photo-oxidation is higher in the alkaline medium (pH 12), with degradation rates of 97% and 25% for initial MB concentrations of 5 and 50 mg/L, respectively. The same trend is remarked when testing both high and low initial dye concentrations, i.e., the acidic pH is unfavorable as the oxidation rate is only 62% and 17%, for initial MB concentrations of 5 and 50 mg/L, respectively. This attitude of the results agrees with the previous work of Gajbhiye (2012). Since the photocatalytic oxidation of MB occurs in the ZnO NPs surface which is affected by the solution pH. The catalyst behavior can be illustrated by the charge density on ZnO NPs surface, which prevails in alkaline medium which increases the OH radicals production (El Haddad et al. 2014).

Statistical optimization of the operating parameters

Initially, Box–Behnken design was chosen and experiments design according to Table 2 was conducted and the relevant results are shown in Table 2, which lists the % of the dye removal, for initial dye concentration of 10 mg/L and 20 min of reaction time. Those results are further analyzed using SAS software. The correlation between the controllable factor (% dye removal) and three important operating parameters (ZnO NP dosage, pH and flow rate) for the dye wastewater treatment is investigated. The significance of the model becomes clear when it shows a good fit between the theoretical and experimental data.

A Box–Behnken design shown in Table 2 lets the exploration of the second-order model expressed in a mathematical polynomial equation (Eq. 5) where the response variable (f) is evaluated as a second-order function of ZnO NP dosage (X1), pH (X2) and flow rate (X3) and assessed as the sum of a constant, three coefficients of first-order (terms in X1, X2 and X3), three coefficients of interaction (X1 X2), (X1 X3) and (X2 X3) and the three coefficients of the second order (X 21 , X 22 and X 23 ) as illustrated in Eq. (3).

A descriptive statistical analysis of variance (ANOVA) such as the probability (p value), Fisher’s (F value) and R2 is used to check the fitness of the model. A t test is used for analyzing all model terms, and any term found to be insignificant at a p value 0.05 was excluded from the model which is determined by Fisher’s F test and probability > F values. As given in Table 3, the p value of the model is 0.003, and since this model describes about 96% of the data variability, it could be concluded that the model is highly significant. The experimental values and the predicted data attained by E (5) are illustrated in Fig. 7. It is proposed that the suggested model is suitable for predicting the dye removal, revealing a good fit.

MATLAB 7.11.0 software was used to produce the graphical representation of the polynomial equation (Eq. 5), and the three-dimensional (3-D) surface and two-dimensional (2-D) contour plots are given in Fig. 8. In such a plot, the polynomial equation allowed the 3-D representation of the dye removal when one of the studied variables is fixed. As seen from Fig. 8 (a, b and c), the reaction parameters, ZnO dose, pH and flow rate values, have a positive or negative effect on the % removal of dye.

The polynomial equation (Eq. 5) permits to show the 3-D surface and the 2-D contour plots and the three-dimensional representation of the investigation (Fig. 8). MATLAB 7.11.0 software was used to draw this graphical representation. As shown in Fig. 8a, the maximum removal rate was predicted when the ZnO dosage was increased. However, at higher ZnO concentrations, the removal efficiency was negatively affected. Thus, the excess increase in ZnO NPs does not grantee a continuous increase in the dye removal rate. Similarly, the increase in pH value is viewed as a pronounced effect on the efficiency of the dye removal rate until a certain limit. Thus the optimal values for ZnO NP dosage and pH value for each process should be obtained. The data in Fig. 8b plot show the interaction between the ZnO NP dosage and the aqueous solution flow rate performing a positive enhancement in the removal rate. Figure 8c shows that increase in the pH value increases and the flow rate improves the dye removal efficiency; however, after a certain point, the removal rate decreased. Thus, ZnO NP dosage and pH together with the flow rate of the solution should be in optimal values to maximize the dye removal rate.

Response surface analysis and Mathematical software (V 5.2., Wolfram research Inc.) were applied to locate the optimum operating variables conditions of rate of MB dye removal. The maximum % dye removal is 94% (f), while the optimum operating their natural values are: 0.45 mg/L, 11 and 370, L/min, for ZnO dosage, pH and flow rate, respectively.

To verify the model’s adequacy for the maximum response predicted value (% dye removal), a further three replicate experiments were conducted at the optimum conditions levels obtained from the model. A good agreement represented between the predictive (94%) and experimental response (93.9%) values satisfies a high validity of this model.

Comparison of MB dye oxidation during the current investigation and the results stated previously in the literature at the optimum operating conditions are given in Table 4. Noticeably, superior oxidation efficiency is given through ZnO-based oxidation process compared with other AOPs. However, solo ZnO oxidation gives 94% compared to 99% for using ZnO in a composite such as ZnO/CuO/UV and ZnO/Hg/UV processes. It should be mentioned that a 94% removal for the solo ZnO system is reasonable compared with the higher efficiencies in using combined catalysts including ZnO.

Kinetic studies of MB oxidation

The photo-oxidation kinetics of MB by ZnO NPs were investigated for different times and various initial MB concentrations (5, 10, 15, 30 and 50 mg/L). Previously, kinetic models are established to describe the oxidation reactions. Therefore, the already-mentioned kinetic models occurred by first- and second-order kinetics are expressed by the following equations: Eq. (6) for first order (Bounab et al. 2015) and Eq. (7) for second order (El Haddad et al. 2014):

where C is the MB concentration, Ct is the MB concentration at the reaction time t, Co is the initial MB concentration and k1 and k2 represent the kinetic rate constants of the first-order reaction kinetic and second-order reaction kinetic, respectively.

Equations (5, 6) are plotted in Fig. 9a, b, and the results fitted with the two orders of reaction obtained are shown in Fig. 9 and Table 4, clearly indicated from comparing the regression coefficient values for the three models that the reaction follows a pseudo-second-order of reaction, as the highest R2 values are for the second-order one. Furthermore, the second kinetic reaction constant, k2, (which is calculated from the slope of the plot in Fig. 9b) is notably affected by the initial MB concentration, decreasing with increasing the initial MB dye concentration which is decreased from 0.0968 to 7 × 10−5 L mg−1 min−1. However, at higher dye concentration with reduced R2 values, the reaction does not follow the second-order kinetics. This assumes the reaction rate is doubled at higher concentration (Soustelle 2013). This result verified that, at higher concentrations, the number of dye molecules in water is increased much higher than the •OH species which is responsible of the photocatalytic oxidation (Xu and Lu 2013). Consequently, the removal rate of the dye is decreased from 97% to only 25%.

The time needed for the reactant to be decreased to half of its quantity in comparison with its initial concentration is called the half-life of a reaction, t1/2 (Pollard and Cruz 2013). The calculated half-life time (shown in Table 5) is affected by the initial MB concentration increase. It is observed that the half-life time is increased with increasing the initial concentration. Ultimately, it is concluded that the Methylene blue removal by ZnO NPs is following the second-order reaction model.

Samet et al. (2012) previously described the treatment of insecticide in wastewater, El Haddad et al. (2014) and Youssef et al. (2016) in the treatment of dyed wastewater using Fenton’s reagent as a photocatalyst by the second-order reaction model. However, on the contrary, Bounab et al. (2015) found that the reaction follows the first-order kinetics on the treatment of m-cresol, using iron-loaded activated carbon.

Conclusion

Photocatalytic oxidation of MB in aqueous streams was investigated using ZnO NPs. Different experimental condition parameters, including UV illumination time, initial MB dye concentration, ZnO NP dosage, pH and flow rate of the aqueous solution, change of dye concentration and different pH values of solutions, were evaluated. A suitable operating condition was selected after the statistical optimization techniques was applied for the three most effective parameters on the process, based on the Box–Behnken experimental design as: 0.45 mg/L ZnO NPs, pH 11 and flow rate 370 mL/min within only 20 min of reaction time and maximizing the removal rate which reaches 94% within 20 min. The kinetic investigation suggested that the photodegradation kinetics of MB followed the second-order kinetics.

References

Abdellah MH, Nosier SA, El-Shazly AH, Mubarak AA (2018) Photocatalytic decolorization of methylene blue using TiO2/UV system enhanced by air sparging. Alex Eng J 57(4):3727–3735

Akar T, Demir TA, Kiran I, Ozcan A, Tunali S (2006) Biosorption potential of Neurospora crassa cells for decolorization of Acid Red 57 (AR57) dye. J Chem Technol Biotechnol 81(7):1100–1106

Ashour EA, Tony MA, Purcell PJ (2014) Use of agriculture-based waste for basic dye sorption from aqueous solution: kinetics and isotherm studies. Am J Chem Eng 2(6):92–98

Azbar N, Yonar T, Kestioglu K (2004) Comparison of various advanced oxidation processes and chemical treatment methods for COD and color removal from a polyester and acetate fiber dyeing effluent. Chemosphere 55:35–43

Beydoun D, Amal R, Low G, McEvoy S (1999) Role of nanoparticles in photocatalysis. J Nanoparticle Res 1(4):439–458

Bindu P, Thomas S (2014) Estimation of lattice strain in ZnO nanoparticles: X-ray peak profile analysis. J Theor Appl Phys 8:123–134

Bounab L, Iglesias O, González-Romero E, Pazos M, Sanroman MA (2015) Effective heterogeneous electro-Fenton process of m-cresol with iron loaded activated carbon. RSC Adv 5:31049–31056

Chakrabarti S, Dutta BK (2004) Photocatalytic degradation of model textile dyes in wastewater using ZnO as semiconductor catalyst. J Hazard Mater 112(3):269–278

Daneshvar N, Salari D, Khataee A (2004) Photocatalytic degradation of azo dye acid red 14 in water on ZnO as an alternative catalyst to TiO2. J Photochem Photobiol, A 162(2):317–322

Dieckmann MS, Gray KA (1998) A comparison of the degradation of 4-nitrophenol via direct and sensitized photocatalysis in TiO2 slurries. Water Res 30(5):1169–1183

Duc DS (2014) Response surface optimization for decolorization of Basic Blue 41 by Fenton’s reagent. Int J Chem Technol Res 6(7):3943–3948

Dutta K, Mukhopadhyay S, Bhattacharjee S, Chaudhuri B (2001) Chemical oxidation of methylene blue using a Fenton-like reaction. J Hazard Mater 84(1):57–71

El Haddad M, Abdelmajid RM, Laamari R, Mamouni R, Saffaj N (2014) Use of Fenton reagent as advanced oxidative process for removing textile dyes from aqueous solutions. J Mater Environ Sci 5(3):667–674

Elboughdiri N, Mahjoubi A, Shawabkeh A, Khasawneh HE, Jamoussi B (2015) Optimization of the degradation of hydroquinone, resorcinol and catechol using response surface methodology. Adv Chem Eng Sci 5:111–120

Gajbhiye SB (2012) Photocatalytic degradation study of methylene blue solutions and its application to dye industry effluent. Int J Mod Eng Res 3:1204–1208

Ghaedi M, Hajjati S, Mahmudi Z, Tyagi I, Agarwal S, Maity A, Gupta VK (2015) Modeling of competitive ultrasonic assisted removal of the dyes—Methylene blue and Safranin-O using Fe3O4 nanoparticles. Chem Eng J 268:28–37

Goncalves MS, Oliveira-Campos AM, Pinto MM, Plasencia PM, Queiroz MJ (1999) Photochemical treatment of solutions of azo dyes containing TiO2. Chemosphere 39:781–786

Gupta VK, Nayak JR, Agarwal AS, Shrivastava M (2011) Removal of the hazardous dye—Tartrazine by photodegradation on titanium dioxide surface. Mater Sci Eng, C 31(5):1062–1067

Houas A, Lachheb H, Ksibi M, Elaloui E, Guillard C, Herrmann J (2001) Photocatalytic degradation pathway of methylene blue in water. Appl Catal B 31:145–157

Jeni J, Kanmani S (2011) Solar nanophotocatalytic decolorisation of reactive dyes using titanium dioxide. Iran J Environ Health Sci Eng 8(1):15–24

Kargi F, Ozmıhc S (2004) Biosorption performance of powdered activated sludge for removal of different dyestuffs. Enzyme Microb Technol 35(2):267–271

Lee KM, Abd Hamid SB (2015) Simple response surface methodology: investigation on advance photocatalytic oxidation of 4-chlorophenoxyacetic acid using UV-active ZnO photocatalyst. Materials 8:339–354

Legrini O, Oliveros E, Braun A (1993) Photochemical processes for water treatment. Chem Rev 93(2):671–698

Lin J, Luo Z, Liu J, Li P (2018) Photocatalytic degradation of methylene blue in aqueous solution by usingZnO-SnO2 nanocomposites. Mater Sci Semicond Proces 87:24–31

Mogharabi M, Nassiri-Koopaei N, Bozorgi-Koushalshahi M, Nafissi-Varcheh N, Bagherzadeh G, Faramarzi MA (2012) Immobilization of laccase in alginate-gelatin mixed gel and decolorization of synthetic dyes. Bioinorg Chem Appl. https://doi.org/10.1155/2012/823830

Montgomery DC (1991) Design and analysis of experiments. Wiley, New York

Pollard TD, Cruz EM (2013) Take advantage of time in your experiments: a guide to simple, informative kinetics assays. Mol Biol Cell 24(8):1103–1110

Rafatullah M, Sulaiman O, Hashim R, Ahmad A (2010) Adsorption of methylene blue on low-cost adsorbents: a review. J Hazard Mater 177:70–80

Rahman MM, Hasna MA, Kazuaki S (2009) Degradation of commercial textile dye by fenton’s reagent under xenon beam irradiation in aqueous medium. J Sci Res 1(1):108–120

Rajendran S, Khan M, Gracia F, Gupta V, Arumainathan S (2016) Ce3+-ion-induced visible-light photocatalytic degradation and electrochemical activity of ZnO/CeO2 nanocomposite. Sci Rep 6:31641

Saggioro EM, Oliveira AS, Pavesi T, Maia CG, Ferreira LF, Moreira JC (2011) Use of titanium dioxide photocatalysis on the remediation of model textile wastewaters containing azo dyes. Molecules 16:10370–10386

Saleh TA, Gupta VK (2012) Photo-catalyzed degradation of hazardous dye methyl orange by use of a composite catalyst consisting of multi-walled carbon nanotubes and titanium dioxide. J Coll Surf Sci 371(1):101–106

Samet Y, Hmani E, Abdelhedi R (2012) Fenton and solar photo-Fenton processes for the removal of chlorpyrifos insecticide in wastewater. Water SA 38(4):537–542

Saravanan R, Karthikey S, Gupta VK, Sekaran G, Narayanane V, Stephen A (2013a) Enhanced photocatalytic activity of ZnO/CuO nanocomposite for the degradation of textile dye on visible light illumination. Mater Sci Eng, C 33:91–98

Saravanan R, Thirumal E, Gupta VK, Narayanane V, Stephen A (2013b) The photocatalytic activity of ZnO prepared by simple thermal decomposition method at various temperatures. J Mol Liq 177:394–401

Saravanan R, Gupta VK, Prakash T, Narayanane V, Stephen A (2013c) Synthesis, characterization and photocatalytic activity of novel Hg doped ZnO nanorods prepared by thermal decomposition method. J Mol Liq 178:88–93

Saravanan R, Joicy S, Gupta VK, Narayanane V, Stephen A (2013d) Visible light induced degradation of methylene blue using CeO2/V2O5 and CeO2/CuO catalysts. Mater Sci Eng, C 33:4725–4731

Saravanan R, Gupta VK, Mosquera E, Graci F (2014) Preparation and characterization of V2O5/ZnO nanocomposite system for photocatalytic application. J Mol Liq 198:409–412

Saravanan R, Khan M, Gupta VK, Gracia MF, Narayanane V, Stephen A (2015a) ZnO/Ag/CdO nanocomposite for visible light-induced photocatalytic degradation of industrial textile effluents. J Colloid Interface Sci 452:126–133

Saravanan R, Khan M, Gupta VK, Gracia MF, Narayanane V, Stephen A (2015b) ZnO/Ag/Mn2O3 nanocomposite for visible light-induced industrial textile effluent degradation, uric acid and ascorbic acid sensing and antimicrobial activity. RSC Adv 5:34645–34651

Sareen D, Garg R, Grover N (2014) A study on removal of methylene blue dye from waste water by adsorption technique using fly ash briquette. Inter J Eng Res Technol. 3(7):278

SAS (19900) SAS/STAT User’s Guide. SAS Institute: Inc., Cary, NC

Shen W, Li Z, Wang H, Liu Y, Guo O, Zhang Y (2008) Photocatalytic degradation for methylene blue using zinc oxide prepared by codeposition and sol–gel methods. J Hazard Mater 152:172–175

Sobczynski A, Dobosz A (2001) Water purification by photocatalysis on semiconductors. Pol J Environ Stud. 10(4):195–205

Soustelle M (2013) An Introduction to Chemical Kinetics, Wiley Publisher

Suarez-Escobar A, Pataquiva-Mateus A, Lopez-Vasquez A (2006) Electrocoagulation-photocatalytic process for the treatment of lithographic wastewater: optimization using response surface methodology (RSM) and kinetic study. Cat Today 266:120–125

Tony MA, Bedri Z (2014) Experimental design of photo-fenton reactions for the treatment of car wash wastewater effluents by response surface methodological analysis. Adv Environ Chem 2014:958134. https://doi.org/10.1155/2014/958134

Tony MA, Mansour SA (2019) Removal of the commercial reactive dye Procion Blue MX-7RX from real textile wastewater using the synthesized Fe2O3 nanoparticles at different particle sizes as a source of Fenton’s reagent. Nanoscale Adv. https://doi.org/10.1039/C8NA00129D

Tony MA, Zhao YQ, El-sherbiney MF (2011) Fenton and Fenton-like AOPs for alum sludge conditioning: effectiveness comparison with different Fe2+ and Fe3+ salts. Chem Eng Commun 198(3):442–452

Tony MA, Purcell PJ, Zhao YQ, Tayeb AM, El-Sherbiny MF (2015) Kinetic modeling of diesel oil wastewater degradation using photo-Fenton process. Environ Eng Mang J 14(1):11–16

Tony MA, Parker H, Clark JH (2016) Treatment of laundrette wastewater using Starbon and Fenton’s reagent. J Environ Sci Health. 51(11):974–979

Tony MA, Parker HL, Clark JH (2018) Evaluating Algibon adsorbent and adsorption kinetics for launderette water treatment: towards sustainable water management. Water Environ J. https://doi.org/10.1111/wej.12412

Xu H, Lu G (2013) On-line spectrophotometric method for decolourizing reaction kinetics of reactive black 5 by Fenton oxidation. Asian J Chem 25(4):7989–7992

Youssef NA, Shaban SA, Ibrahim FA, Mahmoud AS (2016) Degradation of methyl orange using Fenton catalytic reaction. Egypt J Petrol. 25:317–321

Zhao M, Zhang J (2008) Wastewater treatment by photocatalytic oxidation of Nano-ZnO. Global Environ Pol Jpn 12:1–9

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Tayeb, A.M., Tony, M.A. & Ismaeel, E.K. Engineered nanostructured ZnO for water remediation: operational parameters effect, Box–Behnken design optimization and kinetic determinations. Appl Water Sci 9, 43 (2019). https://doi.org/10.1007/s13201-019-0921-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-019-0921-0